Patents

Literature

65results about How to "Avoid defective rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

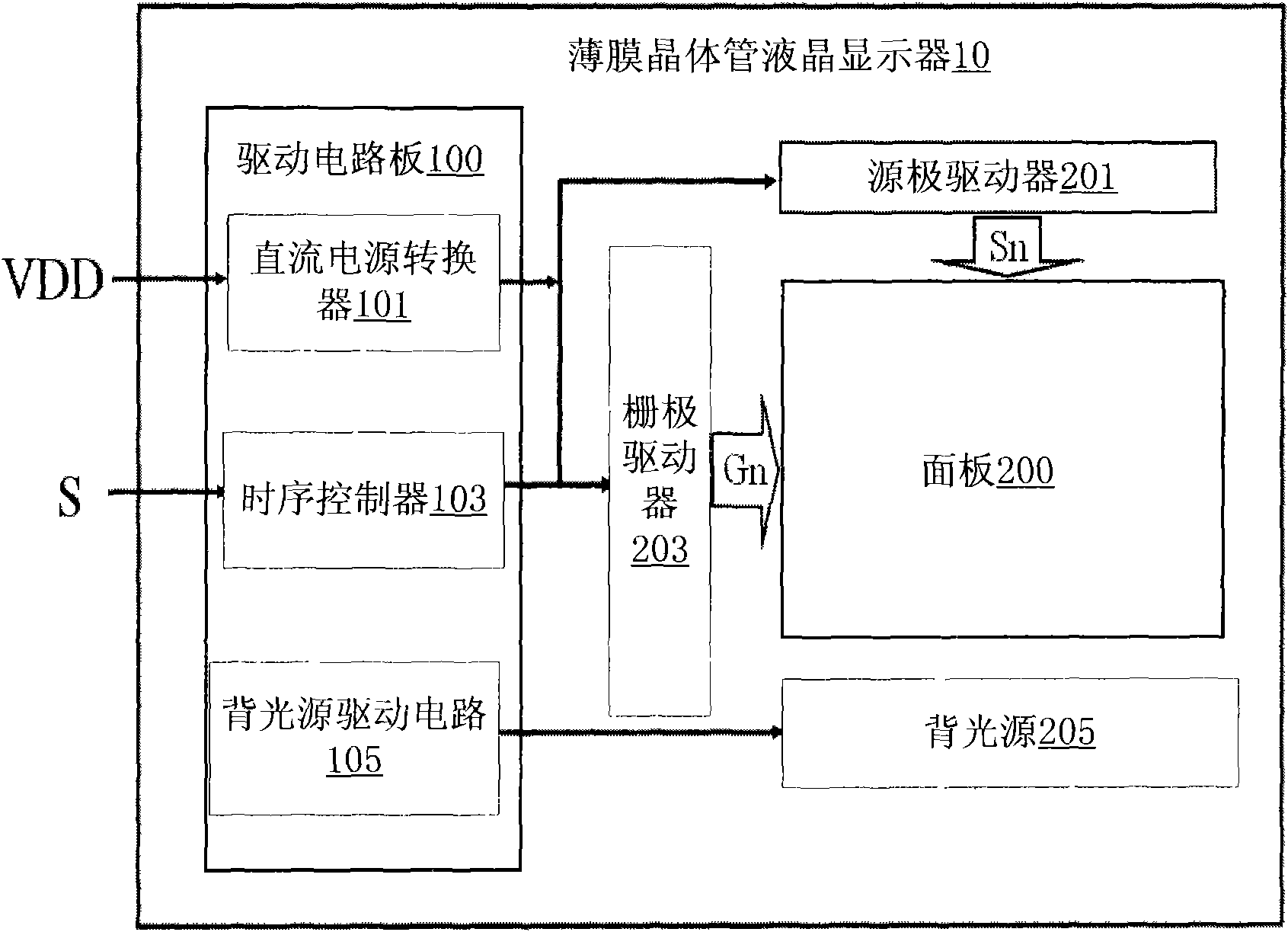

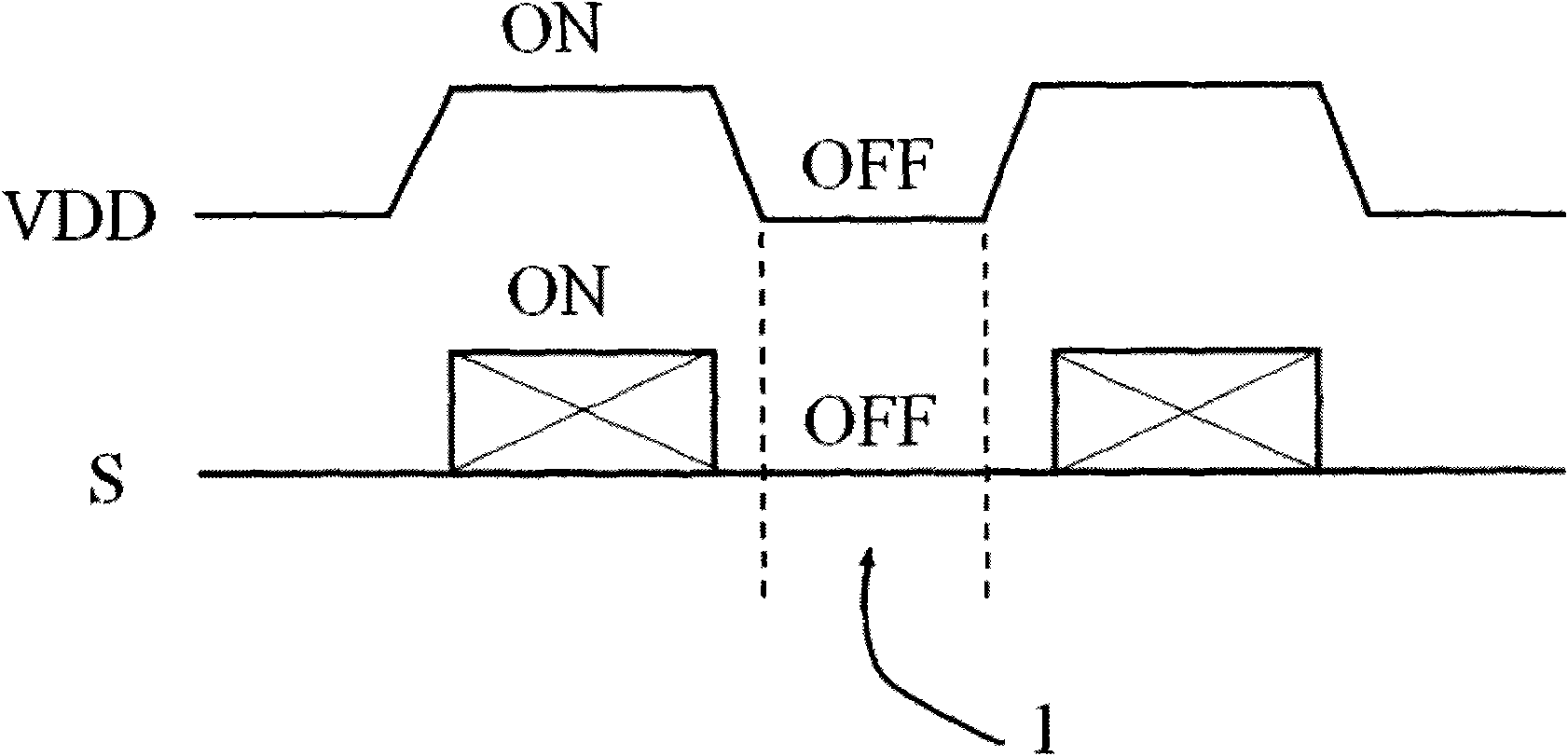

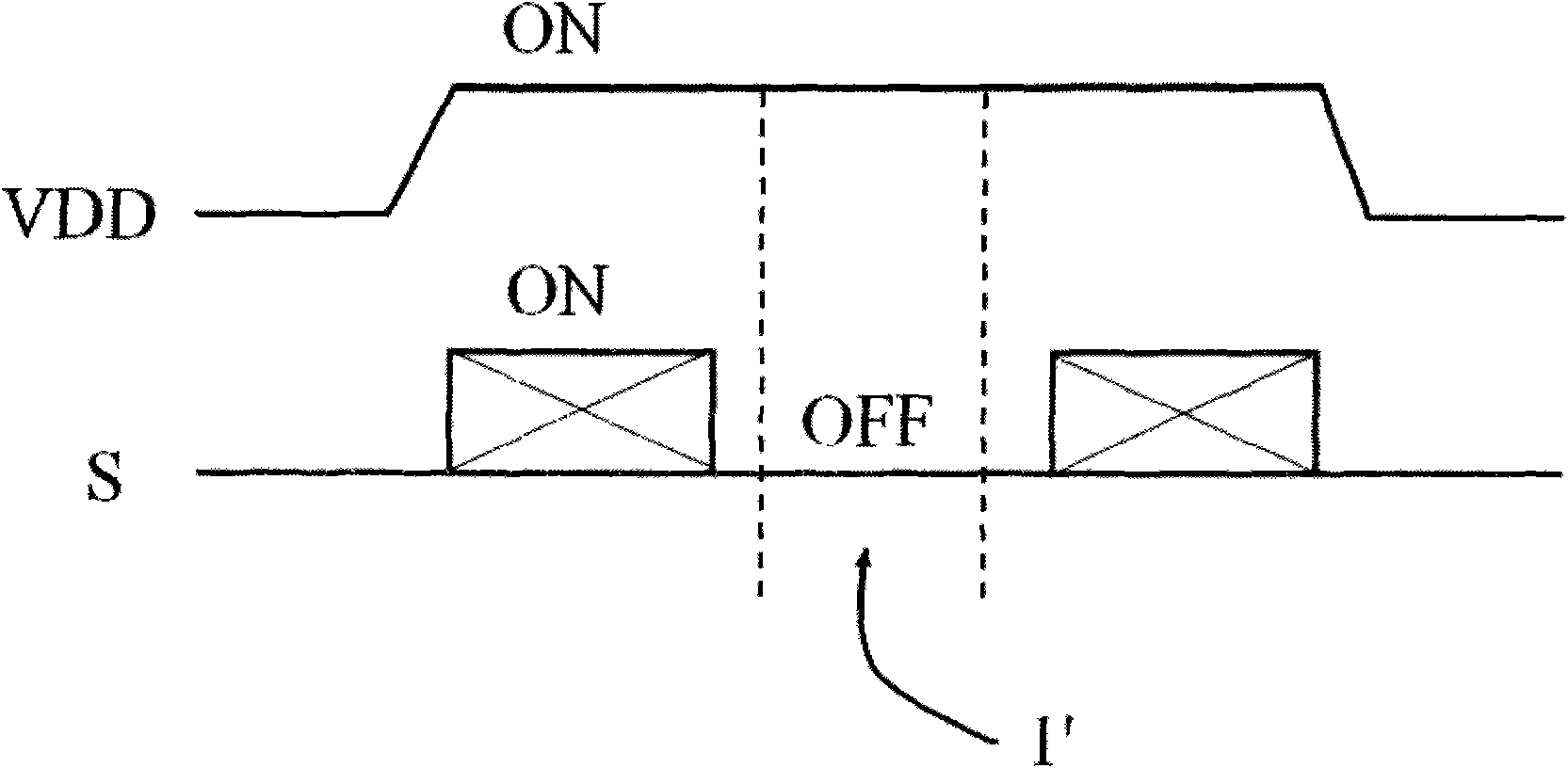

Liquid crystal display and method for detecting and eliminating residual shadows

InactiveCN102103835AAvoid image stickingIncrease timing flexibilityStatic indicating devicesDriver circuitTime schedule

The invention discloses a liquid crystal display and a method for detecting and eliminating residual shadows. The liquid crystal display comprises a driving circuit board, a grid driver and a detecting module, wherein the driving circuit board is provided with a direct-current power converter and a time schedule controller, wherein the direct-current power converter is used for receiving a power signal, and the time schedule controller is used for receiving an input signal; the grid driver is electrically connected with the direct-current power converter and the time schedule controller and also electrically connected on a panel; and the detecting module is electrically connected with the grid driver and used for detecting the power signal and the input signal. When judging that the power signal and the input signal are abnormal, the detecting module outputs an output pulse signal to the grid driver to eliminate residual shadows.

Owner:华映视讯(吴江)有限公司 +1

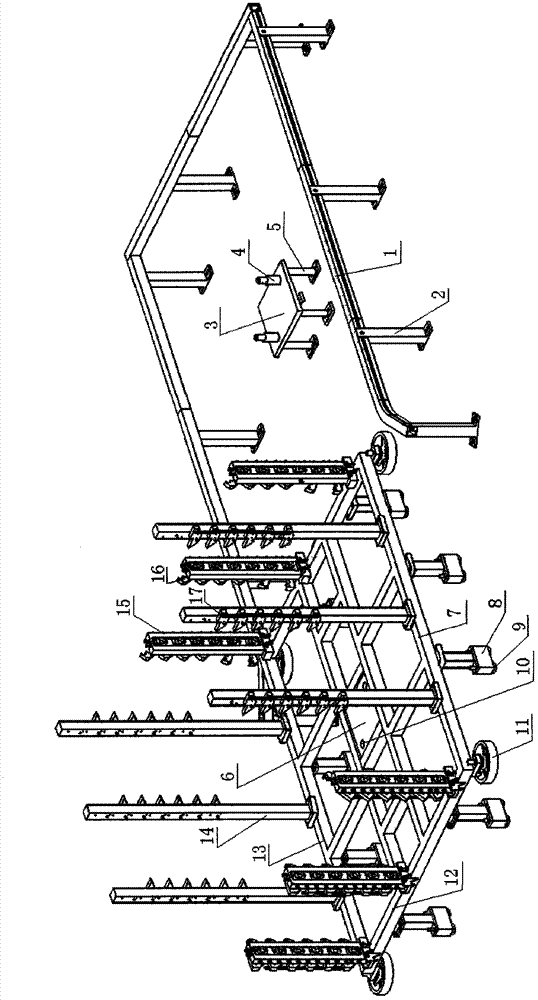

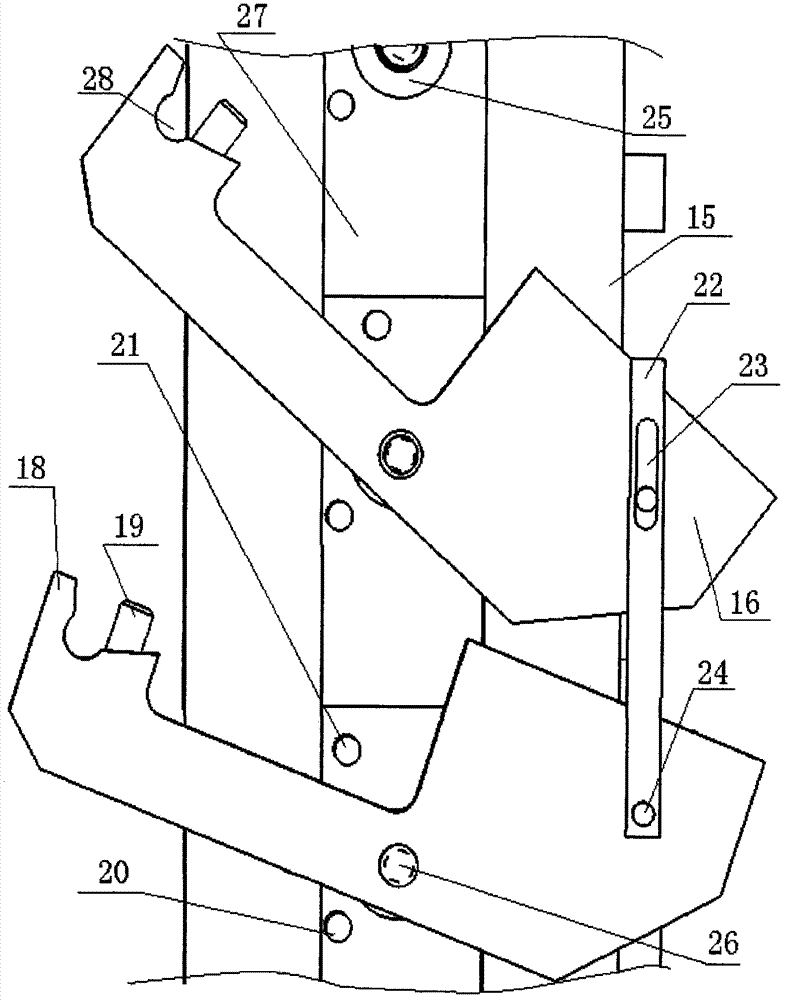

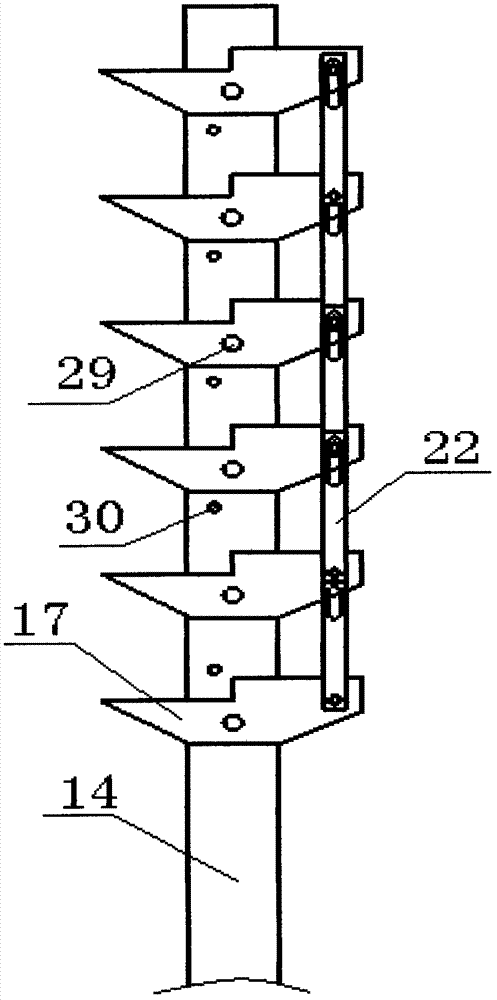

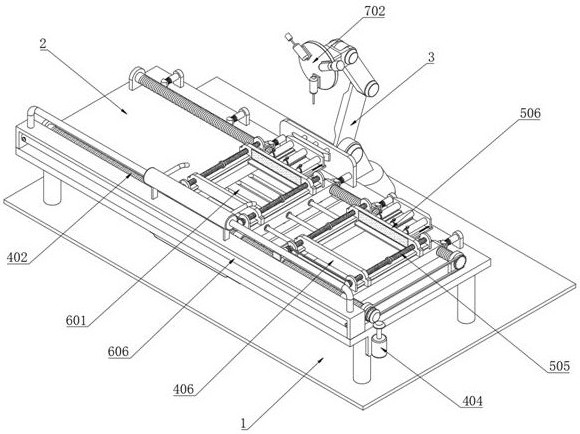

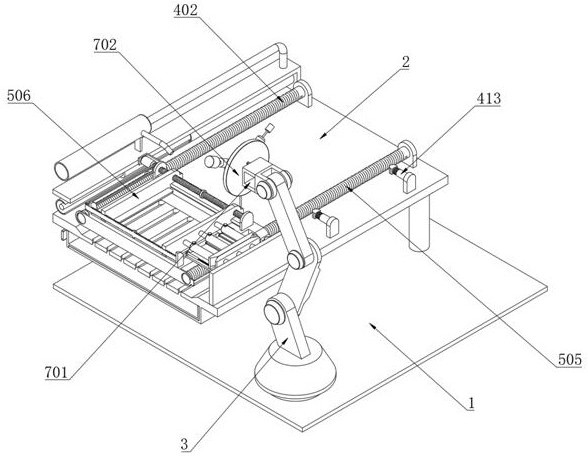

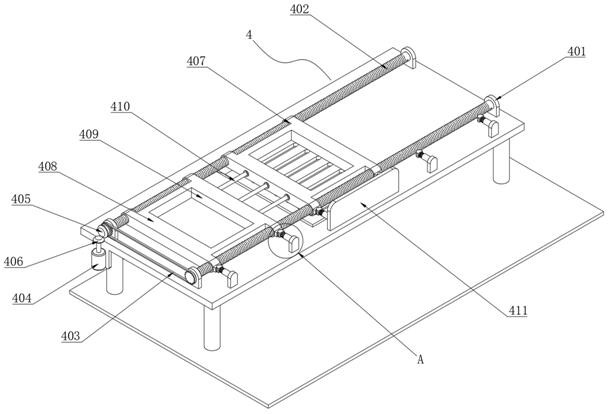

Stamping part stratified shelf for automobile

The invention discloses a stamping part stratified shelf for an automobile. The stamping part stratified shelf comprises a stamping part stratified shelf body and a stamping part stratified shelf positioning system. The stamping part stratified shelf body comprises a base, a lateral support assembly, a vertical support assembly, guide wheels and stand feet, wherein the lateral support assembly is arranged at the upper end of the transverse side of the base, the vertical support assembly arranged at the upper end of a vertical side of the base, and the guide wheels and the stand feet are arranged at the lower end of the base. By means of the technical scheme of the stamping part stratified shelf for the automobile, the operation of a mechanical arm is standard and accurate, moving and stacking of workpieces are ensured maximally, moving and stacking of automobile large stamping parts operated by the mechanical arm are ensured, the defective caused by workpiece deformation due to manual or mechanical carrying and moving is avoided, working efficiency is improved, and production cost is reduced.

