TCP error calibration method of industrial robot

An industrial robot and error calibration technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as errors, low calibration efficiency, and calibration failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

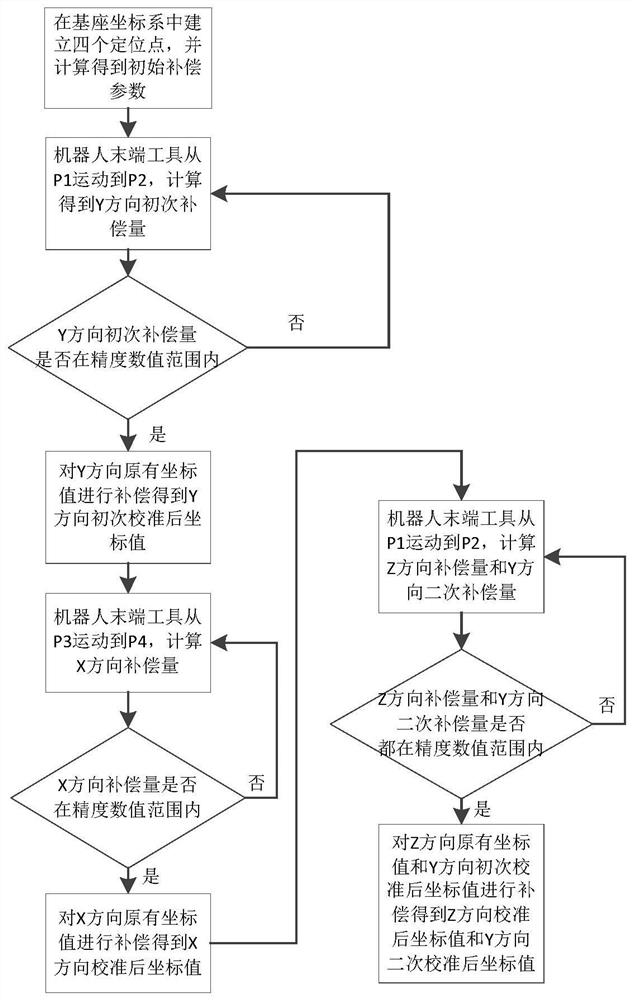

[0053] This embodiment provides a TCP error calibration method of an industrial robot, the flow chart of the method is as follows figure 1 shown.

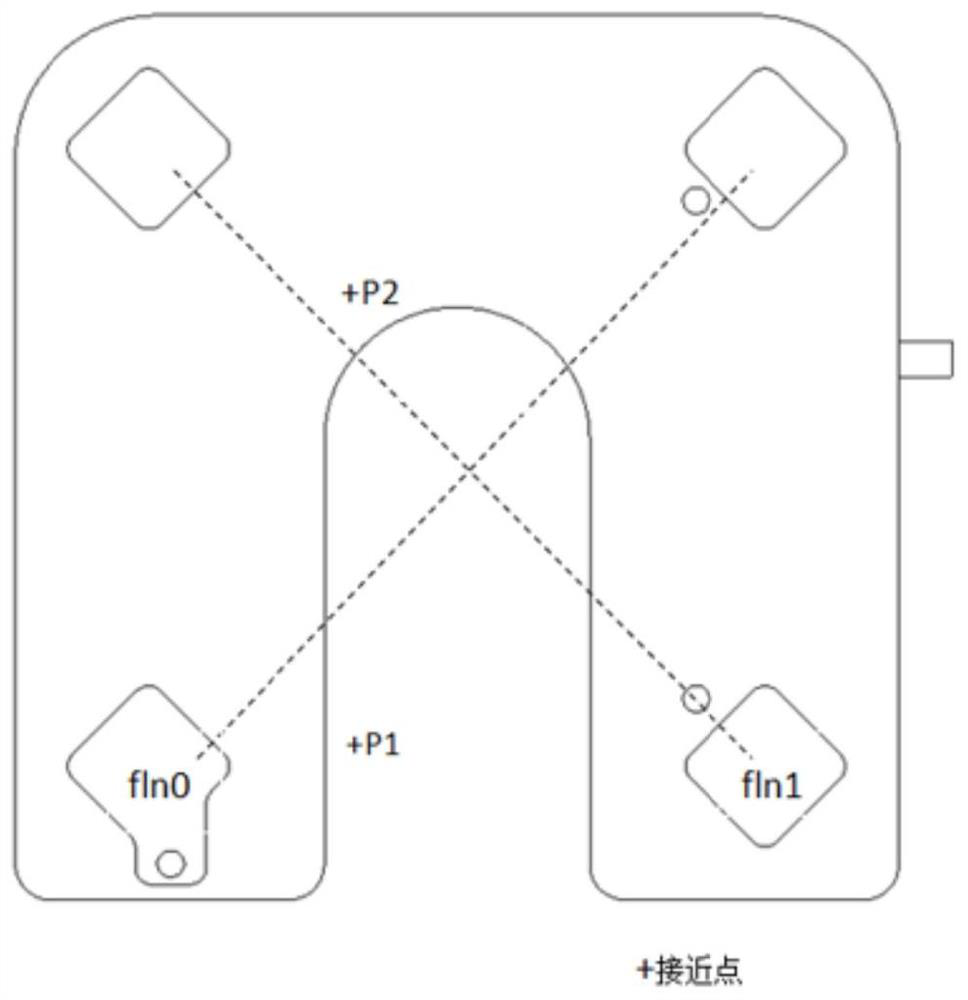

[0054] Such as figure 2 As shown, first establish a base coordinate system, and calibrate the tool coordinate system on the robot end tool through the base coordinate system. After the robot end tool is installed, install two laser sensors on one side of the robot end tool, and two laser sensors The sensor generates the first laser line and the second laser line that intersect with each other. The plane where the first laser line and the second laser line are located is the XOY plane of the base coordinate system. The XOY plane of the tool coordinate system is parallel, and determine the original coordinate value of the X direction, the original coordinate value of the Y direction and the orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com