Patents

Literature

87results about How to "Precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

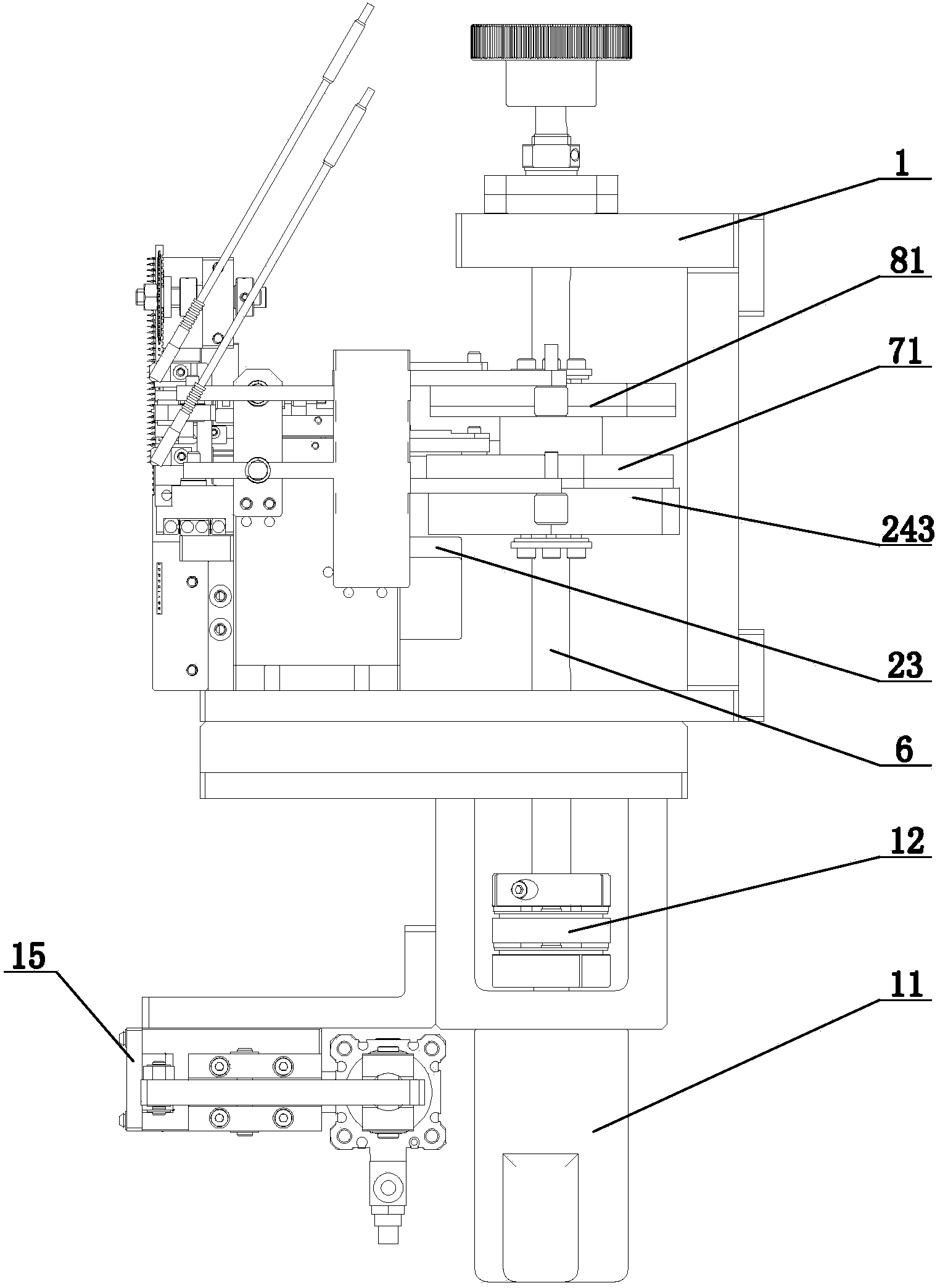

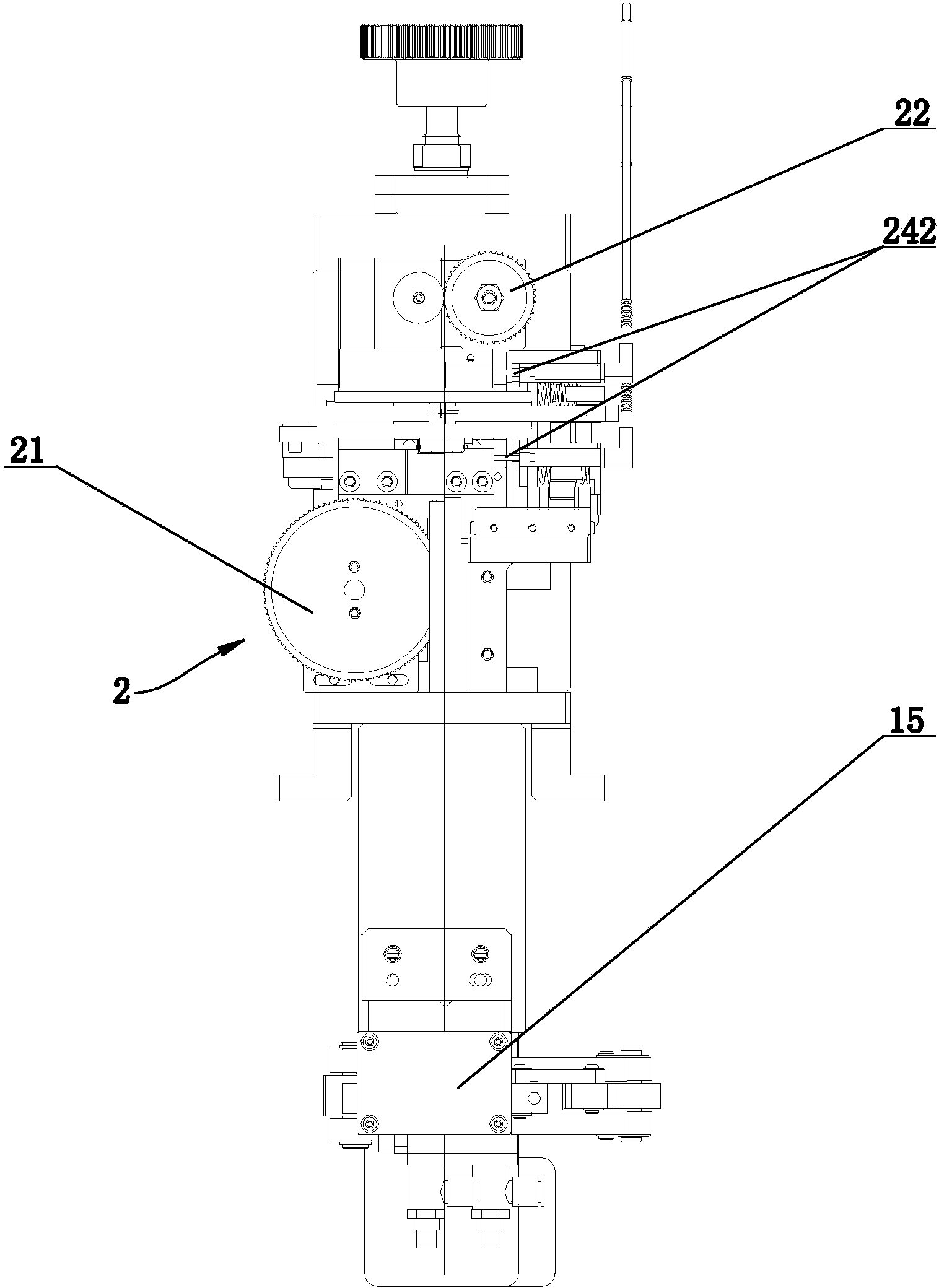

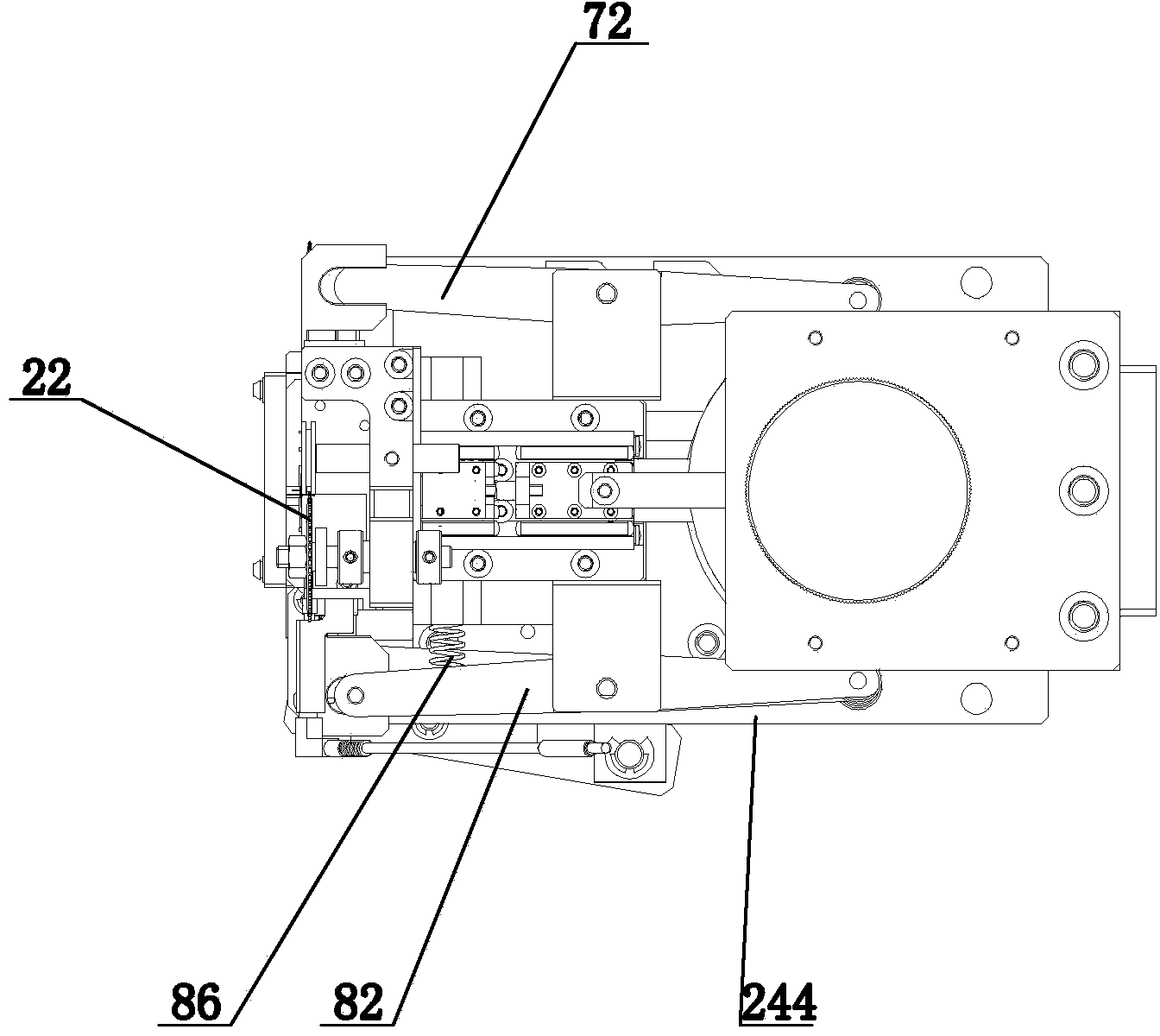

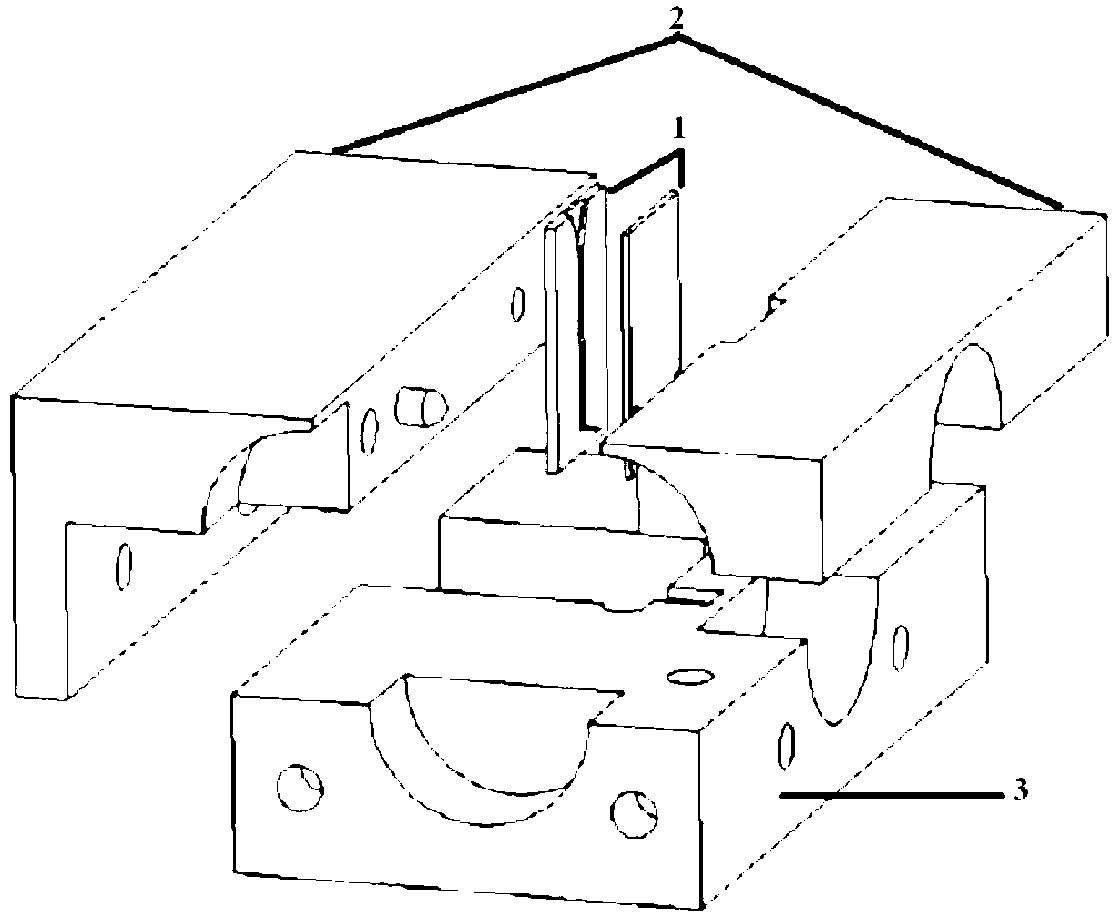

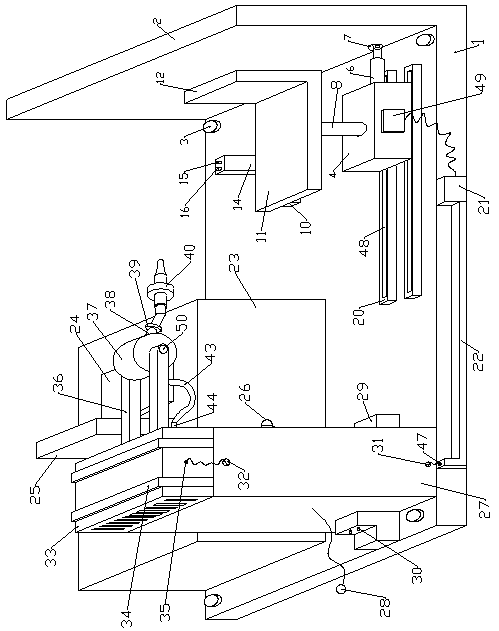

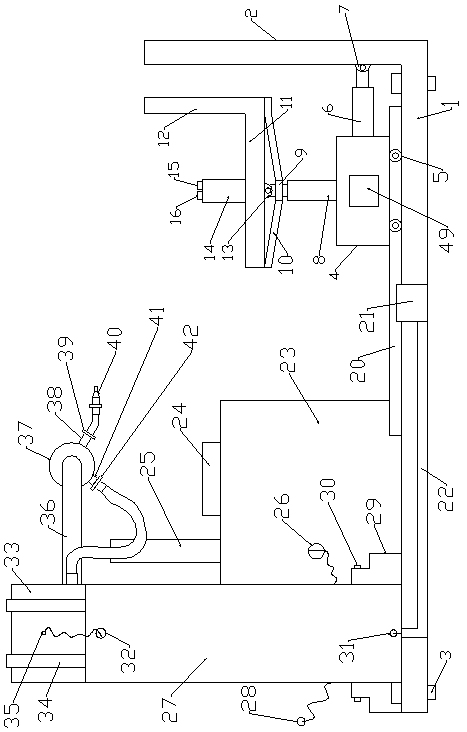

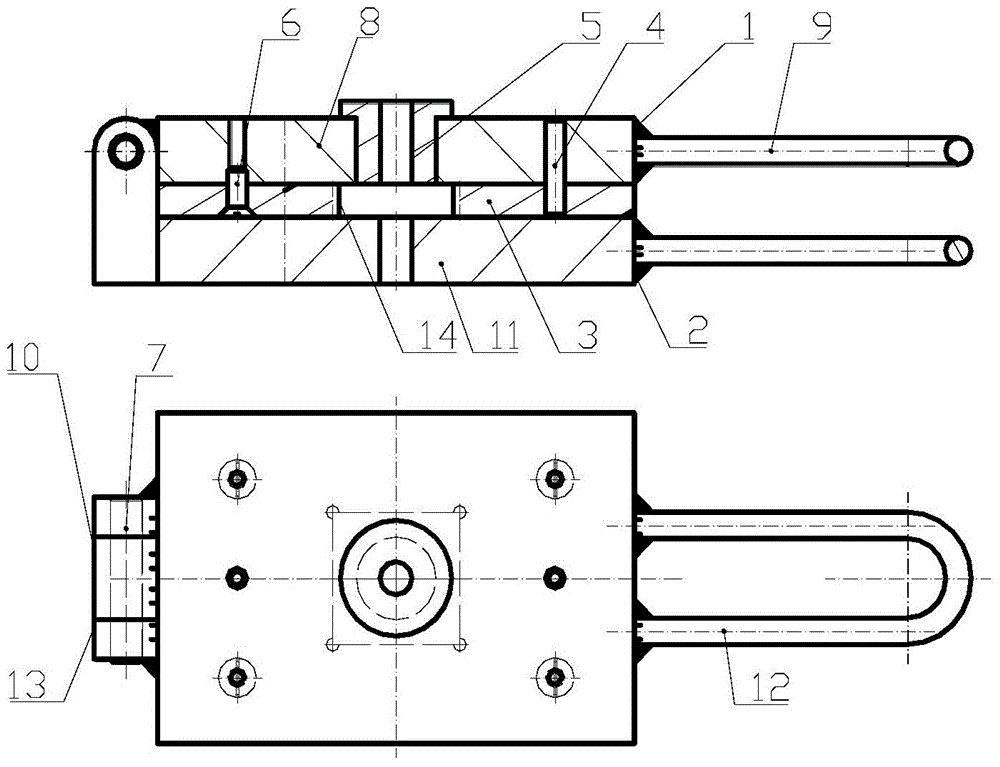

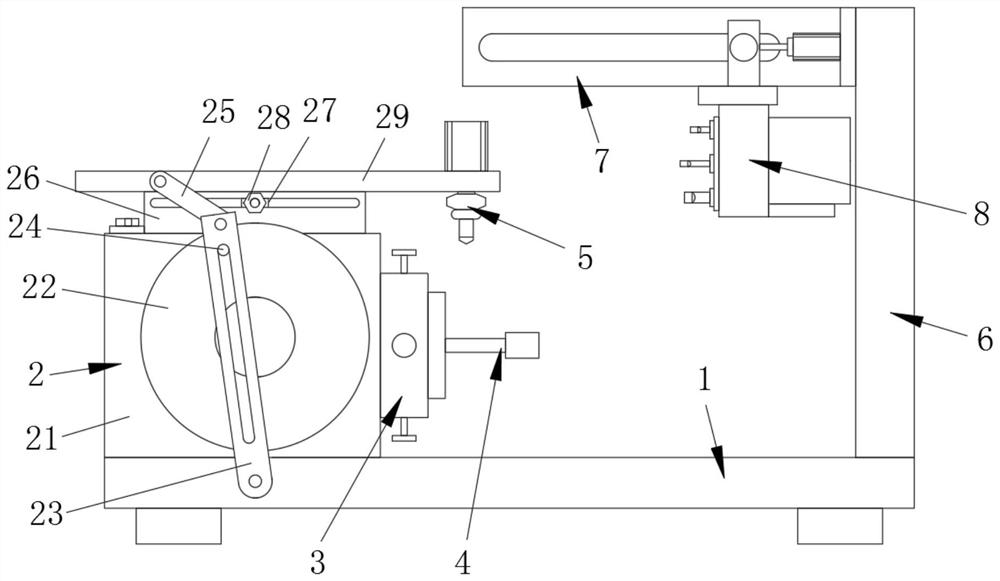

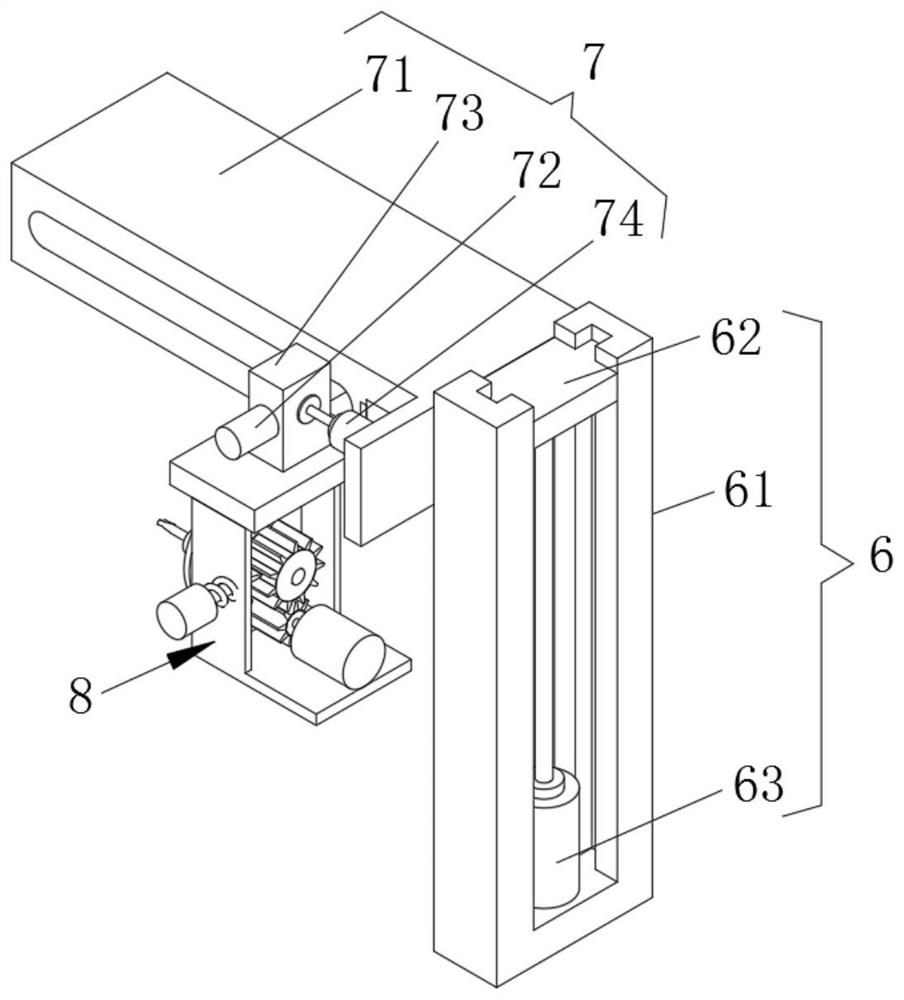

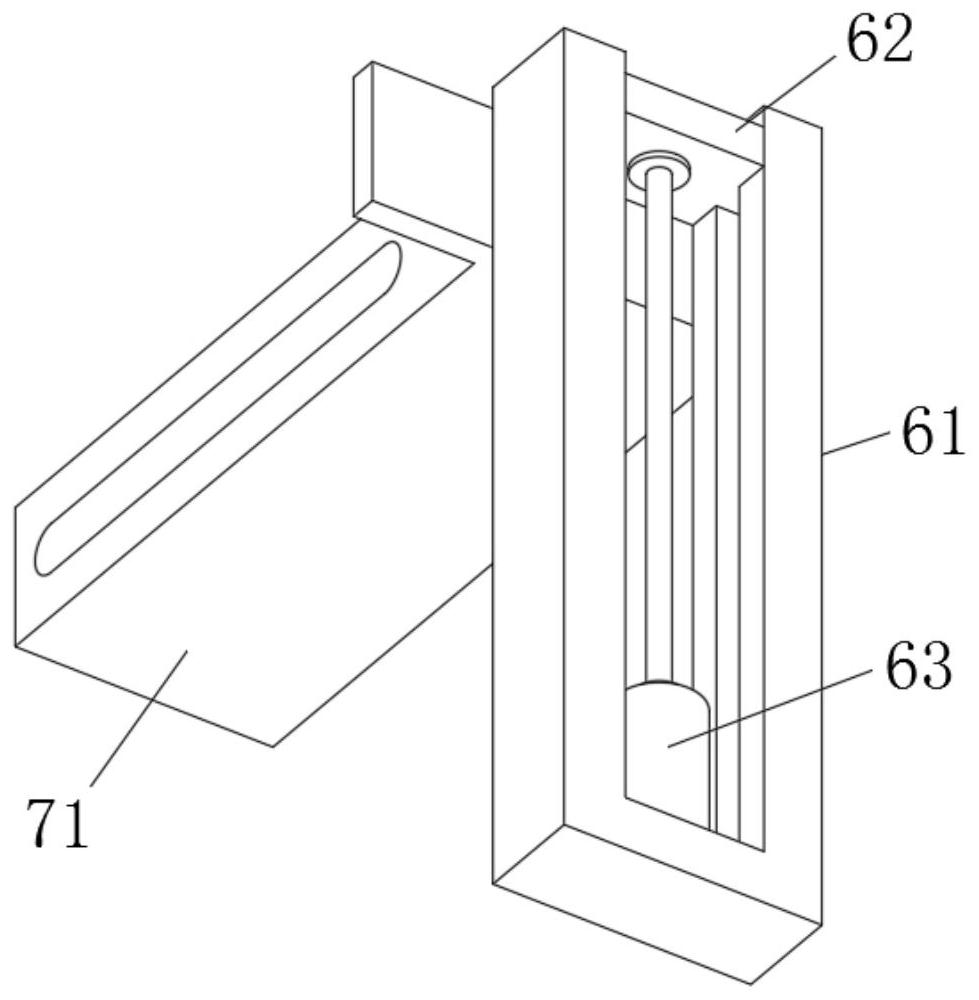

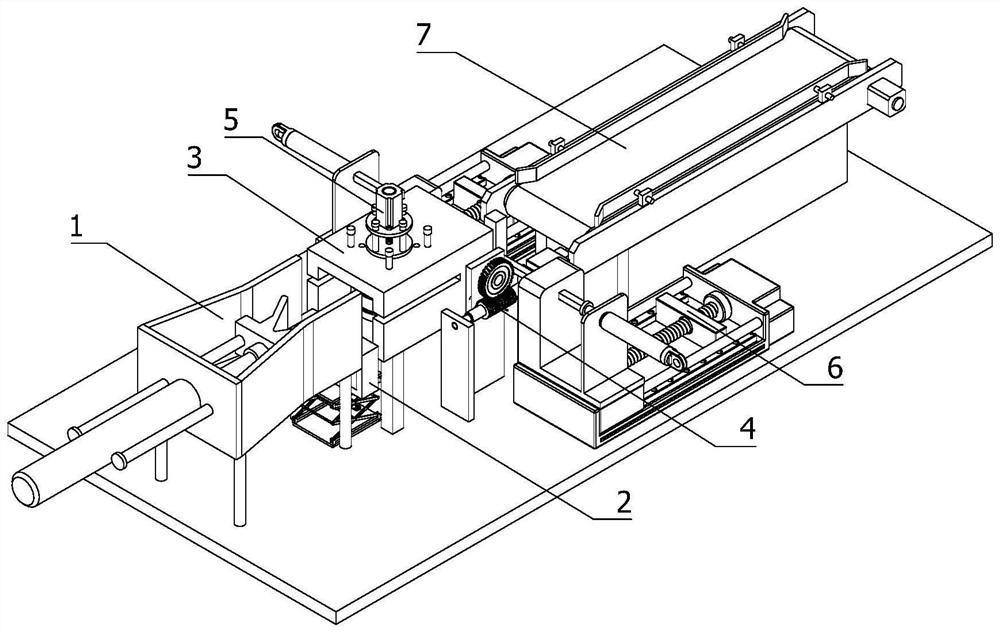

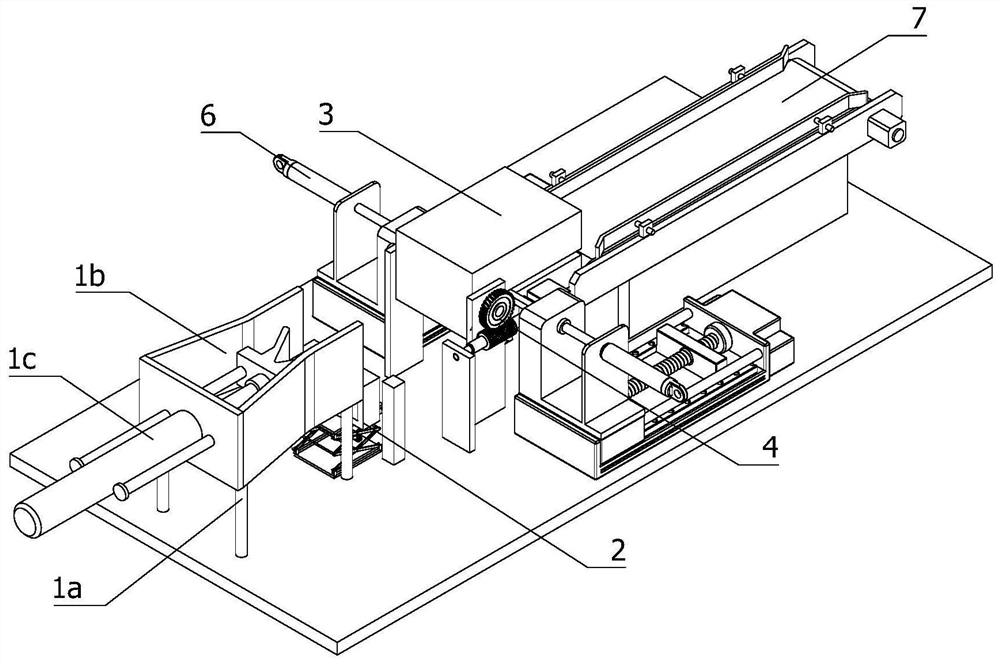

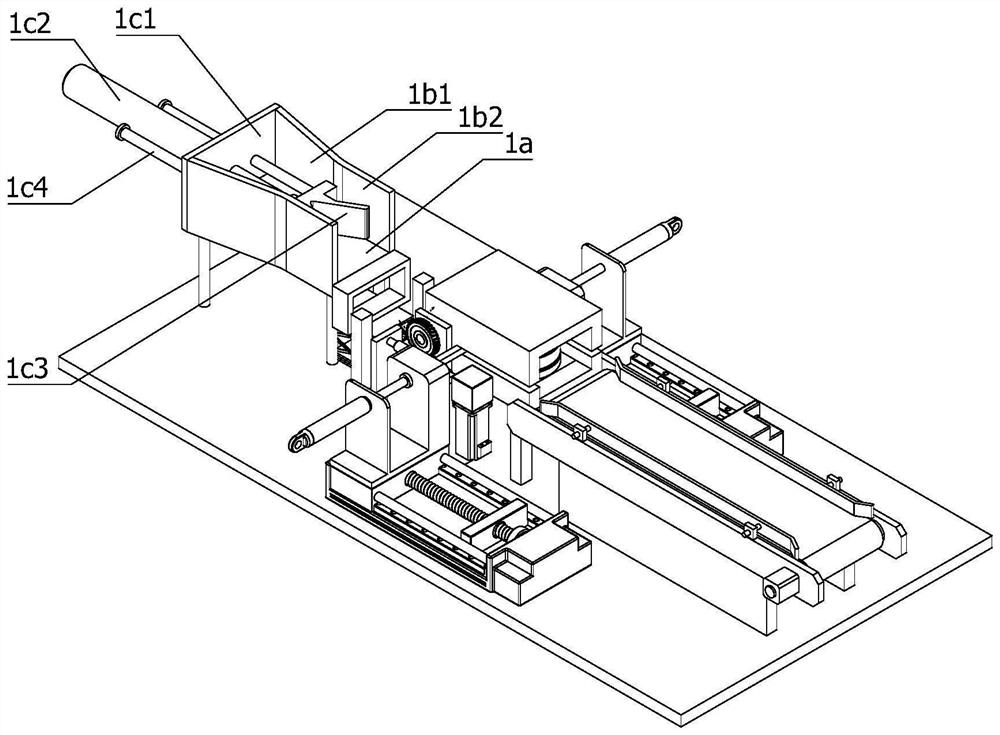

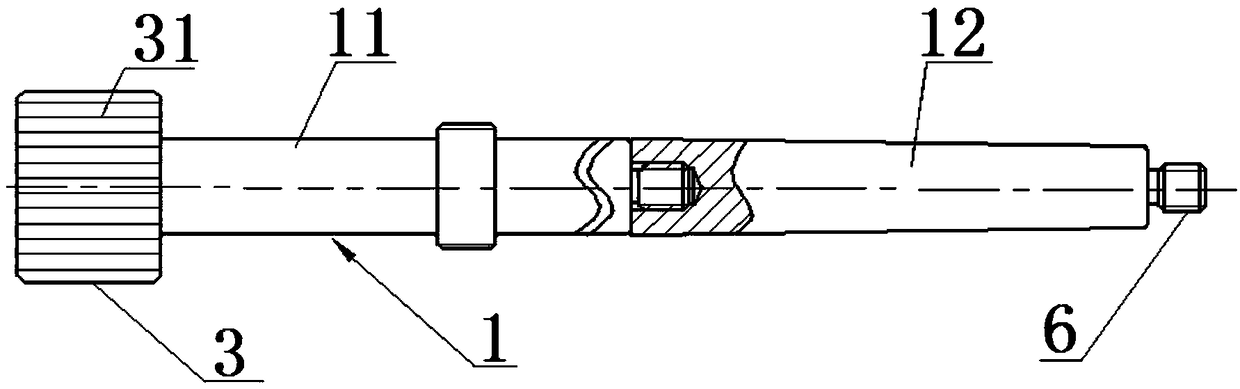

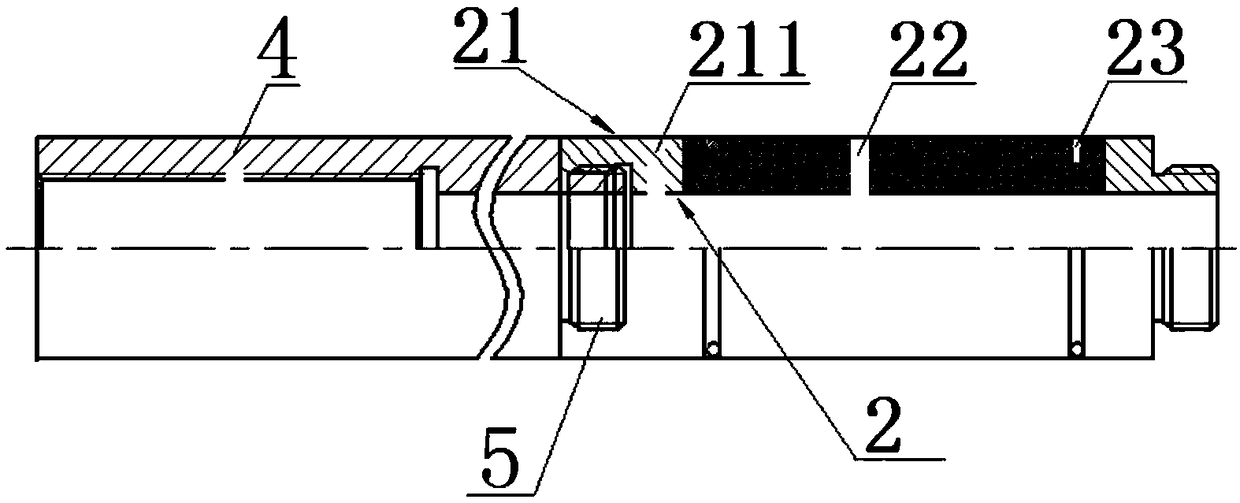

High-speed insertion device for cutting terminal

ActiveCN104037588ACut insert implementationAvoid damageContact member manufacturingContact member assembly/disassemblyBiomedical engineeringInsertion device

The invention discloses a high-speed insertion device for cutting a terminal, and belongs to the technical field of plug connector devices. The high-speed insertion device comprises a machine frame. A feeding device, a clamping and cutting device, a forward-sending device and an insertion device body are arranged on the machine frame. The clamping and cutting device comprises a forward-sending sliding block, wherein a clamping arm and a cutting arm are designed on the forward-sending sliding block, and a clamping jaw is elastically connected to one end of the clamping arm. The insertion device body comprises an insertion through hole, wherein an insertion rod is arranged in the insertion through hole. By means of the high-speed insertion device, the terminal can be clamped and cut through one device, manufacturing cost is reduced, and production efficiency is improved; elastic clamping is conducted on the terminal in the whole process, and therefore damage to the appearance of the terminal is avoided; the pre-insertion step is added, the insertion rod ejects the terminal into a connector plastic shell after the terminal is placed in position in advance, and therefore the terminal is accurately inserted in place, and the yield is greatly increased.