Owner:芜湖德力自动化装备科技有限公司

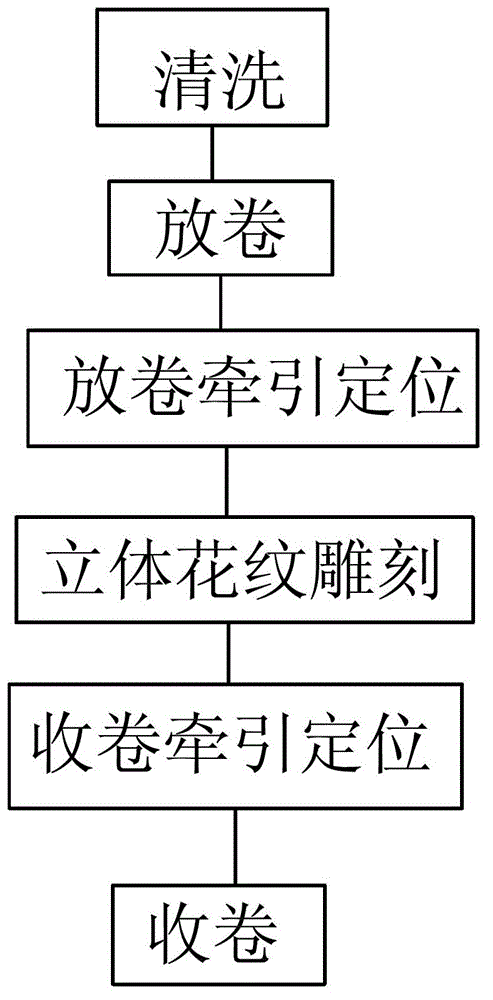

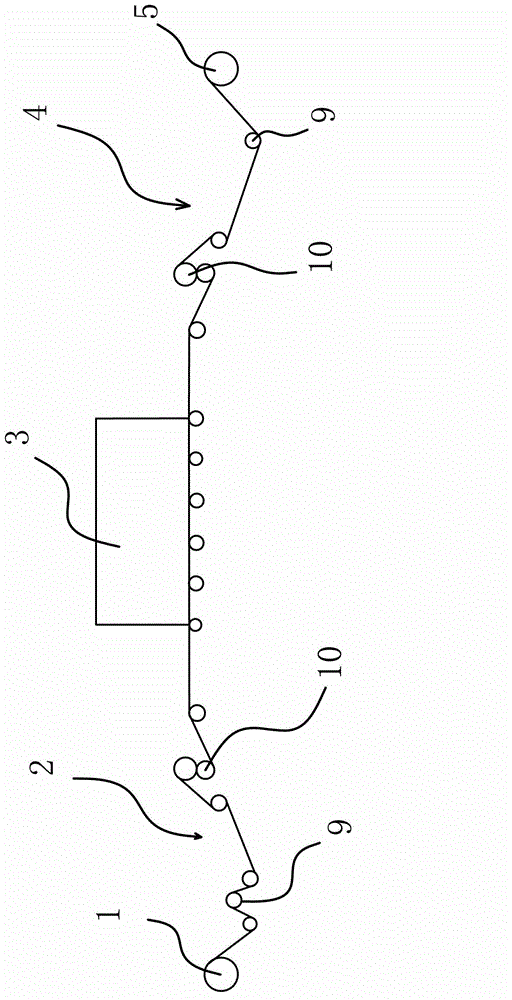

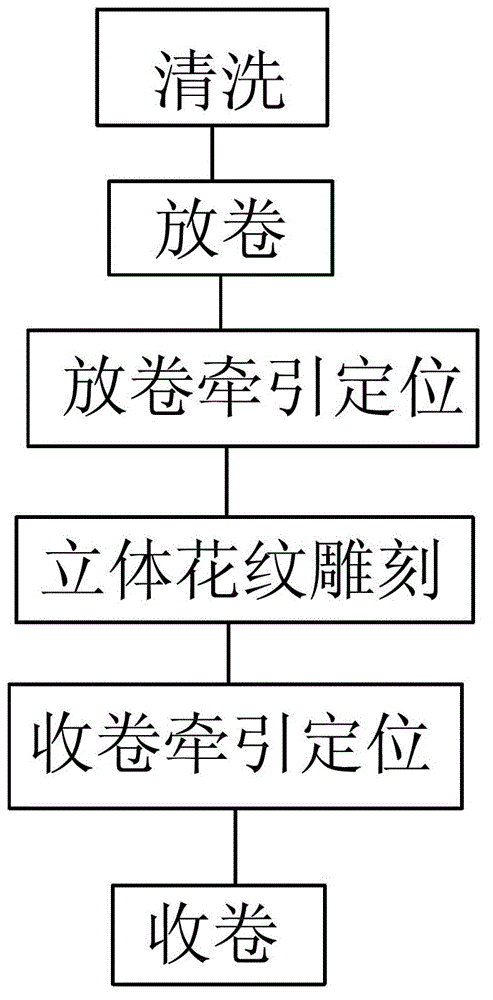

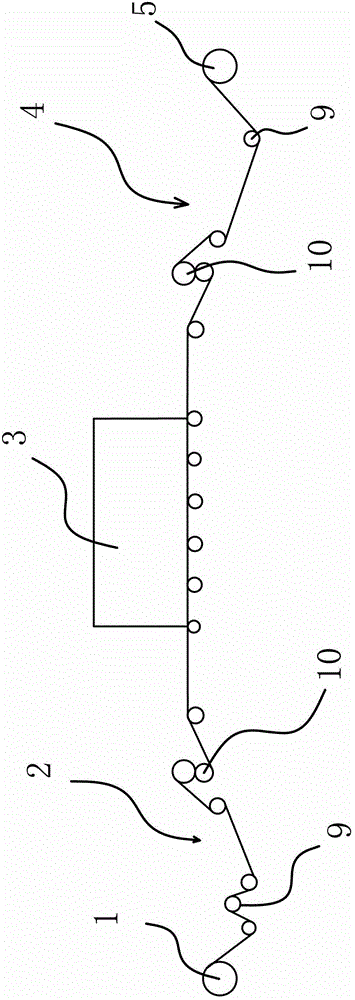

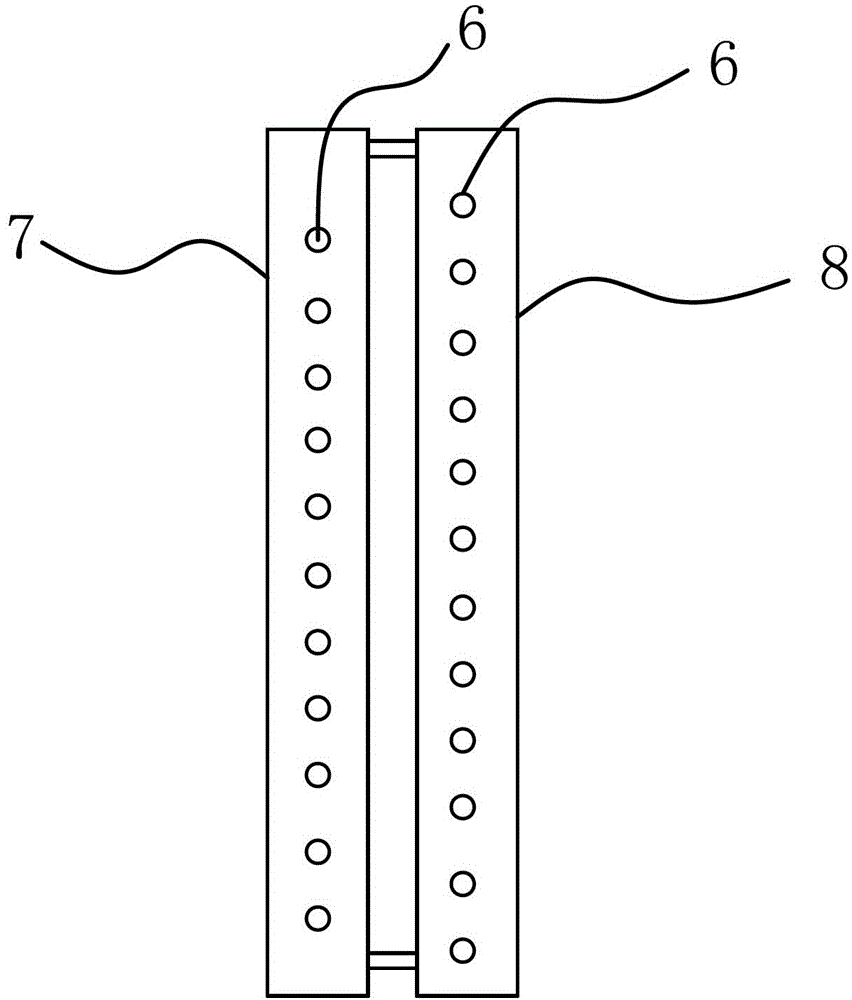

Method for machining stereoscopic patterns of aluminum plate surface

The invention provides a method for machining stereoscopic patterns of an aluminum plate surface, and belongs to the technical field of aluminum alloy surfaces. The method solves the technical problems that an aluminum plate surface cannot be three-dimensionally machined in the prior art and the like. The method includes the working procedures: a, cleaning; b, unreeling; c, unreeling traction positioning; d, stereoscopic pattern engraving; e, reeling traction positioning; and f, reeling. The method for machining the stereoscopic patterns of the aluminum plate surface has the advantages of capability of machining the stereoscopic patterns, simplicity in machining, less pollution and the like.

Owner:浙江铭岛新材料股份有限公司

HSM manufacturing process for arm rod of carbon fiber mechanical arm

The invention discloses an HSM manufacturing process for an arm rod of a carbon fiber mechanical arm. The method comprises the steps that firstly, heat self-expanding high-energy gel, fiber presoakedcloth and a pre-buried pipe are cut; the heat self-expanding high-energy gel wrapped pre-buried pipe is put into a core material mold; the mold is closed and heated to 80-100 DEG C, and the mold is maintained for 3-30 minutes at 80-100 DEG C; at the temperature, the heat self-expanding high-energy gel is micro-expanded in advance and is filled with the core mold cavity, and cooling demolding is carried out to take out the pre-shaped core material; then the fiber pre-soaked cloth wraps the pre-shaped core material, and a prefabricated part is obtained; the prefabricated part is put into a forming mold, the mold is closed and heated to the forming temperature of 120-180 DEG C, and the forming time is 10-60 minutes; and cooling and demolding is carried out, the part is taken out, and the armrod of the carbon fiber mechanical arm is obtained. The arm rod of the carbon fiber mechanical arm is large in bearing capacity and good in rigidity, and the self-weight is light; and the action is stable when the workpiece is grabbed, the moving speed is high, and the positioning precision is good.

Owner:厦门市中豪强碳纤复合材料有限公司

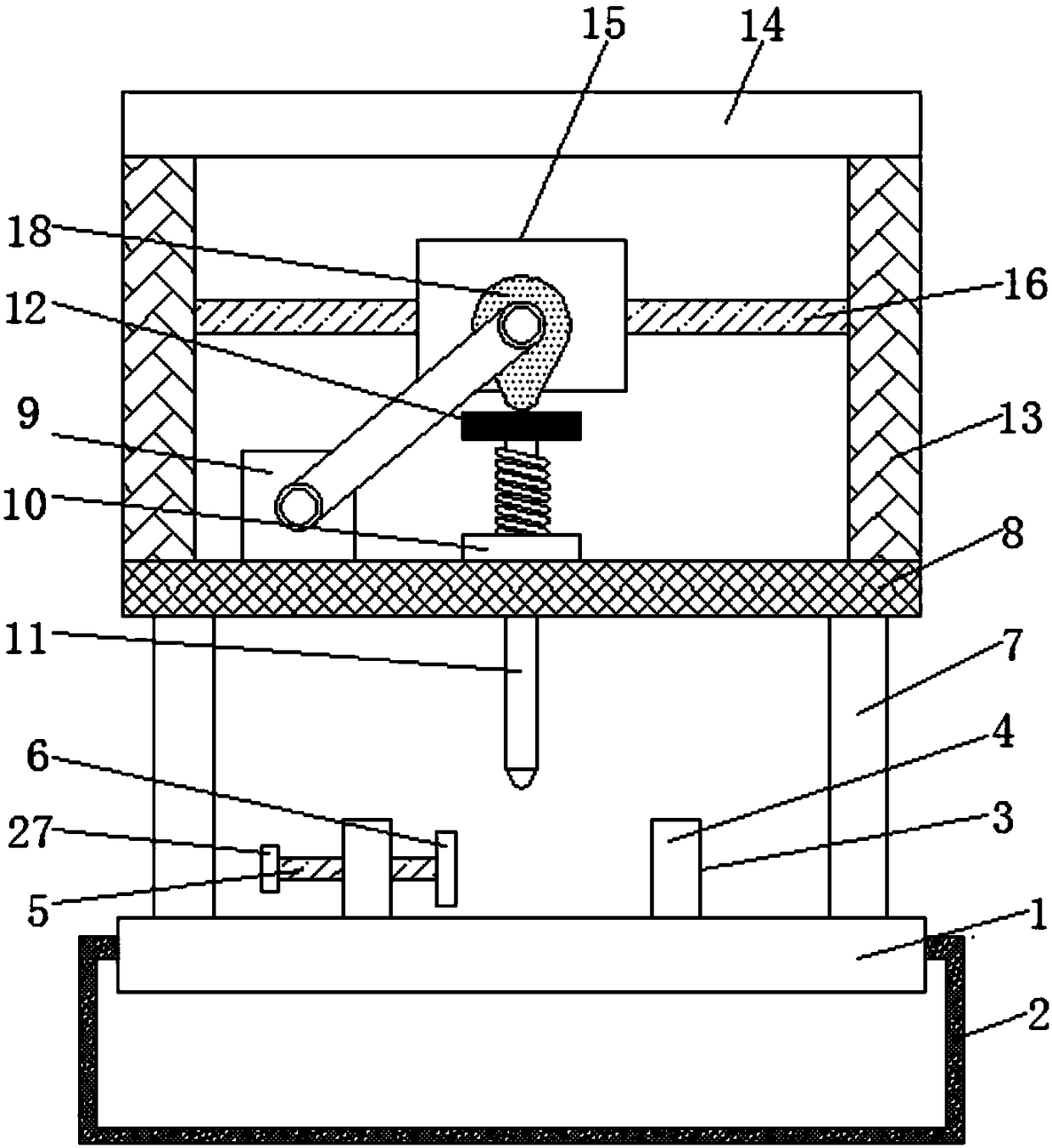

Machining rapid punching machine

InactiveCN108213176AEffectively fixedQuality assuranceNon-rotating vibration suppressionPunchingArchitectural engineering

The invention discloses a machining rapid punching machine which comprises a base; the bottom of the base is fixedly connected with a buffering device; a fixing device is arranged at the center of thetop of the base; the fixing device comprises two fixing columns; the bottoms of the two fixing columns are fixedly connected with the top of the base; a threaded rod is arranged on the fixing columnon one side; one end of the threaded rod penetrates through the fixing column, extends outside the fixing column and is fixedly connected with one side of a fixing plate; the two sides of the top of the base are fixedly connected with the bottom ends of two brackets correspondingly; the top ends of the two brackets are fixedly connected with the two sides of the bottom of a supporting plate; the bottom of the supporting plate is fixedly connected with the bottoms of a motor and a supporting block correspondingly; and a puncher is arranged at the top of the supporting block. The machining rapidpunching machine is simple in structure and convenient to operate, an instrument can be fixed effectively, the punching quality is guaranteed, and defective products are avoided.

Owner:上海多木实业有限公司

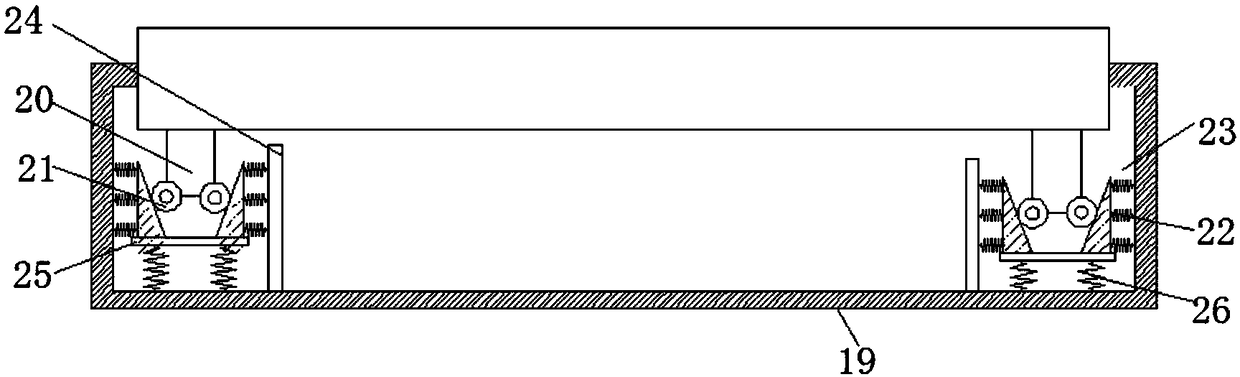

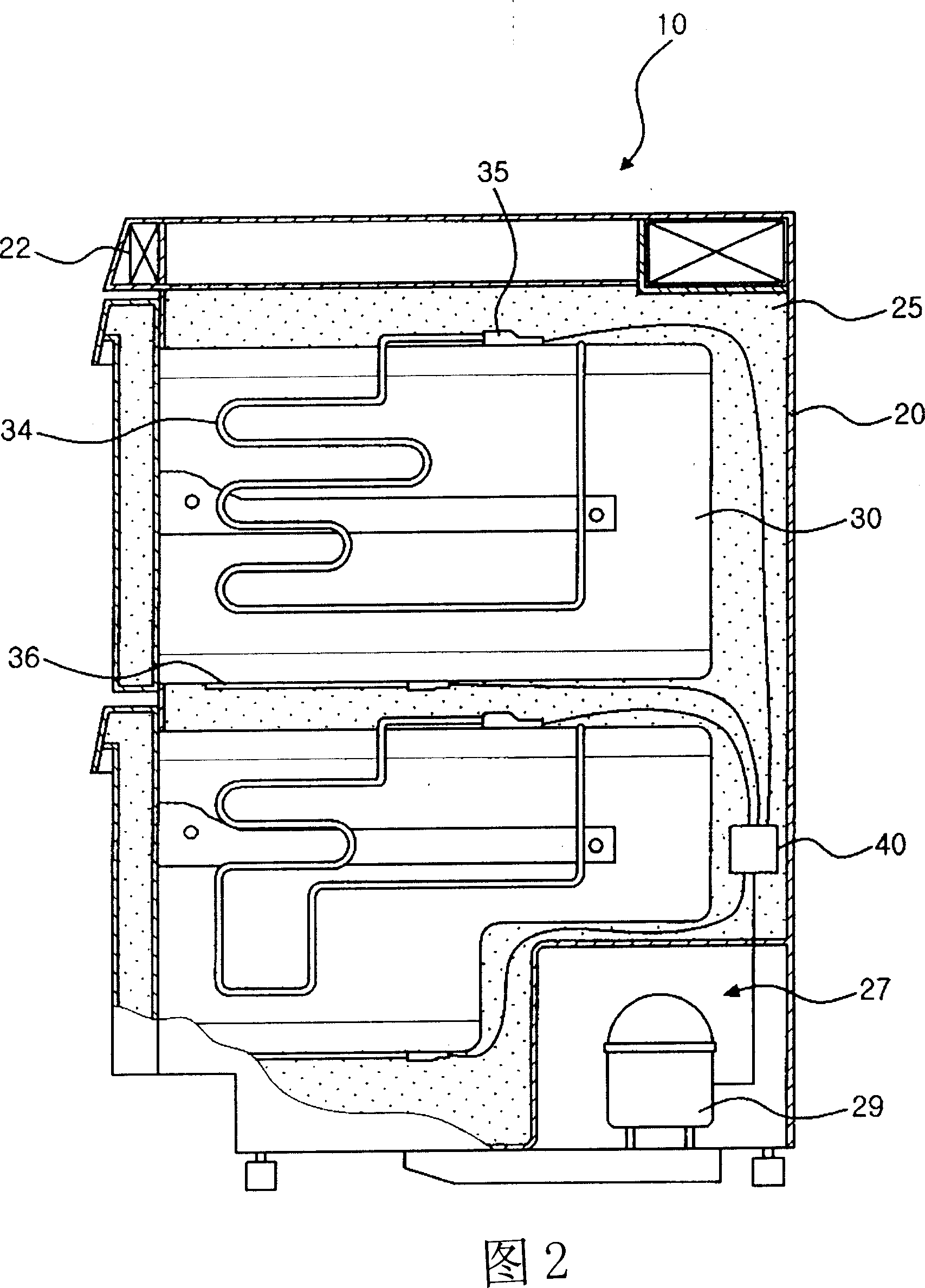

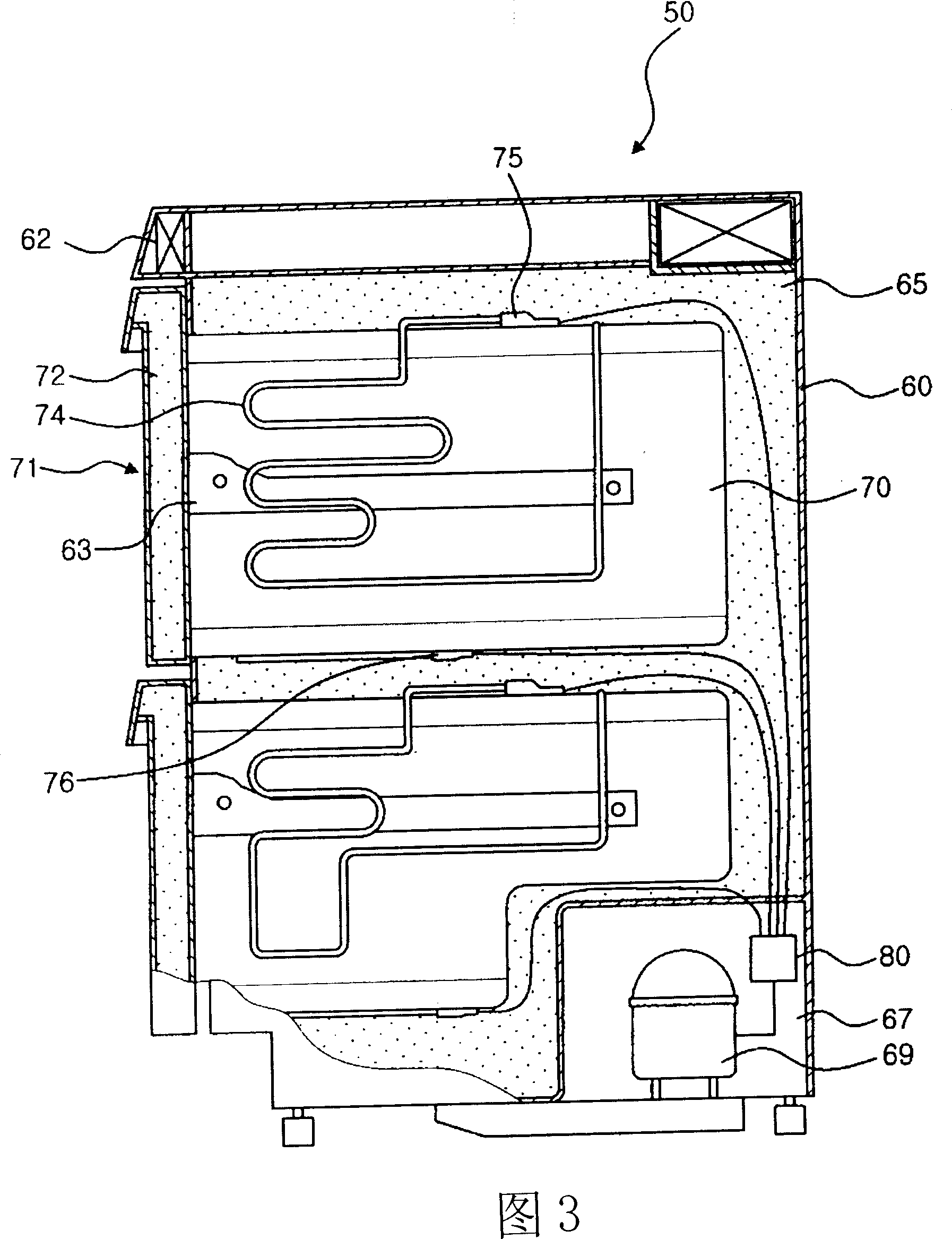

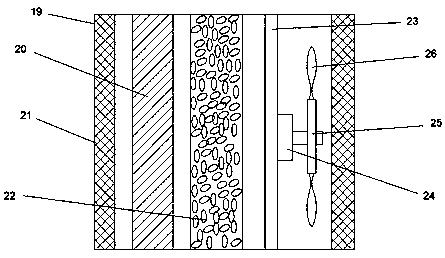

Masking structure of wire box of refrigerator

InactiveCN1952567AAvoid defective rateImprove reliabilityDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention relates to a shadowing structure for refrigerator wire box, comprising inner shell, in which storage room for food is formed and temperature adjusting device is set in it to adjust storing temperature of food; outer shell set at the outside of the inner shell, between which and said inner shell heat insulating material is filled foamingly; mechanical room set at the inside of outer shell lower part, in which the space for cycling device for cycling cool medium to storage room and compressor for compressing and transmitting cool medium is formed; control part set at one side of outer shell, which is connected with temperature adjusting device by wire so as to control the driving of said temperature adjusting device; wire box set in the mechanical room and for accommodating wire, which is used to connect the control part and temperature adjusting device. In the invention because the wire box is not buried in the heat insulating material when the heat insulating material is foaming, repairing or exchanging of production is simple and working efficiency is improved. In addition, because if said wire box is set is known easily badness ratio of production is prevented and production dependence is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

