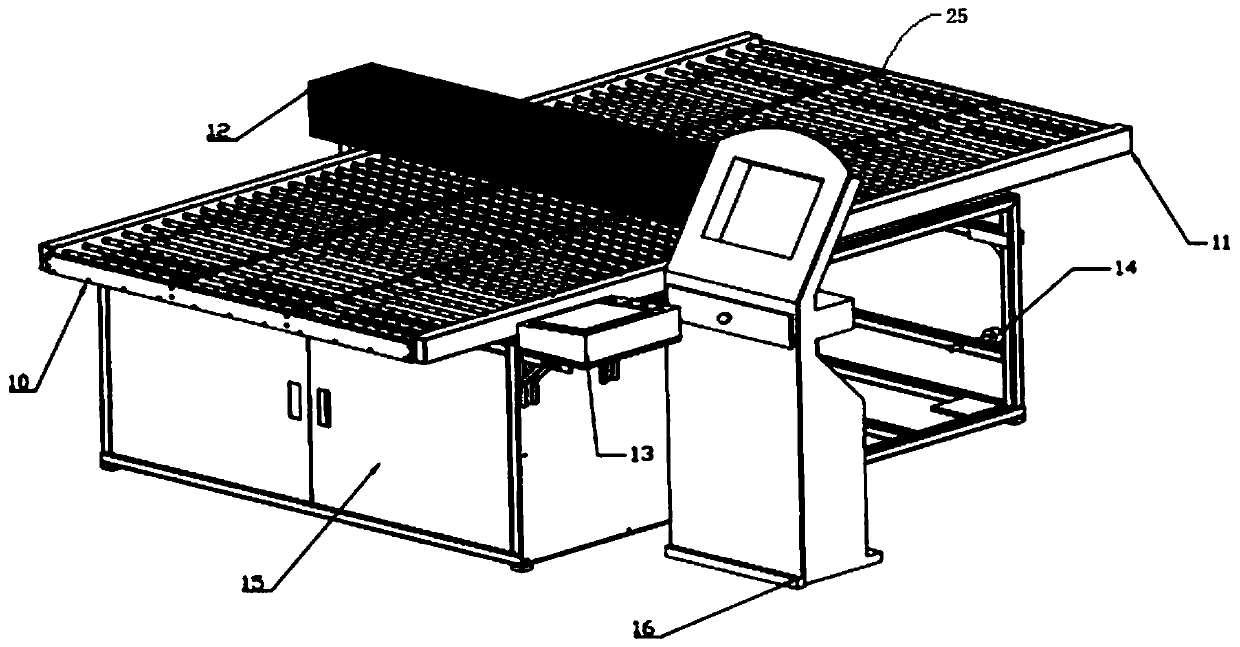

Automatic thickness measuring machine for touch display screen

A technology of touch screen display and automatic measurement, which is applied to measuring devices, instruments, and optical devices, etc. It can solve problems such as time-consuming and labor-intensive, large deviation values, etc., achieve high measurement accuracy, solve defect rates, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