Owner:WEIFANG LOKOMO PRECISION IND

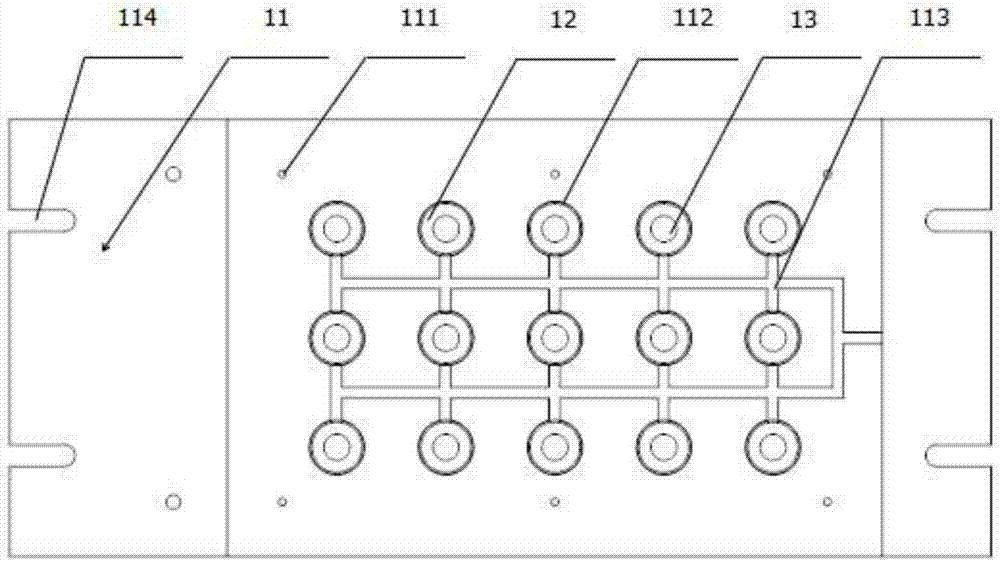

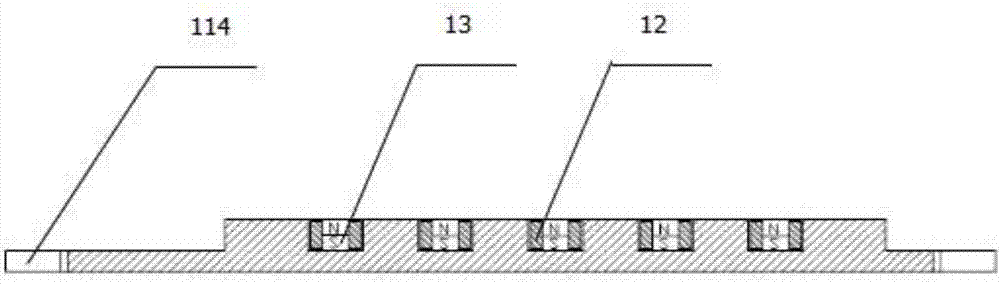

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

Conical arc plate drilling clamp tool

ActiveCN102689037APrecisionSimple structureDrilling/boring measurement devicesPositioning apparatusAcute angleDrill hole

The invention discloses a conical arc plate drilling clamp tool, relates to a drilling clamp tool for plate parts, and aims to solve the problem that the conventional conical arc plate drilling clamp tool cannot simultaneously meet the machining precision of various holes of the conical arc plate. An acute angle formed between a midperpendicular of an upper body and a bottom plane of the base is 83 degrees; a positioning pin is simply arranged in a pin mounting hole and is arranged in a positioning pin cylinder; a spring sleeve is arranged on the positioning pin; a stepped rotating shaft is arranged in a shaft mounting hole; a small diameter end of the stepped rotating shaft is connected with a central hole of a cone; an outer conical surface of the cone is consistent with an inner surface of the conical arc plate; a notch subjected to profile modeling of the conical arc plate is formed on the lower surface of an arc plate drill jig; a through hole is formed on the arc plate drill jig; a positioning groove is formed on an end face which is close to the upper body, of the cone; the arc plate drill jig is buckled on the outer conical surface of the cone; the conical arc plate is inserted into the notch; and a positioning column subjected to profile modeling on the positioning pin is inserted into the positioning groove. The conical arc plate drilling clamp tool is used for a conical arc plate drilling process.

Owner:HARBIN JIANCHENG GRP

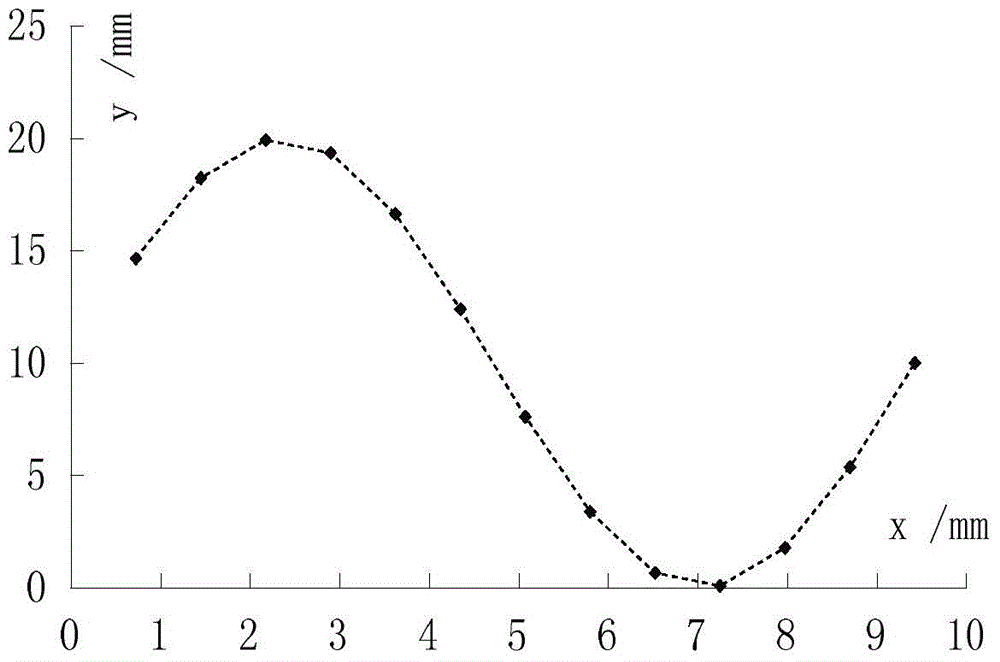

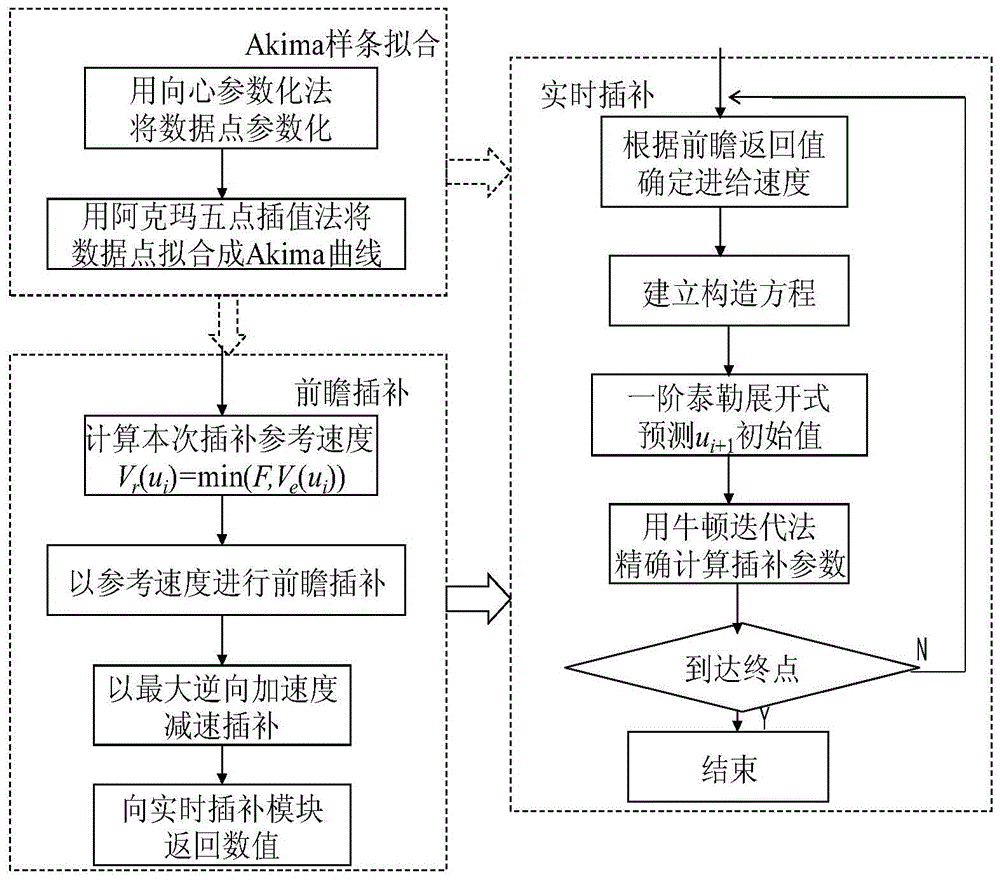

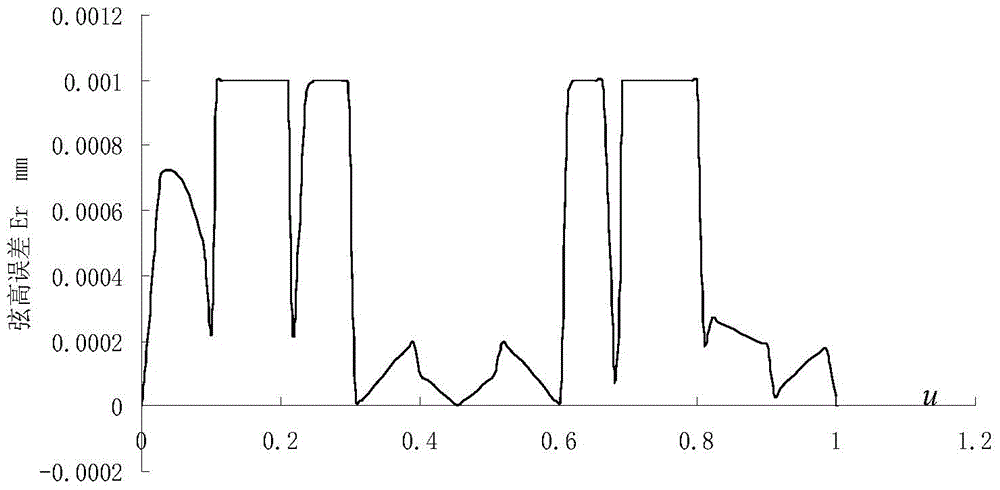

Akima spline fitting based look-ahead interpolation method

InactiveCN104597847APrecisely throughImprove fitting accuracyNumerical controlCurve fittingComputer science

The invention provides an Akima spline fitting based look-ahead interpolation method. The method is characterized in that the Akima spline fitting is that the parameters corresponding to each interpolation point are calculated by the centripetal parameterization method, and then the data points are fitted into a smooth Akima spline by the Akima five-point interpolation method; the look-ahead interpolation is that different values are returned for real-time interpolation by the look-ahead interpolation calculation according to the processing precision requirement, the programming speed of a numerical control system and the maximum speed information; the real-time interpolation is that the real-time feeding speed is adjusted according to the look-ahead interpolation returning value, then a structural equation is created according to the known Akima spline equation and interpolation cycle and other information, then the primary iteration value of the next interpolation method is predicated, and finally the interpolation parameters are accurately calculated by the newton iteration method. According to the method, the data points to be processed are fitted through the Akima spline, so that the actuating efficiency is increased, the smoothness is high, the fitting precision is improved while the interpolation real-time performance is ensured, the accuracy and flexibility are improved, and the actual state of a workpiece can be restored to the maximum.

Owner:中国科学院沈阳计算技术研究所有限公司

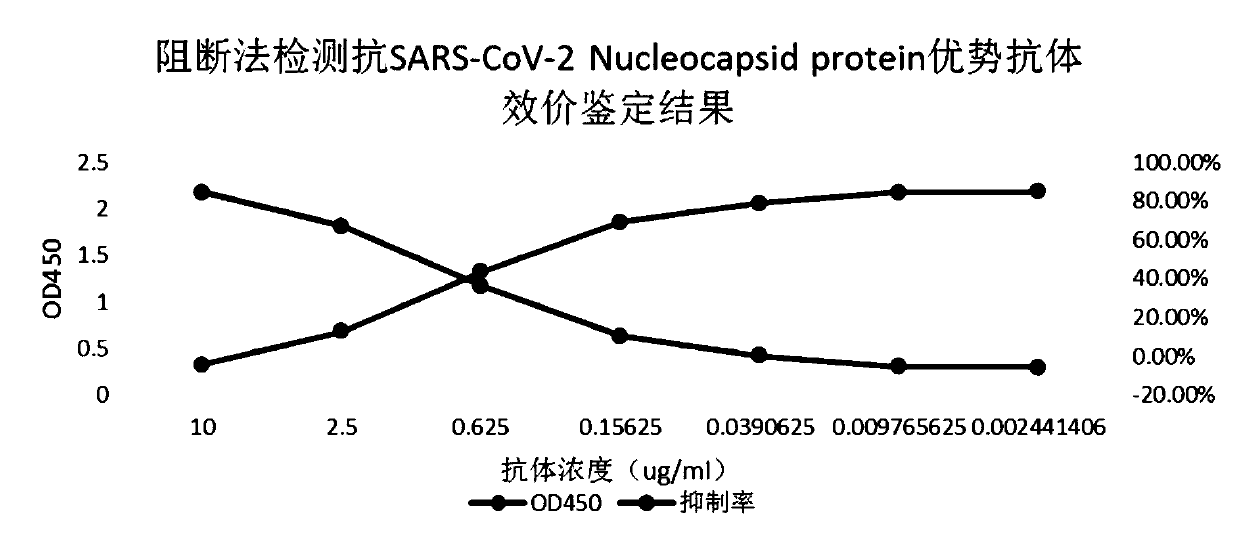

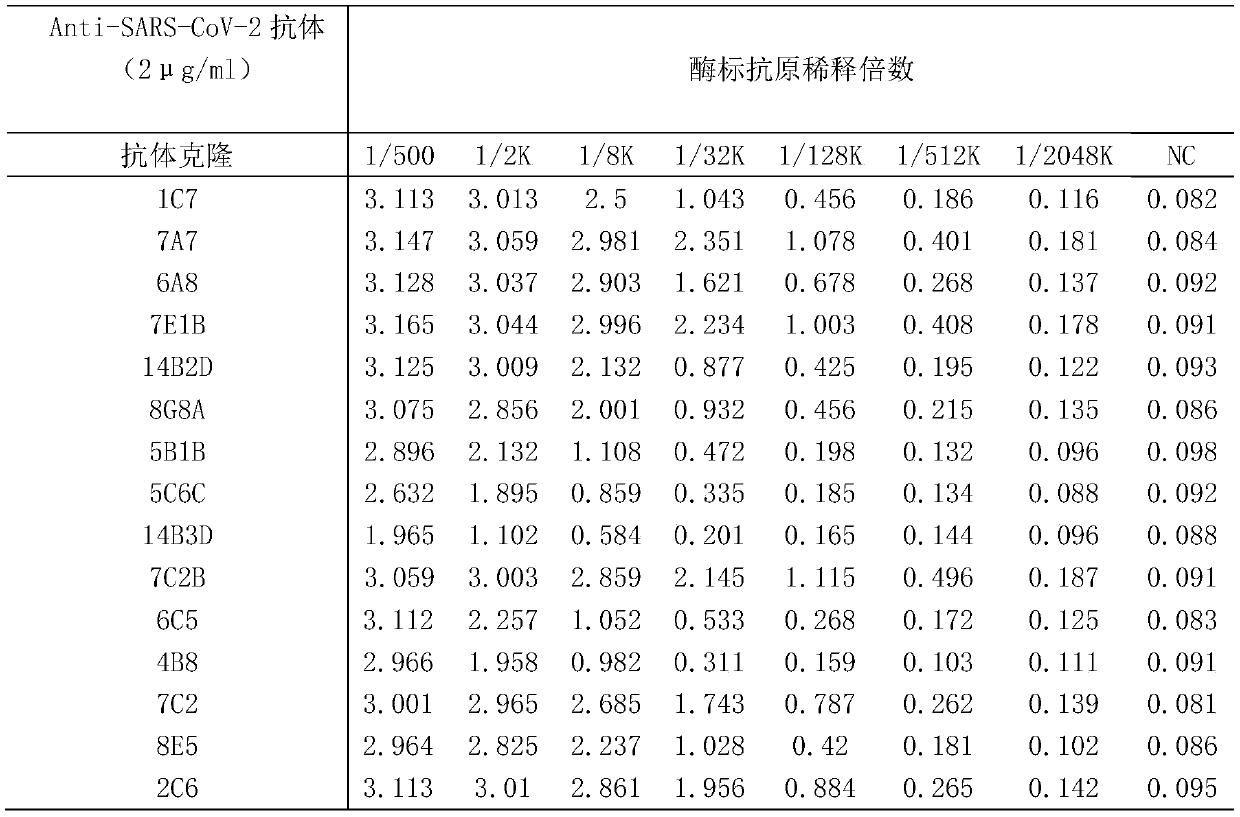

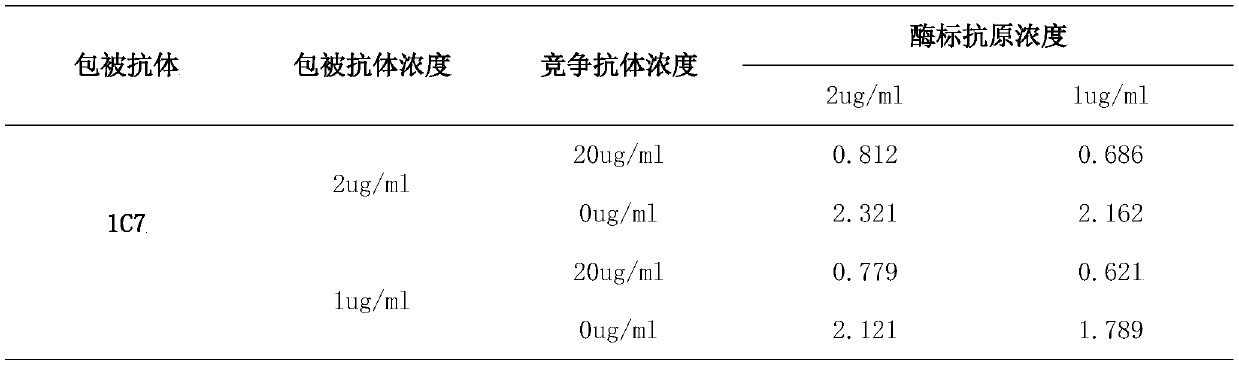

SARS-CoV-2 antibody detection method

PendingCN111474345AQuick checkEasy to detectBiological material analysisAntibody SuppressionAntiendomysial antibodies

The invention discloses an SARS-CoV-2 antibody detection method. The SARS-CoV-2 antibody detection method comprises the following steps: carrying out horseradish peroxidase labeling on recombinant SARS-CoV-2Nucleocapsid protein, meanwhile, selecting an anti-SARS-CoV-2 antibody or a dominant antibody to coat the enzyme-linked plate and sealing; according to a competitive ELISA principle, simultaneously adding a to-be-detected sample and an enzyme-labeled antigen into a test hole of an enzyme-linked plate, performing incubation at room temperature, thoroughly washing the plate, then adding a substrate TMB, performing color development in a dark place, finally, terminating the reaction, measuring a light absorption value at 450 nm, and evaluating the titer of the antibody in the sample by calculating the antibody inhibition rate. According to the method disclosed by the invention, relatively conservative N protein in SARS-CoV-2 and a specific antibody of the N protein are selected as rawmaterials. Compared with a traditional antibody detection method, the detection of the Anti-SARS-CoV-2 specific antibody is completed more quickly, more conveniently and more sensitively, and the method has specificity, sensitivity, accuracy and precision and has important application prospect and value.