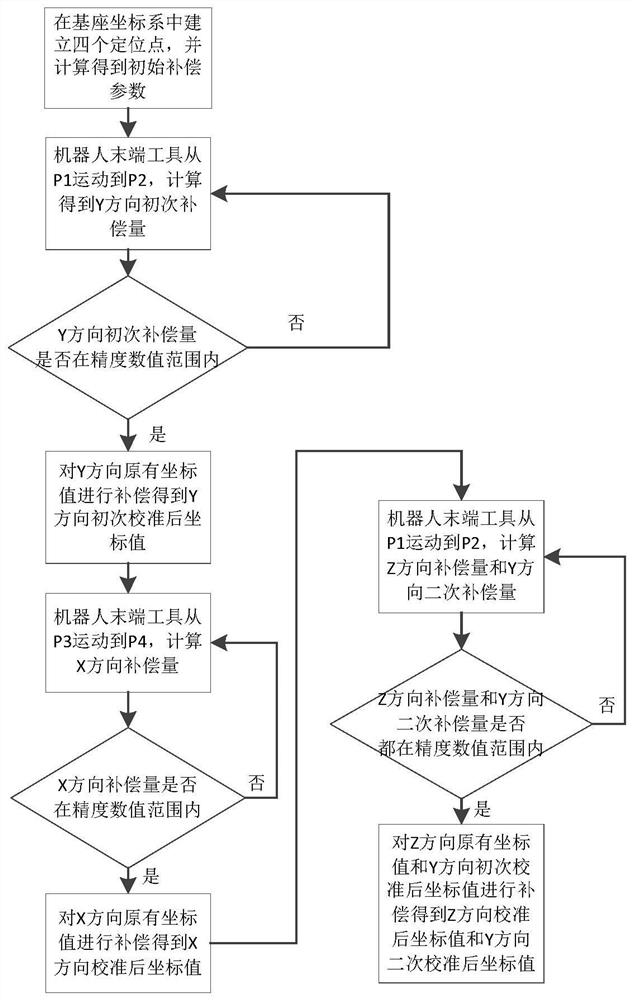

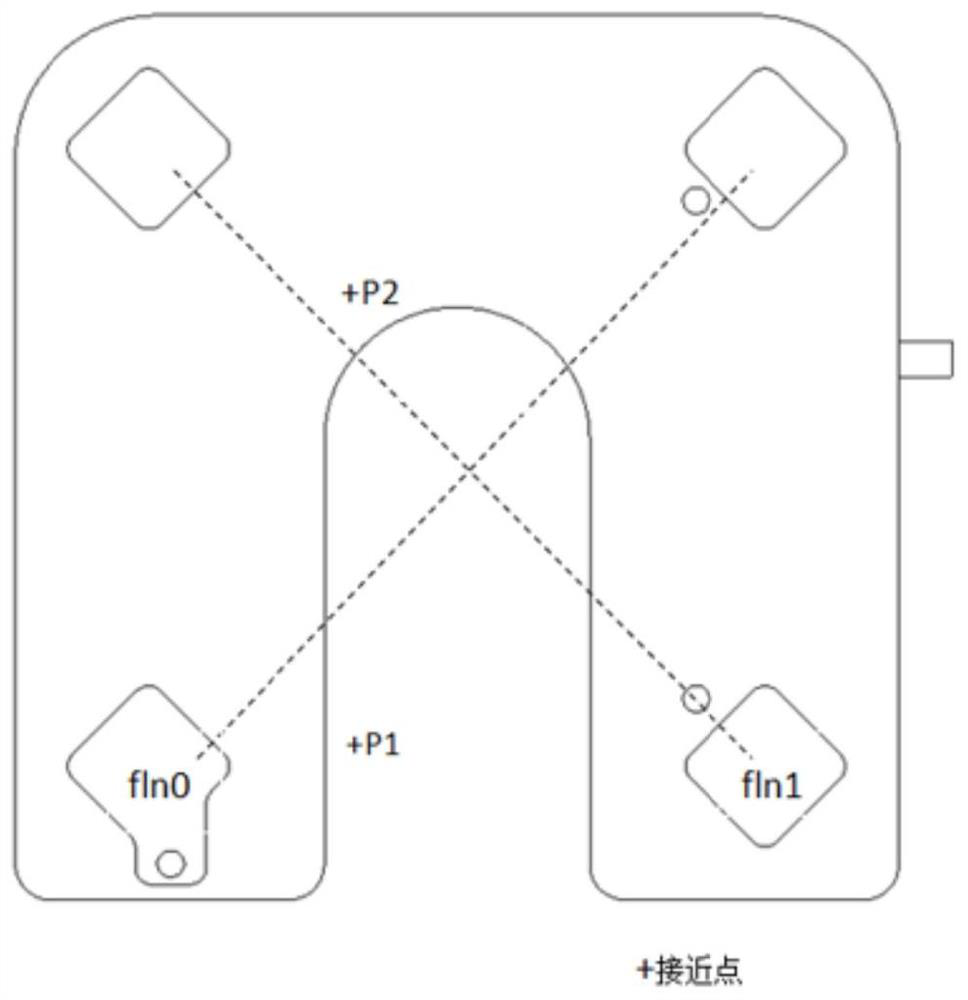

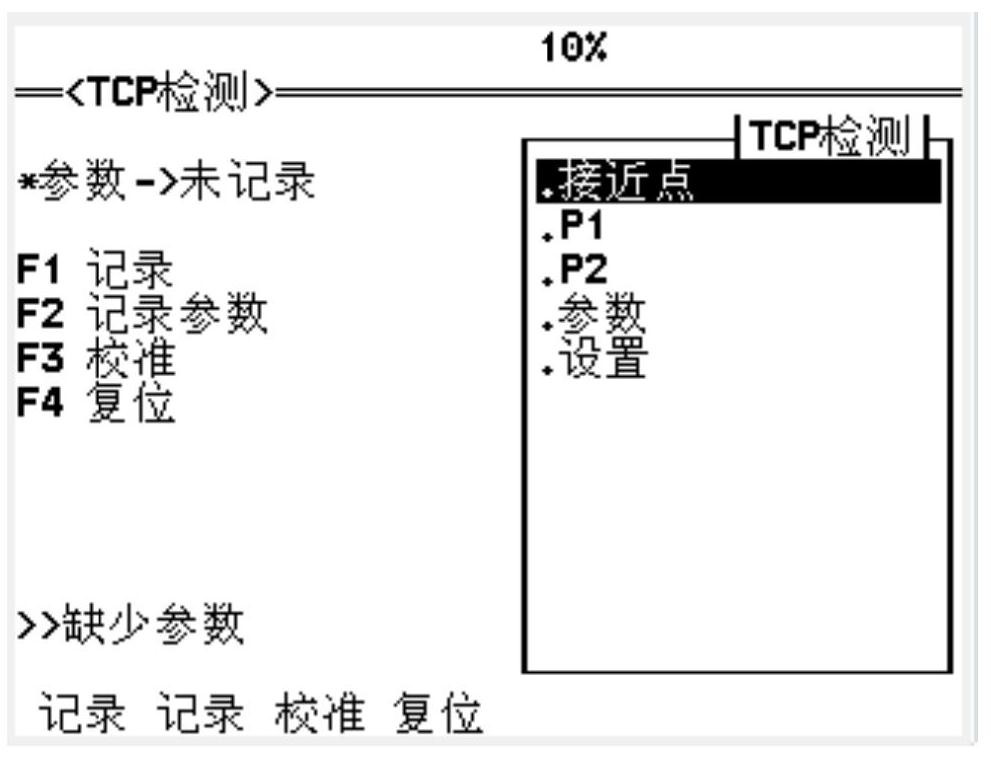

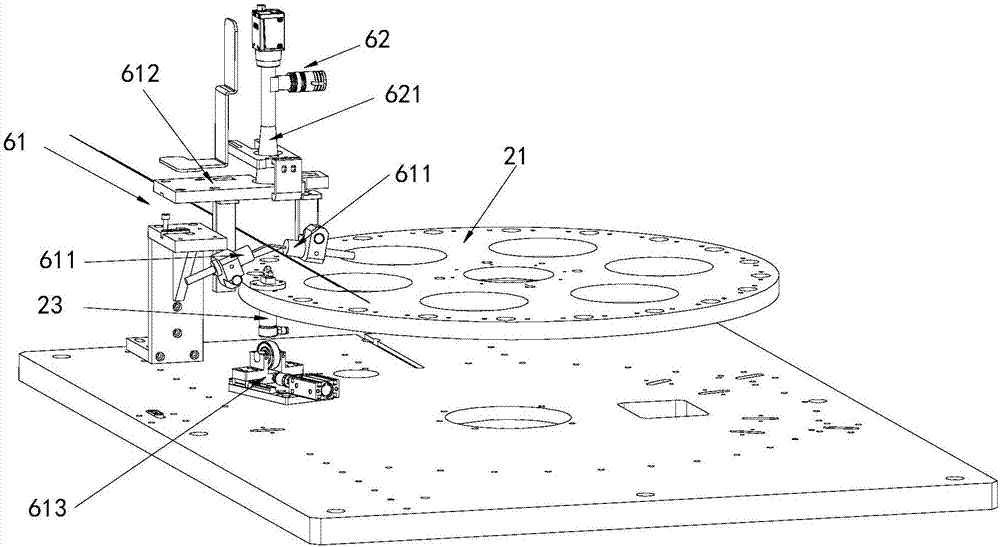

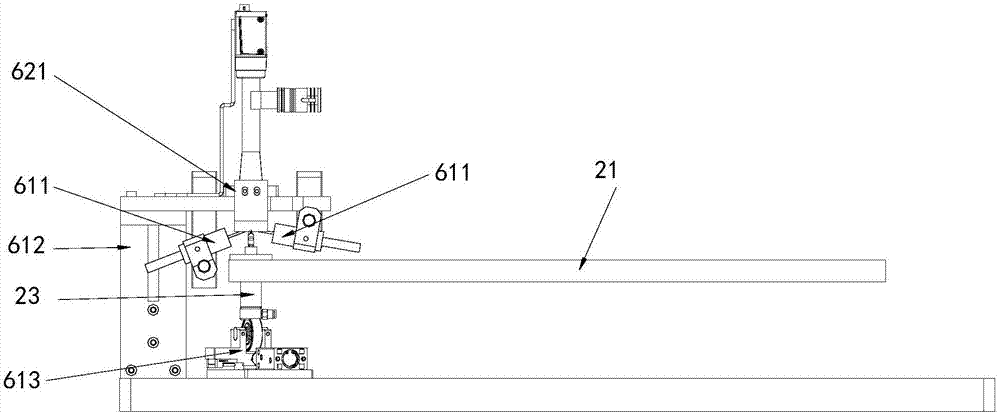

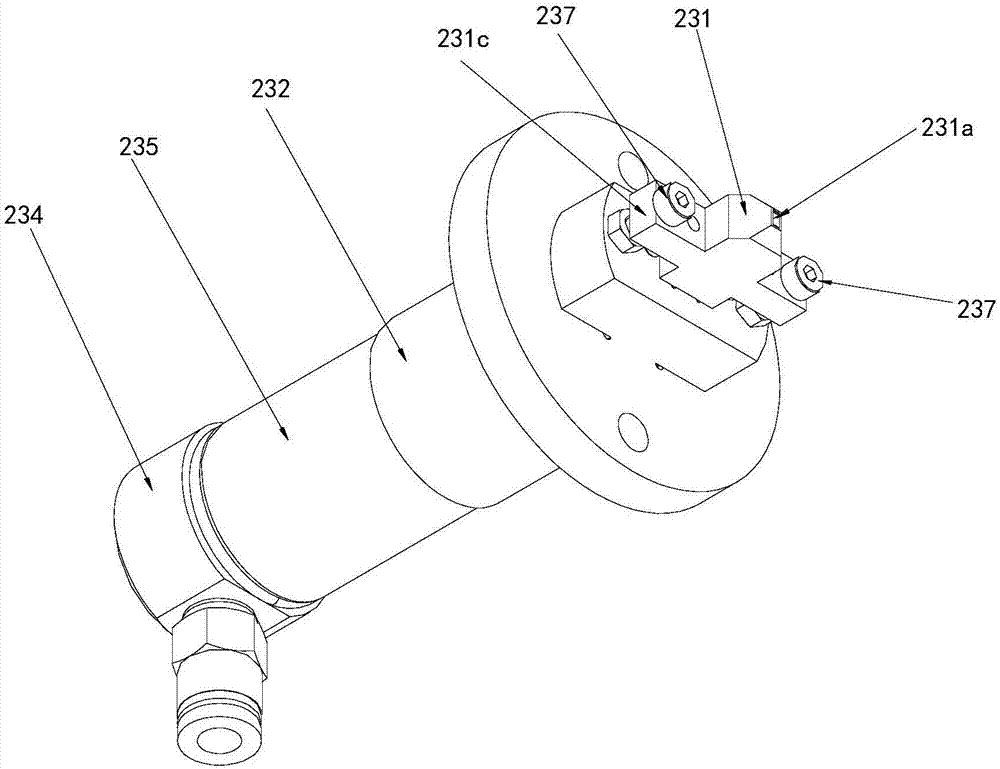

TCP error calibration method of industrial robot

InactiveCN111805548AAvoid defective rateReduced commissioning timeProgramme-controlled manipulatorSimulationLaser sensor

The invention discloses a TCP error calibration method of an industrial robot, and relates to the field of TCP error calibration. Two laser sensors are installed on one side of a robot tail end tool,and the plane where a first laser line and a second laser line are located is a base coordinate system XOY plane. A primarily-calibrated coordination value in the Y direction, a calibrated coordinatevalue in the X direction, a calibrated coordinate value in the Z direction and a secondarily-calibrated coordination value in the Y direction are calculated respectively according to motion interaction parameters of motion of the robot tail end tool in a base coordinate system, the motion of the robot tail end tool is detected by the laser sensors, and a TCP error is calculated and calibrated. When the robot carries out industrial production, when a production period reaches a set value, a TCP detection program is automatically executed, by means of the method, the defective rate caused by theTCP error is effectively avoided, the equipment debugging time is shortened, and the overall production efficiency of equipment is improved.

Owner:江苏亚威创科源激光装备有限公司

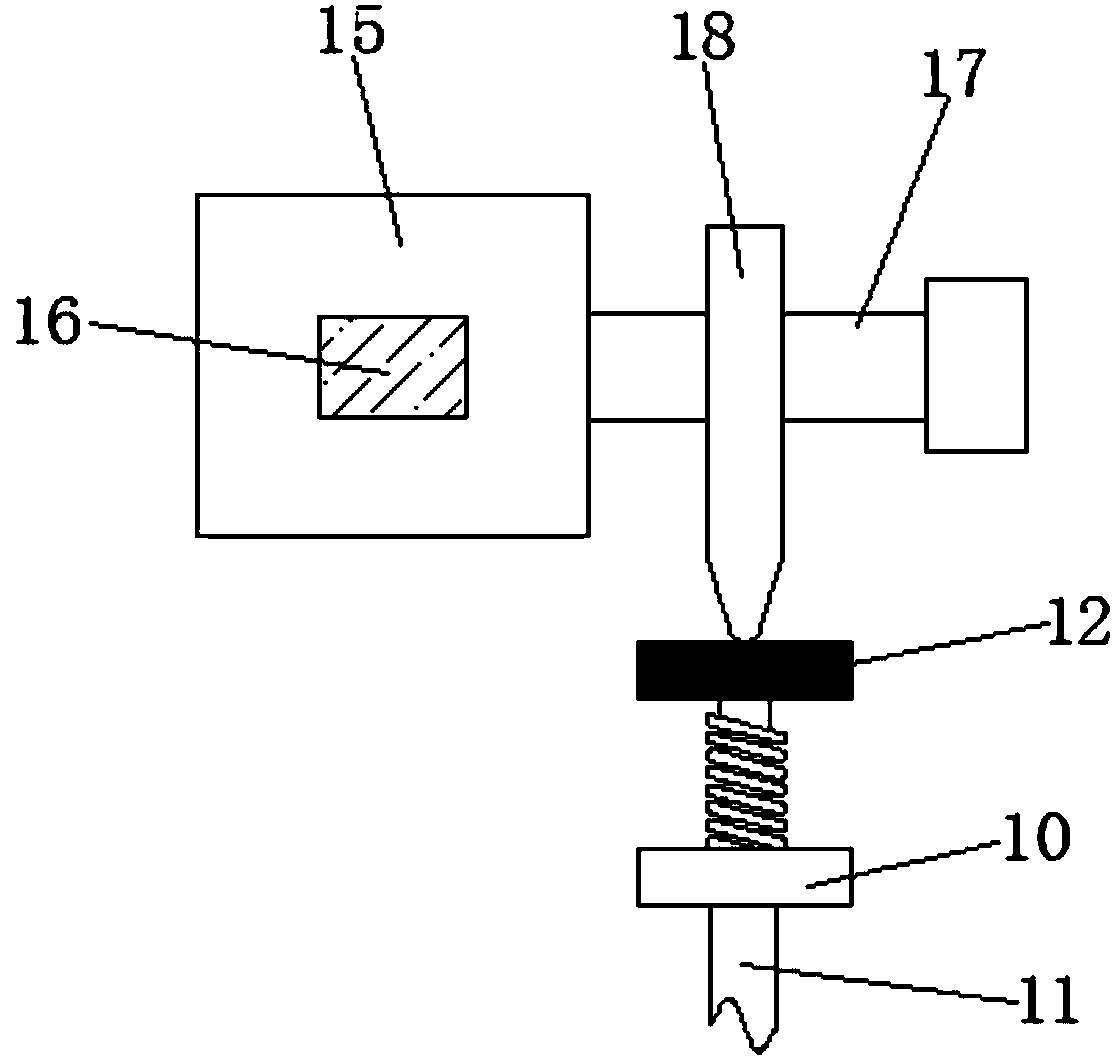

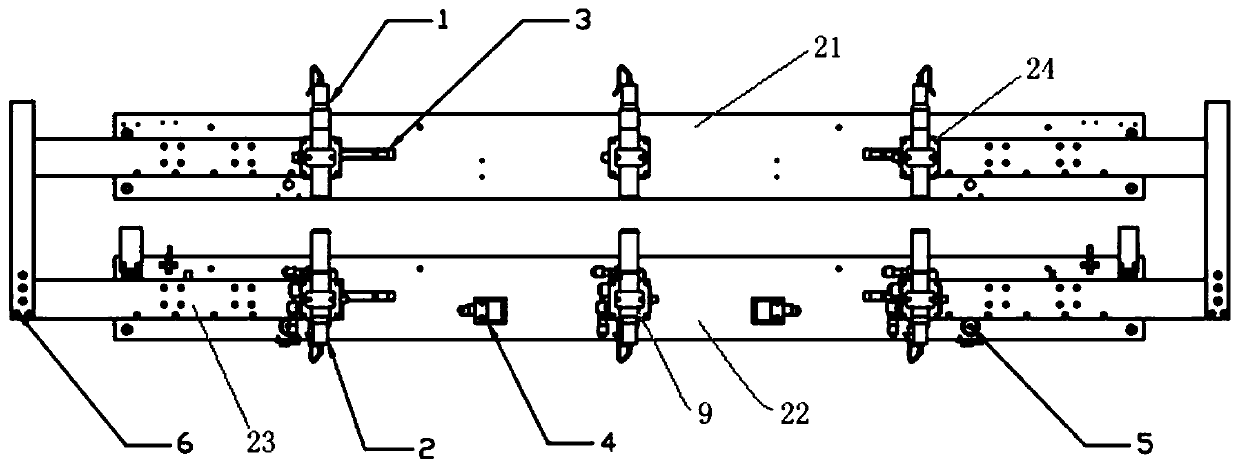

Full-automatic assembly device of LED string lights and welding and detection mechanism thereof

ActiveCN107378243AAvoid defective rateImprove shipment rateLaser beam welding apparatusEngineeringFully automated

The invention discloses a full-automatic assembly device of LED string lights and a welding and detection mechanism thereof. The welding and detection mechanism includes a welding assembly, a power supply assembly and a welding detection assembly, wherein the welding assembly is arranged on a welding position; the welding assembly includes a laser welding head, a welding head bracket and a welding head jacking assembly; the laser welding head is positioned above an LED fixing fixture on the welding position, and the welding head bracket is used for supporting the laser welding head; the welding head jacking assembly is used for driving the LED fixing fixture on the welding position to move upward to be close to wires; the power supply assembly is used for supplying power for the wires, and the welding detection assembly is used for detecting whether or not a patch LED can give out light. The welding and detection mechanism solves the problem that in the manufacture process, welding failure of light beads and wires leads to a defective product rate, and therefore the welding and detection mechanism greatly improves the non-defective product yield of string light production.

