Welding, grinding and polishing switching integrated machining robot

A robotic and integrated technology, applied in the field of robotics, can solve the problems of unfavorable staff for long-term operation and viewing, long time required for workpiece disassembly and assembly, and high labor intensity of staff, so as to avoid the reduction of processing efficiency and improve the processing of workpieces. Efficiency and the effect of reducing the probability of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

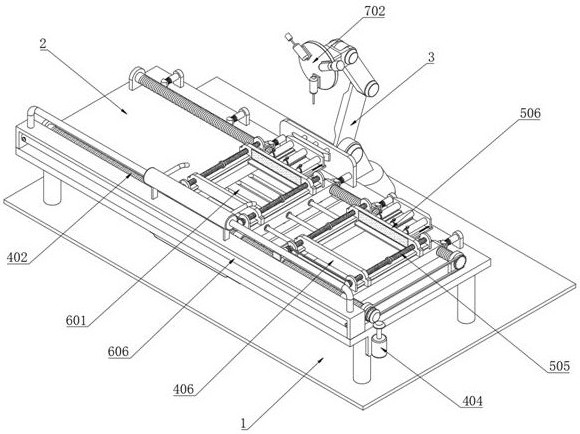

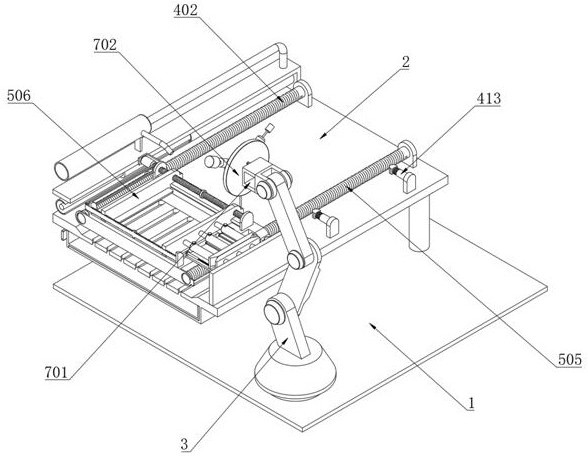

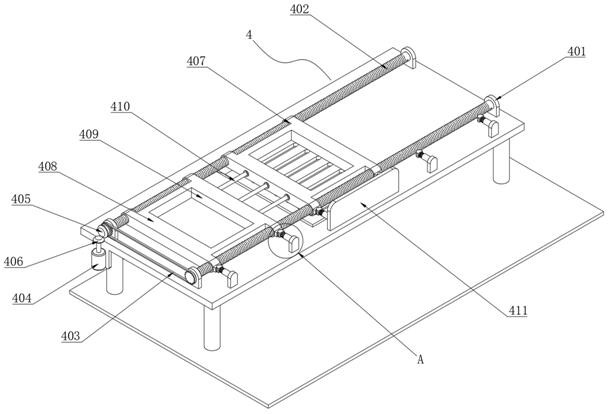

[0040] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a processing robot integrating welding, grinding and polishing, including a substrate 1, a processing table 2 is fixedly installed on the top of the substrate 1, and a processing table 2 is fixedly installed on the top of the substrate 1 corresponding to one side of the processing table 2 The top of the mechanical arm 3 and the processing table 2 is equipped with a positioning alternate movement mechanism 4. The positioning alternate movement mechanism 4 includes a fixed side plate 401, a drive screw 402, a first transmission assembly 403, a drive motor 404, a driven gear 405, and a drive gear 406. , sliding block 407, sliding plate 408, leakage hole 409, fixed link 410, limiting side plate 411, limiting card block 412, limiting telescopic rod 413, limiting spring 414, limiting convex block 415 and limiting concave block 416;

[0041] The top of the processing table 2 is evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com