Owner:BEIJING BIOSYNTHESIS BIOTECH

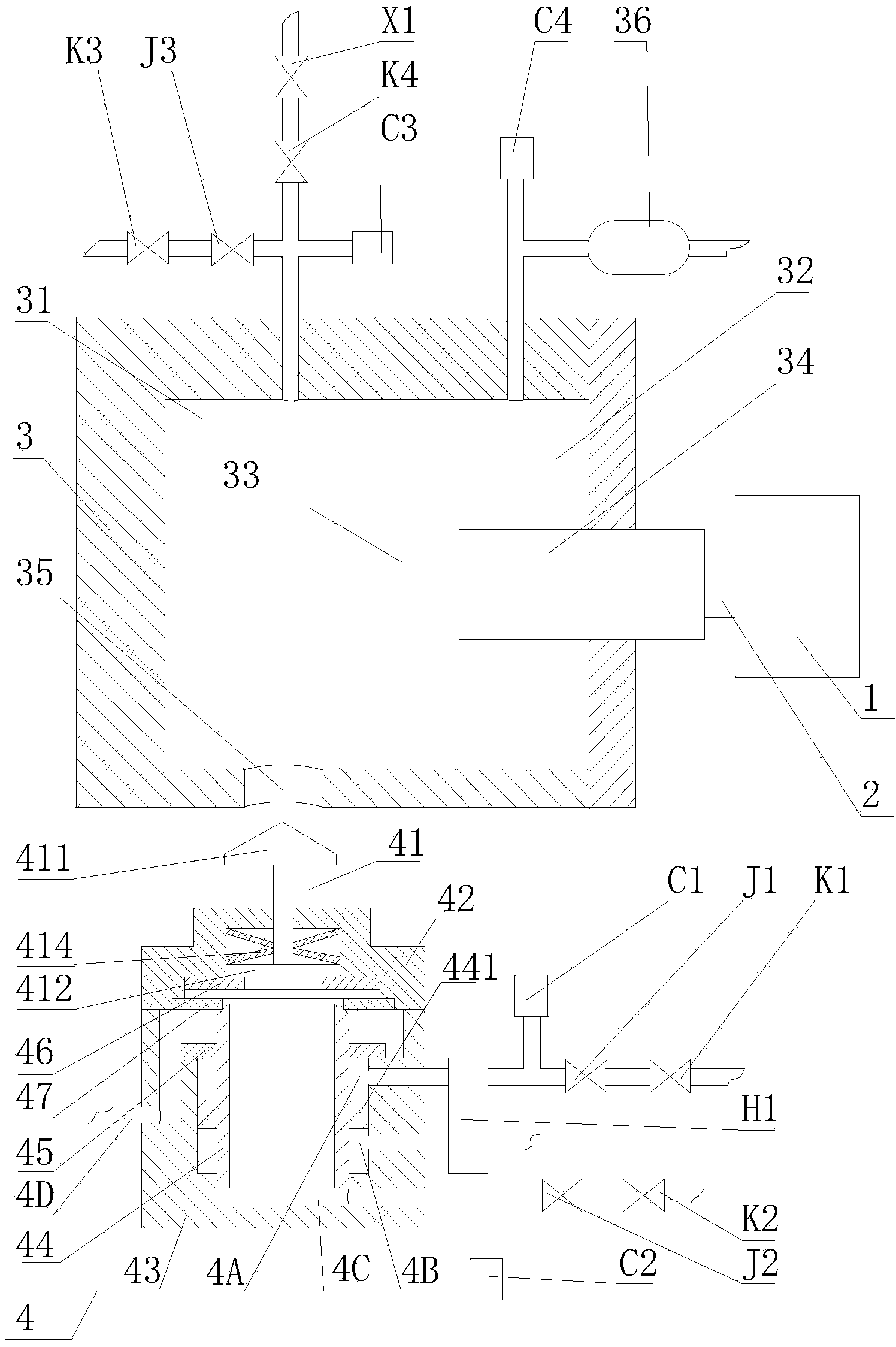

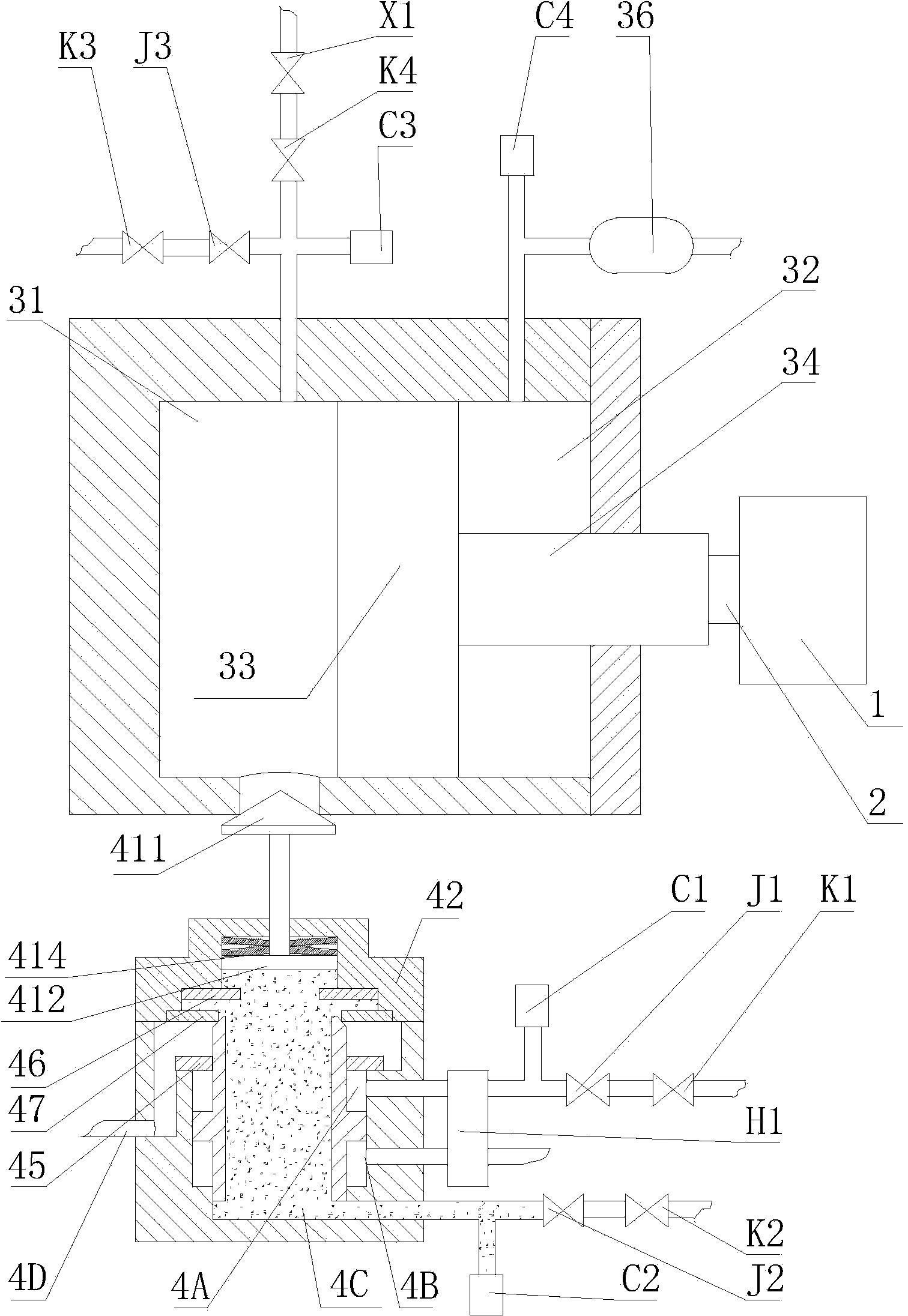

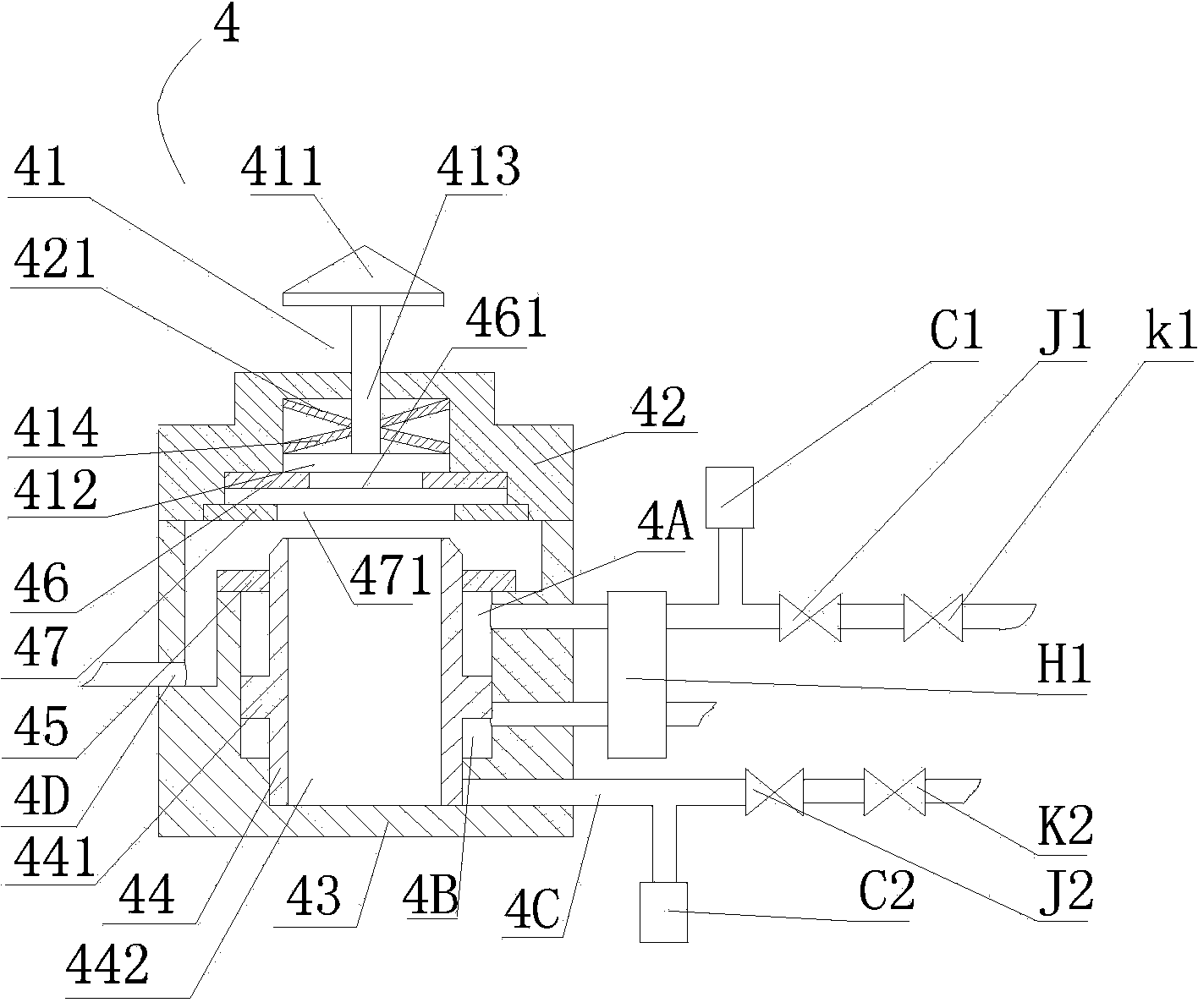

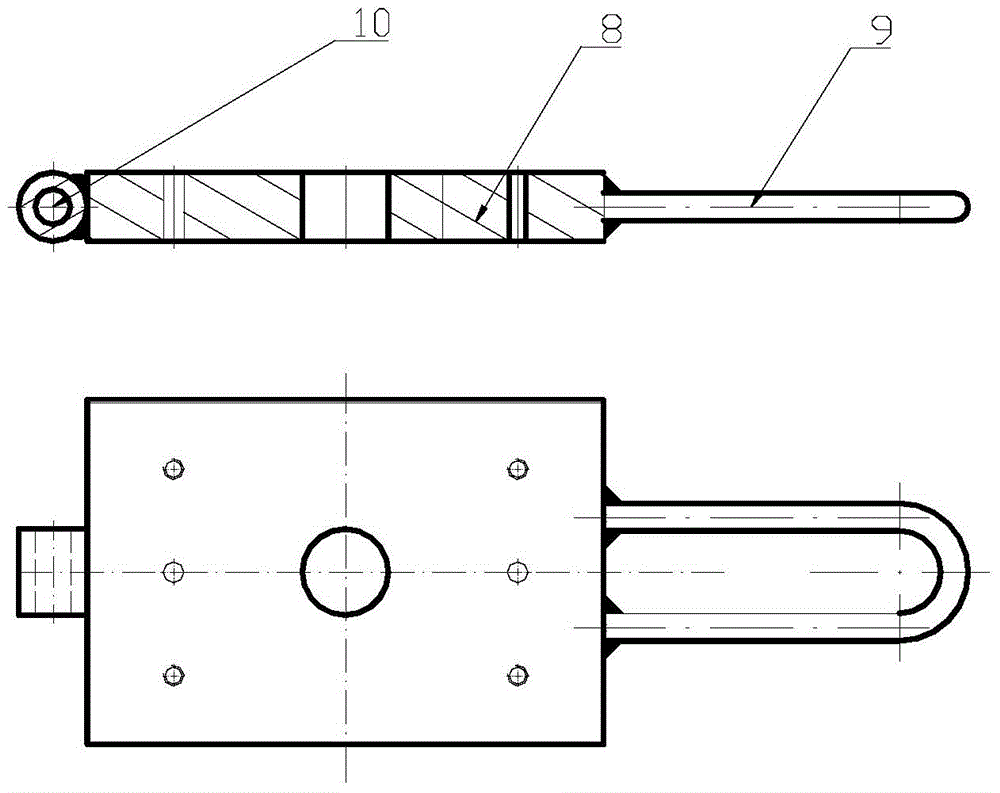

Negative step force testing system

InactiveCN103728095ARapid responseIncrease forceApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingLoop controlEngineering

A negative step force testing system comprises a device under test, a force sensor fixed on the device under test and a negative step force generating device for applying acting force on the device under test. The negative step force generating device comprises a pressure cylinder, a pressure control loop, a pressure piston, a piston rod, an unloading port and a unloading valve, wherein the pressure control loop is connected with the pressure cylinder, the pressure piston divides the cavity in the pressure cylinder into a first pressure cavity and a second pressure cavity, the piston rod is fixedly connected with the pressure piston, the unloading port is formed in the pressure cylinder, and the unloading valve is matched with the unloading port to open or close the unloading port. The unloading port is arranged in the pressure cavity, the piston rod penetrates through the second pressure cavity, the exposed end of the piston rod pushes the device under test, the force sensor senses pressure between the piston rod and the device under test, and the pressure control loop controls the pressure generated when the piston rod pushes the device under test. The negative step force testing system has the advantage of being accurate in initial force, large in initial acting force and adjustable in falling edge time of force.

