Manufacture method of die roller used for impressing electrode micro-grid films

A manufacturing method and technology of mold rolls, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of unclear, uniform and inconsistent electrode micro-grid patterns on the surface of mold rolls, and difficulty in vertical pattern splicing To achieve seamless splicing, unable to meet the imprinting requirements and other problems, to achieve the effect of clear and consistent graphics, excellent mechanical strength and hardness, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The manufacturing method of the mold roll of the imprinted electrode micro-grid film in this embodiment, the specific steps of the manufacturing method are as follows:

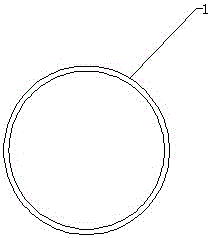

[0023] (1) if figure 1 As shown, a layer of masking glue with a thickness of 2 μm is coated on the outer surface of the mold roll;

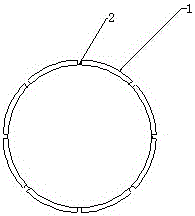

[0024] (2) if figure 2 As shown in the figure, the masking glue layer is etched away by direct writing with a laser direct writing device until it reaches the metal surface of the mold roll, and a groove-shaped electrode microgrid pattern 2 with a width of 5um and a height of 2μm is formed on the mold roll, using a 3W short-wavelength 266nm laser , the line scanning speed is 500mm / s, and the masking glue can be etched away in a few milliseconds;

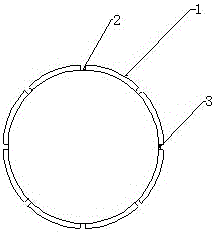

[0025] (3) if image 3 As shown, the mold roll after photoetching is cleaned with ultrasonic water to remove the masking glue remaining on the electrode micro-grid pattern and the slight metal oxide residue on the surface of...

Embodiment 2

[0028] The manufacturing method of the mold roll of the imprinted electrode micro-grid film in this embodiment, the specific steps of the manufacturing method are as follows:

[0029] (1) if figure 1 As shown, a layer of masking glue with a thickness of 3 μm is coated on the outer surface of the mold roll;

[0030] (2) if figure 2 As shown, the masking glue layer is etched away by direct writing with a laser direct writing device until it reaches the metal surface of the mold roll, and a groove-shaped electrode microgrid pattern 2 with a width of 4um and a height of 3μm is formed on the mold roll, using a 3W short-wavelength 266nm laser , the line scanning speed is 500mm / s, and the masking glue can be etched away in a few milliseconds;

[0031] (3) if image 3 As shown, the mold roll after photoetching is cleaned with ultrasonic water to remove the masking glue remaining on the electrode micro-grid pattern and the slight metal oxide residue on the surface of the mold roll...

Embodiment 3

[0034] The manufacturing method of the mold roll of the imprinted electrode micro-grid film in this embodiment, the specific steps of the manufacturing method are as follows:

[0035] (1) if figure 1 As shown, a layer of masking glue with a thickness of 4 μm is coated on the outer surface of the mold roll;

[0036] (2) if figure 2 As shown, the masking glue layer is etched away by direct writing with a laser direct writing device until it reaches the metal surface of the mold roll, and a groove-shaped electrode microgrid pattern 2 with a width of 5um and a height of 4μm is formed on the mold roll, using a 3W short-wavelength 266nm laser , the line scanning speed is 500mm / s, and the masking glue can be etched away in a few milliseconds;

[0037] (3) if image 3 As shown, the mold roll after photoetching is cleaned with ultrasonic water to remove the masking glue remaining on the electrode micro-grid pattern and the slight metal oxide residue on the surface of the mold roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com