Straw incineration haze control device

A straw and waste gas technology, which is applied in the direction of combined devices, incinerators, combustion methods, etc., can solve the problems of incomplete waste gas treatment, low straw enthusiasm, affecting visibility, etc., and achieves a simple and reliable separation principle, simple processing technology, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

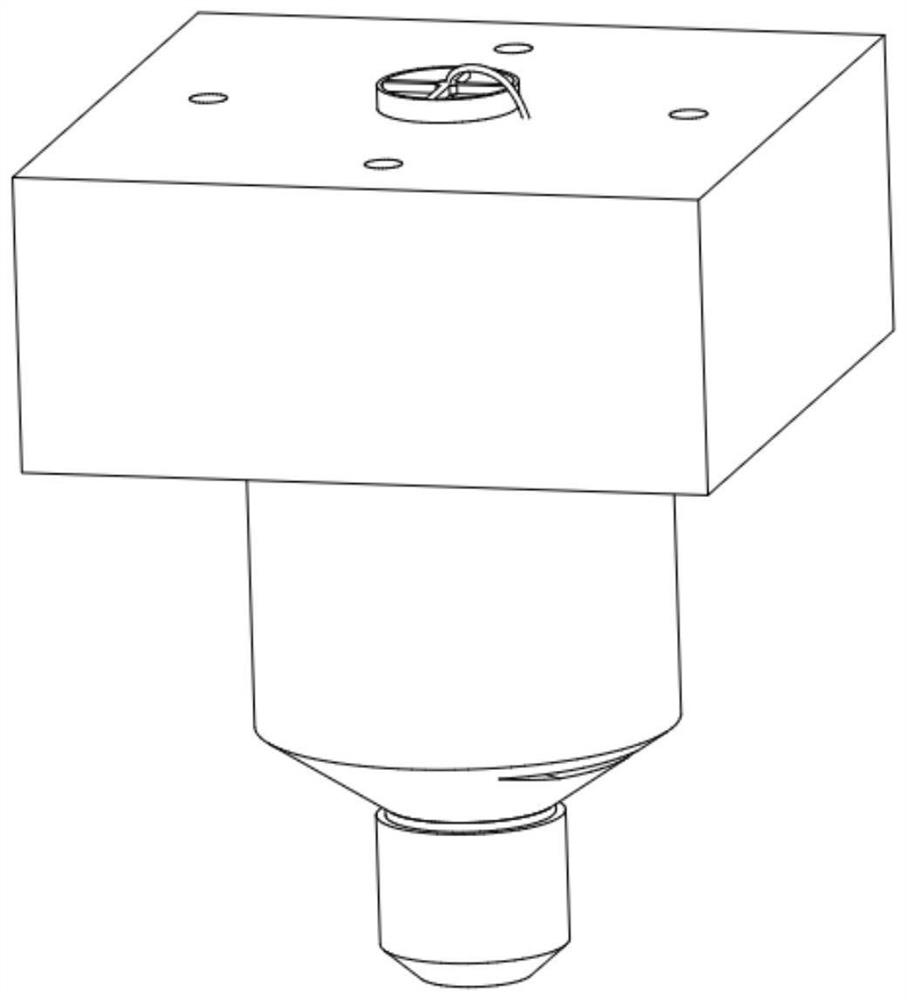

[0028] First, in conjunction with the accompanying drawings, the haze control device for straw burning according to the present invention is described as a whole:

[0029] The exhaust gas mixture to be treated enters the device from the inlet 1 of the spiral air intake shell, and the exhaust gas is separated and discharged from the outlet 2 of the fine exhaust gas filter chamber. After reaching a certain weight, the device is discharged from the dust outlet 4.