Owner:ZHEJIANG UNIV

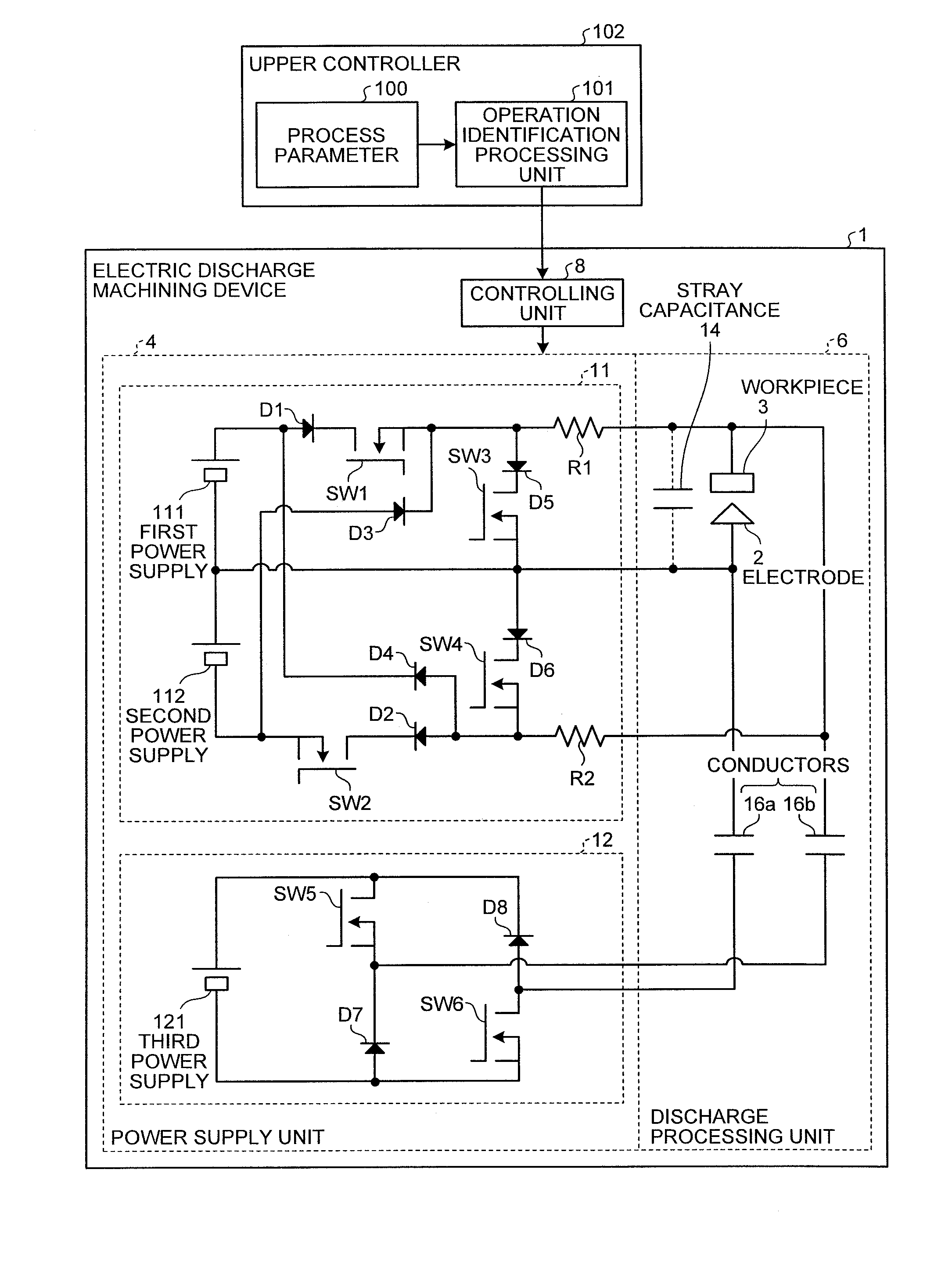

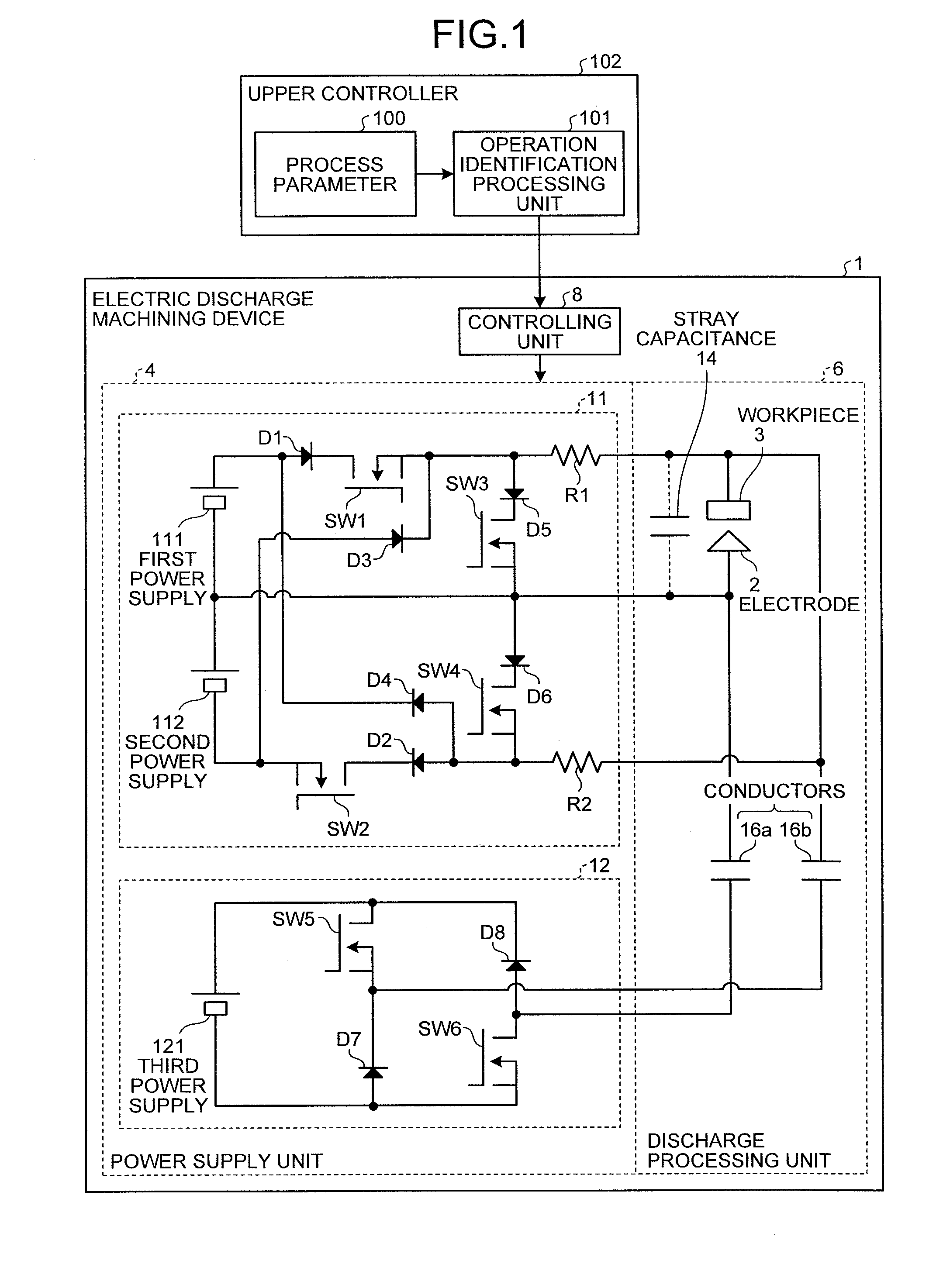

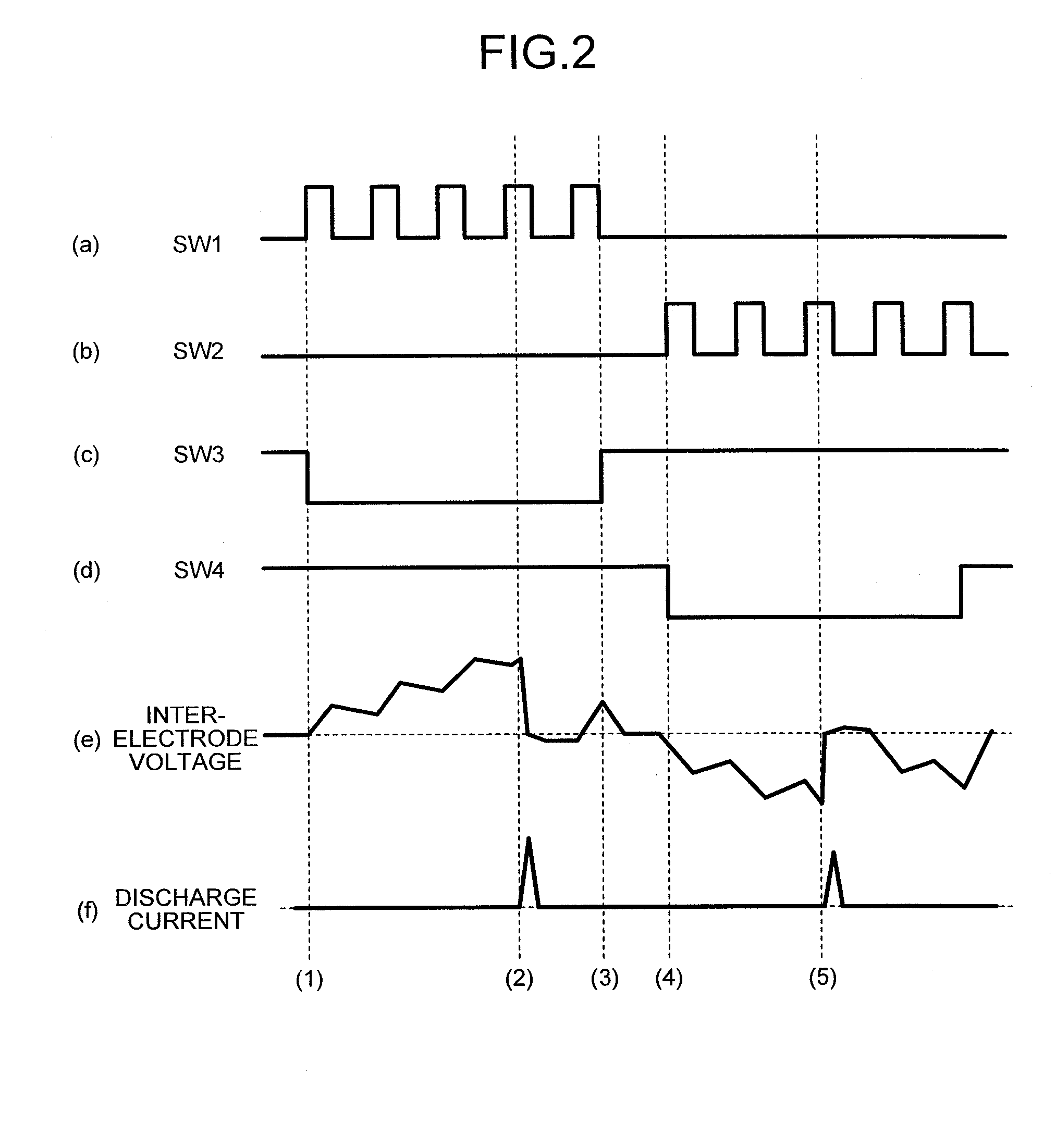

Electric discharge machining device

InactiveUS20100308017A1Desired controllabilityPrecisionDc network circuit arrangementsBatteries circuit arrangementsElectrostatic dischargeVoltage pulse

An electric discharge machining device that performs processing by applying a voltage pulse to space between the processing electrode and the workpiece and suitably switching the polarity of the voltage pulse attains both desired processing accuracy and desired controllability. The electric discharge machining device is provided with the first to fourth switching elements. The controlling unit that controls these switching elements, when setting a period time in which the first switching element is turned on, a period of time in which the fourth switching element is in an on-state in the same period, and, when setting a period time in which the second switching element is turned on, a period of time in which the third switching element is in an on-state in the same period so that a desired voltage pulse is applied to the space between the processing electrode and the workpiece.

Owner:MITSUBISHI ELECTRIC CORP

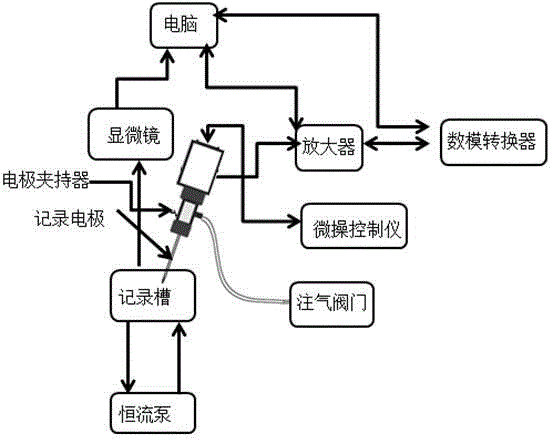

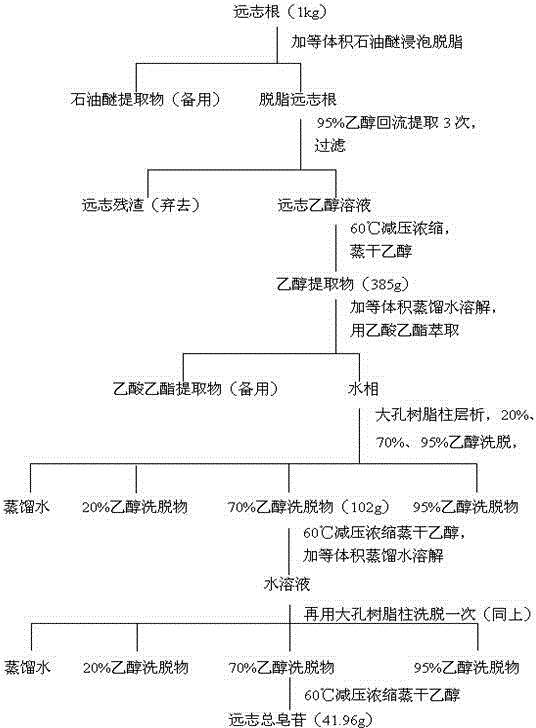

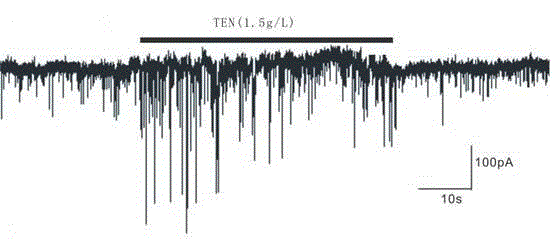

Experiment method for studying effect of tenuigenin on synaptic transmission of rat hippocampal neuron

InactiveCN104132965AGuaranteed accuracyPrecisionMaterial analysis by electric/magnetic meansHippocampal regionNeural cell

The invention discloses an experiment method for studying the effect of tenuigenin on synaptic transmission of rat hippocampal neuron. The method adopts a micro control instrument, a microscopic, and a recording electrode to monitor the spontaneous current state of neuron in tenuigenin with different concentrations, and then the monitor current data is analyzed so as to obtain the influence mechanism and effect of tenuigenin on rat hippocampal neuron. The method adopts a whole-cell patch-clamp technology to research the effect of tenuigenin on spontaneous postsynaptic current in the rat brain hippocampal CA1 area so as to disclose the regulating effect and mechanism of tenuigenin on neuron synaptic transmission, thus the requirements of scientific research and drug development are fulfilled, and at the same time a basis is provided for the further research on the signal transmission mechanism of neuron. The method can be widely used in the pharmaceutical theory researches on neuron, the experiment method and equipment design are scientific and reasonable, and requirements of scientific research can be met.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Deep hole processing method adopting common lathe

The invention discloses a deep hole processing method adopting a common lathe, and relates to the mechanical processing field, in particular to the deep hole processing method adopting the common lathe. The deep hole processing method comprises the following steps: turning the two end surfaces throughout the overall length with machining allowance of 1 mm, chamfering at the two ends of a hole by an angle of 2*30 degrees, using two tips to clamp and roughly turn an excircle with allowance of 0.5mm in single side; clamping one end of a workpiece, supporting the other end of the workpeice by use of a center frame, using an inner hole cutter to roughly turn the inner hole throughout one half the overall length with the allowance of 0.5mm in single side; turning round the workpiece, and roughly turning the other end of the workpiece throughout the rest of the length of the hole with the allowance of 0.5mm in single side of the inner hole; finishing the two end surfaces and controlling the overall length of the workpiece, chamfering the orifices at the two ends by 2*30 degrees; using two ejector pins to clamp and finish the excircle of a cylinder to dimension requirements; using four claws to clamp the excircle, aligning, and using the center frame to support the finished inner hole, wherein the roughness is Ra3.2 and allowance is 0.2mm; repeating the third-step clamping process to finish the inner hole throughout the other half length, wherein the roughness is Ra3.2 and the allowance is 0.2 mm; and carrying out floating boring. The deep hole processing method is simple in processing process, adopts the common lathe to process a deep hole, so that the production cost is reduced, and processing precision can be met.

Owner:SHAANXI ALLIANCE LOGISTICS

Terahertz front-end integrated receiving device based on bulk silicon MEMS (micro-electromechanical system) technical antenna

InactiveCN103219587AReduce processing costsHighly integratedDecorative surface effectsAntenna supports/mountingsIntermediate frequencySuperconductivity

The invention relates to a terahertz front-end integrated receiving device based on a bulk silicon MEMS (micro-electromechanical system) technical antenna, and the device is suitable for terahertz low-frequency stage and belongs to the technical field of terahertz. The device mainly comprises an antenna, a mixer chip, a base and a back panel, wherein the antenna comprises an H-face horn antenna based on a bulk silicon MEMS and a plane gradually changing type plantar slot antenna (ALTSA in short); the mixer chip is a superheterodyne detector and comprises a room temperature schottky diode mixer, a superconductivity tunnel junction mixer, and a hot electron bolometric resistance mixer; the external part of the base remains the position which is in physical match with the chip and an intermediate frequency terminal and the like; and the back panel also remains the space which is in physical match with the chip and the intermediate frequency terminal. According to the device, the antenna is processed through the bulk silicon MEMS technology; the processing precision of the terahertz device can be satisfied; and the device is convenient to manufacture and produce in mass, and is easy to assemble. Through the integral assembling method of the antenna, the mixer and a bias circuit, the success ratio of micro-packaging the components is improved, the integration level of the integral receiving device is improved; and the device has the advantages of small size, light weight and low cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

