Method for combining pot or kettle with heating device

A heating device and pot body technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of many manpower, limited speed, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

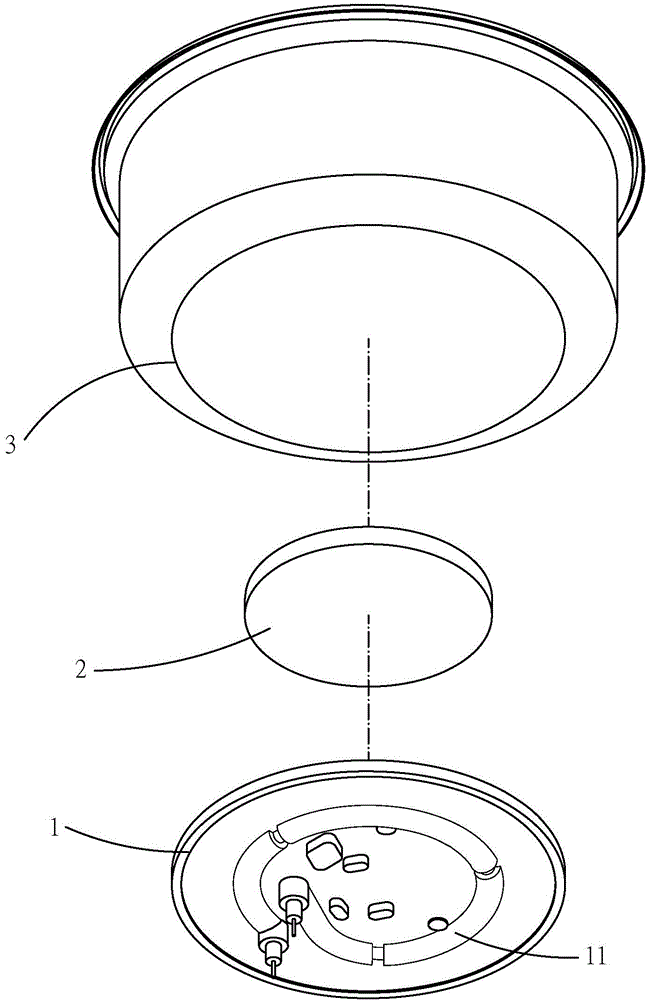

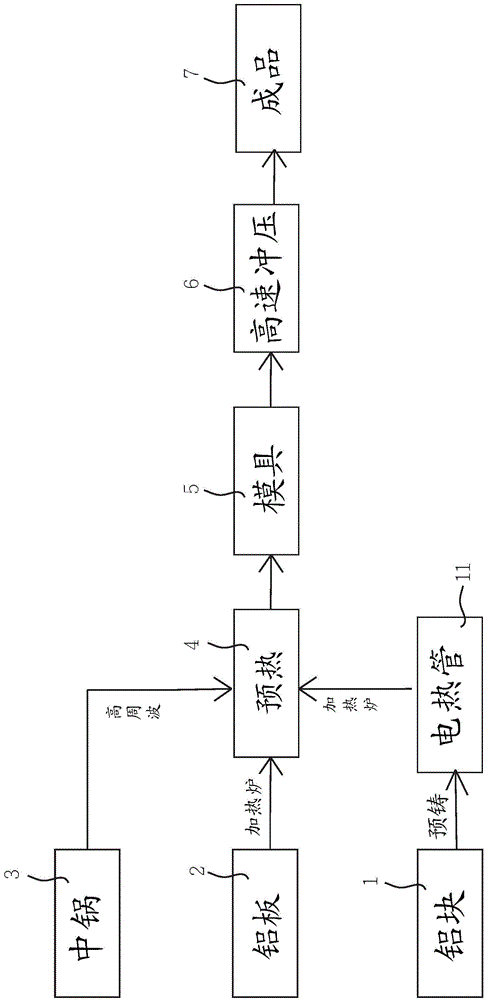

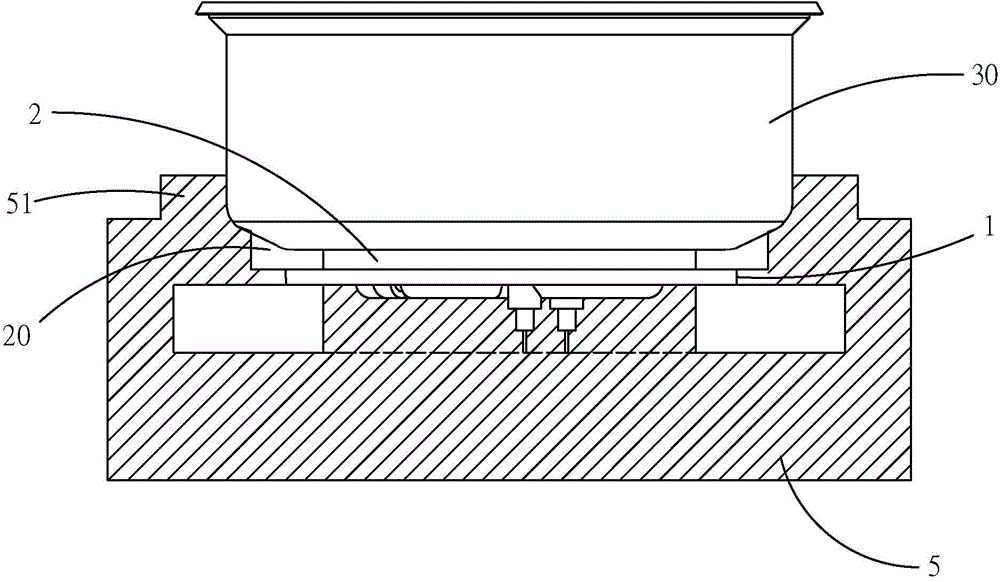

[0017] First, see figure 1 As shown, it is a three-dimensional exploded view of the electric cooker completed by using the process of the present invention. It first pre-casts the electric heating tube into an aluminum block, and the electric heating tube 11 is the same as the traditional one. Cast into the molding of an aluminum block 1. The middle pot 3 has the same structure as the conventional one, but it is a pot body made of stainless steel, and to combine two metals of different materials, the existing methods are either poor in combination, or low in production capacity, and require manpower and labor. The processing steps are complicated, so the cost is extremely high, and the most important thing is the high defect rate.

[0018] However, the manufacturing method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com