Full-automatic error correcting control device and method for paperboard production line

A control device and production line technology, which is applied in the direction of machining/deformation, can solve the problems of slow response speed, large amount of slitting edge, poor control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following, the full-automatic deviation correction control device for the cardboard production line of the present invention will be further explained and described in detail with reference to the accompanying drawings and specific implementation methods.

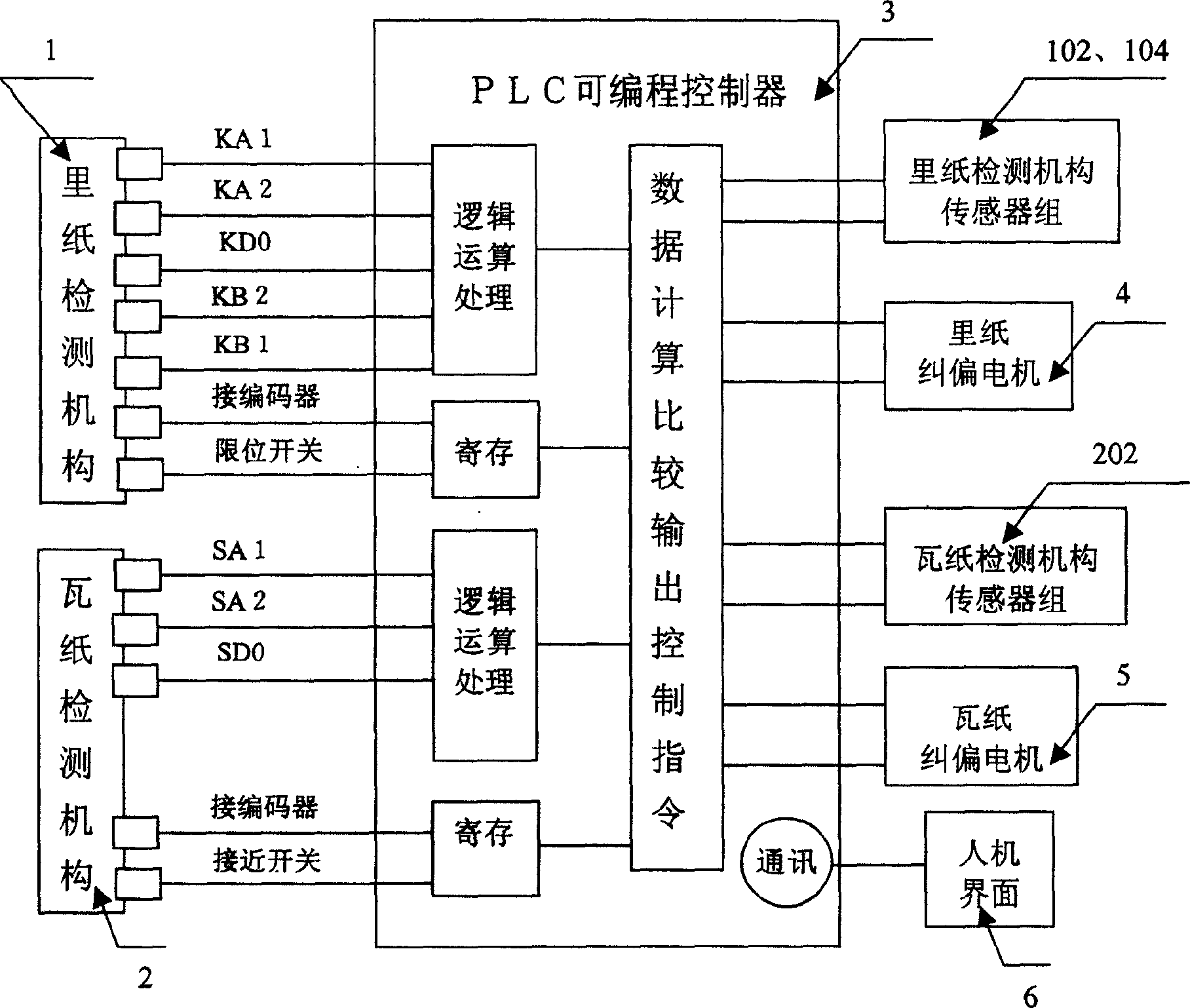

[0035] figure 1 It is a principle block diagram of a specific embodiment of the automatic deviation correction control device for the cardboard production line of the present invention. In this embodiment, the full-automatic deviation correction of a corrugated cardboard production line is taken as an example, and the present invention is illustrated and described in detail by taking the deviation correction of the basic single-facer paper material centering mode.