Owner:ZHUHAI BOJAY ELECTRONICS

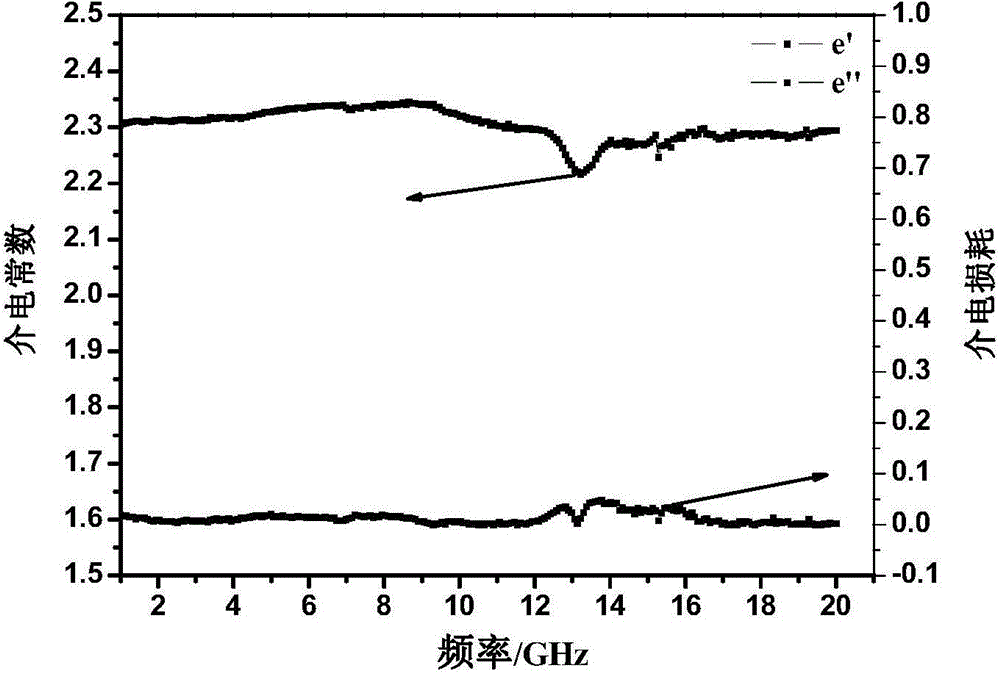

Preparation method of cross-linked polystyrene with high light transmittance

InactiveCN104672390AImprove qualityImprove densification performanceHigh energy electron irradiationCross-link

The invention discloses a preparation method of cross-linked polystyrene with high light transmittance, and belongs to the field of cross-linking polymerization of polymers. The method comprises steps as follows: 1), a polystyrene solution is prepared and uniformly mixed with divinyl benzene in a certain proportion; 2), the mixed solution is subjected to freezing layer by layer and high-energy electron irradiation layer by layer; 3), later forming of a cross-linked polystyrene material is completed through a temperature control process. The method has the main characteristics as follows: a product is pure and transparent and doesn't have defects of bubbles, impurities and the like; 2) the cross-linking polymerization process is performed at an ultralow temperature, and the product qualification ratio is high; 3), the product has excellent light transmittance, stable dielectric property, higher processing mechanical property and the like.

Owner:WUHAN UNIV OF TECH

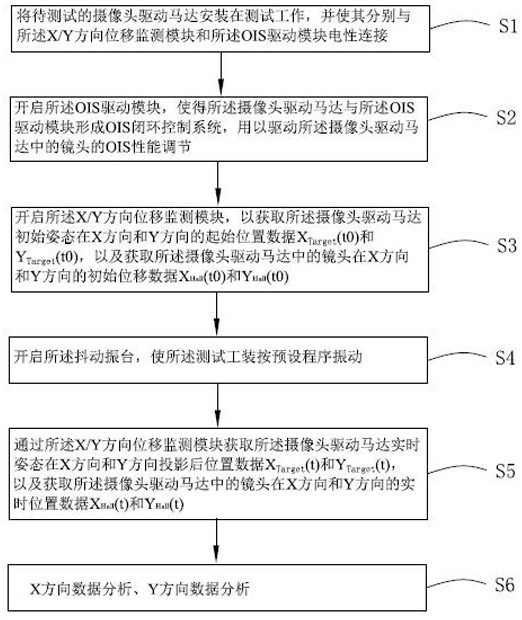

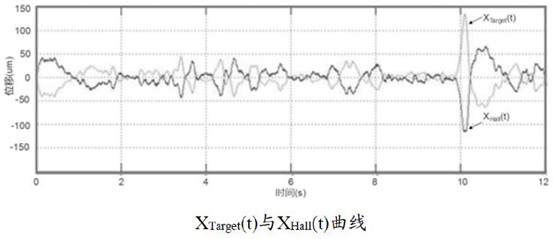

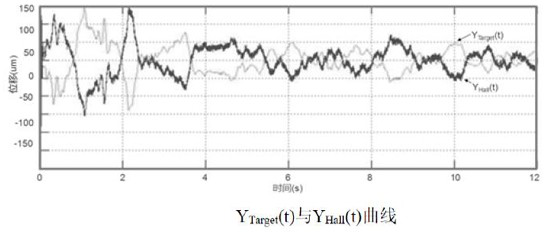

Method for testing optical image stabilization performance of camera driving motor

ActiveCN111879499AAvoid defective rateAvoid rework repair problemsOptical apparatus testingVibration testingLoop controlComputational physics

The invention provides a method for testing the optical image stabilization performance of a camera driving motor, and the method comprises the following steps: enabling the camera driving motor to beinstalled on a testing tool, and enabling the camera driving motor to be electrically connected with an X-direction displacement monitoring module, a Y-direction displacement monitoring module and anOIS driving module; starting the OIS driving module so as to enable the camera driving motor and the OIS driving module to form an OIS closed-loop control system; starting an X-direction displacementmonitoring module and a Y-direction displacement monitoring module to obtain X-direction initial position data and Y-direction initial position data of a camera driving motor; starting a shaking table; obtaining real-time X-direction and Y-direction displacement data of a camera driving motor through an X-direction displacement monitoring module and a Y-direction displacement monitoring module; and enabling the upper computer to analyze the X-direction data and the Y-direction data to judge whether the OIS performance reaches the standard or not. Compared with the prior art, the method for testing the optical image stabilization performance of the camera driving motor is good in reliability, the production efficiency is effectively improved, and the production cost and the reject ratio risk are reduced.

Owner:CHANGZHOU RAYTECH OPTRONICS CO LTD

Welding, grinding and polishing switching integrated machining robot

InactiveCN114102321AScientific and reasonable structureEasy to useEdge grinding machinesPolishing machinesGear wheelElectric machinery

The welding, grinding and polishing switching integrated machining robot comprises a base plate, a machining table is fixedly installed at the top end of the base plate, a mechanical arm is fixedly installed at the position, corresponding to one side of the machining table, of the top end of the base plate, and fixing side plates are evenly, symmetrically and fixedly installed at the top end of the machining table; a driving screw rod is rotatably mounted between the two fixing side plates correspondingly, and one end of the driving screw rod penetrates through and is fixedly connected with a first transmission assembly. The machining robot is scientific and reasonable in structure and safe and convenient to use, and through the arrangement of a driving motor, a driven gear, a sliding block and a sliding plate, the machining efficiency of the machining robot in use is improved; according to the machining robot, the overall economic benefit of workpiece machining is improved, by arranging a conduction sliding rail, a clamping screw rod and a movable clamping plate, the adjustability of the machining robot when the machining robot is used for machining workpieces of different sizes is improved, and the workpiece clamping efficiency of the machining robot is indirectly guaranteed.

Owner:JIAXING UNIV

Two-step preparation method for light and high-strength fiber composite material product through heat self molding (HSM) heat self-expansion prefabricated core material

The invention discloses a two-step preparation method for a light and high-strength fiber composite material product through a heat self molding (HSM) heat self-expansion prefabricated core material. Firstly, shapable pre-forming heat self-expansion high-energy glue is put into a product core material mould, and the mould is closed tightly, and heating is conducted at the temperature of 80-100 DEG C for 3-30 min; the glue is expanded slightly, wherein the volume multiplying power before and after slight expansion is 1.01-1.5, a core material mould cavity is fully filled with the glue, and cooling and demoulding are conducted; and then the glue is wrapped with a fiber prepreg cloth and then put into a forming mould, the forming mould is closed tightly, heating is conducted at the temperature of 120-180 DEG C for 10-60 min, the shapable pre-forming heat self-expansion high-energy glue in the mould continues to be heated to generate inside-to-outside expansion force, and the fiber prepreg cloth is solidified and formed at the high temperature; and cooling, demoulding and product taking are conducted. The two-step preparation method for the light and high-strength fiber composite material product through the HSM heat self-expansion prefabricated core material is suitable for a piece which is wrapped with the fiber prepreg cloth and needs stereo supporting, and the product with the thickness being larger than 1cm and with the complex shape.

Owner:厦门市中豪强碳纤复合材料有限公司

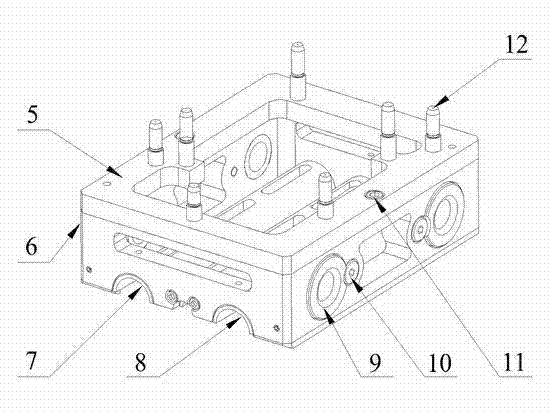

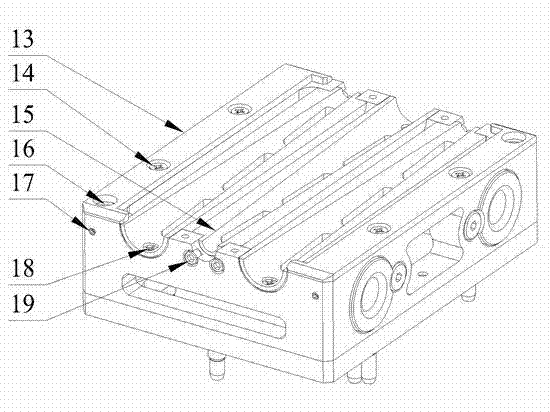

Positioning detecting device and positioning detecting method for collecting pipe of heat exchanger on core assembly part

ActiveCN104043956AThe installation position is correctAvoid defective rateMeasurement devicesMetal working apparatusEngineeringMicro heat exchanger

The invention relates to a positioning detecting device and a positioning detecting method for a collecting pipe of a heat exchanger on a core assembly part. The positioning detecting device comprises a positioning piece inserted into the collecting pipe and a driving device used for driving the positioning piece to move up and down, wherein the positioning piece is opposite to the collecting pipe; the positioning detecting device also comprises a controller respectively connected with the driving device and the core assembly part. Compared with the prior art, the device and the method have the advantages that after the positioning piece is inserted into the collecting pipe, the controller judges whether the insertion depth of the positioning piece in the collecting pipe reaches the insertion depth, preset by the controller, of the positioning piece or not, and sending a clamp clamping signal to the core assembly part after determining that the insertion depth of the positioning piece in the collecting pipe reaches the preset insertion depth; the core assembly part clamps the clamp according to the signal, so as to ensure that the mounting position of the collecting pipe is accurate, avoid occurrence of defective products and improve the yield of finished products.

Owner:SHANGHAI HEKE EQUIP MFG

Automatic circulation crushing device for solid waste treatment

InactiveCN109012841AImprove work efficiencyImprove convenienceCombination devicesGrain treatmentsWork in processWaste treatment

The invention relates to an automatic circulation crushing device for solid waste treatment. The automatic circulation crushing device for solid waste treatment comprises a machine body, wherein a feed hopper is arranged above the machine body in a penetrating way; one end of the feed hopper penetrates through and extends into the machine body; a first crushing wheel is movably arranged in the machine body; a second crushing wheel is arranged on one side of the first crushing wheel; a first block rod is movably arranged under the first crushing wheel; and a second block rod is movably arrangedunder the second crushing wheel. The automatic circulation crushing device for solid waste treatment has the beneficial effects that crushing is carried out through the first crushing wheel and the second crushing wheel, so that the working efficiency of the automatic circulation crushing device for solid waste treatment is improved; filtering is carried out through a leakage net conveyor belt, so that the convenience and the automation in sieving semi-finished products are improved; and dedusting is carried out through a dedusting device, so that powder dust produced when the automatic circulation crushing device for solid waste treatment works is reduced, and the harm of the powder dust on working personnel is reduced.

Owner:金紫媚

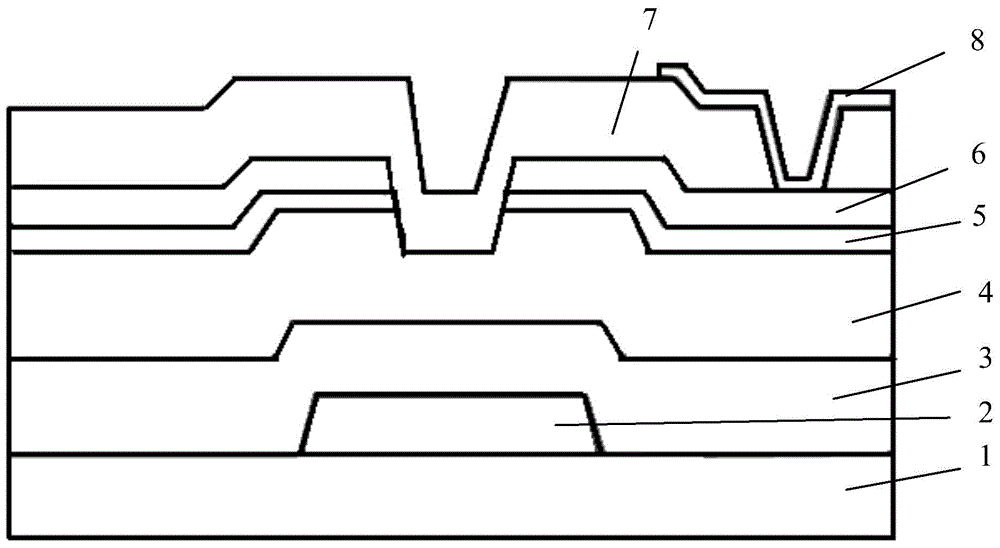

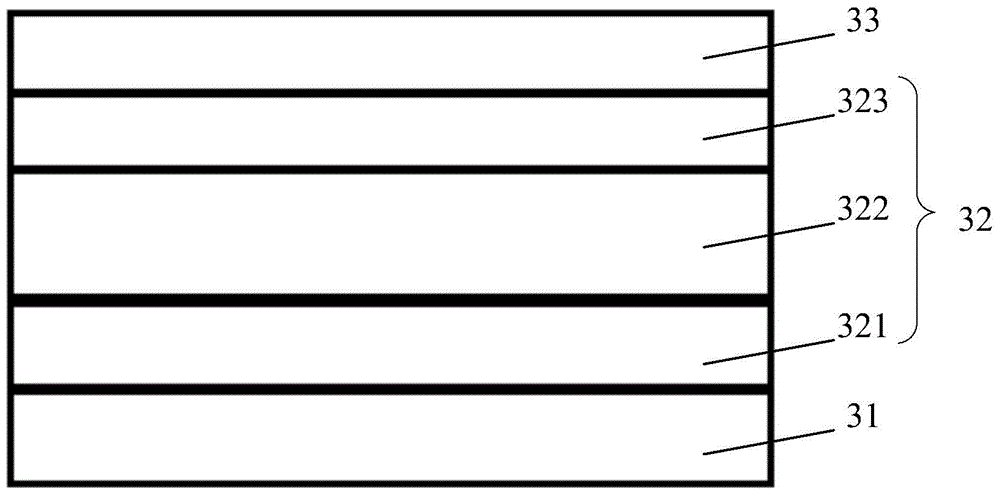

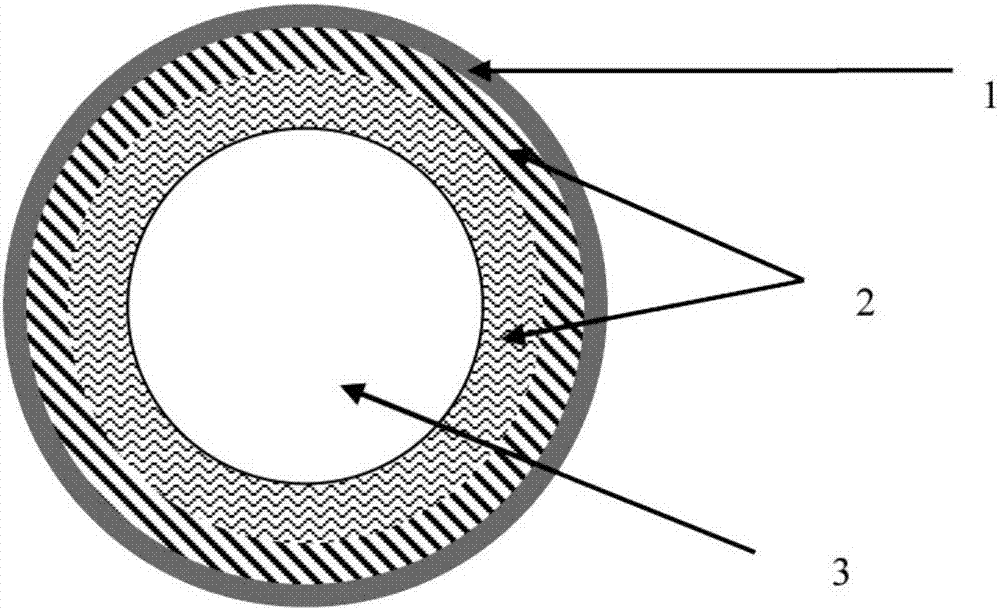

Thin film transistor, manufacturing method thereof, array substrate and display device

ActiveCN104966740AReduce driftImprove stabilityTransistorSolid-state devicesInsulation layerCharge carrier

The invention discloses a thin film transistor, a manufacturing method thereof, an array substrate and a display device, which belongs to the technical field of thin film transistors. The thin film transistor comprises a substrate, a gate electrode, a gate insulation layer and an active layer. The gate insulation layer comprises an inner defect prevention layer and an interface defect prevention layer, wherein the inner defect prevention layer is located between the interface defect prevention layer and the gate electrode; the inner defect prevention layer is used for reducing inner defects of the gate insulation layer; and the interface defect prevention layer is used for reducing defects of a contact interface between the gate insulation layer and the active layer. Through arranging the gate insulation layer in the above mode, the defect number of the inner part of the gate insulation layer and the defect number of the contact surface between the gate insulation layer and the active layer can be reduced, accumulation of carriers (positrons) inside the gate insulation layer and on the contact surface between the gate insulation layer and the active layer can thus be reduced, thin film transistor threshold voltage offset phenomena can be effectively reduced, and the defect rate of the thin film transistors is reduced.

Owner:BOE TECH GRP CO LTD

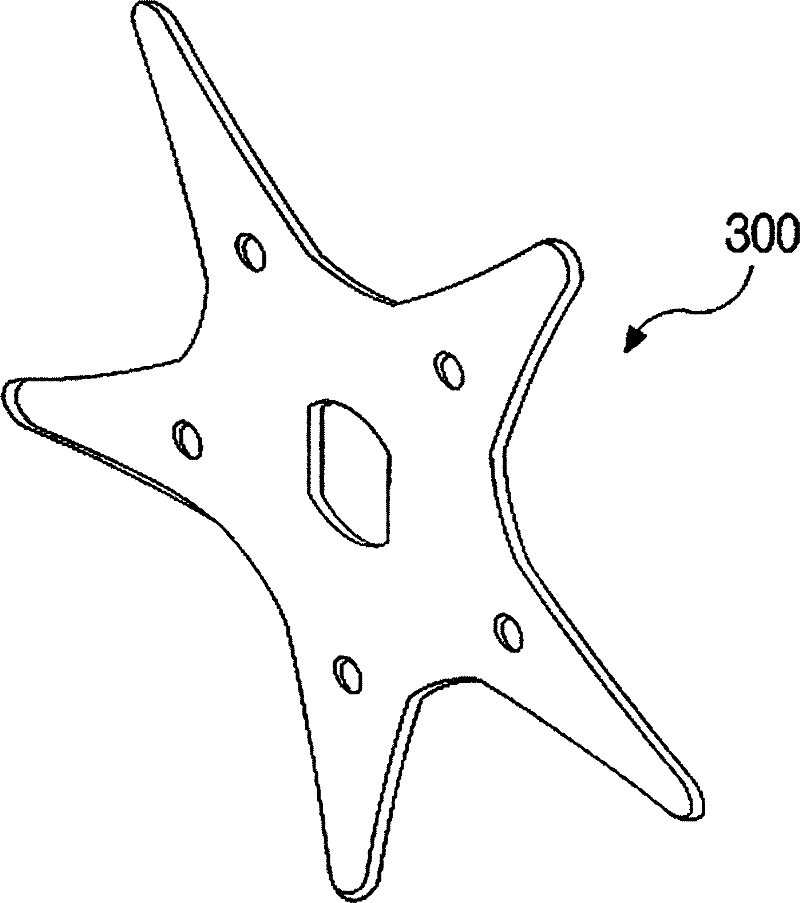

Aluminum pressing out board of unnecessary shearing process and use for method of production fish reel parts thereof

InactiveCN102476133AImprove workabilityAchieve homogenizationExtrusion diesReelsMethods of productionMechanical engineering

An extruded rectangular aluminum panel without the need of shearing process and a fish reel part manufacturing thereof using the same are provided to improve the efficiency of manufacturing fish reel parts, such as a handle arm or a drag, from the extruded rectangular aluminum panel. CONSTITUTION: A method for manufacturing a fish reel part using an extruded rectangular aluminum panel (100) is as follows. A 7075 aluminum rod is put into an extruder. The melt of the7075 aluminum rod is extruded into a rectangular plate with a width of 55 to 150mm, a length of 1000 to 2000mm, and a thickness of 2.5 to 3.9mm. The extruded aluminum rectangular panel is pressed and cut by a press machine to obtain a handle arm or a drag.

