Novel vending machine based on manipulator

A vending machine and manipulator technology, applied in the field of new vending machines, can solve the problems of bulkiness of the whole machine, rising maintenance cost and high cost, and achieve the effects of expanding the scope of use, improving the volume ratio and improving the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention provides a new type of vending machine based on a manipulator. In order to make the present invention more obvious and understandable, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

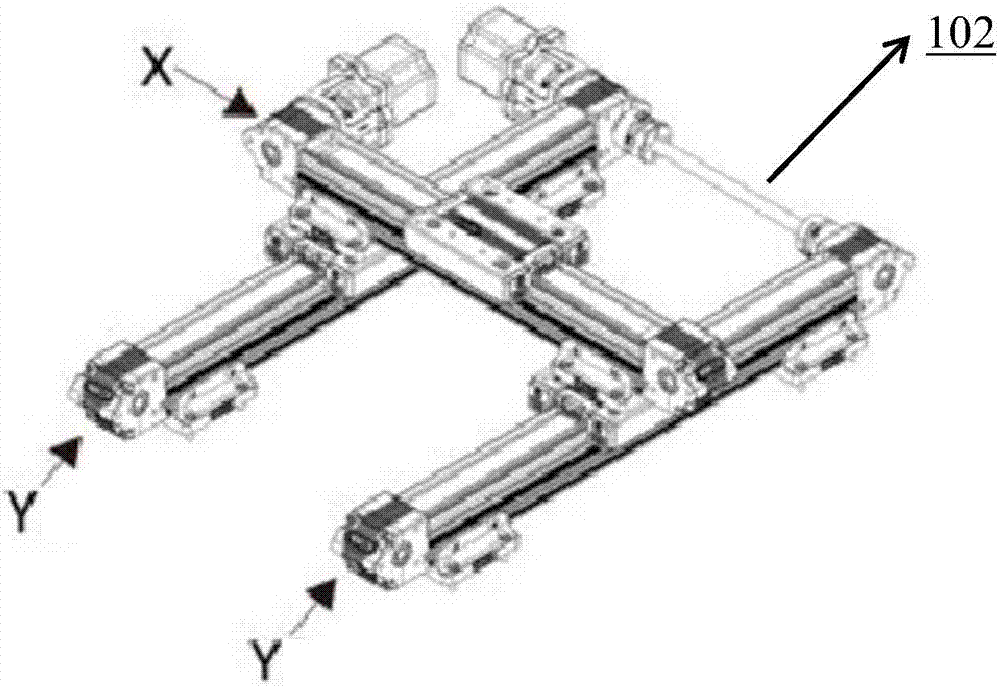

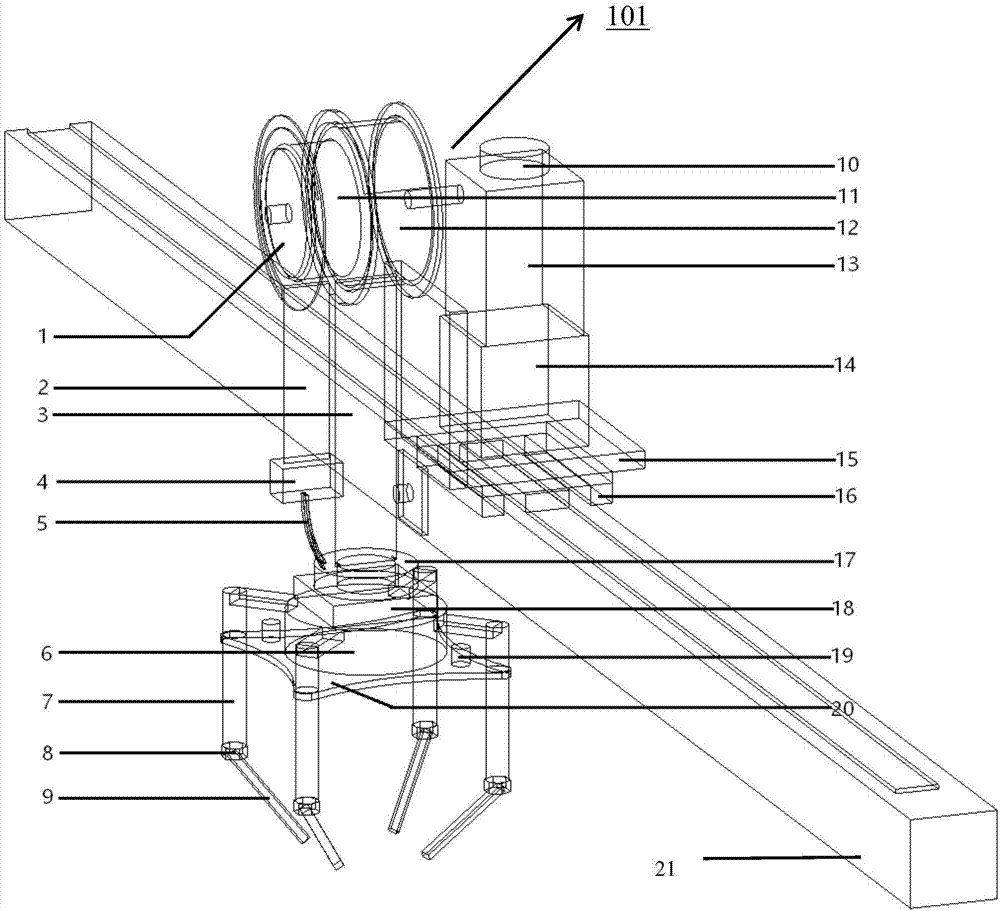

[0055] Such as figure 1 and Figure 4 As shown, the vending machine of the present invention mainly includes a horizontal and vertical synchronous slide assembly 102 , a manipulator assembly 101 , a cabinet 25 and a storage box 32 . The horizontal and vertical synchronous slide assembly 102 is fixed in the cabinet 25 , and the storage box 32 is placed in the cabinet 25 .

[0056] The manipulator assembly 101 is connected with the horizontal and vertical synchronous sliding table assembly 102, the manipulator assembly 101 can be vertically lifted and can move laterally, so that it is accurately located above each cargo lane of the storage box 32, then the manipulator assembly 101 can be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com