Automatic coil wall-thickness reduction and drawing device and drawing method of small-diameter capillary tube

A stretching device and small-diameter technology, applied in the field of processing capillary tubes with an outer diameter of less than 8 mm, stretching small-diameter capillary tubes, and automatic coil wall-reducing stretching devices, can solve low efficiency, large consumption of auxiliary materials, and investment Low output rate and other issues, to achieve the effect of improving input-output rate, strong quality controllability, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

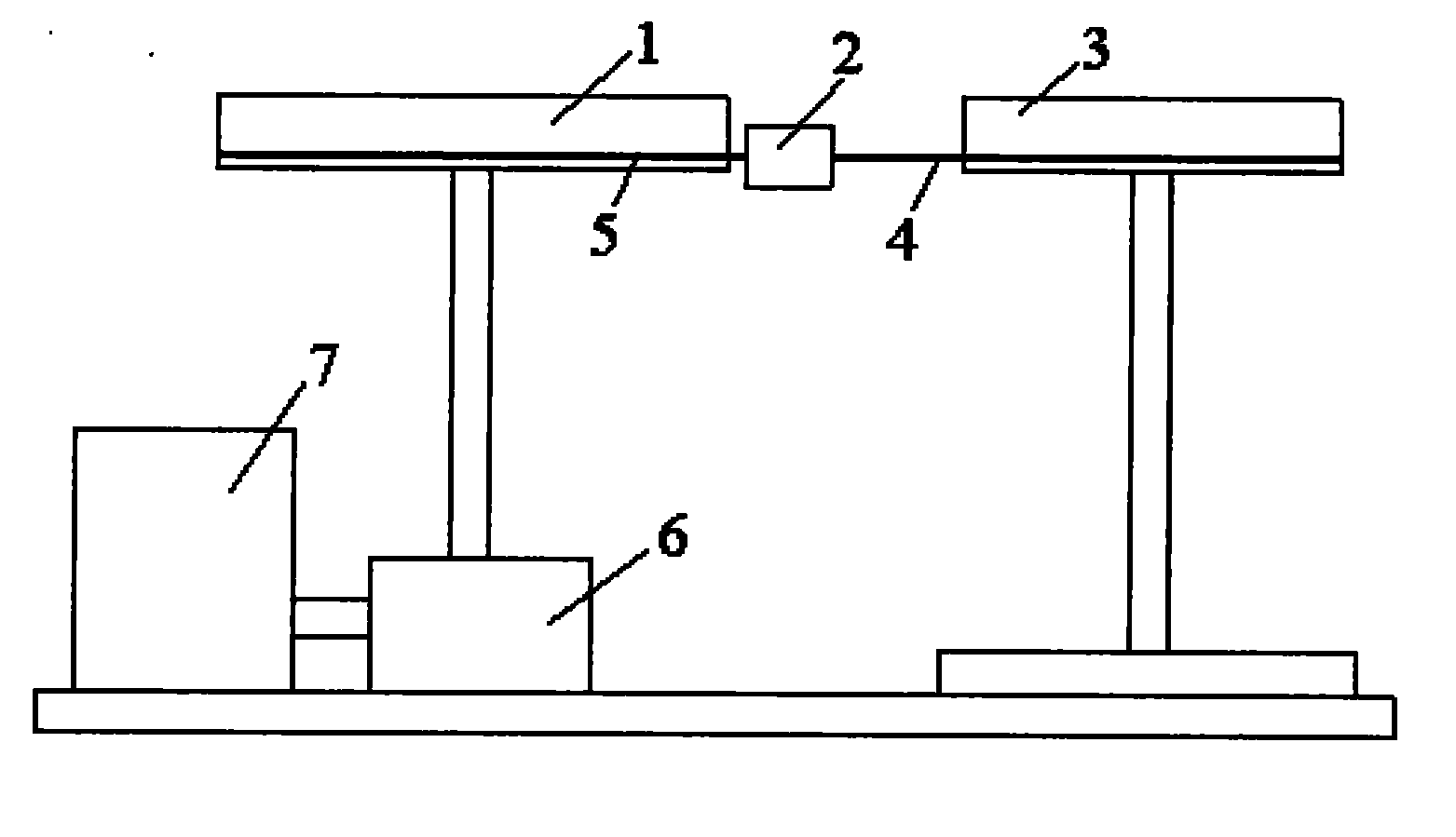

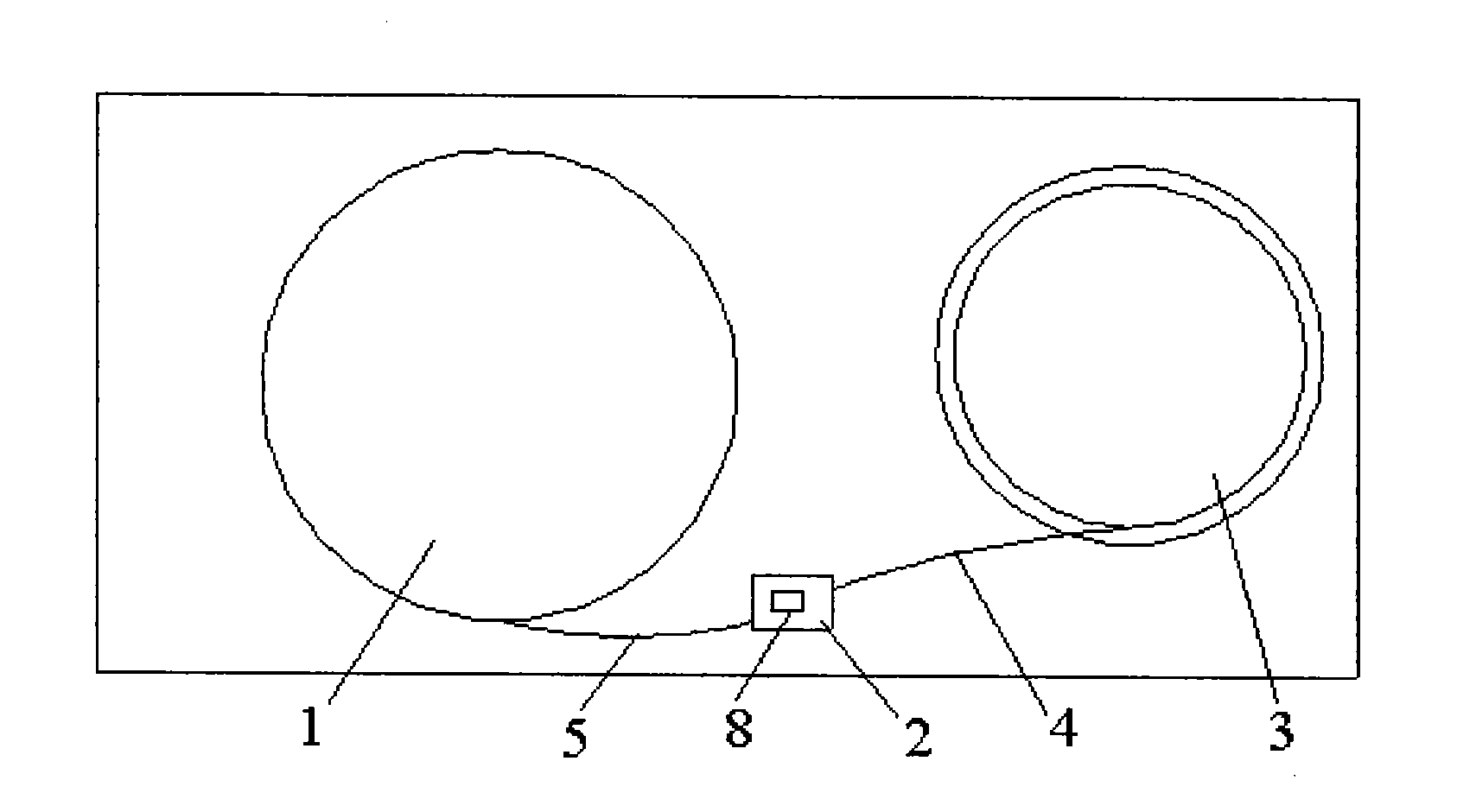

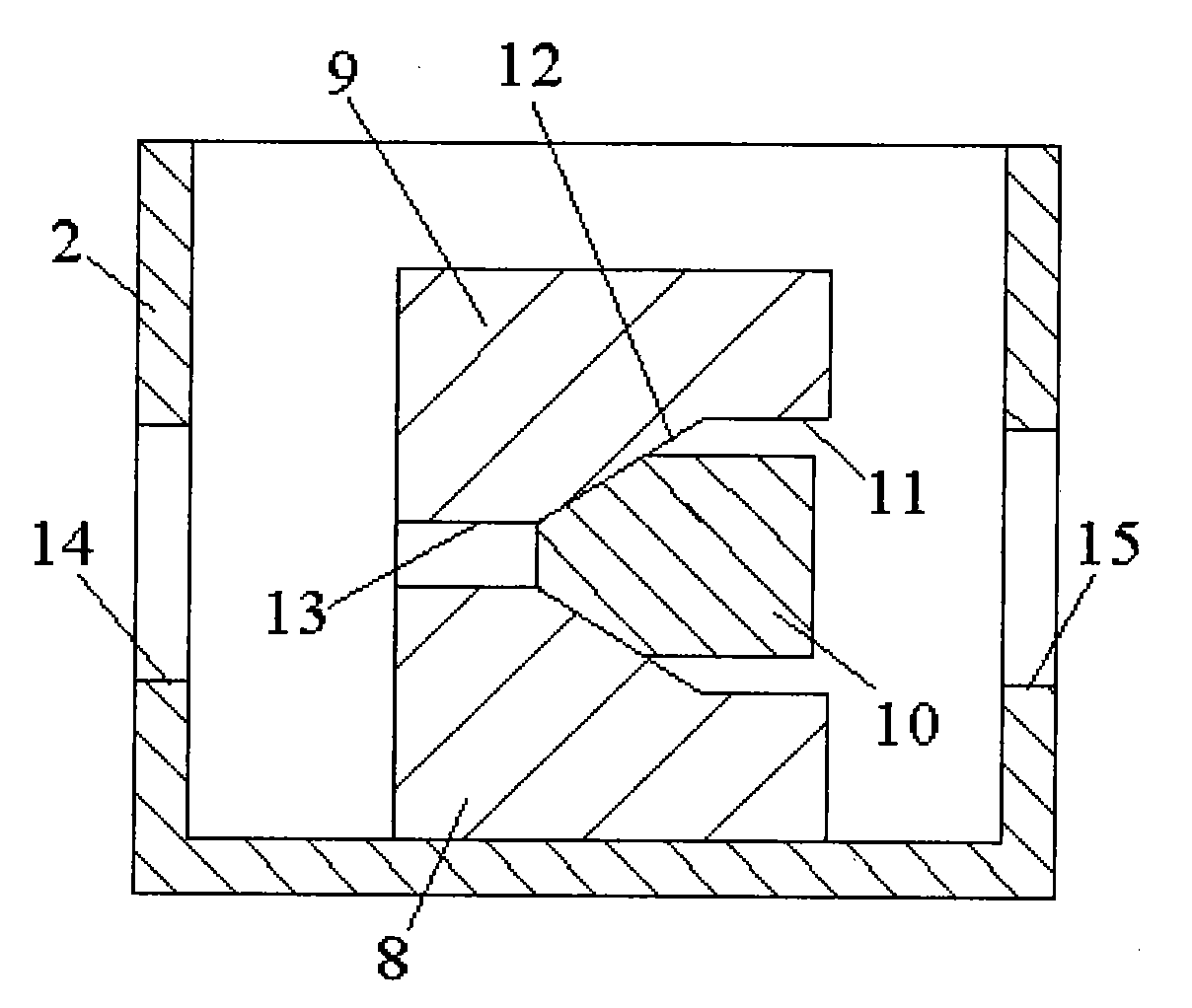

[0023] Such as figure 1 and figure 2 As shown, the structure of the stretching device of the present invention includes a motor 7, the power output shaft of the motor 7 is connected with the power input shaft of the gearbox 6, the power output shaft of the gearbox 6 is fixedly connected with a stretching disc 1, and the stretching The tray 1 is provided with a bayonet, and the stretching device also includes a mold box 2 and a discharge tray 3 . The mold box 2 is a hollow shell, and the mold box 2 is provided with a mold 8, and the structure of the mold 8 is as follows: image 3 As shown, the drawing outer mold 9 is included, and a groove is processed on the drawing outer mold 9, and the groove is composed of a circular table hole 12 and a cylindrical hole 11 arranged coaxially from the inside to the outside, and the large diameter end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com