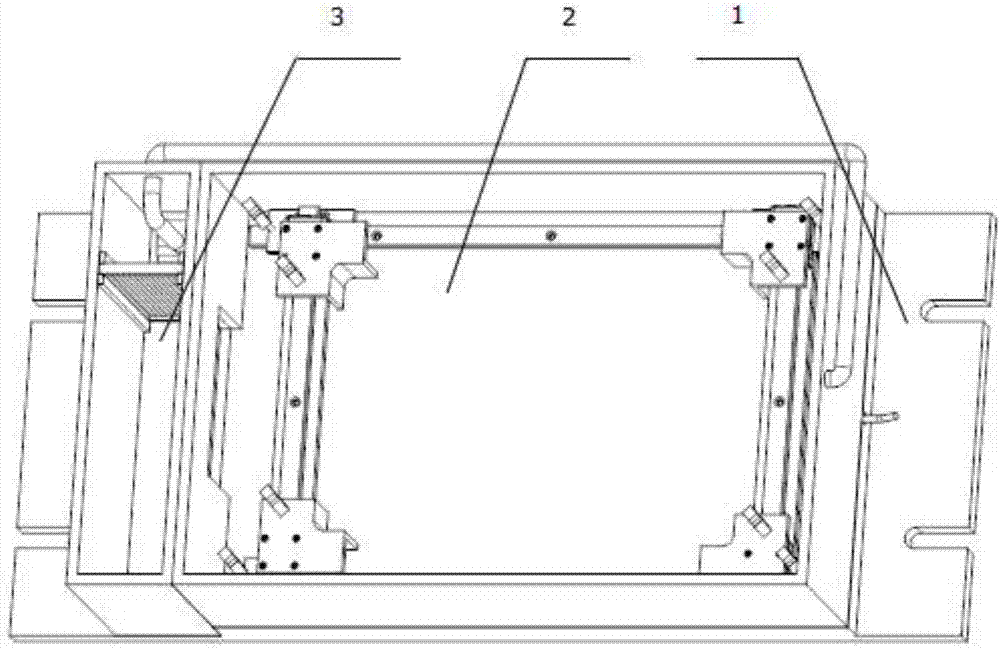

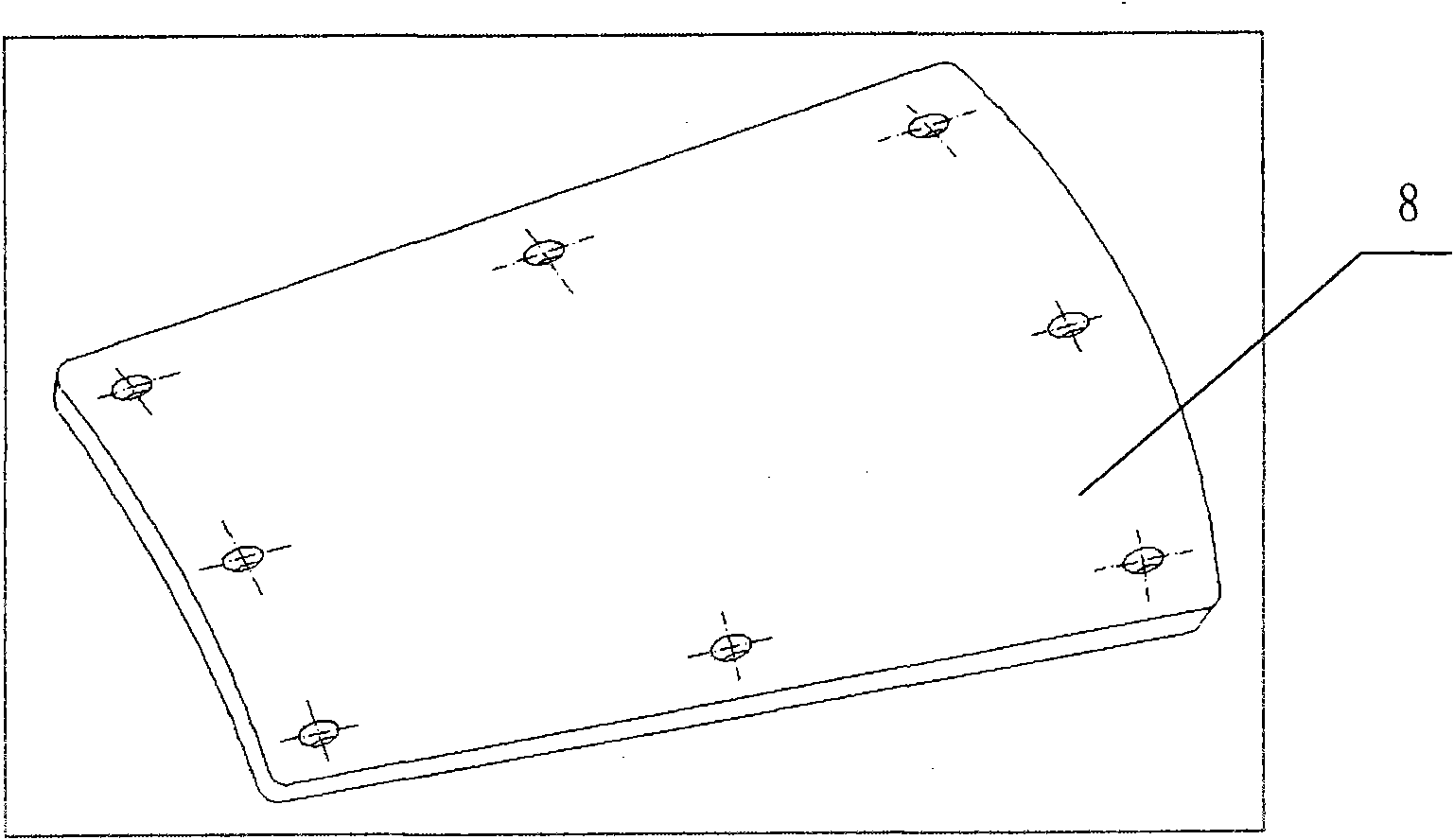

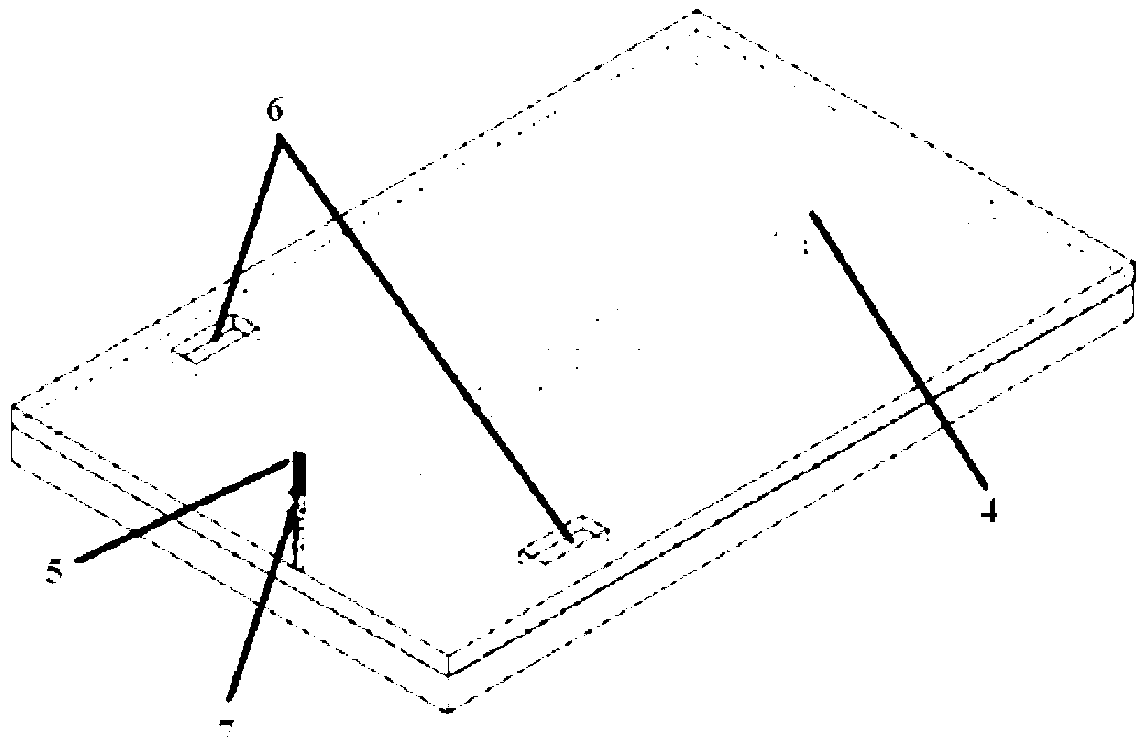

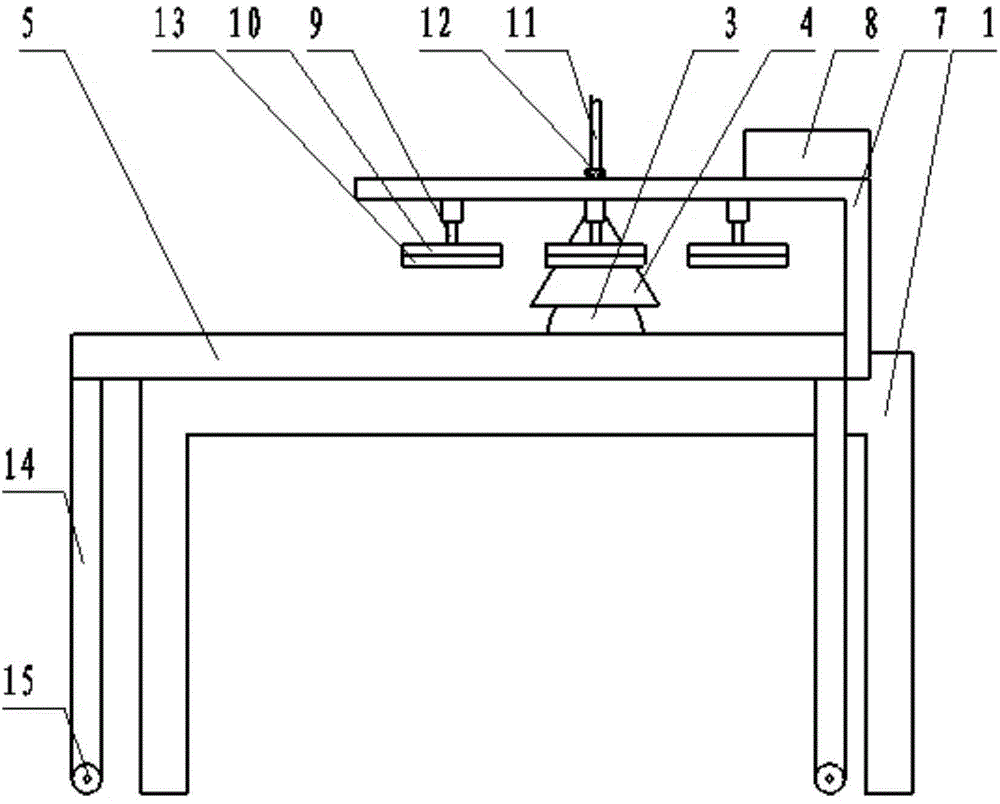

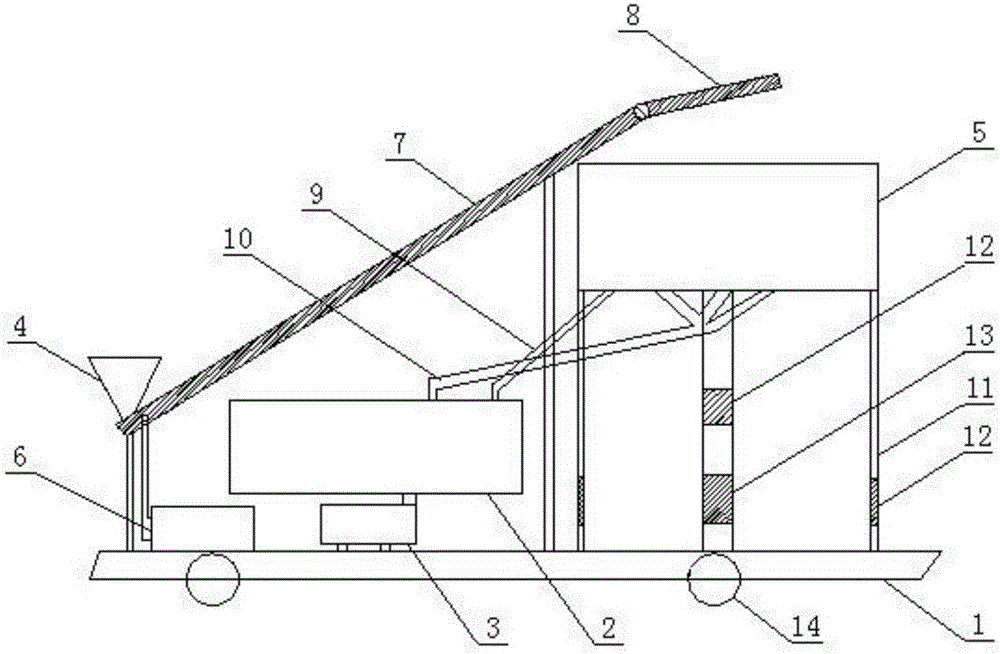

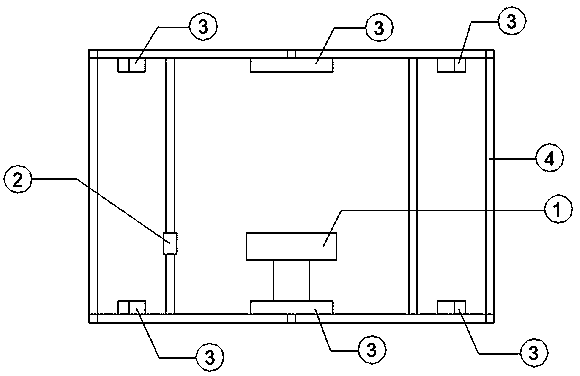

Woodworking plate saw safe, easy and convenient to operate

InactiveCN104149134AMeet the machining accuracyReduce labor intensityCircular sawsFixed frameEngineering

The invention discloses a woodworking plate saw safe, easy and convenient to operate. The woodworking plate saw comprises a machine frame (1). A fixed working platform (2) is connected to the left side of the machine frame (1). A saw web (3) is arranged on the fixed working platform (2), and a protective cover (4) is arranged above the saw web (3). A sliding push table (5) is arranged on the right side of the fixed working platform (2) and connected with the machine frame (1) through a guide rail (6). A fixed frame (7) is connected to the guide rail (6), and a hydraulic device (8) is arranged on the fixed frame (7) and connected with a pressing plate (10) through a hydraulic rod (9). The pressing plate (10) is located above the sliding push table (5), a rubber mat (13) is connected to the pressing plate (10), a supporting frame (14) is connected to the lower portion of the sliding push table (5), and idler wheels (15) are arranged at the bottom of the supporting frame (14). According to the woodworking plate saw, a plate is automatically and tightly pressed through the hydraulic device, the hydraulic rod and the pressing plate, the labor intensity is reduced, the safety is improved, and convenience is further brought to sawing work.

Owner:ZHEJIANG HONLY FUSHI WOOD

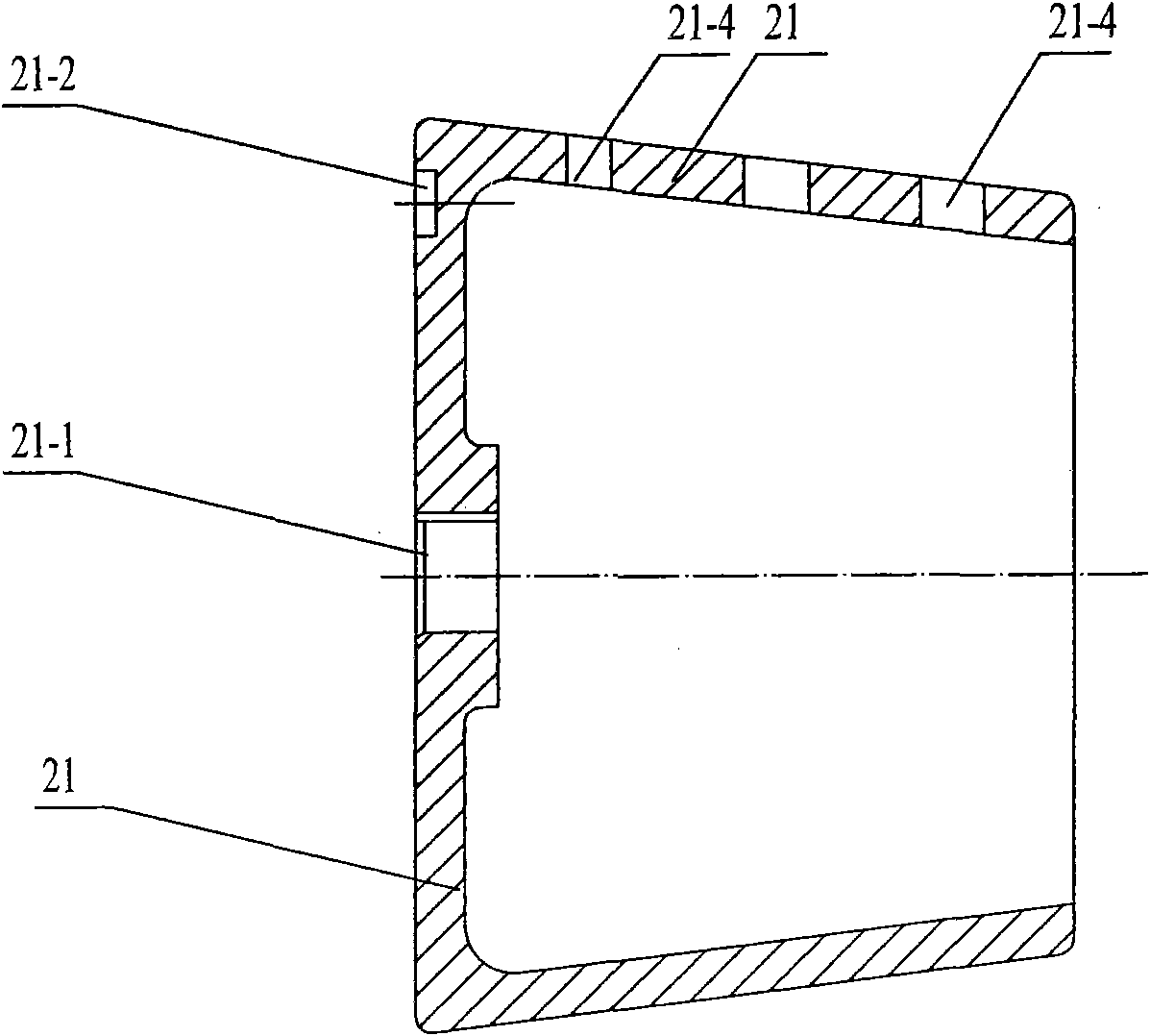

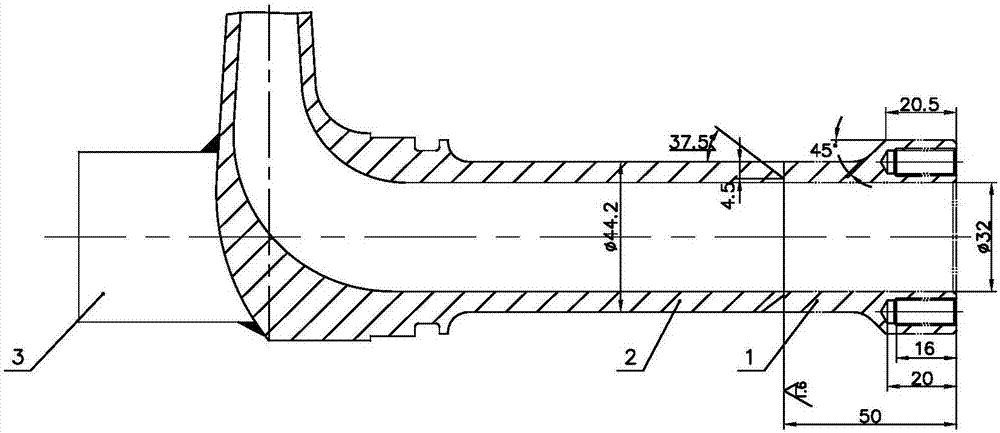

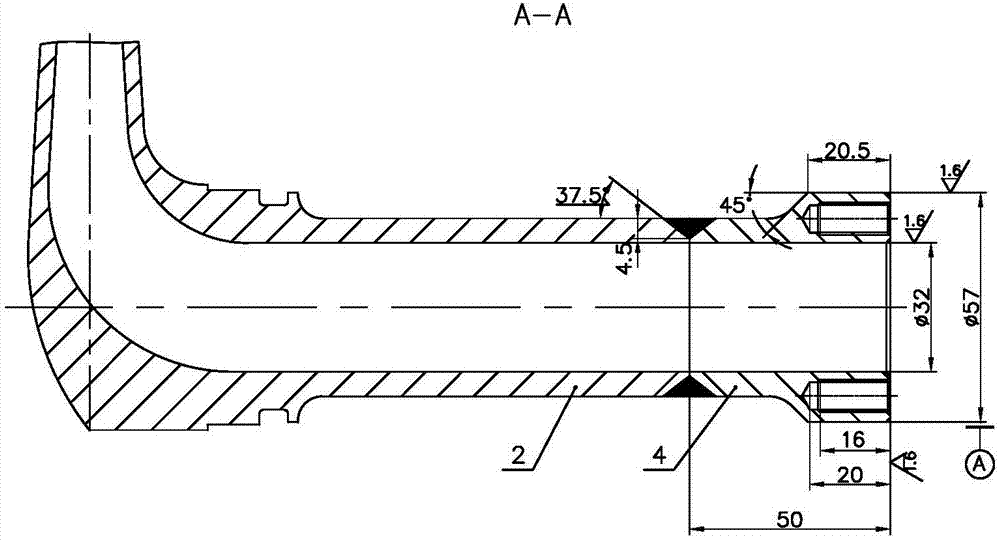

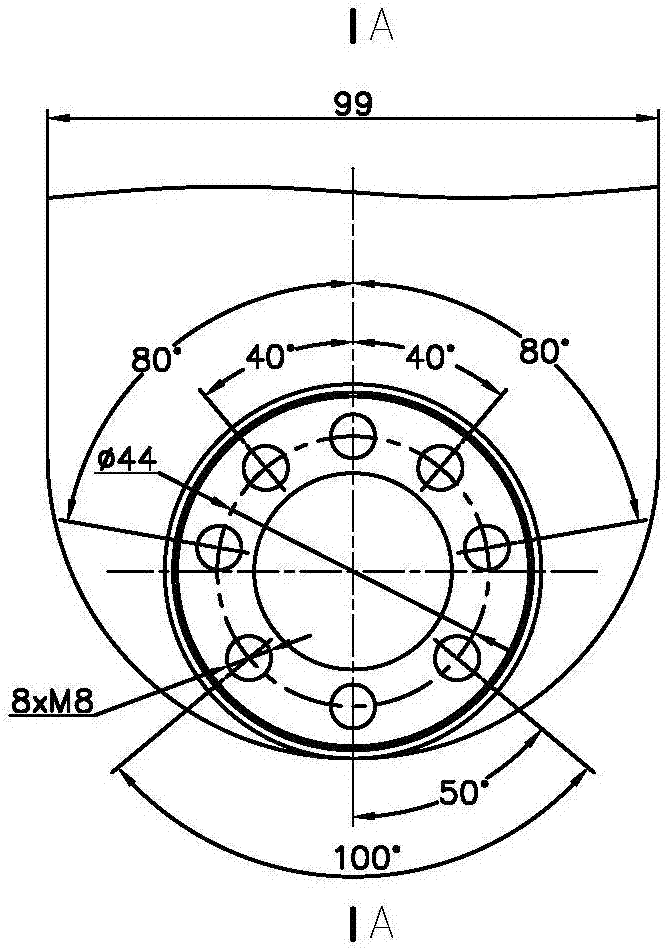

Machining method of tension bush clamp for shifting fork groove of automobile gear sleeve

The invention discloses a machining method of a tension bush clamp for a shifting fork groove of an automobile gear sleeve. The machining method includes a step of sequentially connecting a front connecting plate, a connecting seat and a positioning seat and a step of machining an elastic tension bush and a pull rod, wherein the step of machining the elastic tension bush includes feeding, machining by a machine tool, quenching, rough machining of a grinding machine, tempering, finish machining of the grinding machine, wire-electrode cutting low-speed wire cutting and inspection. The invention aims to provide the machining method of the tension bush clamp for the shifting fork groove of the automobile gear sleeve and solves the problem that a gear sleeve and the tension bush clamp move relatively when an existing tension bush clamp is used for clamping the automobile gear sleeve to machine the shifting fork groove.