Owner:朴顺花

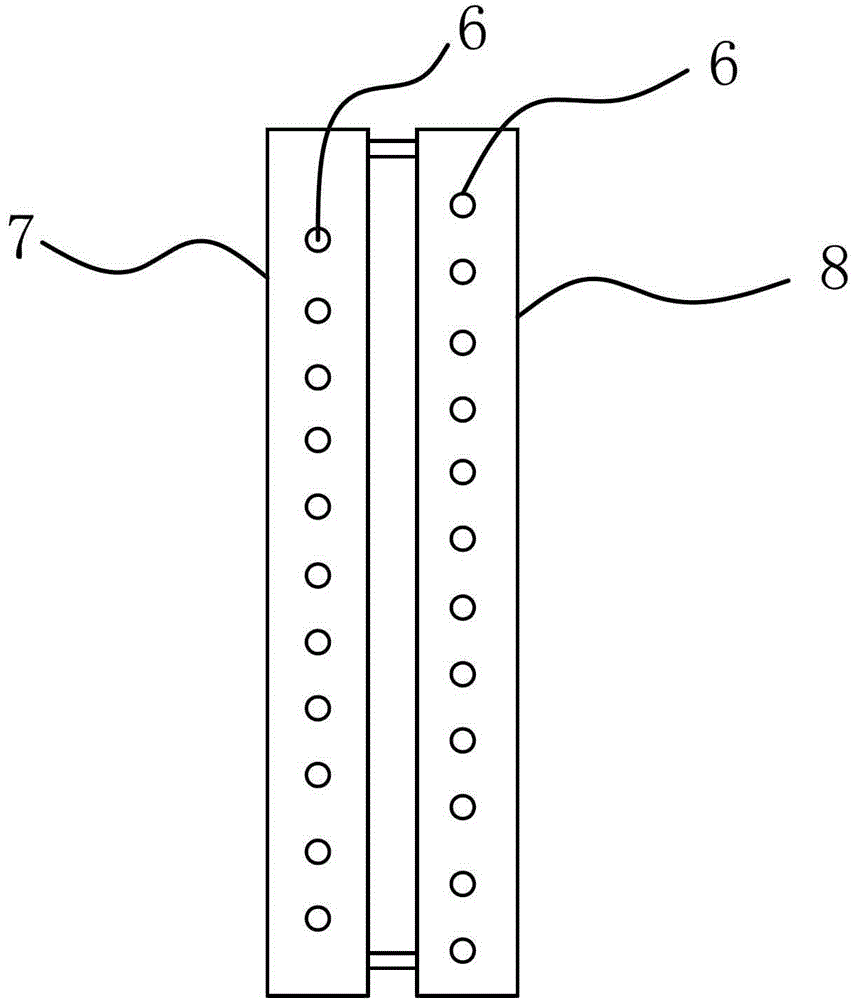

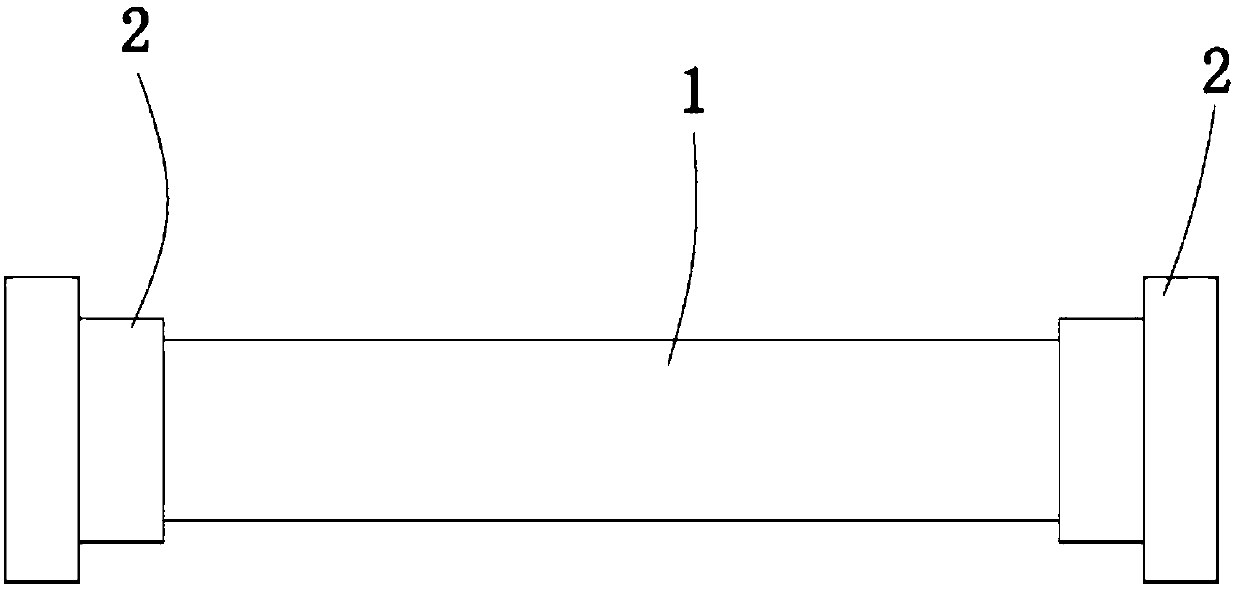

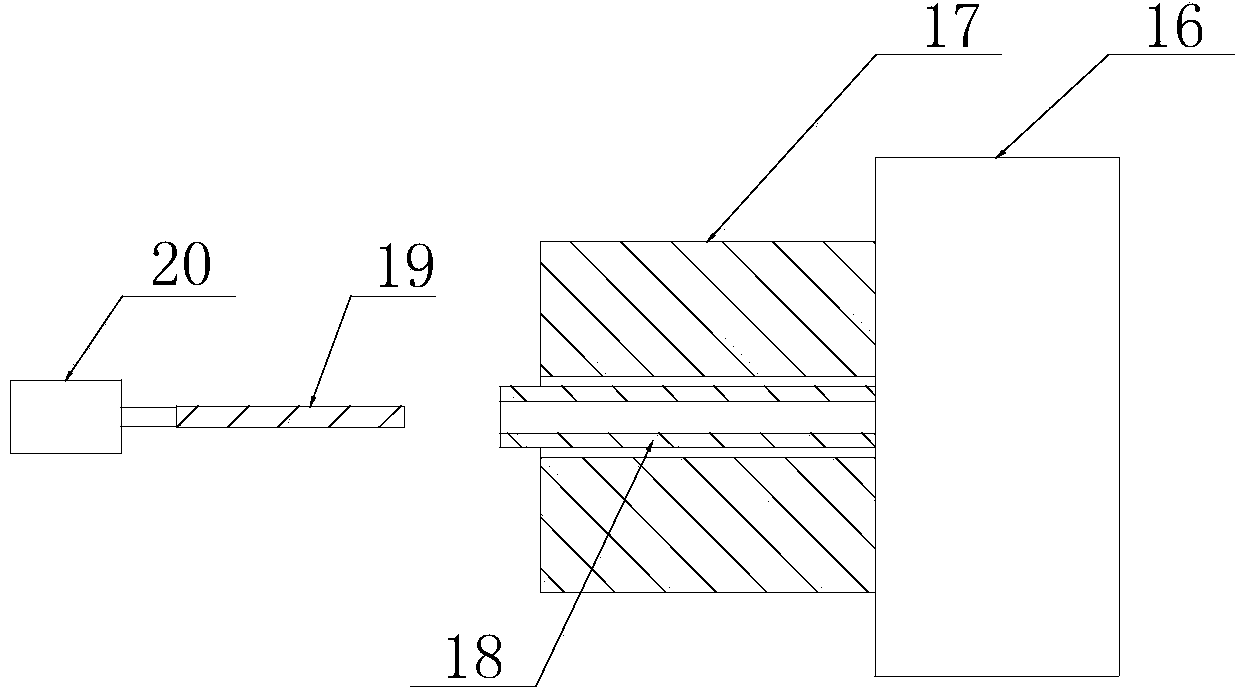

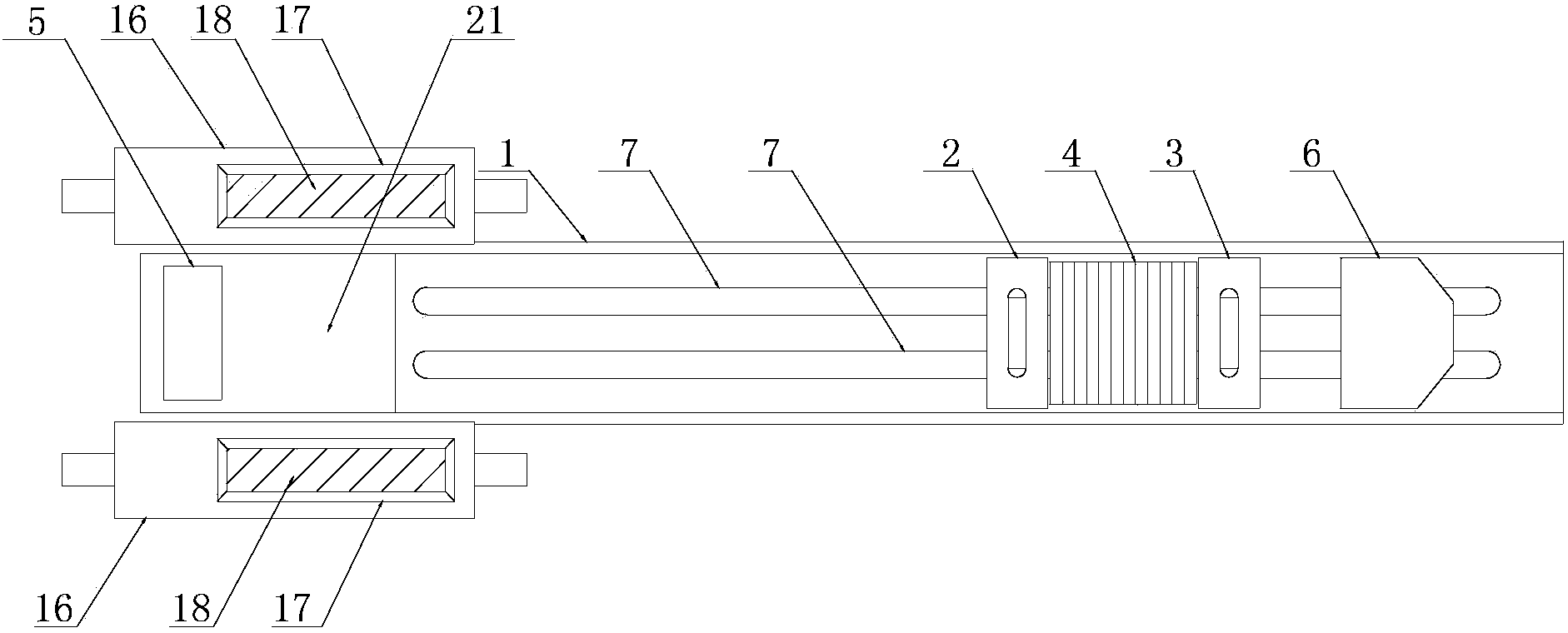

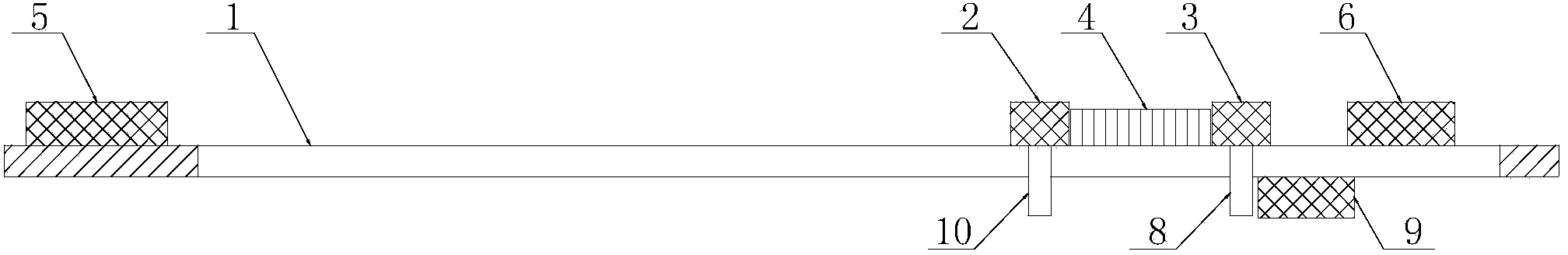

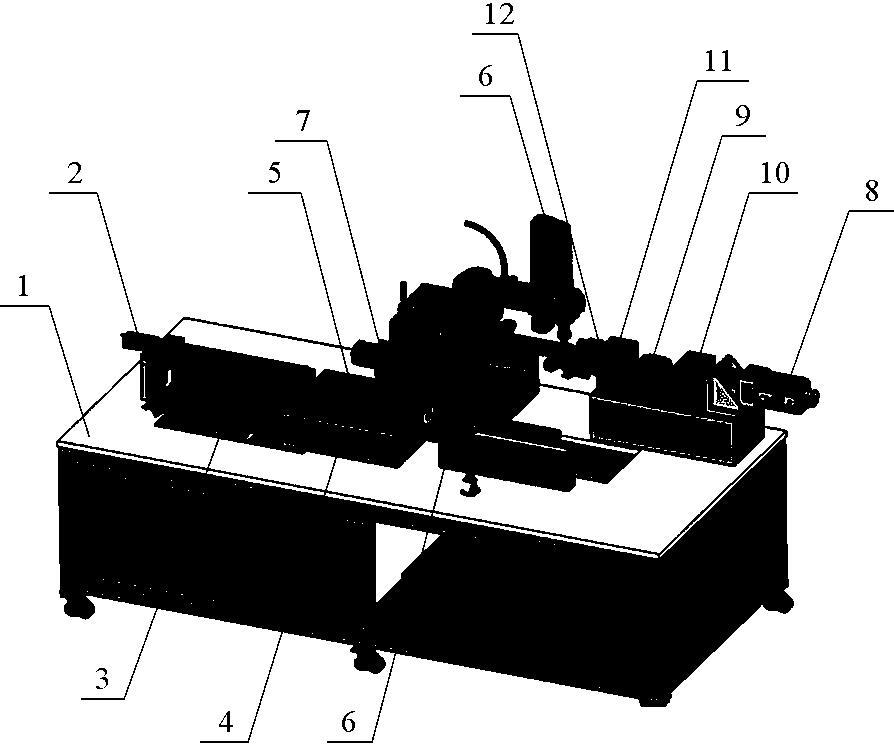

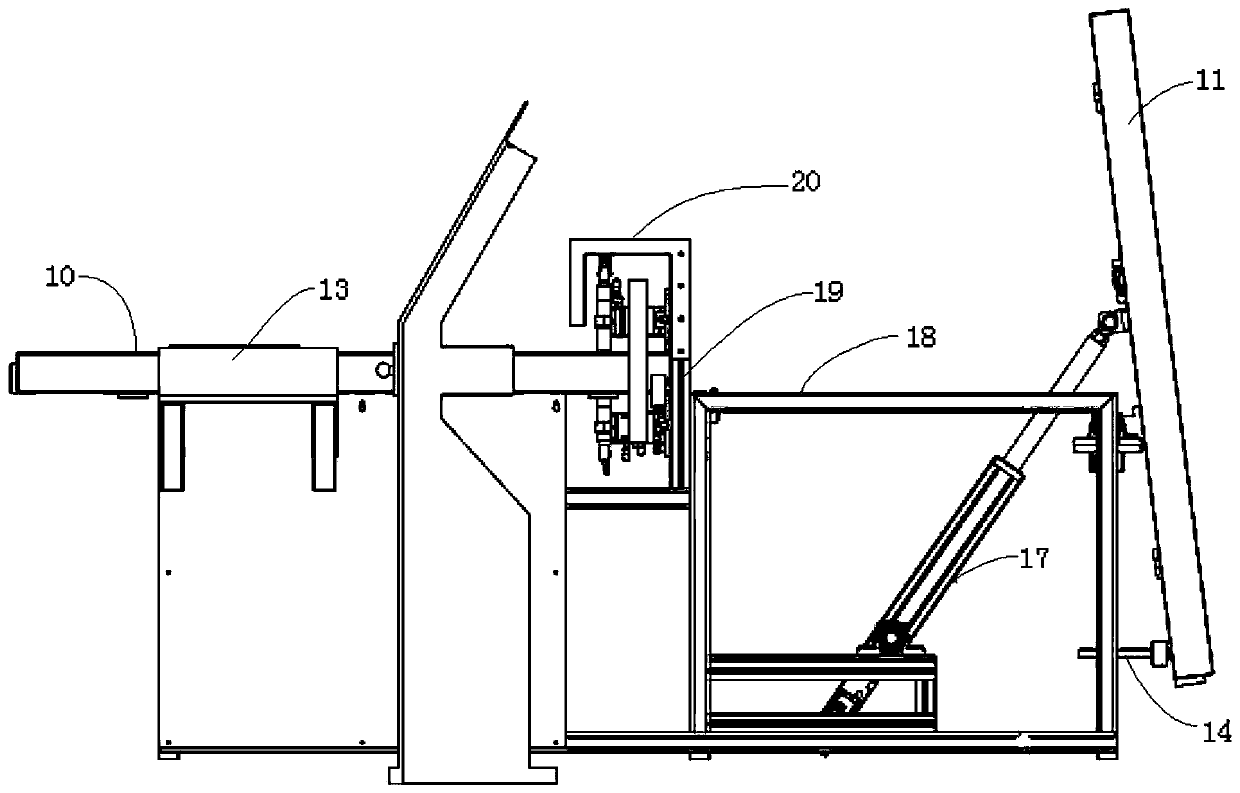

Round bar heating and twisting system and control method thereof

PendingCN110849745AShort work scheduleAvoid safety hazardsStrength propertiesEngineeringHeating effect

The invention relates to a round bar heating and twisting system and a control method thereof. The round bar heating and twisting system is characterized by comprising a working platform (1), and a pushing mechanism (2), a bar temporary storage platform (3), a bar heating mechanism (4), a mechanical grabbing device (8) and a bar twisting mechanism are arranged on the working platform (1); the steps of pushing, feeding, heating, grabbing, twisting and the like of the round bar are sequentially realized; the twisting completion amount of the round bar in unit time is far larger than that of manual operation, the working efficiency is high, meanwhile, the defective rate and the error rate caused by excessive errors due to manual fatigue operation are low; meanwhile, the heating effect is effectively achieved through a mechanical device and a detection device, and the twisting precision is guaranteed.

Owner:江苏天宝利自动化科技有限公司

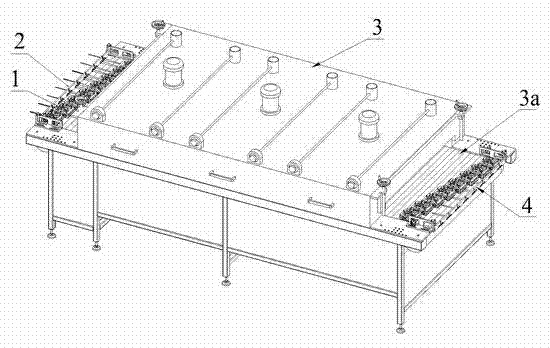

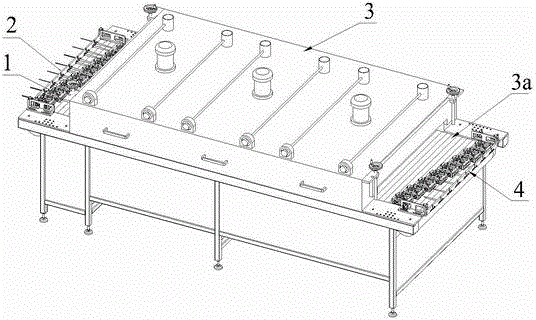

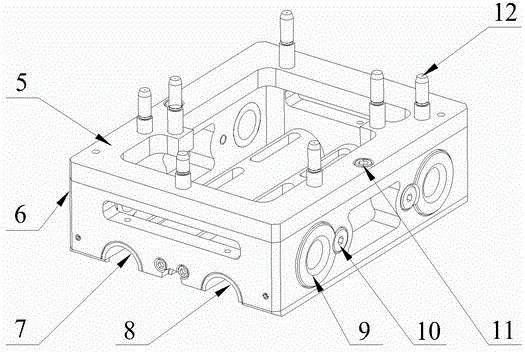

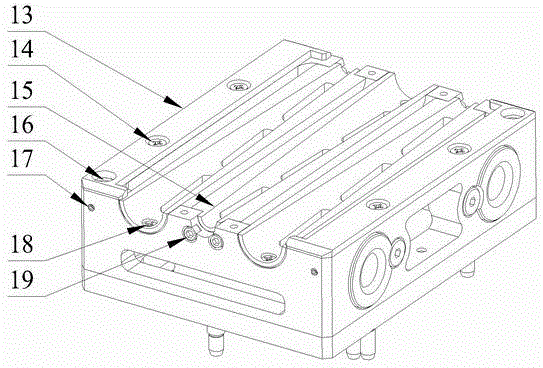

Tunnel type oven berth mechanism suitable for automatic online and offline

ActiveCN102815531AReliable disengagementAvoid abnormal wear and tearConveyor partsEconomic benefitsOnline and offline

The invention discloses a tunnel type oven berth mechanism suitable for automatic online and offline and belongs to the technical field of product postprocessing auxiliary devices. The mechanism comprises an entrance berth group, an exit berth group and a carrier, the entrance berth group is arranged at the entry end of a tunnel type oven through a lateral seat frame I, the exit berth group is arranged at the exit end of the tunnel type oven through a lateral seat frame II, gaps are reserved among the entrance berth group, the exit berth group and a link plate, and the carrier is automatically conveyed from the entrance berth group to the exit berth group through the link plate. According to the tunnel type oven berth mechanism suitable for the automatic online and offline, when the tunnel type oven is used for baking products, the automatic online and offline is achieved, unmanned and automated joint of working procedures from start to finish are convenient to achieve, the production cost is greatly reduced, the production efficiency is improved, the risk of human injuries caused by high temperature overflow wind of the oven entrance and exit is prevented, the product reject ratio caused by the fact that the manual picking and placing of products are prone to pollute product surfaces is avoided, the economic benefits are improved, and the tunnel type oven berth mechanism is easy to popularize and apply.

Owner:怡得乐电子(杭州)有限公司

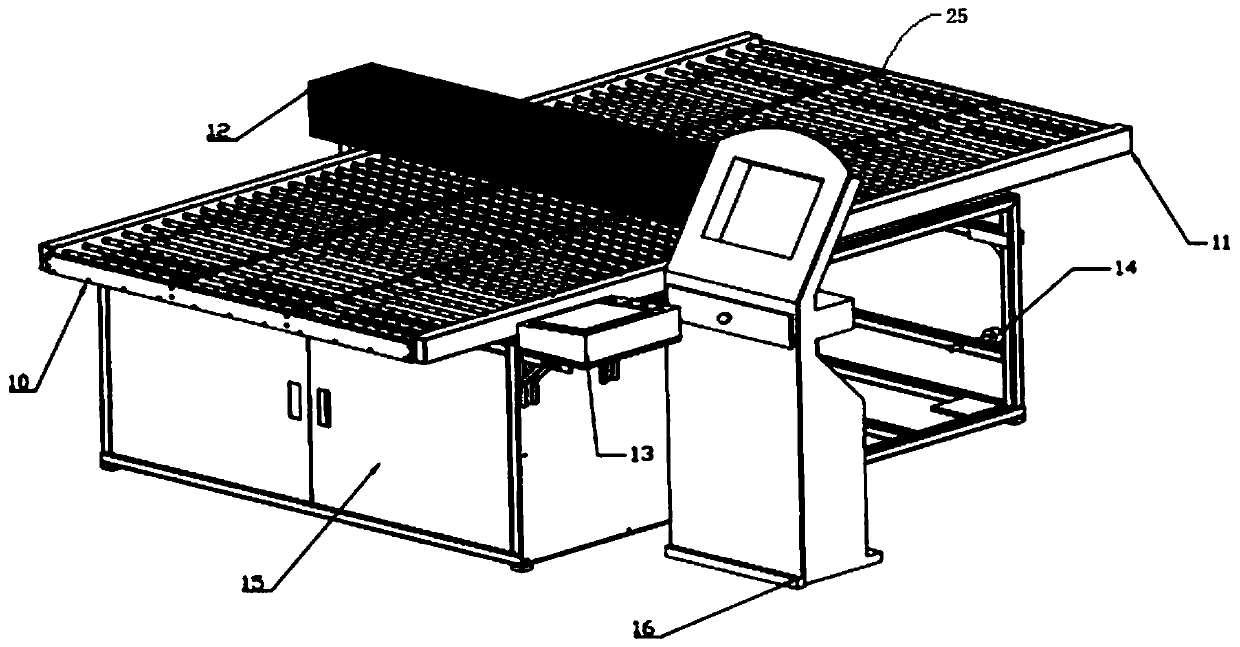

Automatic thickness measuring machine for touch display screen

InactiveCN110906873AReduce manufacturing costEasy to operateUsing optical meansControl engineeringInteraction device

The embodiment of the invention discloses an automatic thickness measuring machine for a touch display screen. The automatic thickness measuring machine comprises an overturning conveying platform, afixed conveying platform, a displacement adjusting mechanism and a man-machine interaction device. The overturning conveying platform and the fixed conveying platform are both installed on a rack, thedisplacement adjusting mechanism is arranged between the fixed conveying platform and the overturning conveying platform and is installed on a displacement adjusting mechanism support, and the displacement adjusting mechanism support is fixed to the rack. According to the invention, the thickness of a touch panel can be measured at fixed points, three points can be measured at one time, and the online mobile real-time measurement also can be realized. The automatic thickness measuring machine has the advantages of simple operation, high measurement precision and stable transmission, the measurement data is automatically stored in the man-machine interaction device, and the measurement data can be copied and directly printed by a USB flash disk, so that the measurement efficiency and accuracy are significantly improved, the reject ratio caused by personnel contact measurement is solved, the product quality is improved, and the manpower and the enterprise production cost are saved.