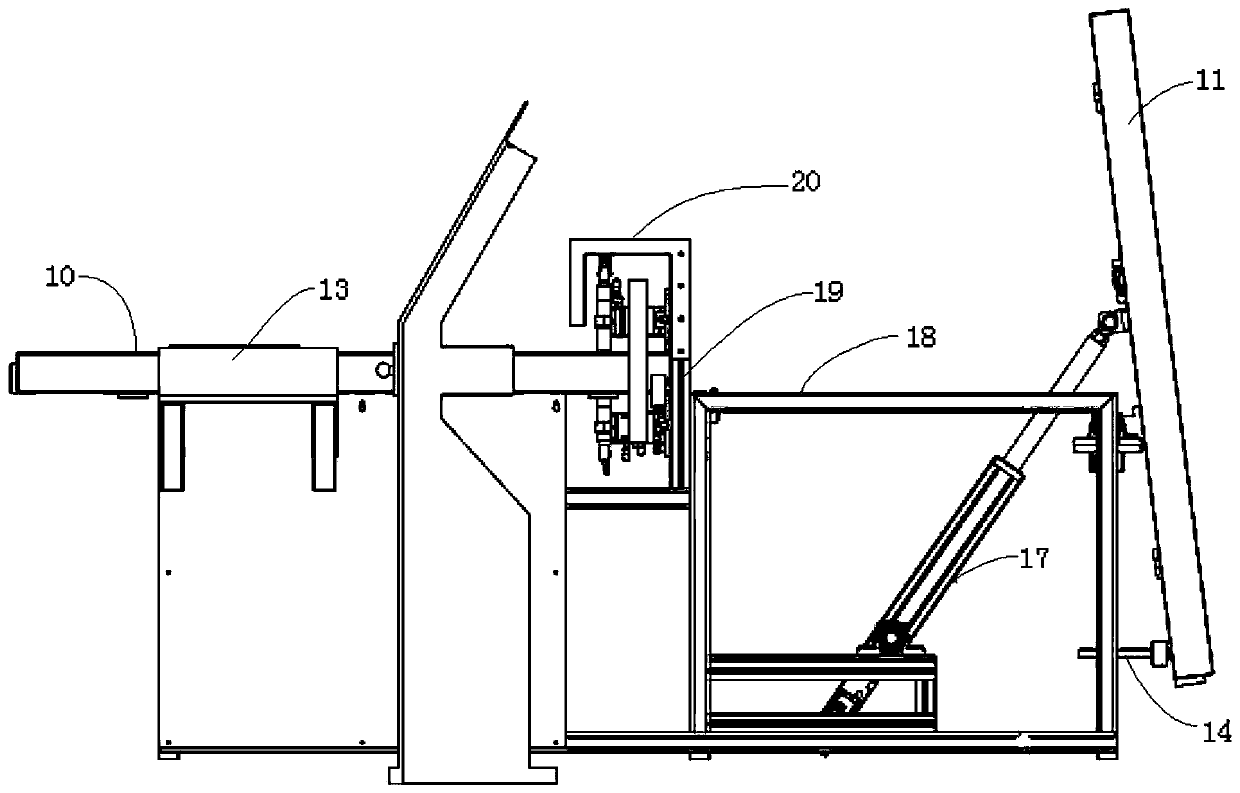

Method used

Image

Examples

Embodiment example 1

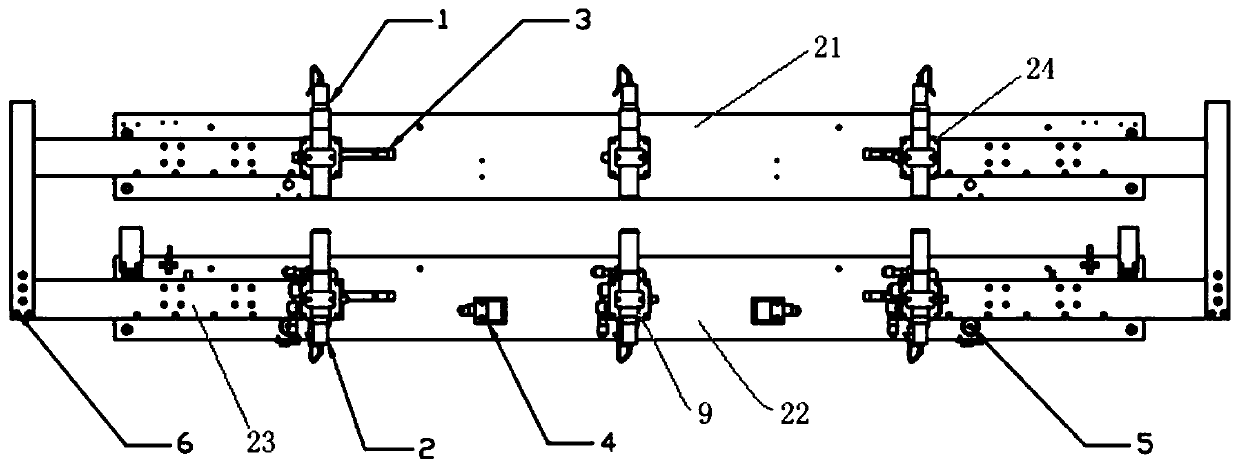

[0038] Clean the panel after etching (size 730×920mm*0.3mm), use this automatic touch screen thickness measuring machine, take 3 groups in the vertical direction, each group has 3 points, 9 points of measurement, the transmission speed is 2.5 m / min, and the measurement The time is 50 seconds (including loading and unloading), please refer to the measurement results Figure 5 , the measured value is the average value of the entire panel (1-2) area, the measurement results are shown in Table 1, and the thickness unit is um.

[0039] serial number Thickness 1# Thickness 2# Thickness 3# category date time 1 302.5 315.3 314.6 OK 2019 / 7 / 8 23:45:17 9 304.5 313.6 307.4 OK 2019 / 7 / 8 23:45:28 3 304.5 308.9 306.5 OK 2019 / 7 / 8 23:45:40

Embodiment 1

[0040] The measured value of cleaning panel after table 1 embodiment 1 etching

Embodiment 2

[0042] Clean the panel after etching (size 1100×1300mm*0.4mm), use this automatic touch screen thickness measuring machine, take 3 groups in the vertical direction, each group has 33 points, 99 points of measurement, the transmission speed is 2.5 m / min, and the measurement The time is 72 seconds (including loading and unloading), please refer to the measurement results Figure 6 , the measurement value is the average value in the entire panel area, the measurement results are shown in Table 2, and the thickness unit is um.

[0043] serial number Thickness 1# Thickness 2# Thickness 3# category date time 1 397.3 398.8 397.8 OK 2019 / 7 / 9 16:13:04 2 398.2 399 398.1 OK 2019 / 7 / 9 16:13:05 3 398.7 398.8 398.6 OK 2019 / 7 / 9 16:13:06 4 397 398.9 398.2 OK 2019 / 7 / 9 16:13:07 5 398.2 399.1 398.5 OK 2019 / 7 / 9 16:13:08 6 398.4 399.1 397.9 OK 2019 / 7 / 9 16:13:09 7 398.2 398.9 398 OK 2019 / 7 / 9 16:13:10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com