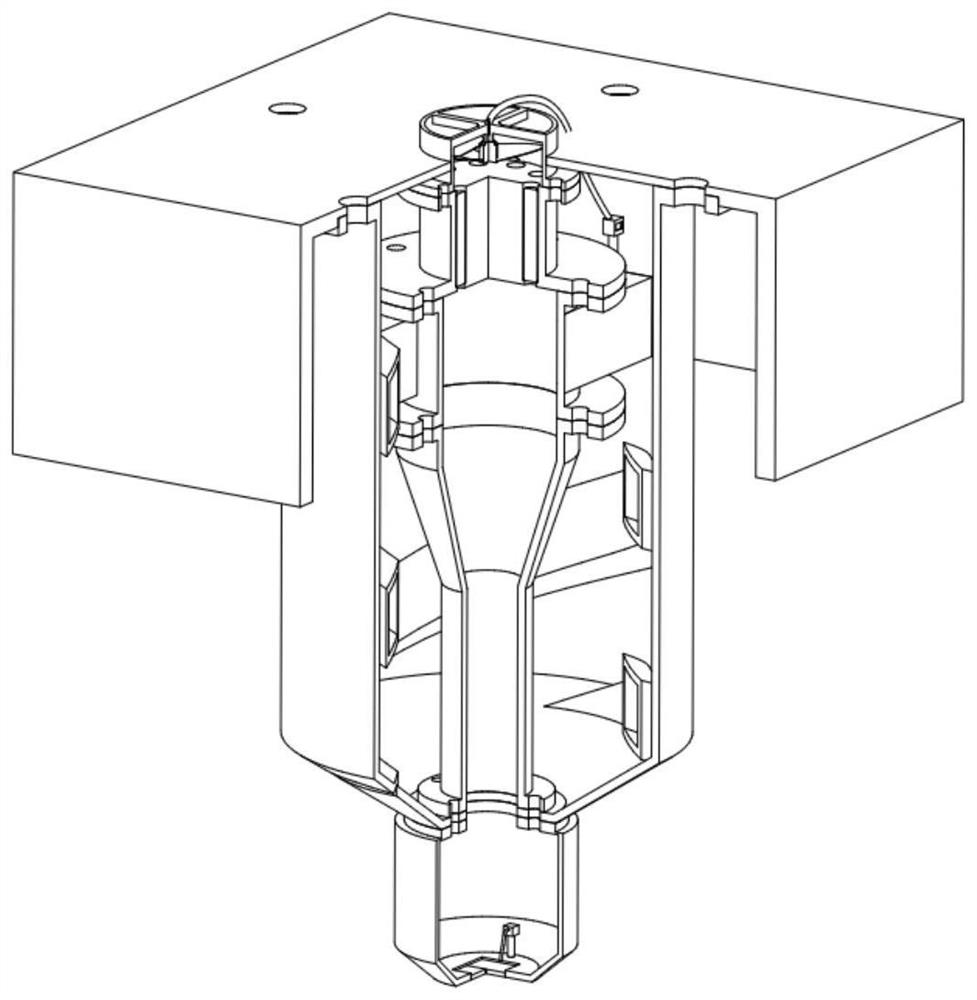

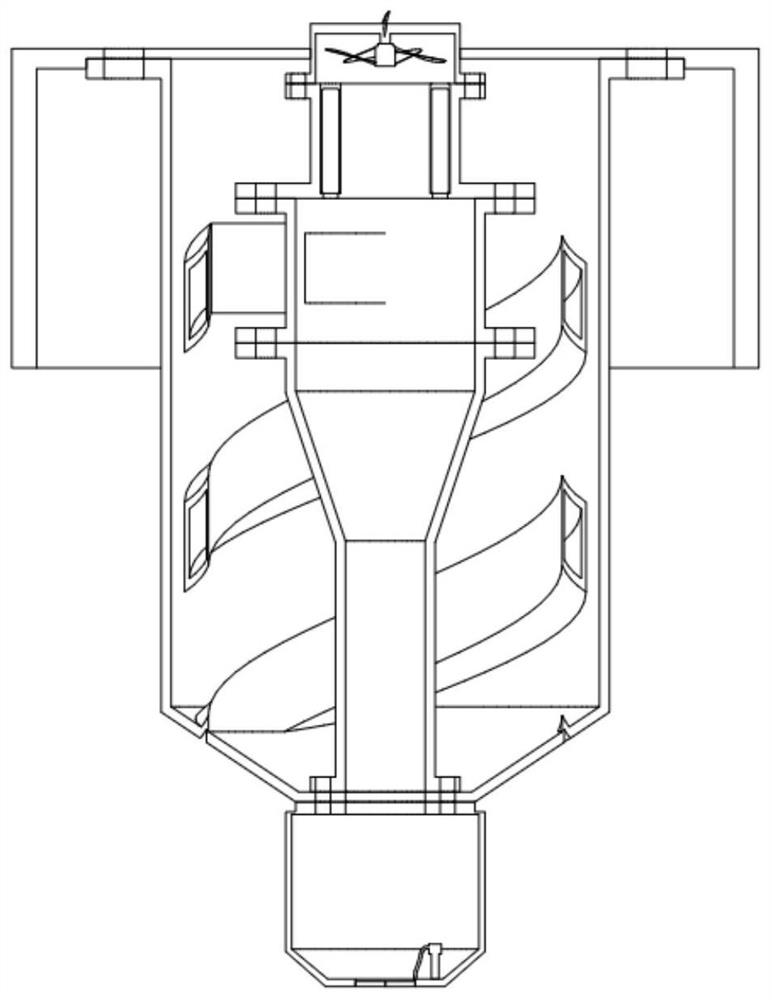

[0030] Figure 4 It is a structural exploded view of a new type of straw incineration haze control device. From top to bottom in the figure, there are chimney cover 5, blast chamber 6, blast impeller 7, filter element 8, exhaust gas fine filter chamber 9, air velocity sensor 10, Double tangential air intake chamber 11, centrifugal waste gas separation chamber 12, spiral air intake housing 13, weight sensor 14, dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com