Owner:赫得纳米科技(黄石)有限公司

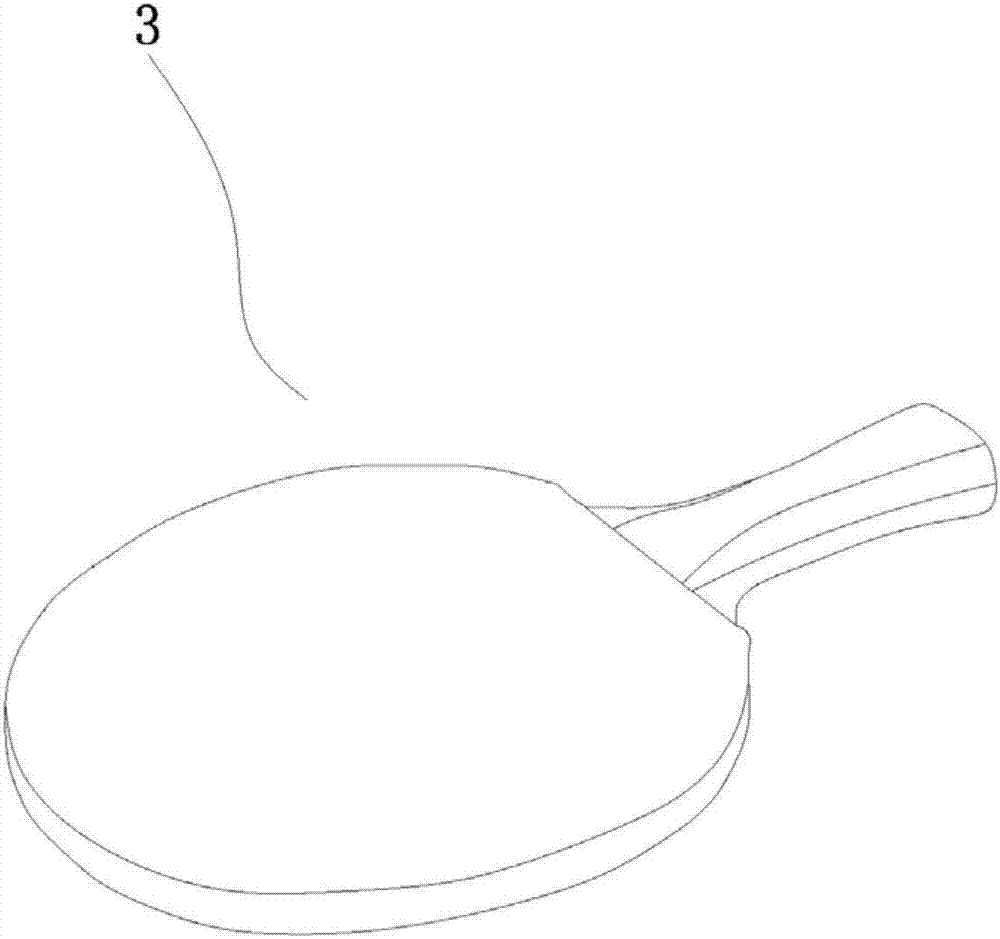

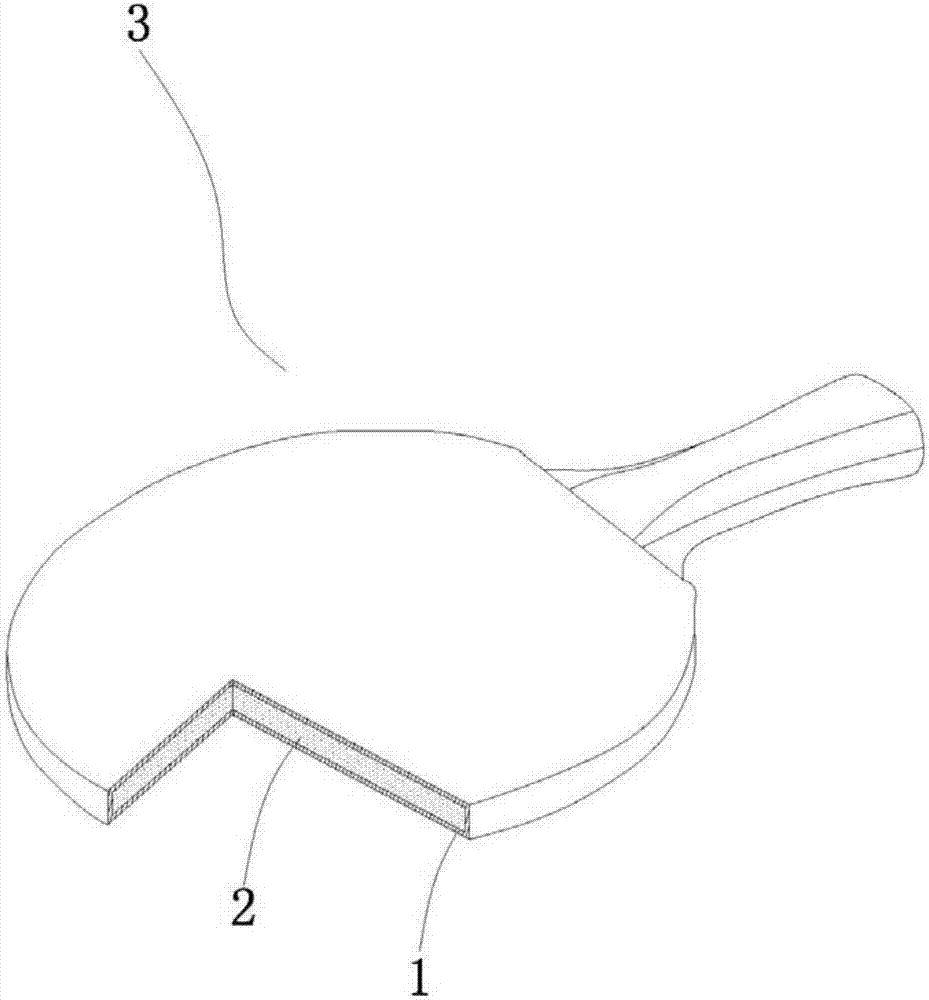

Method for preparing ping-pong bat through HSM forming process

The invention discloses a method for preparing a ping-pong bat through an HSM forming process. The method comprises the steps that thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming is placed in a product core material die and the die is tightly closed, the thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming is heated for 3-30 minutes at 80-100 DEG C, and micro-expansion is carried out, wherein a volume multiplying power before and after the micro-expansion is 1.01-1.5, a core material die cavity is fully filled with the thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming, cooling and die release are carried out, then the thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming is wrapped with a fiber prepreg and placed in a forming die, and the die is tightly closed, and the thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming is heated for 10-60 minutes at 120-180 DEG C, wherein the thermally-self-expansion high-energy glue capable of being subjected to shaping pre-forming continues to be heated to generate an expansion force from inside to outside, and the fiber prepreg is subjected to high-temperature curing forming; and cooling and die release are carried out, and a product is taken. The ping-pong bat prepared by the method disclosed by the invention is high in strength and low in reject ratio.

Owner:厦门市中豪强碳纤复合材料有限公司

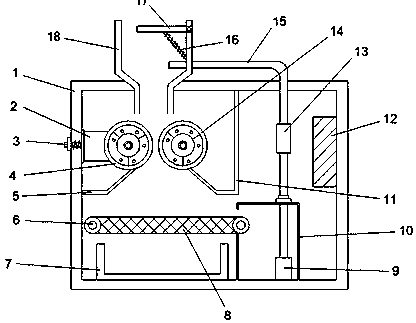

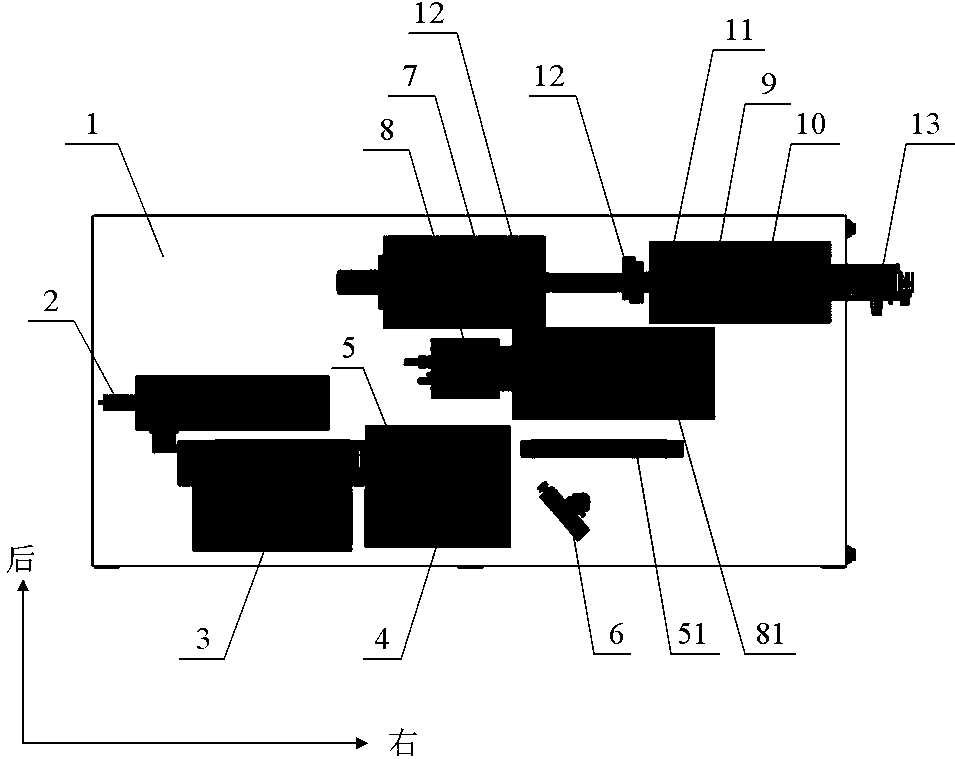

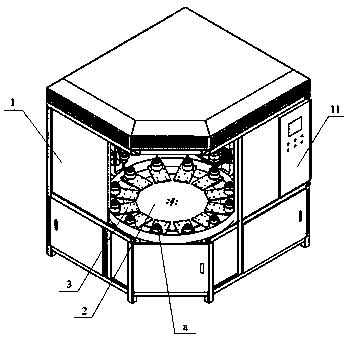

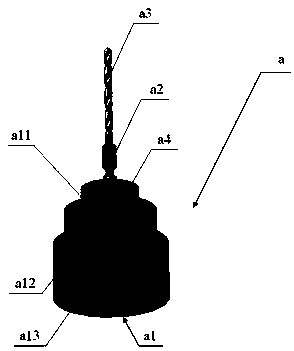

High-frequency brazing system of hexagonal handle twist drill and working method thereof

InactiveCN109175570ASmall structure sizeReduced structure lengthHigh frequency current welding apparatusSoldering auxillary devicesAutomatic controlEngineering

The invention relates to a high-frequency brazing system of a hexagonal handle twist drill and a working method thereof. The operation steps of hexagonal handle feeding, scaling powder feeding, flux feeding, twist drill bit feeding, rotation, heating, pressing and the like are realized in sequence through automatic control of the flow operation; the completed amount in unit time is far higher thanthat of the manual operation; the working efficiency is higher; the rejection rate caused by errors due to manual fatigue operation is prevented; the error rate is lower; and through mechanical devices, the welding effect is effectively achieved, and the welding precision is guaranteed.

