Cleaning Equipment and Cleaning Method for Printer Toner Cartridge Parts

A technology for cleaning equipment and printers. It is applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using tools. It can solve problems such as low pass rate, incompleteness, and inability to remove, and achieve load reduction and shipment rate. The effect of improving and improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

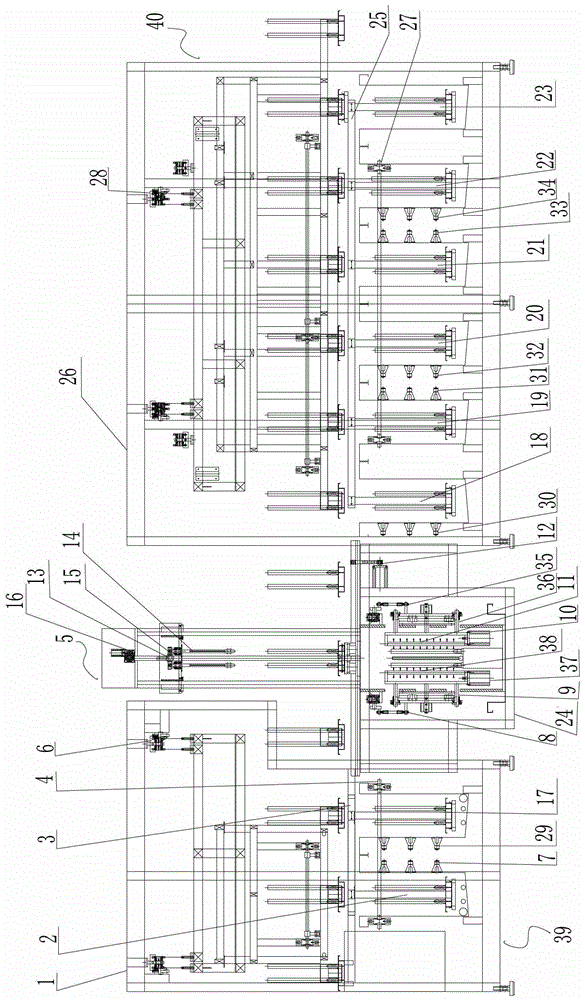

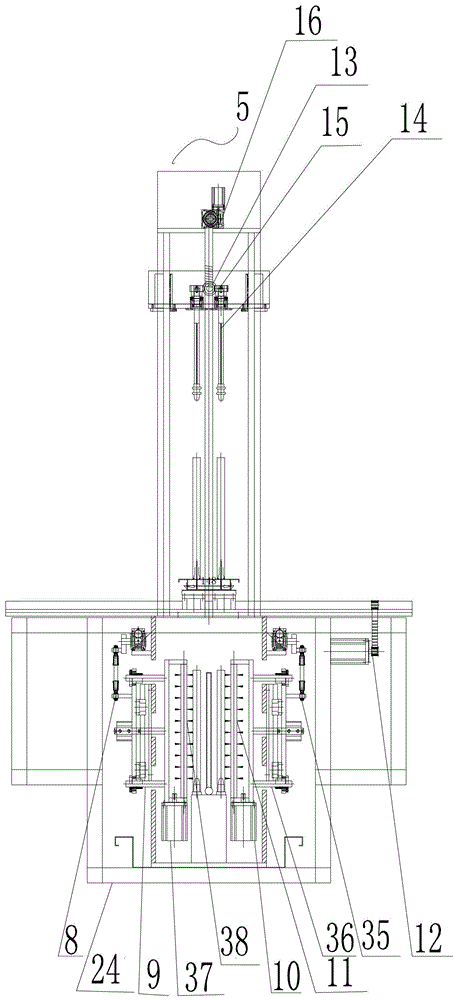

[0028] Such as figure 1 and Figure 5 as shown, figure 1 It is the front view of the special cleaning equipment for printer drum parts; Figure 5 It is the left view of the special cleaning equipment for printer drum parts.

[0029] A kind of special cleaning equipment for printer drum parts, comprising brush cleaning equipment 5, alkali cleaning equipment 39 and fine cleaning equipment 40, alkaline cleaning equipment 39 and brush cleaning equipment 5, brush cleaning equipment 5 and fine cleaning equipment 40 are respectively connected by connecting pieces.

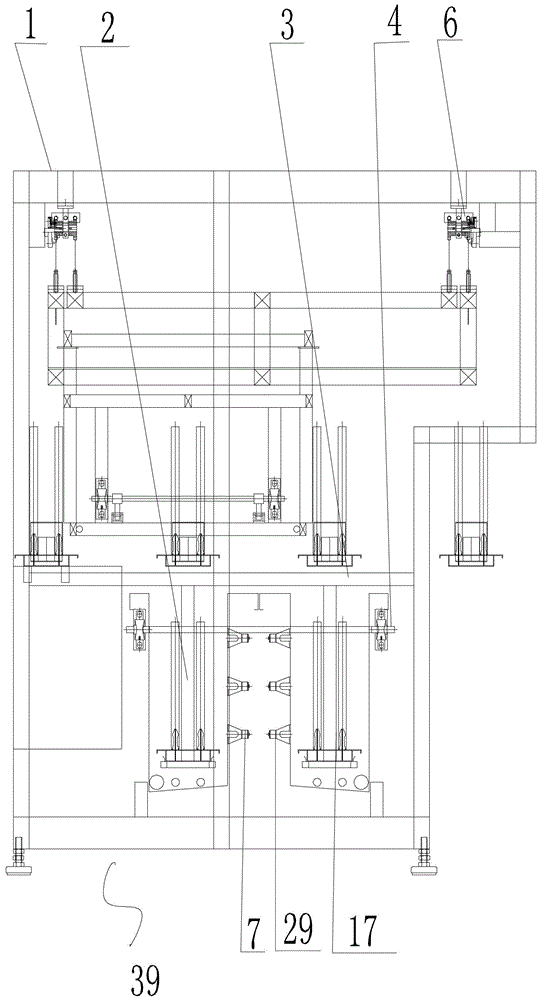

[0030] Such as figure 2 as shown, figure 2 It is the front view of the alkaline cleaning equipment.

[0031] Alkaline washing equipment 39 comprises the first frame 1, the first tank body 2, the first throwing lifting device 3, the first shaking device 4, the first lifting device 6, the first ultrasonic system 7, the second tank body 17 and the first Two ultrasonic systems 29, the first throwing lifting device 3 i...

Embodiment 2

[0039] A cleaning method for a cleaning device for a drum part of a printer, comprising the following steps:

[0040] The drum parts of the printer pass through the first tank body 2 and the second tank body 17 on the alkali cleaning equipment 39 in sequence, and then enter the first scrubbing device 11 and the second scrubbing device 38 on the scrubbing device 5 after two times of caustic cleaning, and perform twice Scrub, then enter the third tank body 18, the fourth tank body 19, the fifth tank body 20, the sixth tank body 21, the seventh tank body 22, and the eighth tank body 23 on the fine cleaning equipment 40 in sequence, and the rinsing and purification are completed get the product.

[0041] The temperature of alkali washing is 40-60°C, 40°C, 45°C, 50°C, 55°C, 60°C are all acceptable, and the time is 2-3 minutes; the reagent used for alkali washing is soap powder.

[0042] The reagent used for scrubbing is soap powder, and the scrubbing time is 2 to 3 minutes.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com