High-frequency brazing system of hexagonal handle twist drill and working method thereof

A high-frequency brazing and twist drill technology, which is applied to high-frequency current welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high error rate, low work efficiency, and unguaranteed welding accuracy, so as to avoid welding dislocation, The effect of ensuring welding quality, reducing system structure size and layout length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

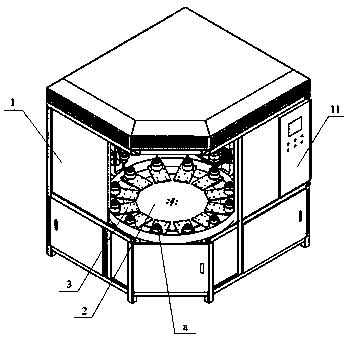

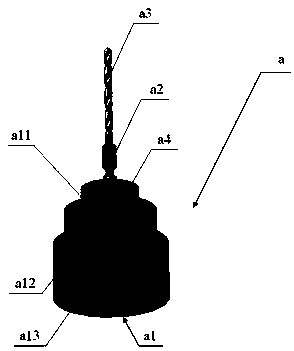

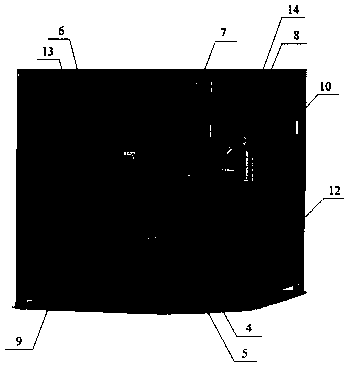

[0035] A high-frequency brazing system for hexagonal shank twist drills, including a working cabinet 1, a rotating working platform 2 is located inside the working cabinet 1, a rotating driving motor 4 and a transmission device 5 are installed under the rotating working platform 2, and the rotating driving motor 4 passes through the The transmission device 5 drives the rotary working platform 2 to rotate around the central axis. Several mounting pallets 3 are arranged at equal intervals on the upper surface of the rotary working platform 2 in the circumferential direction, and a working mold a is arranged on the radially outer side of each mounting pallet 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com