Owner:CHONGQING MACHINE TOOL GROUP

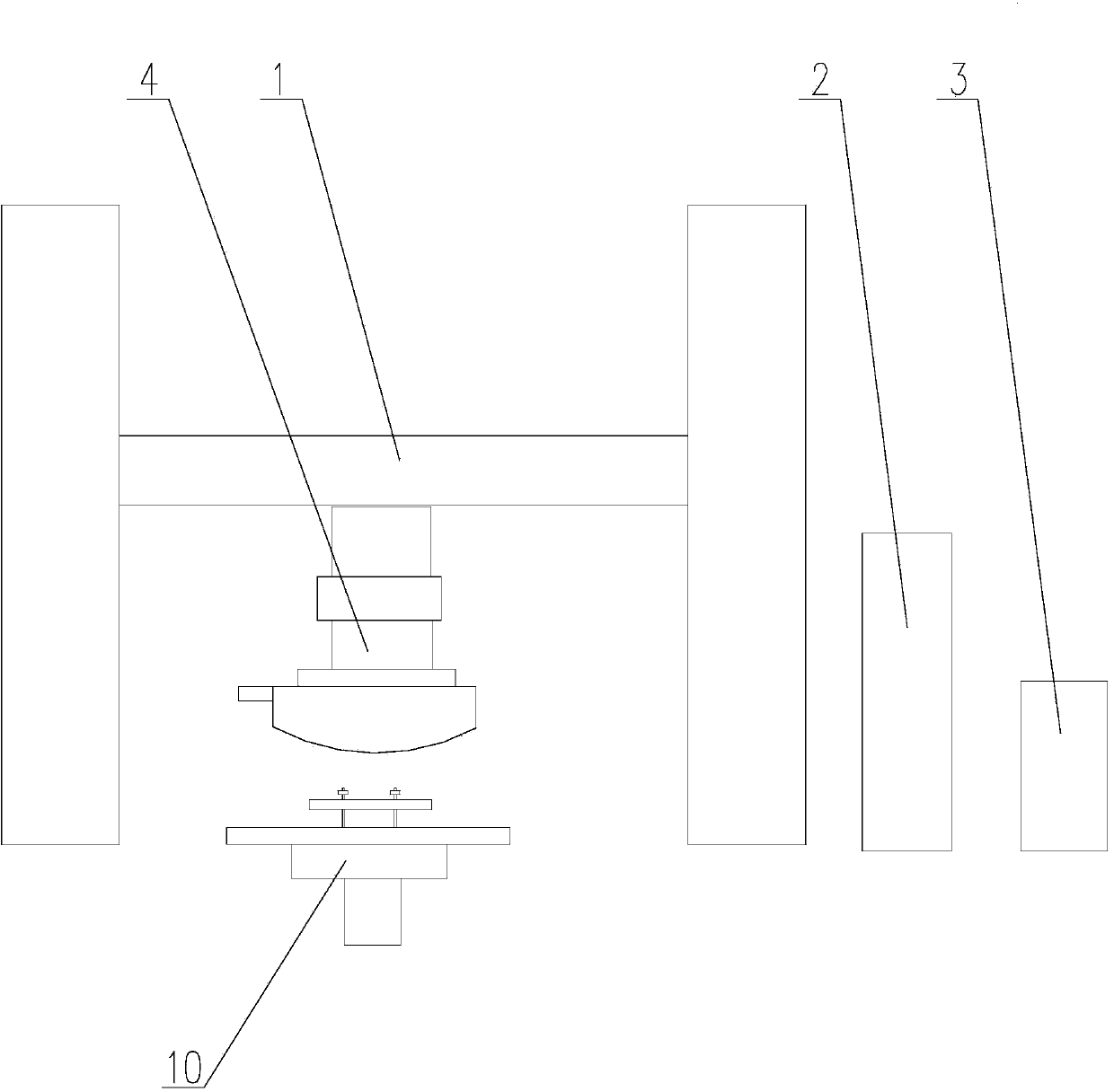

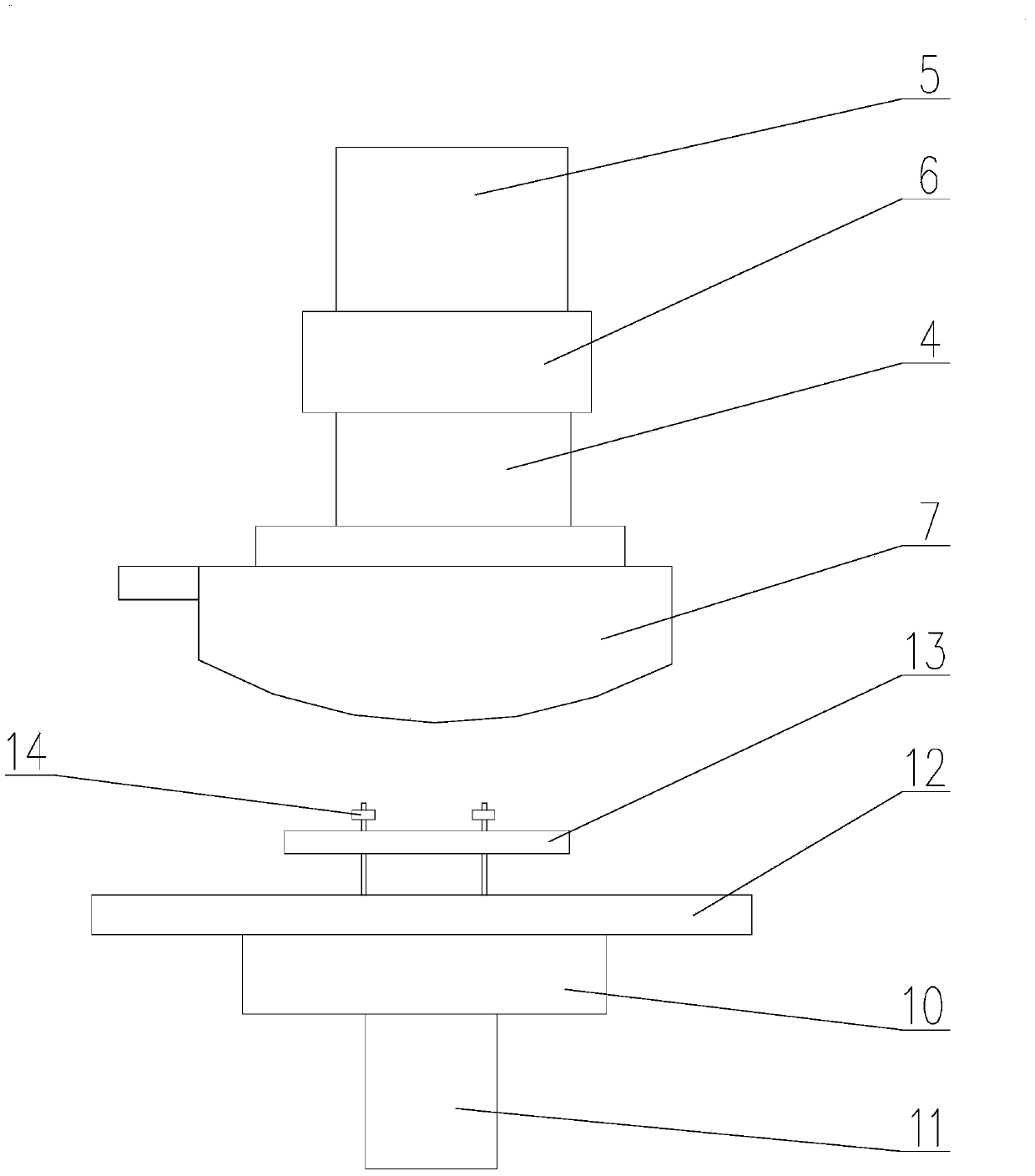

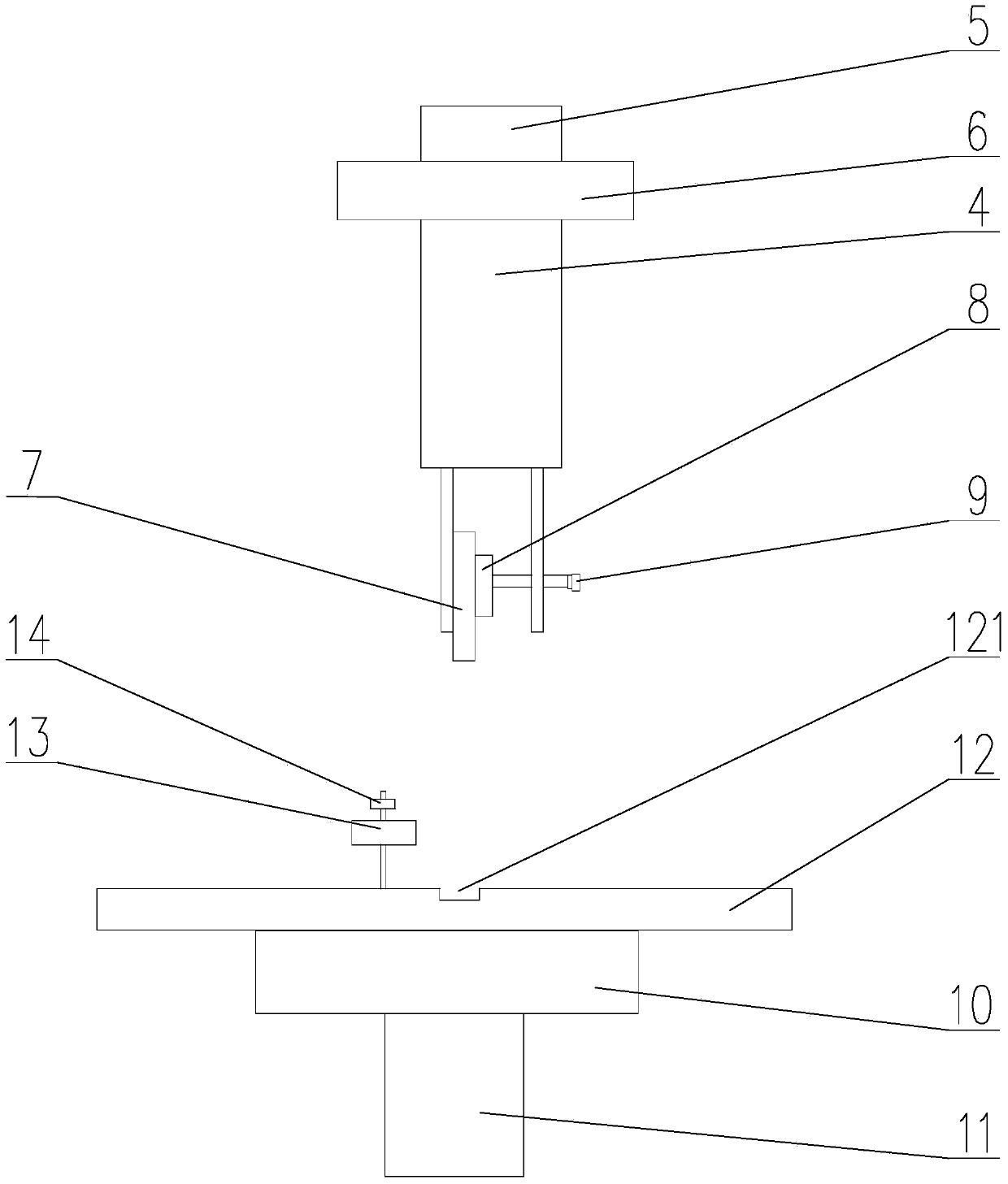

Universal testing machine capable of measuring cutting force

InactiveCN104006911ARealize the quantification of cutting forceAchieve quantificationApparatus for force/torque/work measurementInvestigating machinabilityIceboxControl engineering

The invention relates to the field of frozen meat cutting equipment, in particular to a universal testing machine capable of measuring cutting force. The universal testing machine capable of measuring cutting force comprises an operating main body, an upper clamp body and a lower clamp body, wherein the upper clamp body and the lower clamp body are arranged corresponding to each other up and down and are both mounted on the operating main body. A cutter is mounted at the lower end of the upper clamp body, and a downward pressing disk used for storing a cut object is mounted at the upper end of the lower clamp body. An adjusting device used for controlling the upper clamp body to move up and down and a force sensor are arranged inside the operating main body, the output end of the force sensor is connected with a controller, and the controller can obtain the force which is applied by the cutter in the sample cutting process according to output signals of the force sensor. By the adoption of the universal testing machine, the size variation of cutting force of the cutter acting within certain displacement can be accurately reflected, the quantization of frozen meat cutting force can be achieved, and thus a refrigeration and preservation technology of a refrigerator can be better evaluated; moreover, the cutter can be effectively fixed, a cut sample can be well fixed, and therefore test errors are reduced to be minimum.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