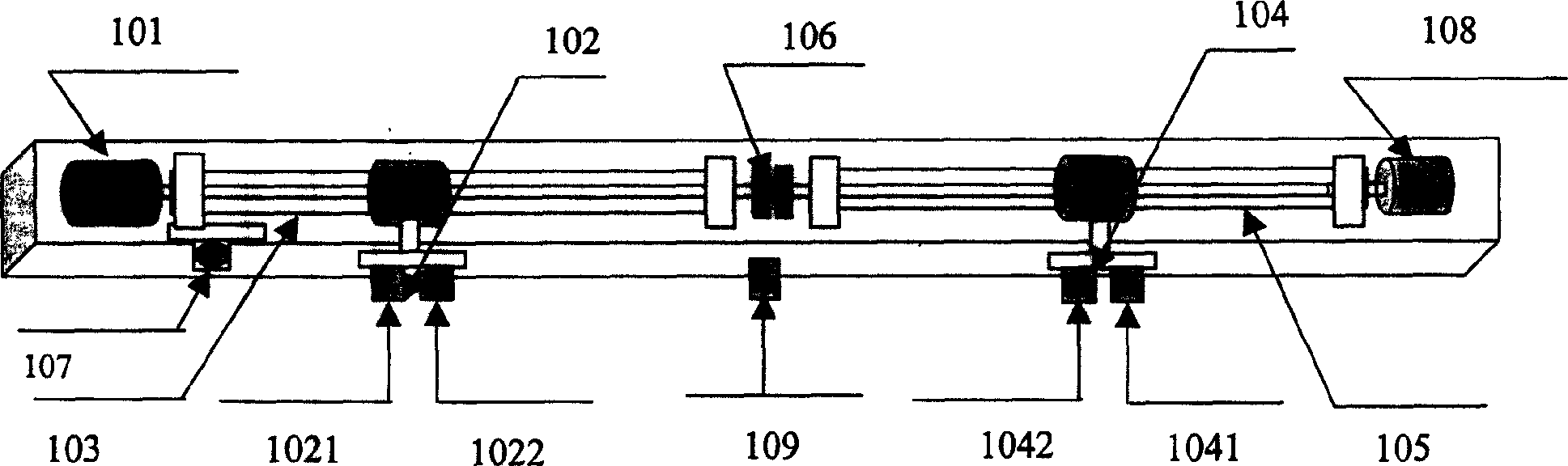

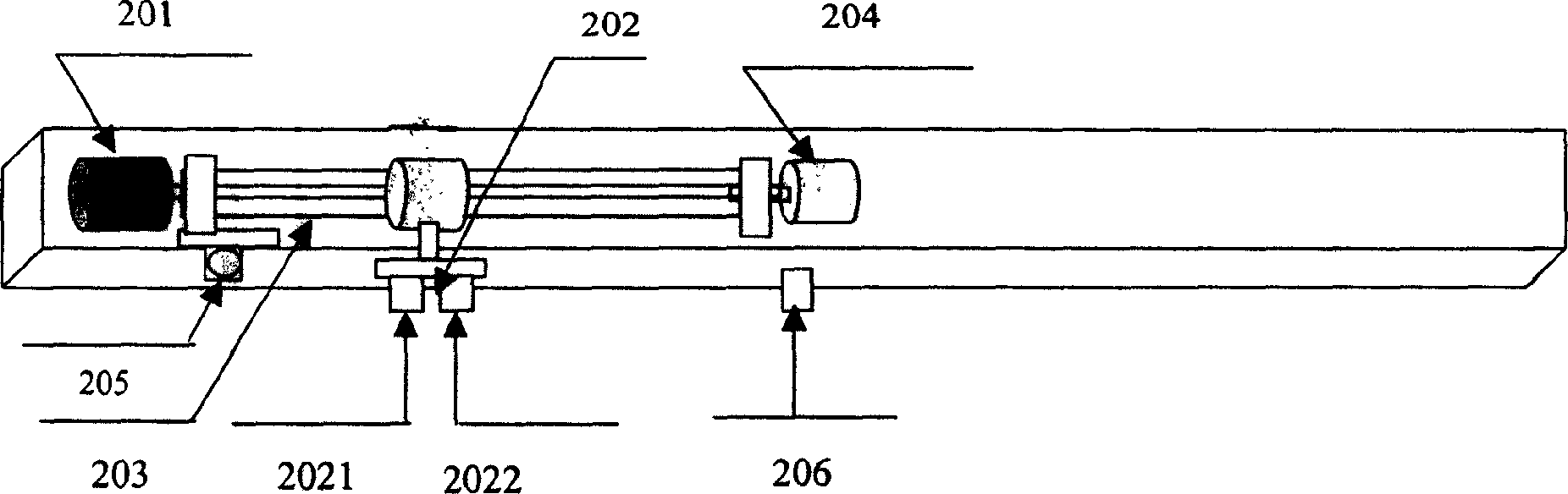

[0036] In this embodiment, the automatic deviation correction control device of the cardboard production line includes two sets of detection mechanisms installed to detect the horizontal position and offset of paper materials, namely, the inner pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com