Owner:江苏天宝利自动化科技有限公司

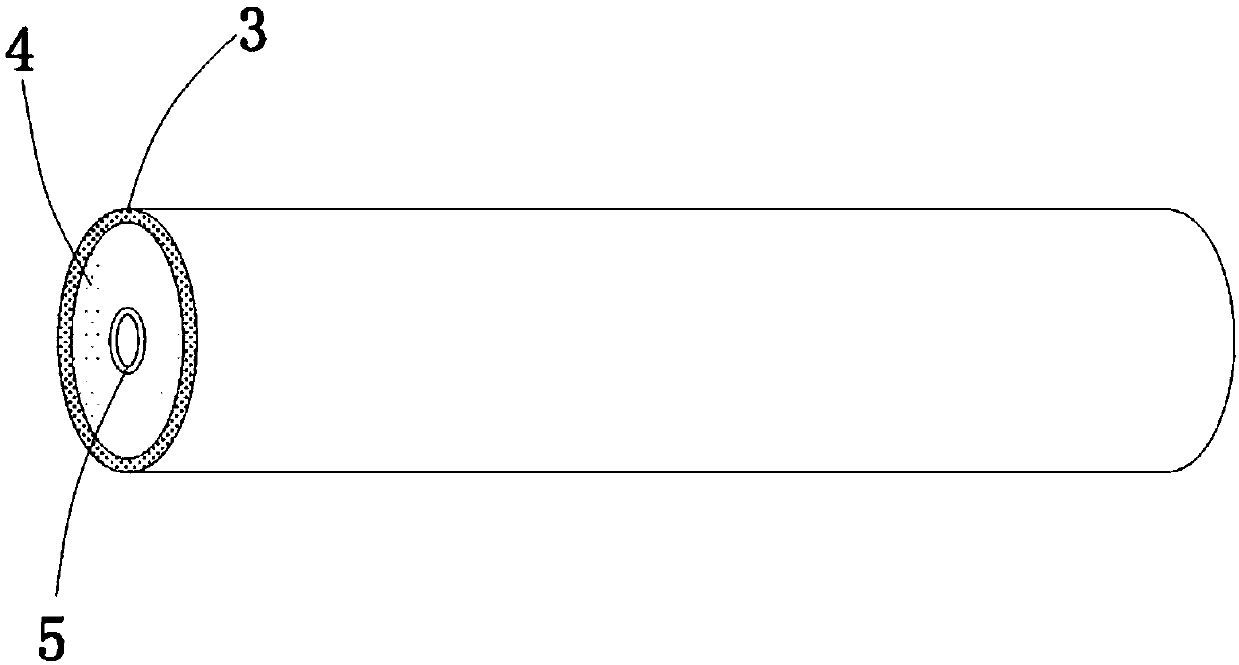

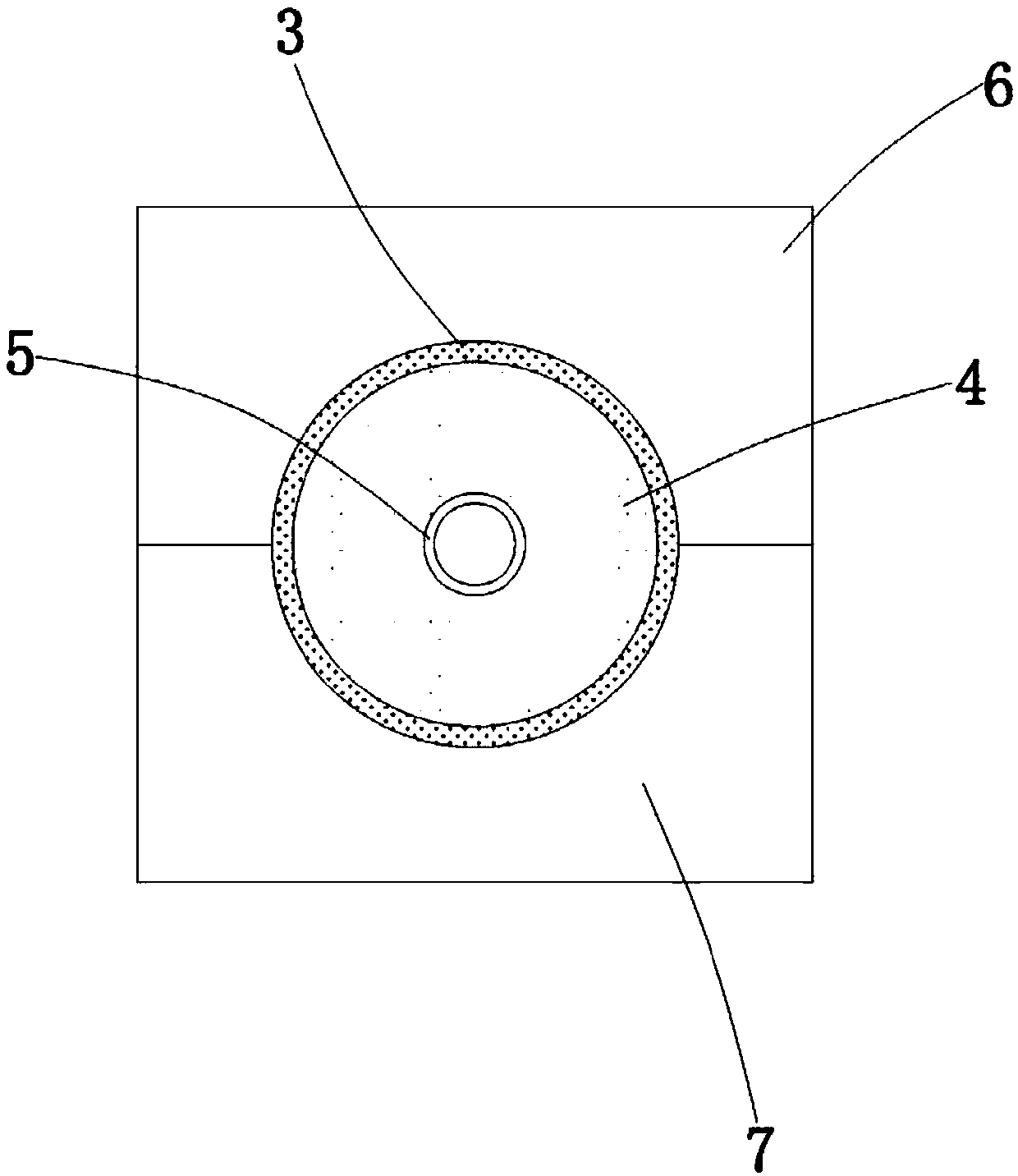

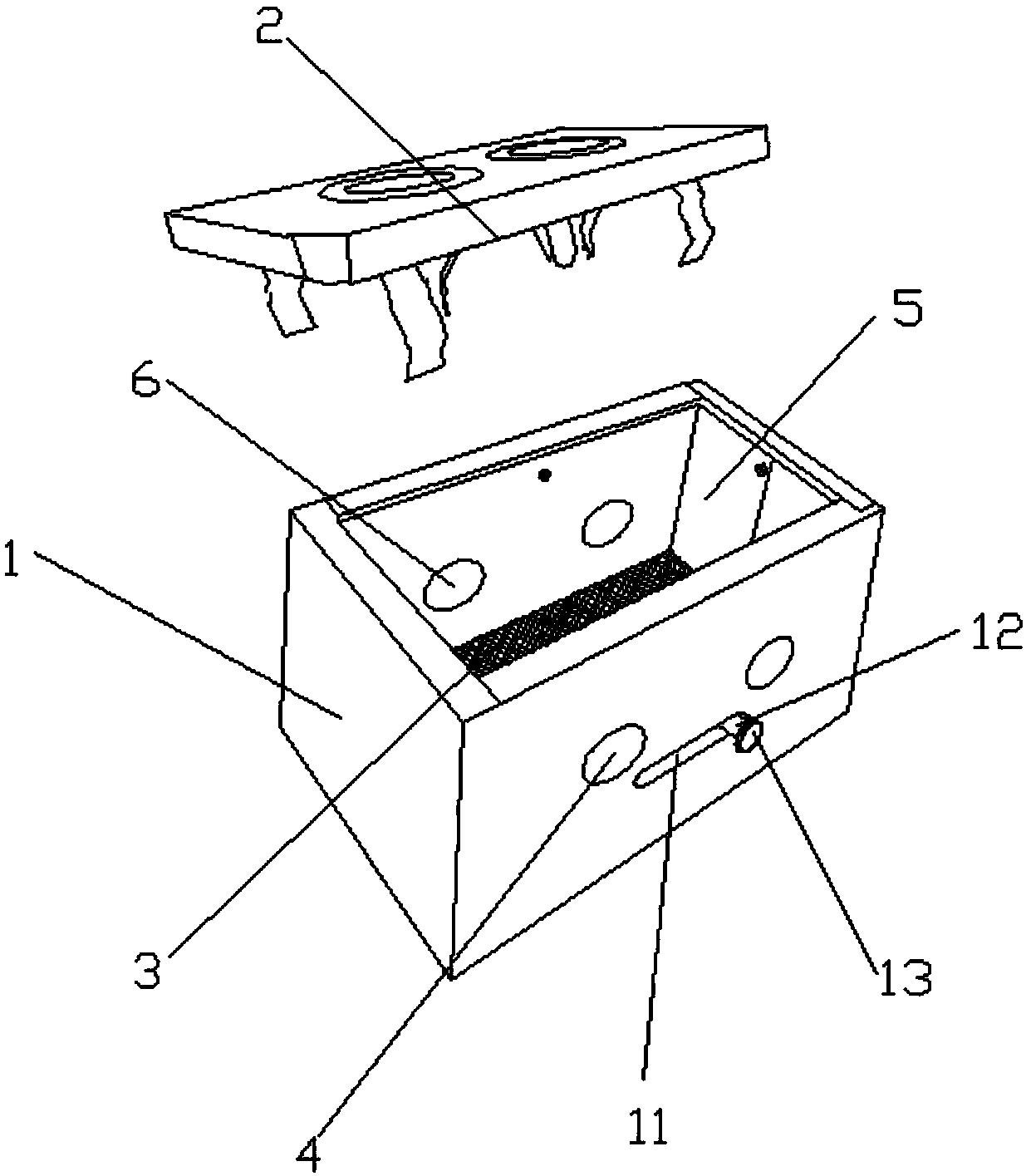

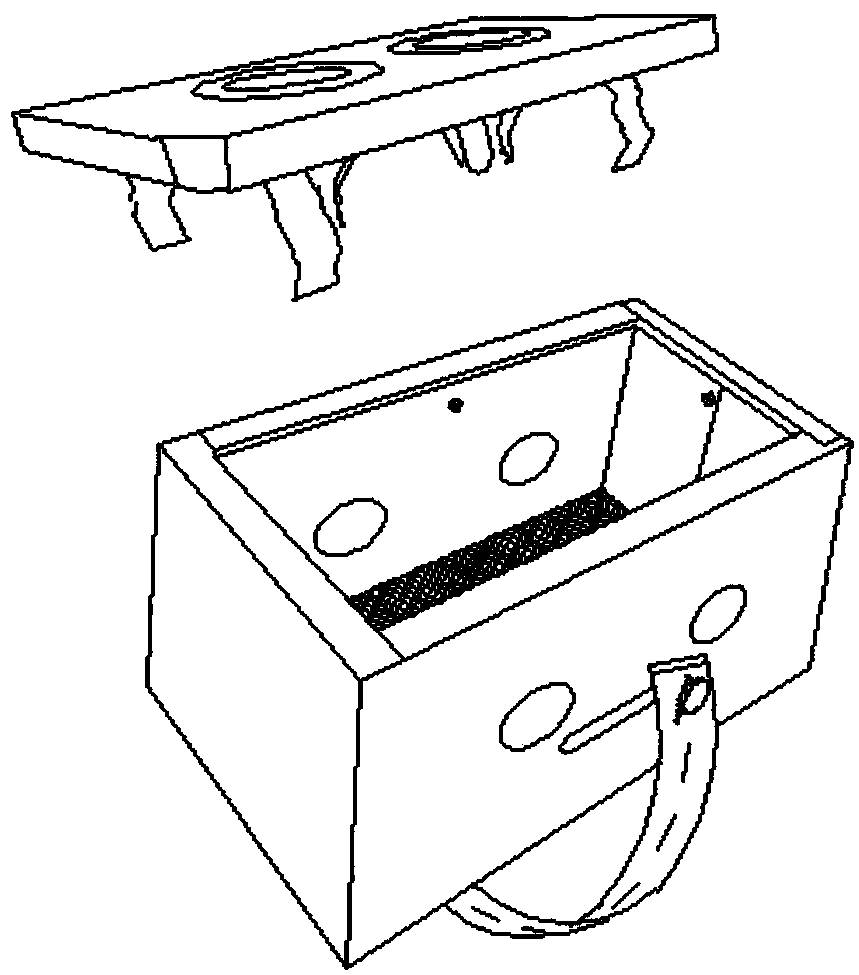

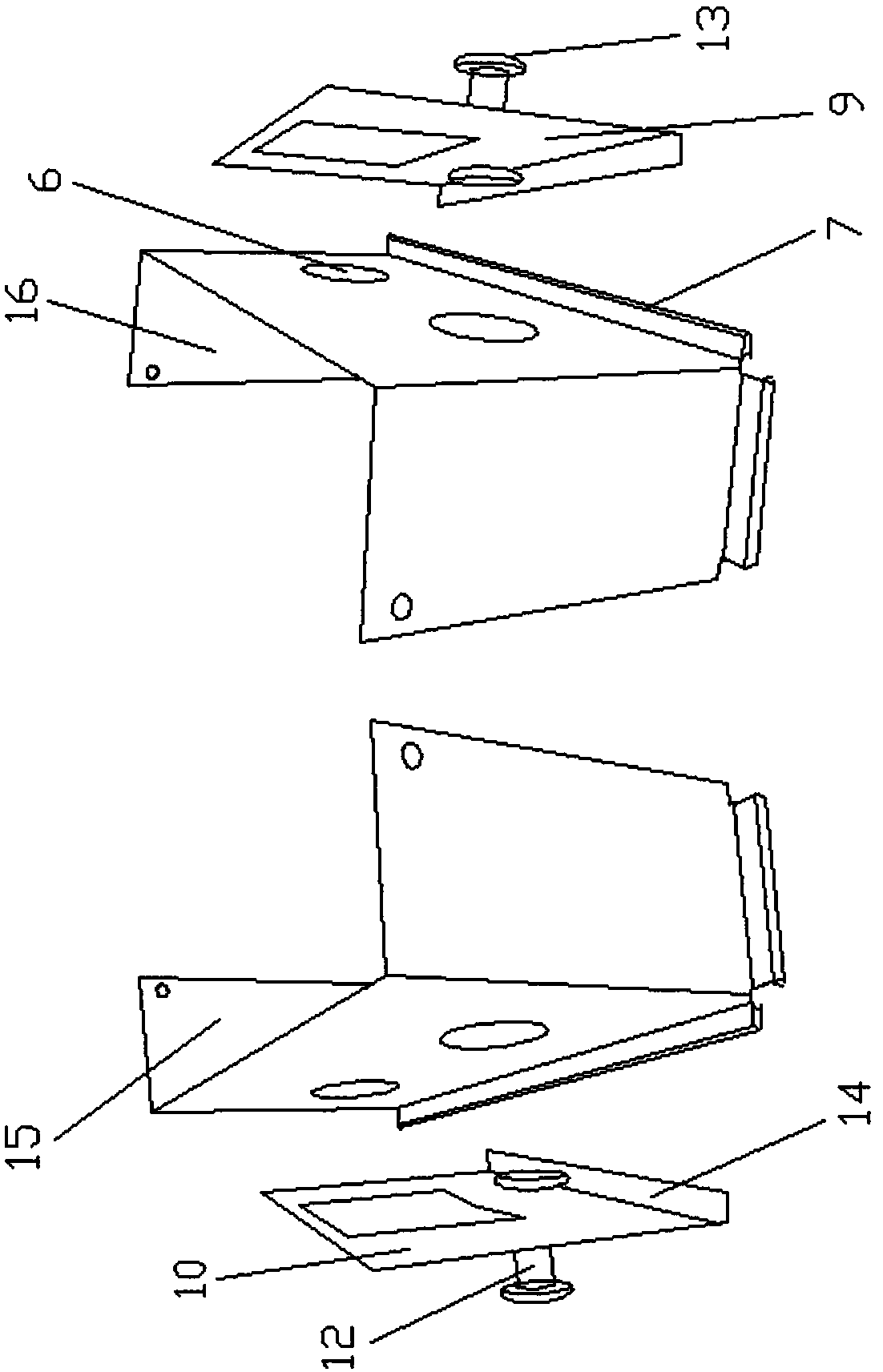

Moxibustion box

PendingCN108553294AExtended service lifeAvoid heat conductionDevices for heating/cooling reflex pointsSlide plateEngineering

The invention relates to a moxibustion box. The moxibustion box comprises a box body and a box cover, wherein the box body is lined with a metal frame, a plurality of through holes corresponding to air holes are formed in the metal frame, sides extend outwards form the periphery of the lower end of the metal frame so as to form a gap between the metal frame and the inner surface of the box body, asliding plate is arranged in the gap, baffling pieces corresponding to the through holes are arranged on the sliding plate, and the sliding plate is controlled to move by an adjusting rod. Accordingto the moxibustion box, a nailing process in the production process of the box body is omitted, the production step is simplified, the defective rate is decreased, accessories are convenient to dismount and replace, and the moxibustion box is durable.

Owner:蕲春一品堂蕲艾制品有限公司

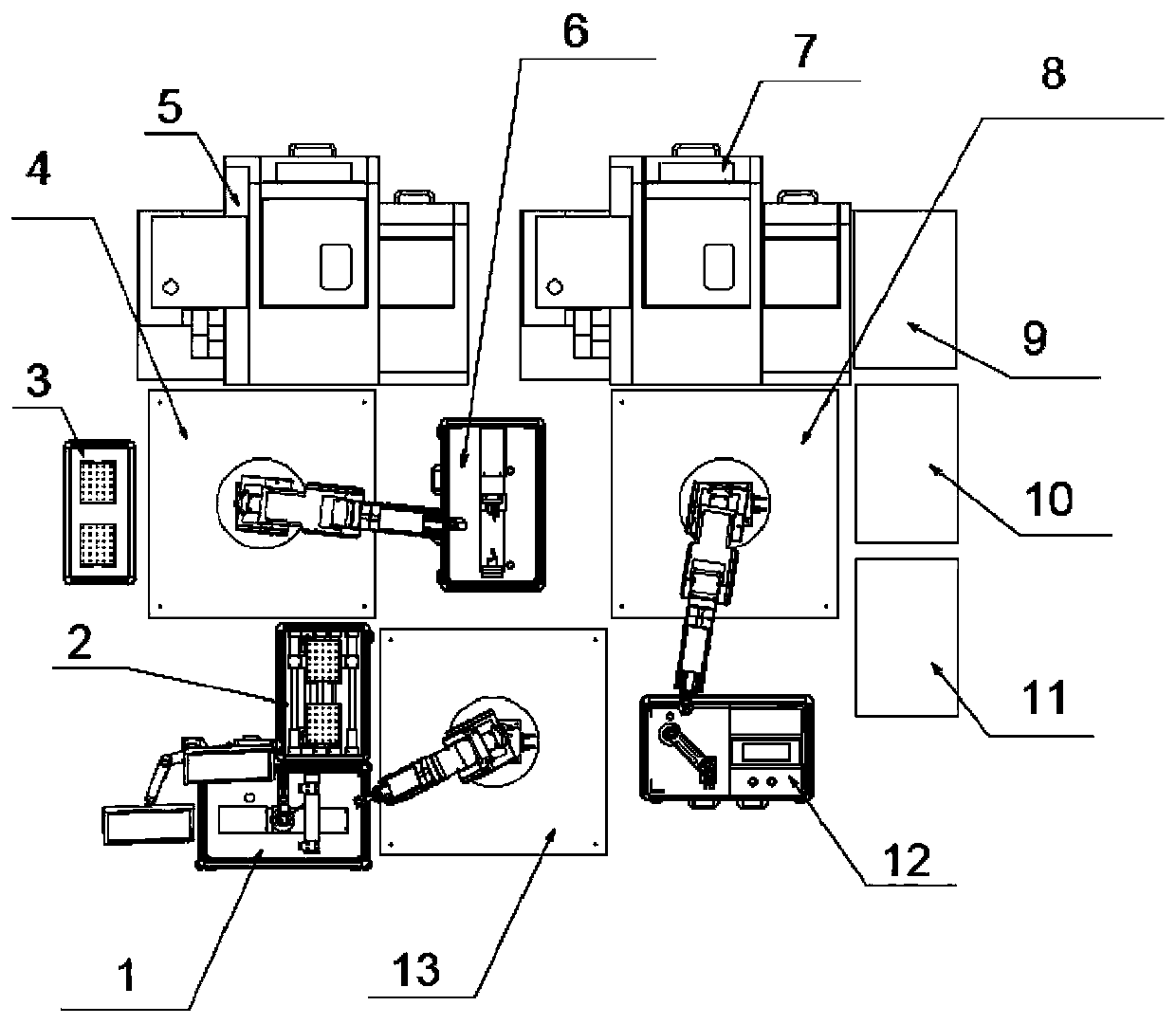

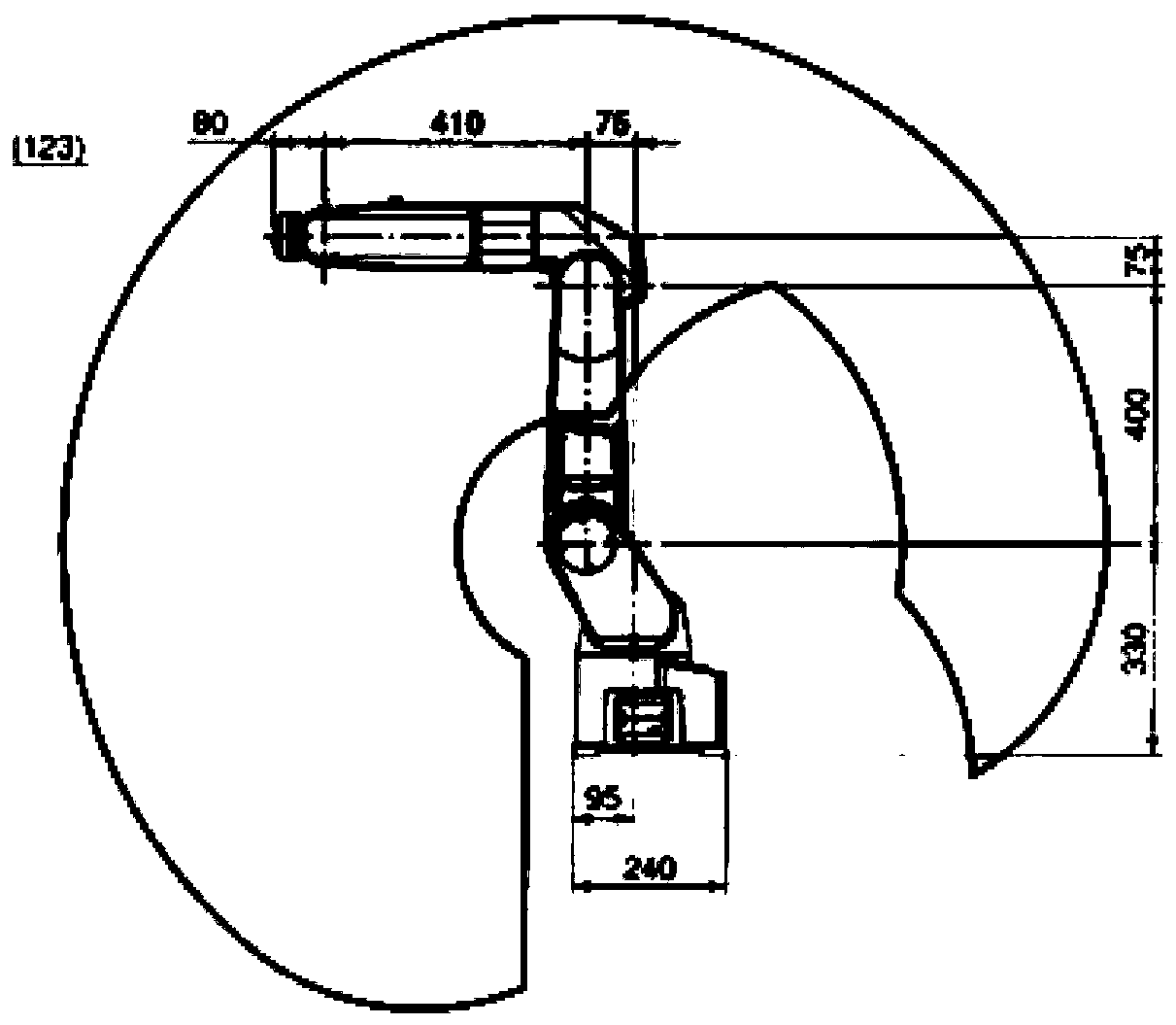

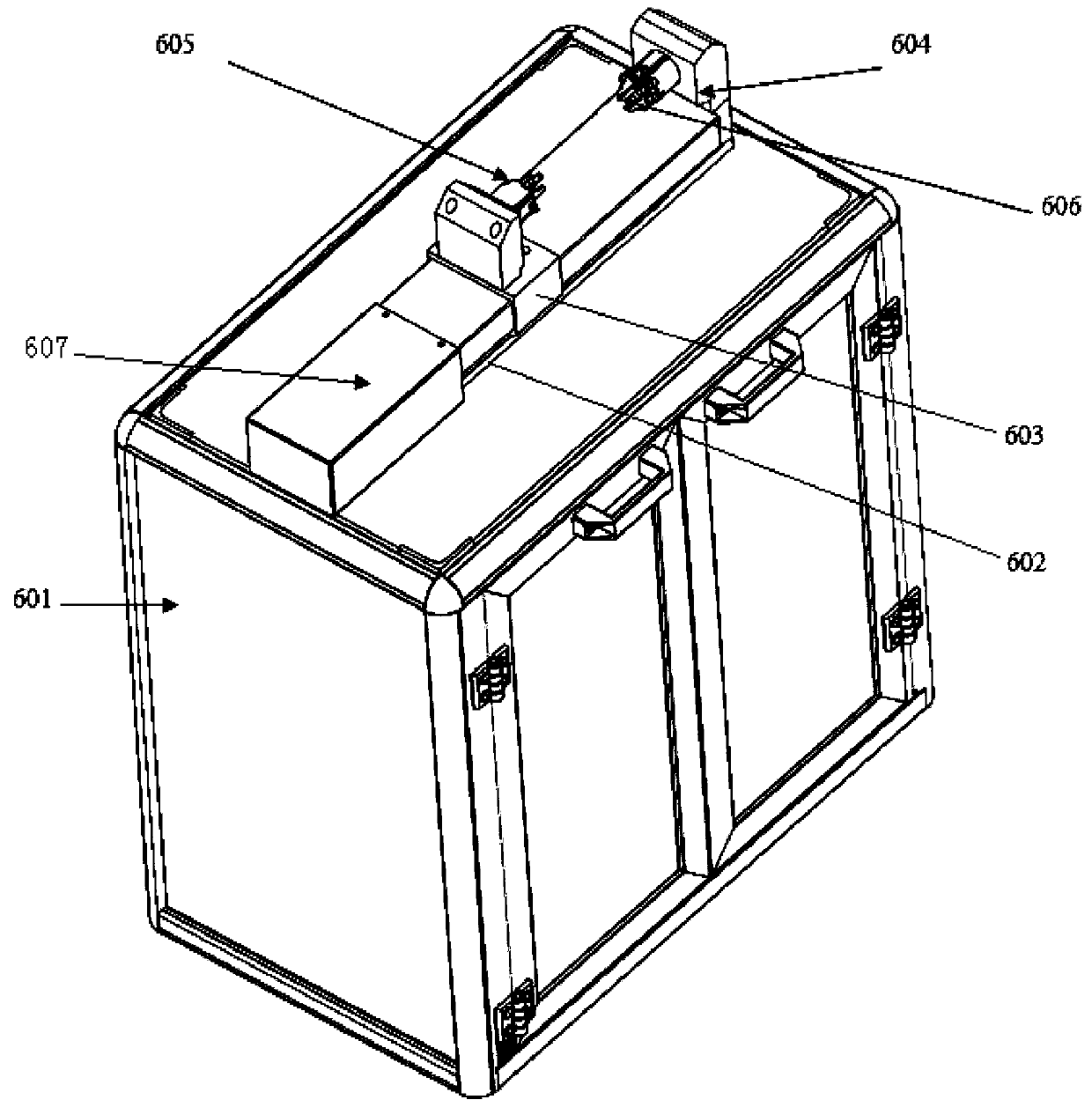

RC intelligent manufacturing production line for optical communication precision parts

PendingCN110977494ARealize unmanned on-dutyAchieve integrationOther manufacturing equipments/toolsNumerical controlProduction line

The invention discloses an RC intelligent manufacturing production line for optical communication precision parts. The manufacturing production line comprises a detection unit, a movable tray unit, afixed tray unit, a cleaning unit, a conversion unit, a first numerical control machine tool, a second numerical control machine tool, a first robot, a second robot and a third robot, the mounting bases of the first robot, the second robot and the third robot are arranged in a triangular shape, the fixed tray unit is mounted in the taking and placing range of one side of the first robot, and the first numerical control machine tool is mounted in the taking and placing range of the other side of the first robot. The second numerical control machine tool is installed in the taking and placing ranges of the first robot and the second robot, the cleaning unit is installed in the taking and placing ranges of the second robot and the third robot, and the detection unit and the movable tray unit are installed in the taking and placing range of the third robot. The conversion unit is mounted in the triangular middle vacancy and in the taking and placing range of the first and second robots. According to the invention, perfect combination of continuous production without shutdown, working unit integration, accurate positioning intellectualization, processing and production flexibility, robotguarding unattended operation and overlapping of processing and auxiliary time is achieved.

