A method for reusing lead sludge produced by smear leaching acid

A technology of leaching acid and lead mud, which is applied in the direction of recycling technology, lead-acid battery electrodes, battery recycling, etc., can solve the problems of increasing environmental protection treatment fees, not using too much added amount, occupying labor and equipment, etc., to achieve Improve the input-output ratio, reduce production costs, and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

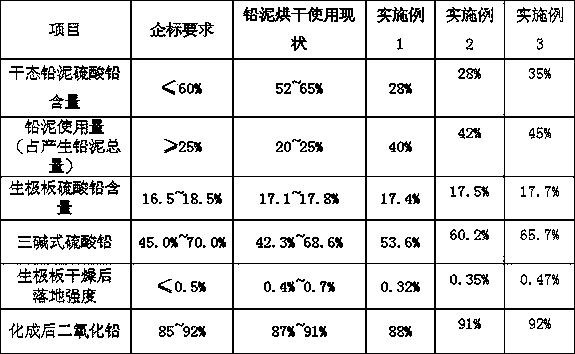

Embodiment 1

[0030] Take out the lead slime that has been settled for 1 hour from the sedimentation tank of the smear machine; place the pulled out lead slime in a rolling mixer and stir for 30 minutes before taking it out; add pure water to the stirred lead mud to make its apparent density 2.0 g / cm 3 , so as to make pasty lead slime; take by weighing 2.5% of the paste-like lead paste formula amount for subsequent use; wherein the components of the positive lead paste and their weight percentages are: 1.4g / ml dilute sulfuric acid 6.1%, pure water 9.1%, pasty lead mud 2.5%, red lead 2.65%, red powder 0.39%, polyester staple fiber 0.08%, and the rest is lead powder.

[0031] First add lead powder and auxiliary materials into the paste mixing machine and stir for 5-7 minutes, then add the above-mentioned amount of pure water within 1 minute to enter the wet mixing stage of the paste process, and add the above-mentioned weighed water within 3-5 minutes after the start of wet mixing. For good ...

Embodiment 2

[0034] Take out the lead slime that has been settled for 2 hours from the sedimentation tank of the smear machine; place the pulled out lead slime in a rolling mixer and stir for 45 minutes and then take it out; add pure water to the stirred lead mud to make its apparent density 2.5 g / cm 3 , so as to make paste lead paste; take by weighing 3.5% paste lead paste of positive lead paste formula for subsequent use; wherein the components and weight percentages of positive lead paste are: 1.4g / ml dilute sulfuric acid 6.5%, pure water 9.15%, paste lead mud 3.5%, red lead 2.9%, red powder 0.4%, polyester staple fiber 0.2%, and the rest is lead powder.

Embodiment 3

[0037] Take out the lead slime that has been settled for 3 hours from the sedimentation tank of the smear machine; place the pulled out lead slime in a rolling mixer and stir for 60 minutes before taking it out; add pure water to the stirred lead mud to make its apparent density 3.0 g / cm 3 , so as to make paste lead paste; take by weighing 4.5% paste lead paste of positive lead paste formula for subsequent use; wherein the components and weight percentages of positive lead paste are: 1.4g / ml dilute sulfuric acid 7.0%, pure water 9.2%, paste lead mud 4.5%, red lead 3.2%, red powder 0.4%, polyester staple fiber 0.5%, and the rest is lead powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com