High-precision positioning method for LED chip array arrangement

An LED chip and array arrangement technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of chip integration failure, high investment cost, affecting the chip integration yield rate, etc., to ensure the uniformity and consistency of color temperature. performance, and the effect of improving the delivery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]The existing ordinary chip placement equipment has a low accuracy of only ±30um in chip positioning; while high-precision chip placement equipment can improve the accuracy to ±10um, but the price of high-precision chip placement equipment is as high as nearly one million yuan. Replacement of high-precision chip placement equipment Equipment saving investment is too high. In order to solve the above problems, this embodiment provides a high-precision positioning method for LED chip arrays, which can improve the positioning accuracy of the chips to below ±10um by using existing common chip arrangement equipment.

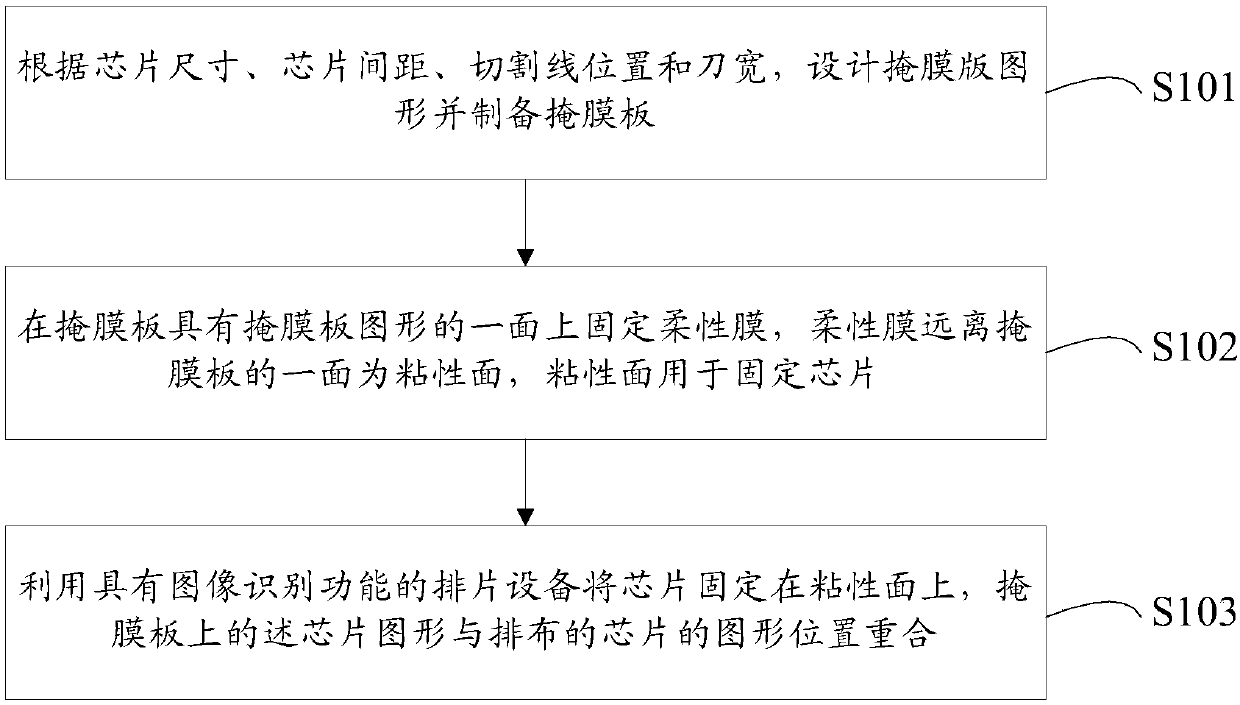

[0046] figure 1 A process flow chart of the high-precision positioning method of the LED chip array in this embodiment is given. See figure 1 , the positioning method, including:

