Preparation method of cross-linked polystyrene with high light transmittance

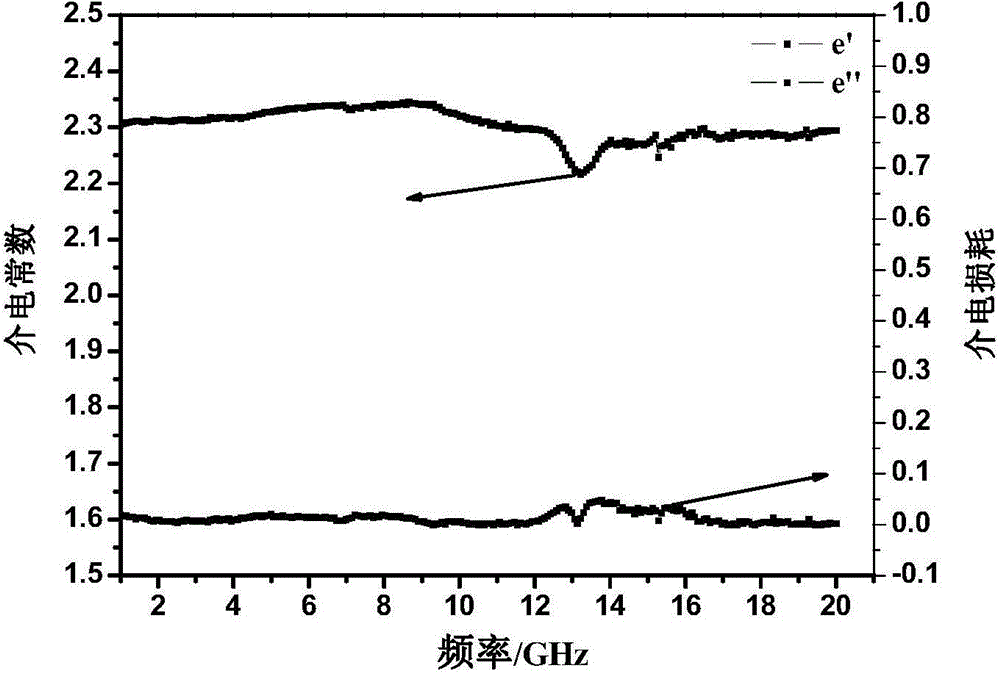

A cross-linked polystyrene, high light transmittance technology, applied in the field of polymer materials, can solve the problems of inevitable volume shrinkage of the reaction system, uneven network structure distribution, limited product material purity, etc., to achieve excellent optical properties and media. Electrical properties, solving the problem of volume shrinkage, and improving the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of high light transmittance cross-linked polystyrene, the method comprises the following steps:

[0026] 1. Preparation of polystyrene mixed solution: dissolve polystyrene powder with styrene to obtain polystyrene solution with a viscosity of 500-3000mPa·s, and then mix polystyrene solution with Divinylbenzene is mixed evenly to obtain the first layer of mixed solution;

[0027] 2. "Layer-by-layer freezing" and "layer-by-layer irradiation": Pour the first layer of mixed solution into an open flat-bottomed mold with a thickness of 0.1mm to 3.3mm, and then place the mold in liquid nitrogen or ethanol freezing liquid. The liquid level of the freezing liquid is lower than the edge of the mold, and it is placed for a period of time until the first layer of mixed solution becomes the first layer of transparent solidified body. The high-energy electron radiation dose rate is adjusted between 50Gy / min-500Gy / min, and the first...

Embodiment 1

[0030] 1) Obtain a polystyrene solution by dissolving styrene, a polystyrene powder with a viscosity of 2000mPa·s, and then configure a first-layer mixed solution of a polystyrene solution and divinylbenzene with a mass ratio of 1000:50;

[0031] 2) Then pour the first layer of mixed solution into the open mold with a flat bottom surface, place the mold in liquid nitrogen / ethanol mixed freezing liquid, and freeze until the first layer of mixed solution becomes the first layer of transparent solidified body;

[0032] 3) Utilizing high-energy electrons to irradiate and cross-link the first layer of transparent solidified body;

[0033] 4) Obtain the second layer of mixed solution according to the method of step 1);

[0034] 5) Pour the second layer of mixed solution in step 4) into the mold of the first layer of transparent solidified body that has undergone radiation crosslinking treatment in step 3), and the freezing liquid is frozen until the second layer of mixed solution be...

Embodiment 2

[0038] 1) Obtain a polystyrene solution by dissolving styrene, a polystyrene powder with a viscosity of 2000mPa·s, and then configure a first-layer mixed solution of a polystyrene solution and divinylbenzene with a mass ratio of 1000:20;

[0039] 2) Then pour the first layer of mixed solution into the open mold with a flat bottom surface, place the mold in liquid nitrogen / ethanol mixed freezing liquid, and freeze until the first layer of mixed solution becomes the first layer of transparent solidified body;

[0040] 3) Utilizing high-energy electrons to irradiate and cross-link the first layer of transparent solidified body;

[0041] 4) Obtain the second layer of mixed solution according to the method of step 1);

[0042] 5) Pour the second layer of mixed solution in step 4) into the mold of the first layer of transparent solidified body that has undergone radiation crosslinking treatment in step 3), and the freezing liquid is frozen until the second layer of mixed solution be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com