Owner:丹东富田精工机械有限公司

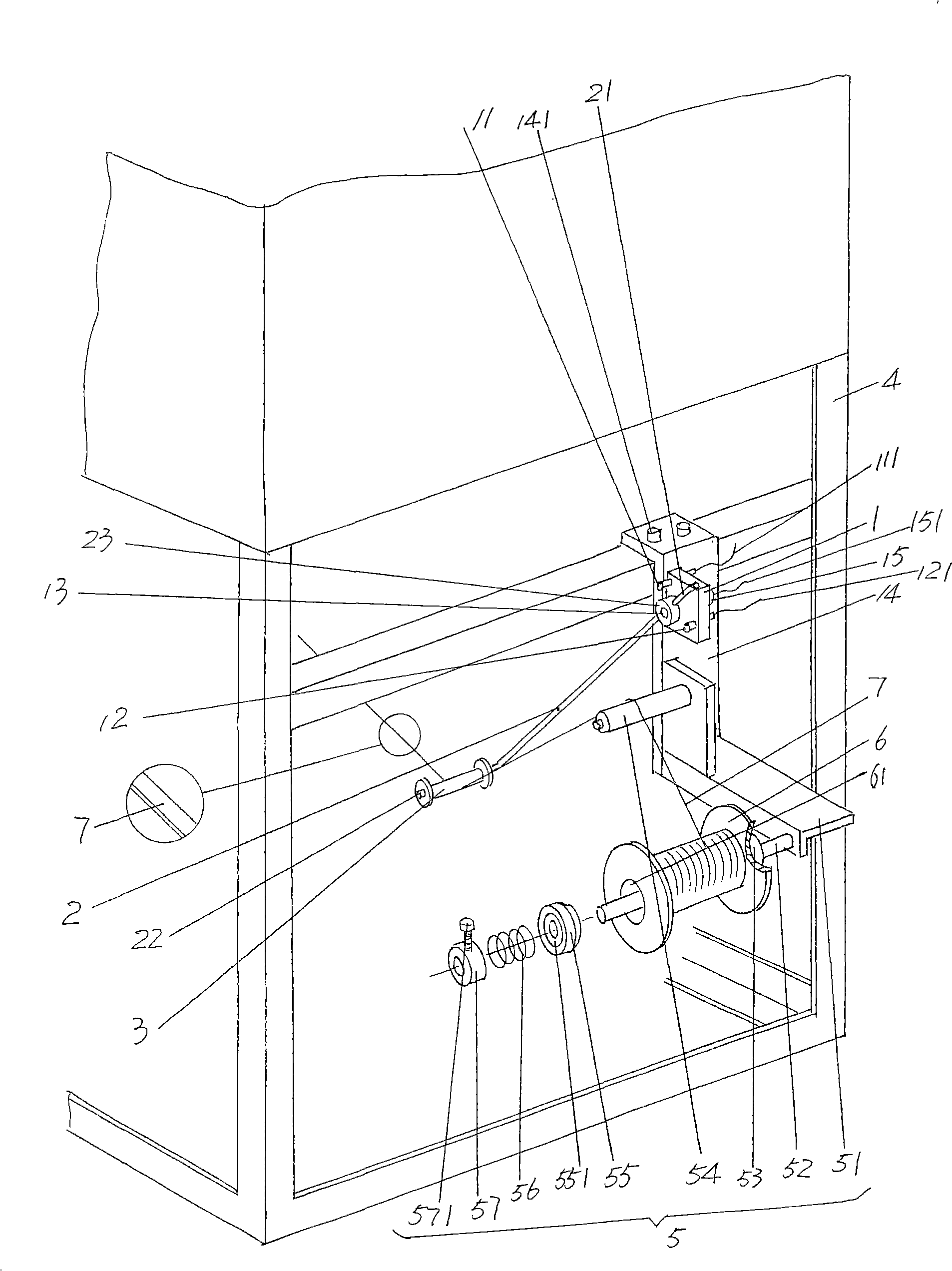

Automatic tension control apparatus for longitudinally covered wire

ActiveCN101335123AAvoid wastingEnsure longitudinal package pitchCable/conductor manufactureAutomatic controlEngineering

The invention discloses a tension automatic control device of longitudinally wrapped wires, pertaining to the field of processing technology of electric wires and cables. The tension automatic control device of the invention comprises a tension sensor, a swing stem and a guide roll. The tension sensor is installed on a braider and provided with a first sensing pin and a second sensing pin which are electrically connected with a controller of the braider respectively by signal wires. The swing stem is connected on the tension sensor and a swing stem contact at the upper end of the swing stem is corresponding to the first sensing pin and the second sensing pin while the lower end of the swing stem forms a free end and is provided with a bending part on which the guide roll is arranged. The tension automatic control device of the invention has the advantages of ensuring that the longitudinally wrapped wires enter the braider to be outside conducting wires through lapping, namely outside the wire core, under the constant tension, thereby not only being beneficial to the avoidance of wasting the longitudinally wrapped wires, but also ensuring the consistent longitudinally wrapped pitch of the longitudinally wrapped wires so as to avoid the occurrence of the defect rate.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

Testing system, crack noise monitoring device and method for monitoring crack noise

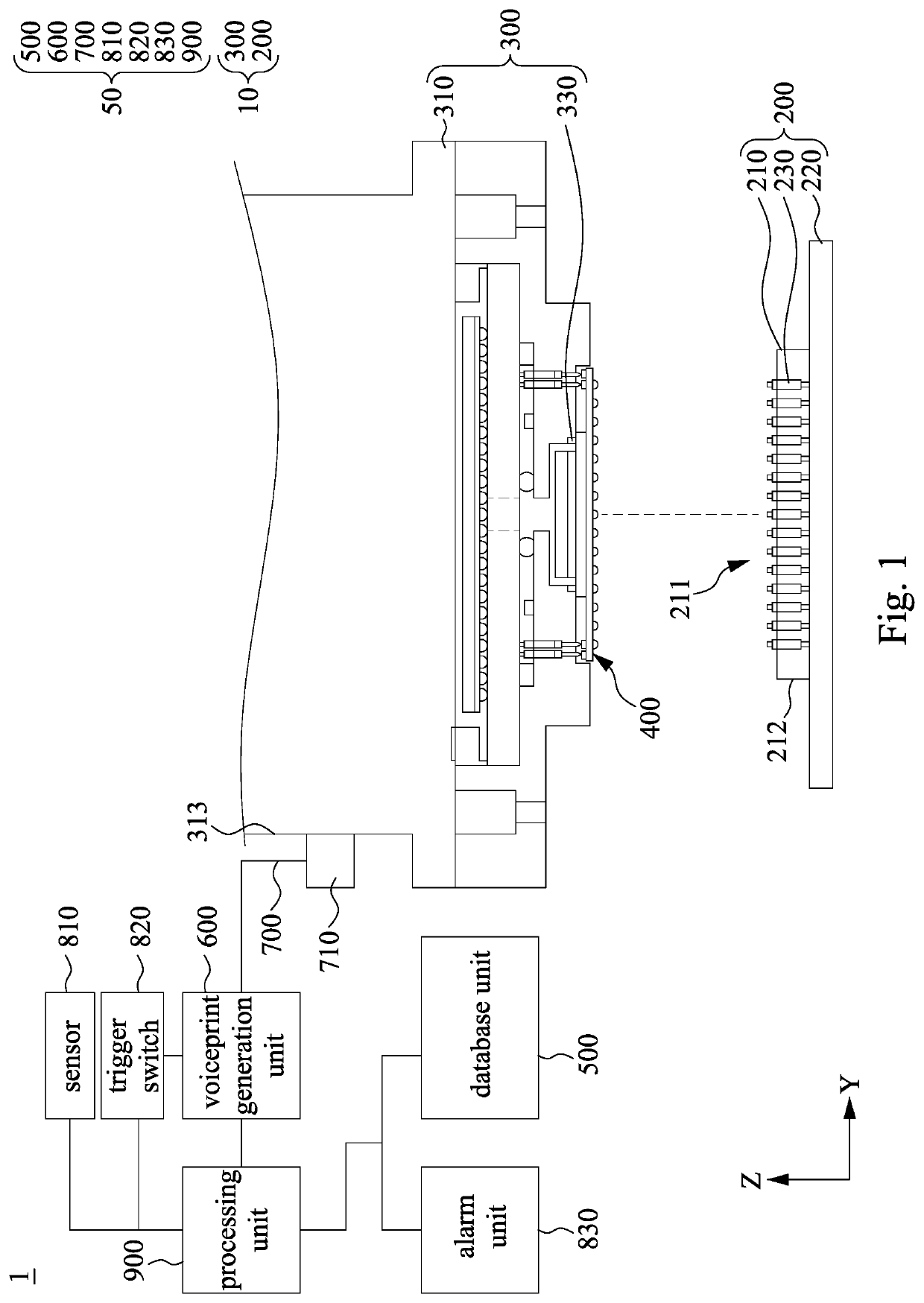

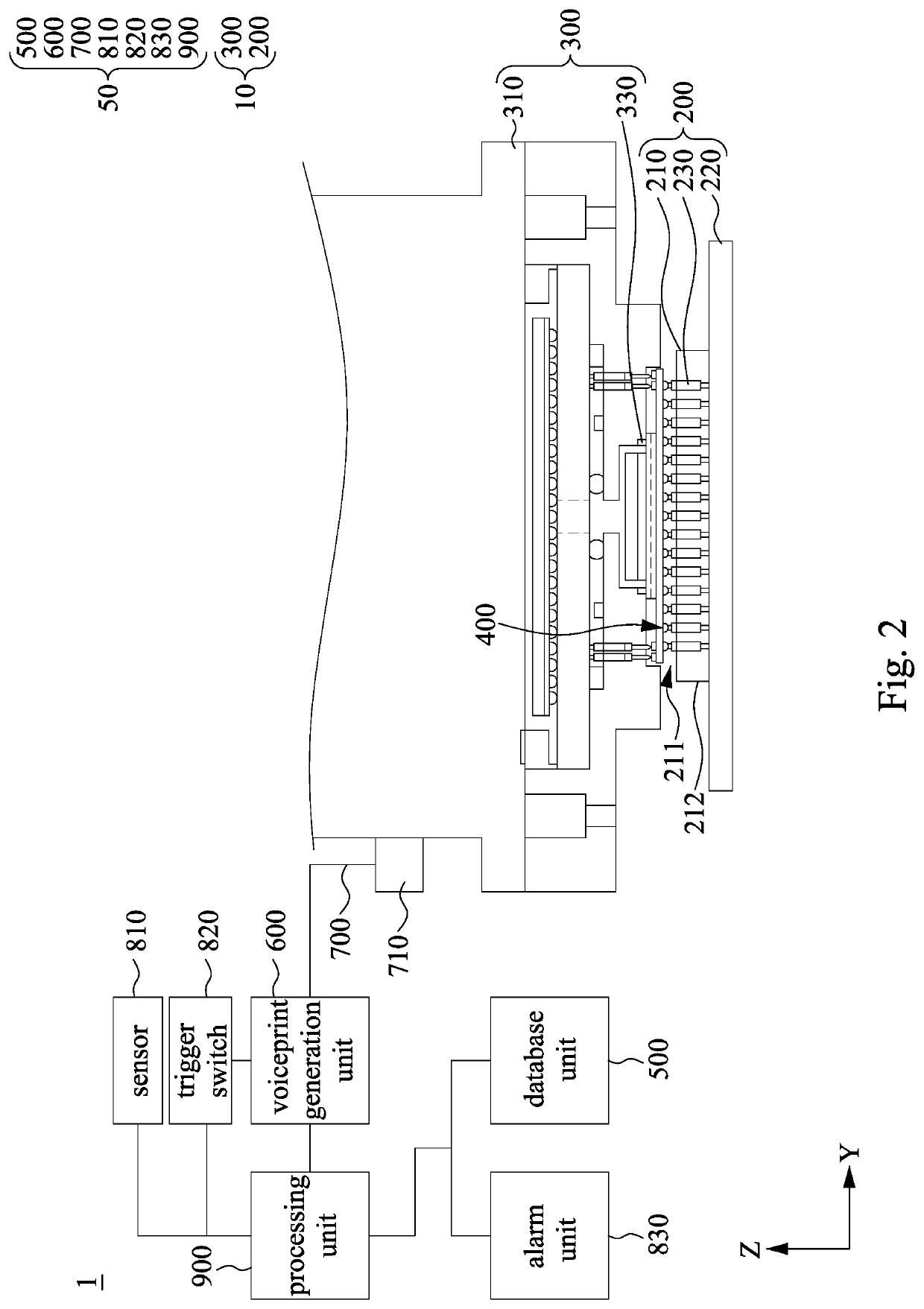

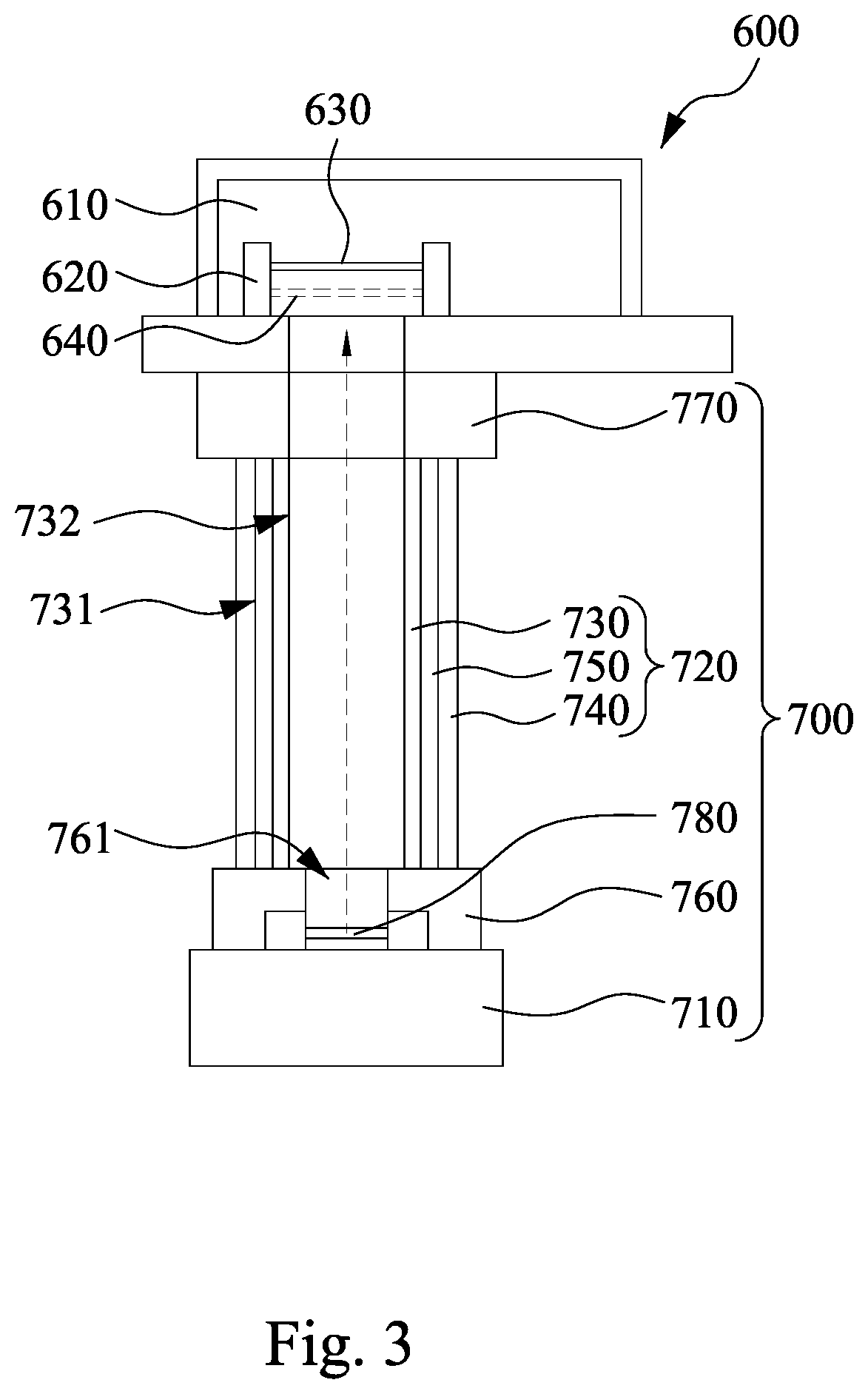

ActiveUS20220293121A1Avoid defective rateLow costMicrophonesMaterial analysis using acoustic emission techniquesNoise monitoringEngineering

A testing system includes a testing apparatus and a crack noise monitoring device. The testing apparatus includes a testing stage and an element pickup module for pressing a semiconductor element on the testing stage. The crack noise monitoring device includes a database unit, a sound conduction set, a voiceprint generation unit and a processing unit. The database unit has a first voiceprint pattern. The sound conduction set is connected to the voiceprint generation unit and the testing apparatus for transmitting a sound wave from the semiconductor element to the voiceprint generation unit. The voiceprint generation unit receives and converts the sound wave into a second voiceprint pattern. The processing unit is electrically connected to the voiceprint generating unit and the database unit for determining whether the first voiceprint pattern is identical to the second voiceprint pattern.

Owner:GLOBAL UNICHIP CORPORATION +1

Method for machining stereoscopic patterns of aluminum plate surface

The invention provides a method for machining stereoscopic patterns of an aluminum plate surface, and belongs to the technical field of aluminum alloy surfaces. The method solves the technical problems that an aluminum plate surface cannot be three-dimensionally machined in the prior art and the like. The method includes the working procedures: a, cleaning; b, unreeling; c, unreeling traction positioning; d, stereoscopic pattern engraving; e, reeling traction positioning; and f, reeling. The method for machining the stereoscopic patterns of the aluminum plate surface has the advantages of capability of machining the stereoscopic patterns, simplicity in machining, less pollution and the like.

Owner:浙江铭岛新材料股份有限公司

Preparing method of high-strength fiber composite material

ActiveCN107089049ALow technical requirementsHigh strengthLaminationLamination apparatusGlass fiberFiber

The invention relates to a preparing method of a high-strength fiber composite material. The preparing method includes the following steps of cutting, rolling, performing, forming and demolding. Fiber composite material cloth in use is at least one of carbon fiber composite material cloth and glass fiber composite material cloth, and a polymeric film in use comprises a high-temperature thermocuring resin film and a high-viscosity polymer composite material. The strength of a product can be effectively promoted after the prepared fiber composite material is formed. The forming process is easy to operate, high in efficiency and low in requirement for the technology of operators, and common personal can implement operation.

Owner:厦门市中豪强碳纤复合材料有限公司

Tunnel type oven berth mechanism suitable for automatic online and offline

ActiveCN102815531BReliable disengagementAvoid abnormal wear and tearConveyor partsOnline and offlineEconomic benefits

Owner:怡得乐电子(杭州)有限公司

A kind of method that adopts hsm molding technology to prepare ice-curved rod

ActiveCN107718604BAffect batch stabilityOvercome warpage and other defect ratesDomestic articlesFiberHigh energy

The invention discloses a method for preparing an ice bent lever through an HSM forming process. Shapeable preformed thermal self-expanding high-energy rubber is placed into a product core material mold at first, the mold is assembled, heating is conducted for 3-30 min at 80-100 DEG C, slight expansion is conducted, wherein the volume multiplying rate before and after slight expansion is 1.01-1.5,a core material mold cavity is filled, cooling and demolding are conducted, a part is wrapped with prepreg then and put into a forming mold, the mold is assembled, heating is conducted for 10-60 minat 120-180 DEG C, wherein the shapeable preformed thermal self-expanding high-energy rubber continues being heated, expansion force is formed from inside to outside, and the fiber prepreg is subjectedto high-temperature curing forming; and cooling and demolding are conducted, and the part is taken out. The ice bent lever prepared through the method is high in strength and low in reject ratio.

Owner:厦门市中豪强碳纤复合材料有限公司

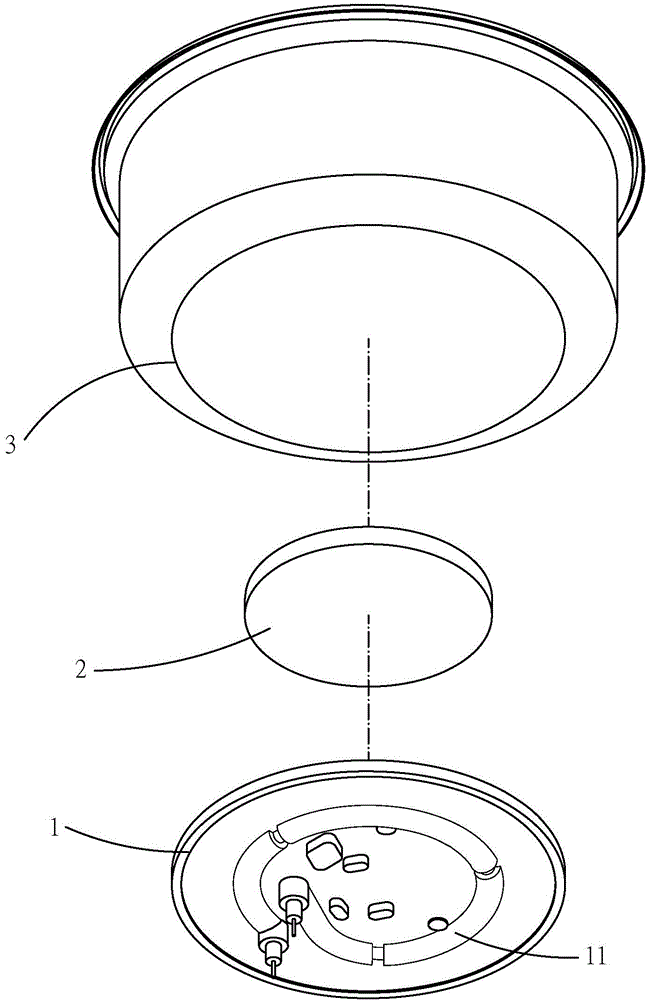

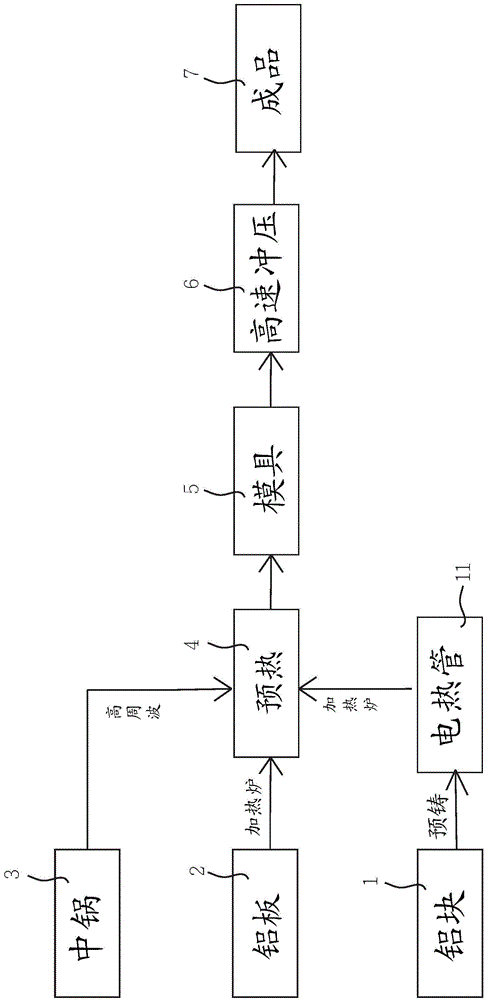

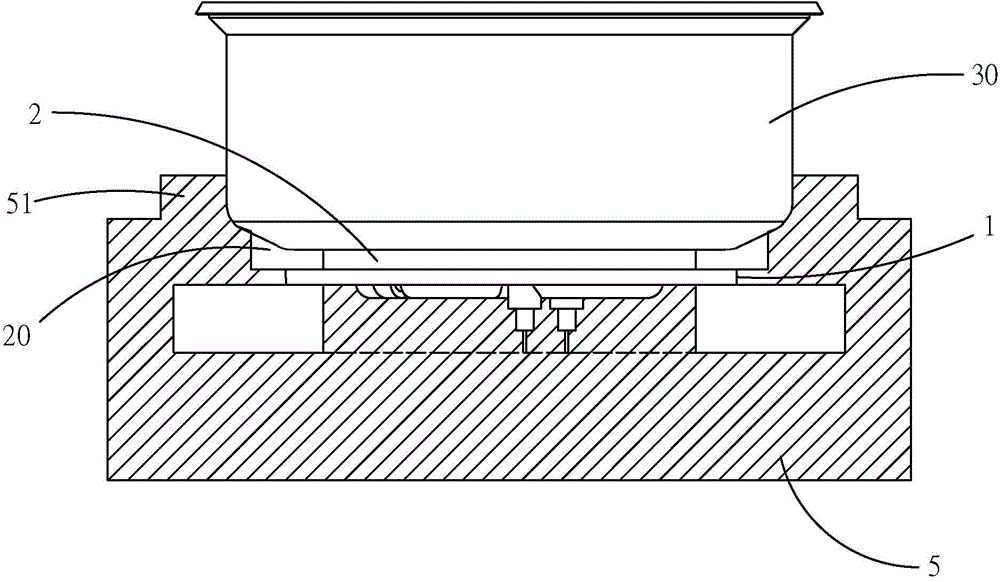

Method for combining pot or kettle with heating device

The invention relates to a method for combining a pot or kettle with a heating device, in particular to a method for combining the bottom of the stainless steel pot or kettle with an aluminum block and aluminum plate where an electric heating pipe or magnetic conductive metal is preformed. Mainly, the electric heating pipe or magnetic conductive metal wraps the aluminum block in a precasting mode, and then the pot or kettle which has already been heated to a set temperature and the aluminum block and aluminum plate are punched respectively at high speed and high pressure, so instant press-drawing is conducted between the bottom of the pot or kettle and the aluminum block, the aluminum block wrapped by the electric heating pipe or magnetic conductive metal can be closely combined with the bottom of the pot or kettle, speed is high, disengagement is avoided, lots of labor can be saved particularly, machining steps are simplified, and the aims of increasing the yield and saving energy can be achieved.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com