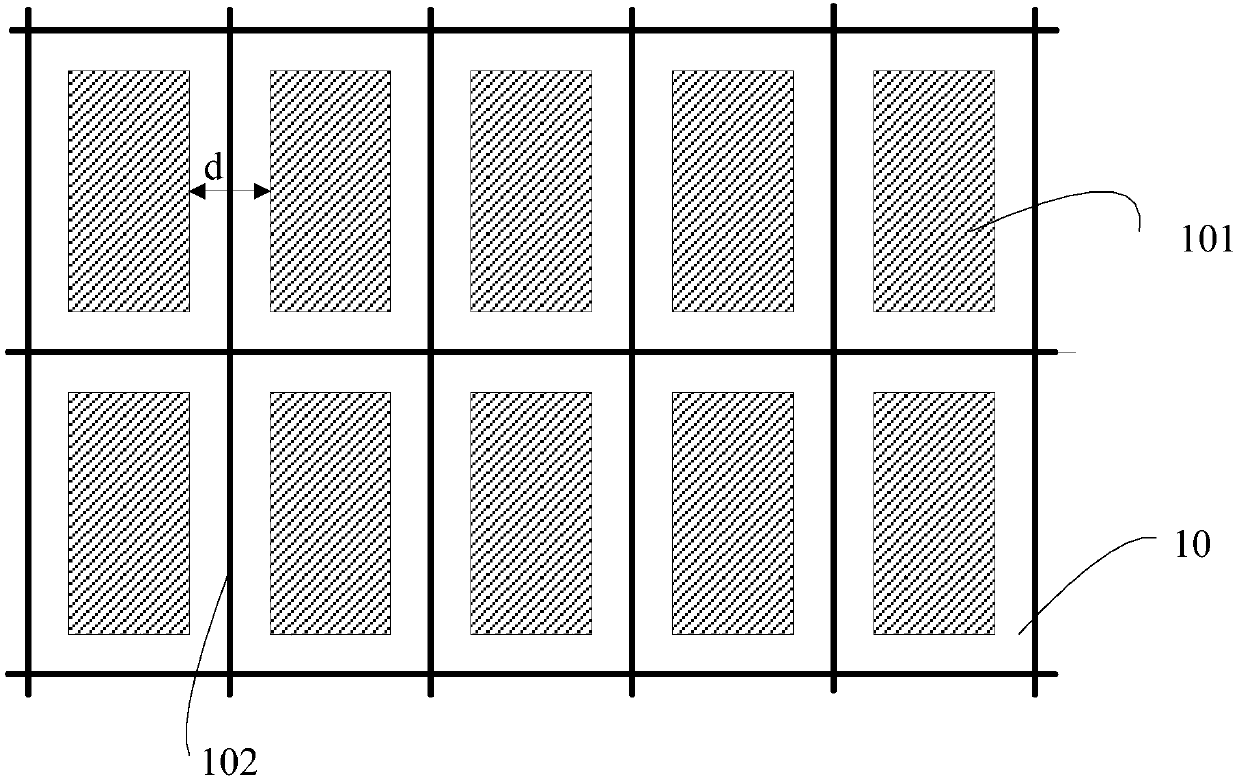

[0047] Step S101: figure 2 A top view schematic diagram of step S101 in this embodiment is given, and a mask pattern is designed and a mask plate is made according to the chip siz...

Embodiment 2

[0056] Figure 6 A process flow chart of the high-precision positioning method of the LED chip array in this embodiment is given. See Figure 6 , the positioning method, including:

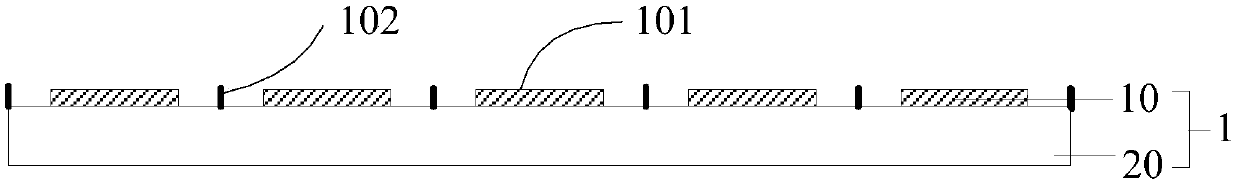

[0057] Step S201: Figure 7 A top view schematic diagram of step S201 in this embodiment is given, and a mask pattern is designed and a mask plate is made according to the chip size, the chip spacing d, the position of the cutting line 102 and the knife width.

[0058] Figure 8 A cross-sectional schematic diagram of step S201 in this embodiment is given, please refer to Figure 7 and Figure 8 , forming a light blocking layer 10 on the glass substrate 20, using photolithography technology to etch the light blocking layer 10 to form a mask pattern, the mask pattern includes a plurality of chip patterns 101 arranged in an array, and the chip pattern 101 The light blocking layer 10 is etched away.

[0059] Need to explain is, Figure 7 There are 10 chip patterns 101 in the mask plate given i...

Embodiment 3

[0066] figure 1 The process flow chart of the high-precision positioning method of the LED chip array in this embodiment is given, please refer to Figure 11 , the present embodiment provides a high-precision positioning method for an LED chip array, including:

[0067] Step S301: Design a mask pattern and make a mask plate according to the chip size, chip pitch, dicing line position and knife width. The mask pattern includes a plurality of chip patterns arranged in an array.

[0068] Step S302: Fix the flexible film on the side of the mask plate having the pattern of the mask plate, the side of the flexible film 2 away from the mask plate is an adhesive surface, and the adhesive surface is used to fix the chip.

[0069] It should be noted that the flexible film in the present invention is a transparent film with a temperature resistance greater than 150°C. The flexible film can be a double-sided adhesive film or a single-sided adhesive film. If the flexible film is a double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com