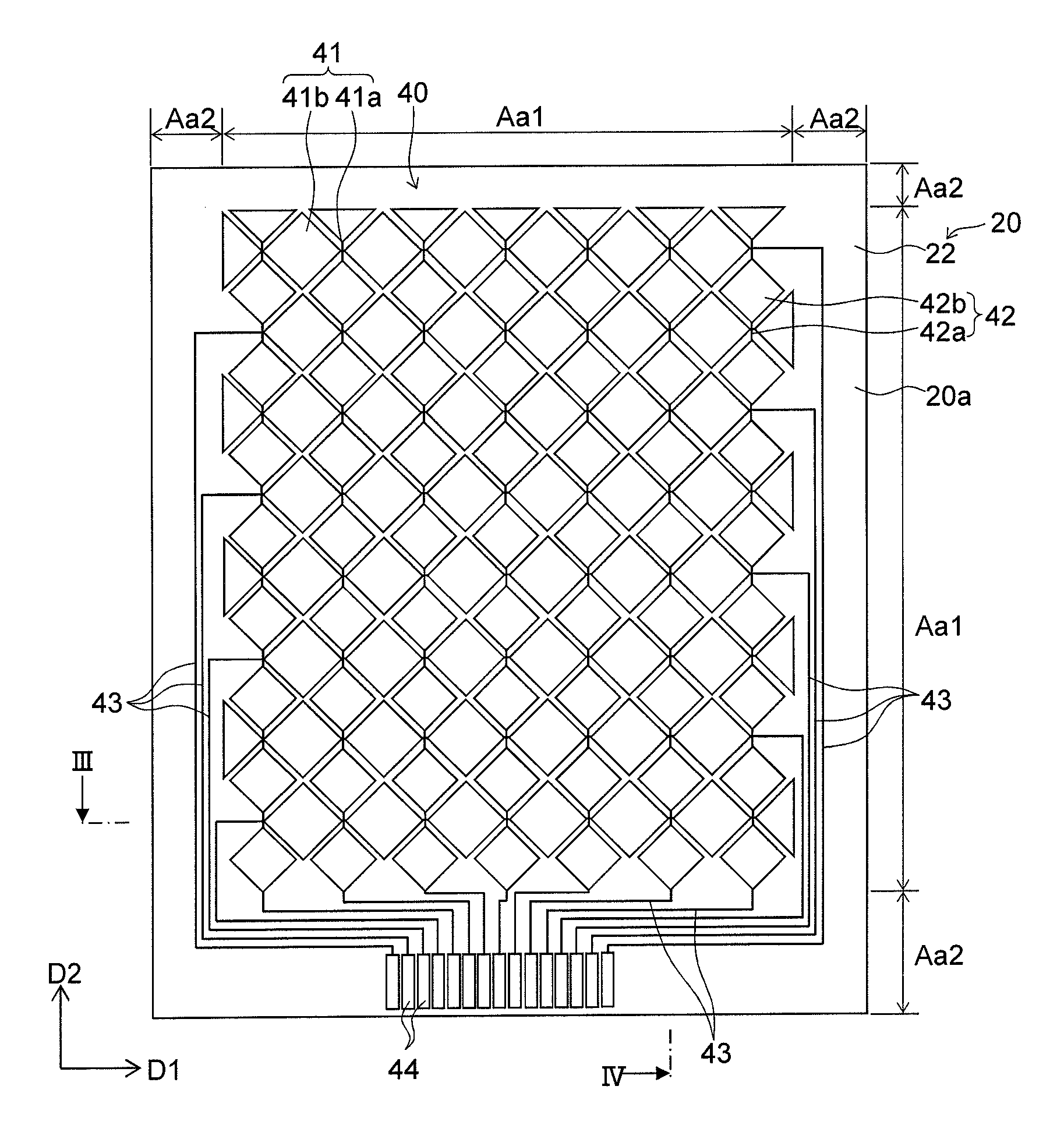

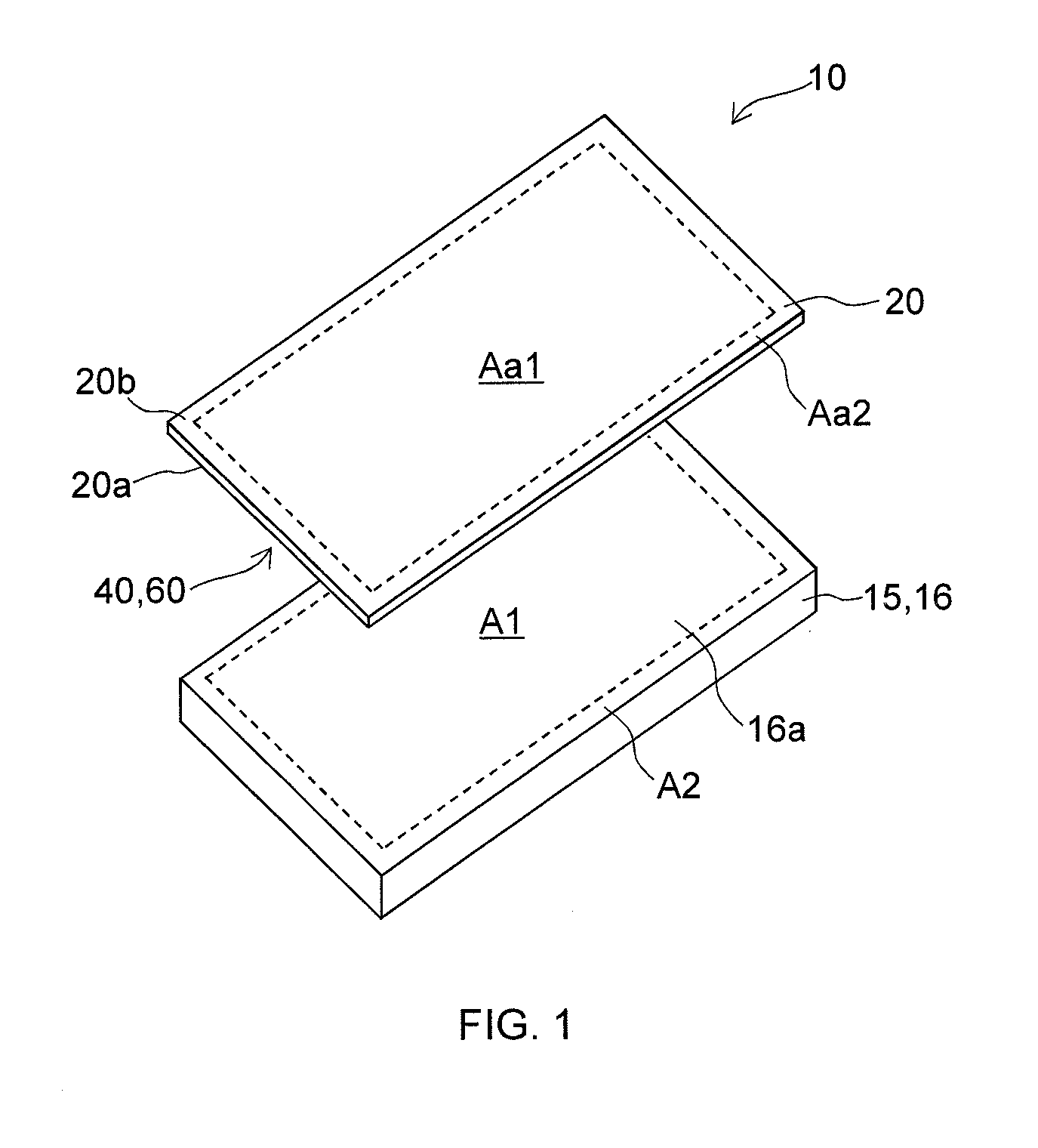

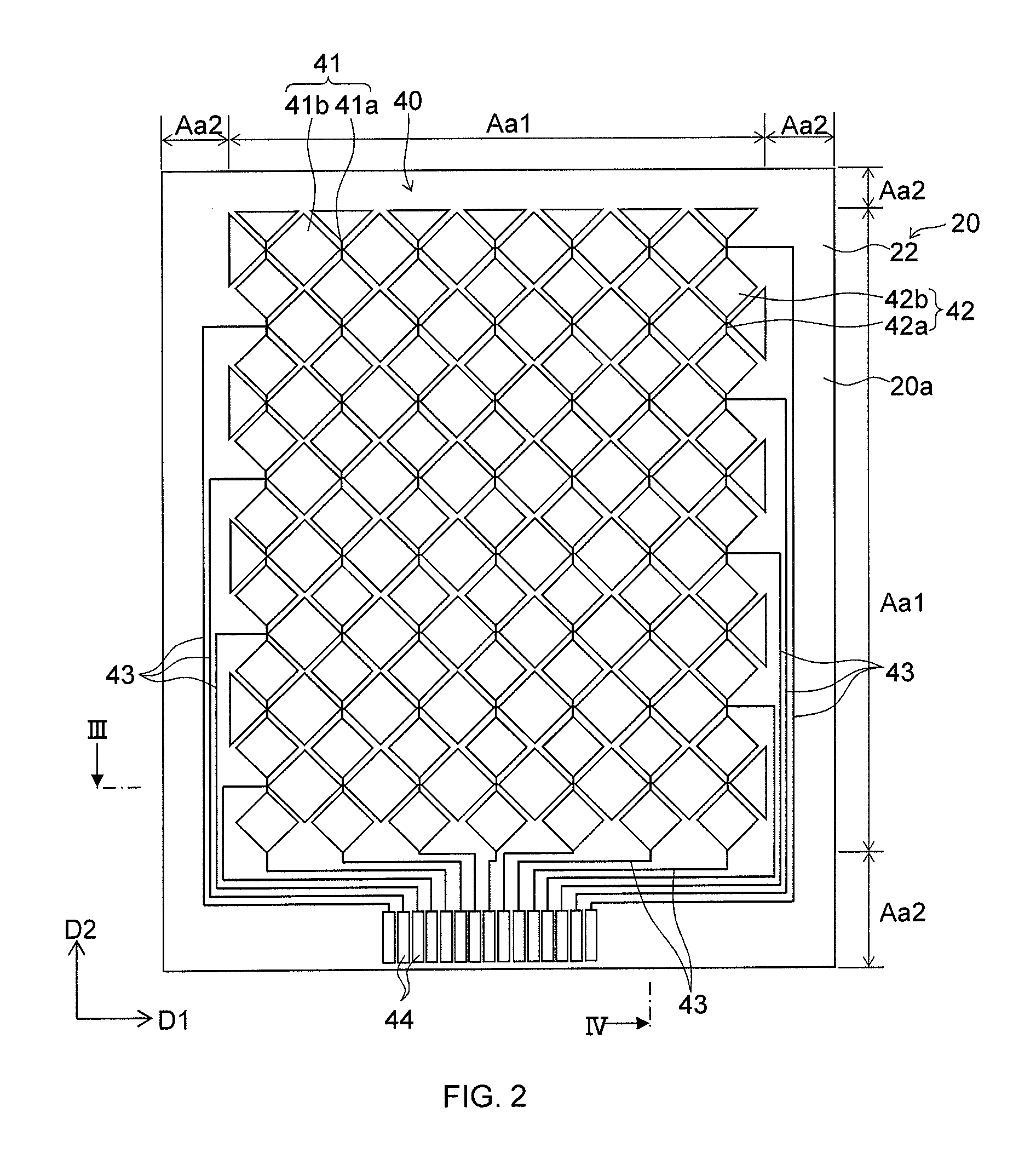

Method of manufacturing cover glass, cover glass and cover glass-equipped display device

ActiveUS20160266671A1High external dimensional accuracySimple designCasings/cabinets/drawers detailsGlass/slag layered productsEdge surfaceEngineering

The objective is to provide a cover glass having edge surfaces and a through-hole, formed with high external dimensional precision. The cover glass has a unit substrate comprising glass, and a resinforced portion containing a resin material provided on the edge surfaces of the unit substrate.

Owner:DAI NIPPON PRINTING CO LTD

Pulmonary function examination system with automatic seat adjustment function and application method of system

InactiveCN109646237ASolve the problem of inaccuracy and inappropriatenessHigh precisionOperating chairsDental chairsEconomic benefitsEngineering

The invention relates to a pulmonary function examination system with an automatic seat adjustment function and an application method of the system. A supporting base is fixedly installed on a base, apulmonary function examination instrument is fixedly installed on the supporting base, and two parallelly-arranged horizontal supporting rods are fixedly installed at the top of the supporting base;a rotation shaft is fixedly installed between the ends of the two horizontal supporting rods, a rotation sleeve sleeves the outer side of the rotation shaft, and a first leakage hole and a second leakage hole are formed in the rotation cylinder; connection pipes are installed in the second leakage hole, the first leakage hole and the rotation cylinder, one end of each connection pipe is communicated with an air inlet through an air conveying pipe, and the other end of each connection pipe is communicated with an oral cavity anastomat; an automatic seat adjustment device is installed on the portion, of the base, below the corresponding position of the oral cavity anastomat, the supporting base is of a cuboid cavity structure, and a distributor plate is installed in the supporting base; an external power line is arranged at the outer side of the distributor plate, and the pulmonary function examination instrument is connected with a computer analysis mainframe through a wire and the distributor plate. The system helps to smoothly carry on air blowing operation, all-around comprehensive improvement is conducted from the precision degree of a detection result and the use experience ofa patient, and the system has great social and economic benefits.

Owner:PEOPLES HOSPITAL OF HENAN PROV

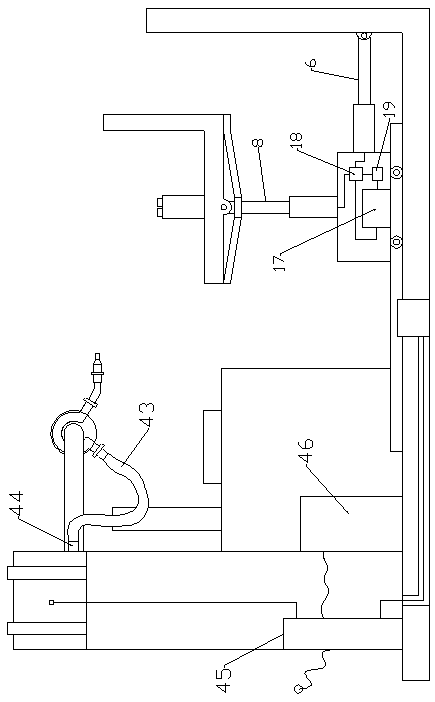

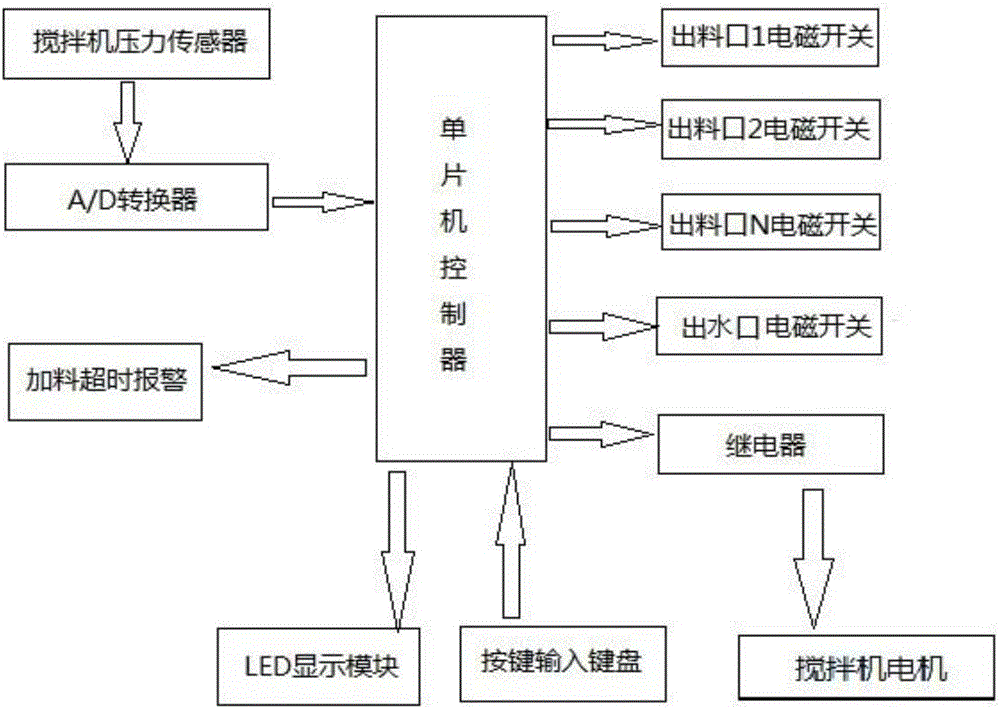

Intelligent mortar stirrer

InactiveCN105835229AImprove reliabilityPrecisionMixing operation control apparatusIngredients proportioning apparatusSingle chipMaterials science

The invention discloses an intelligent mortar stirrer. The intelligent mortar stirrer comprises a base, a mortar stirring groove and a stirrer motor and further comprises a material storage partition groove and a feeding port which are formed in the base; the feeding port conveys raw materials to the material storage partition groove through a motor and a conveying device; the material storage partition groove comprises at least one material trough and a water trough which are connected with the mortar stirrer; a water outlet of the water trough and a material outlet of the material trough are each provided with an electromagnetic switch; a support of the material storage partition groove is provided with a pressure sensor and an intelligent module which comprises a single-chip microcomputer controller; the signal input end of the single-chip microcomputer controller is connected with the pressure sensor; and the signal output end of the single-chip microcomputer controller is connected with the stirrer motor and connected with the electromagnetic switches arranged on the material outlet of the material trough and the water outlet of the water trough. The intelligent mortar stirrer can automatically perform material throwing and stirring according to the set mortar matching ratio and the consistence, and the mortar reliability is improved.

Owner:TIANJIN 20 CONSTR

Cold metal transition welding repairing method for wear or breakage of jet nozzle of universal pitot tube pump

InactiveCN107470851AMeet the machining accuracyHigh automation efficiencyNon-electric welding apparatusCentrifugal pumpPetrochemical

The invention belongs to the field of repairing general-purpose pitot tube centrifugal pumps in the petrochemical industry, and relates to a repair method for general-purpose pitot tube pump nozzle wear or fracture cold metal transition welding. The method includes the following steps: (1) according to the damage degree of the pitot tube nozzle, determine the repair plan of the nozzle; (2) find the processing reference for the worn sealing ring, and make the tooling; (3) remove the output end of the damaged pitot tube nozzle , Process the welding groove; (4) Make a new nozzle output end blank according to the survey drawing; (5) Match the new nozzle output end with the original shaft; (6) Cold metal transition welding; (7) Surfacing layer Relieve stress; (8) Remove welding tooling, finishing, drilling. The invention removes the damaged output end, reprocesses a blank, assembles it with the original nozzle output end, adopts the cold metal transition welding method, and then reprocesses it to the original size, so as to restore the service performance of the pitot tube pump nozzle.

Owner:浙江翰德圣智能再制造技术有限公司

Gradient thermal insulating layer and preparation method and preparation device thereof

ActiveCN107160748ASatisfy machining accuracy and package requirementsApplicable to practical applicationLamination ancillary operationsThermal insulationHigh concentrationAdhesive

The invention relates to a gradient thermal insulating layer and a preparation method and a preparation device thereof. The preparation method comprises the following steps: cutting two or more pieces of a heat insulating material according to the size of the internal surface of a to-be-heat-insulated workpiece; smearing an adhesive to the internal surface of the workpiece, bonding the cut heat insulating material on the internal surface of the workpiece in sequence, and bonding two adjacent layers of the heat insulating material; spraying steeping liquid of two or more different concentrations on the surface of the heat insulating material; and drying to obtain the gradient thermal insulating layer, wherein the heat insulating material is flexible porous heat insulating material, the steeping liquid has hardening characteristic after drying, and the spraying sequence for the steeping liquid of different concentrations is from high concentration to low concentration. The invention also provides a device for preparing the gradient thermal insulating layer. The gradient thermal insulating layer has gradually changed hardness gradient, which is more suitable for practical applications.

Owner:CHINA BUILDING MATERIALS ACAD

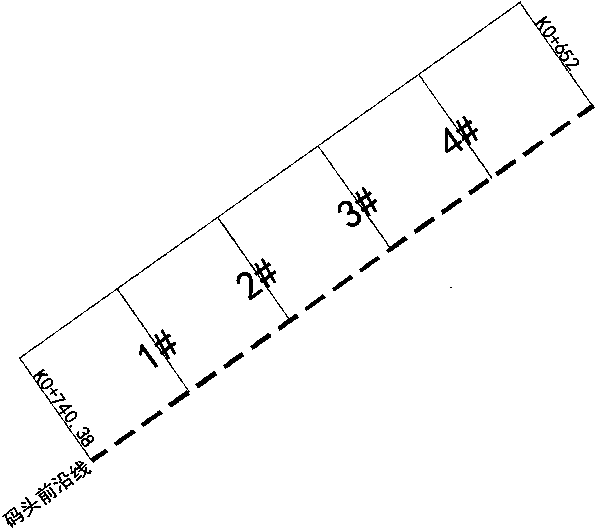

Sonar detecting bracket and caisson seam measuring method

PendingCN109343038AGuaranteed launch rangeSimple structureAcoustic wave reradiationWater resource assessmentNondestructive testingEngineering

Owner:HOHAI UNIV +3

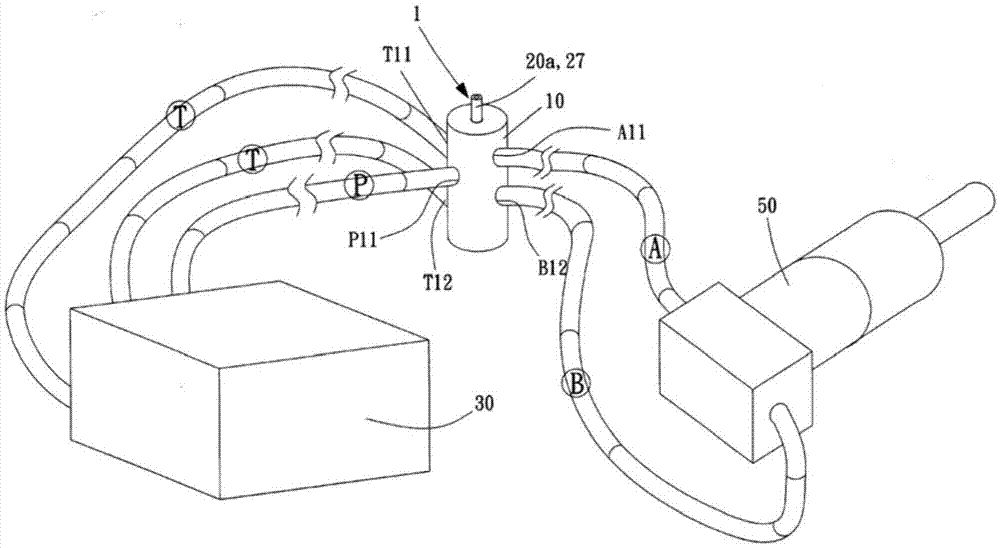

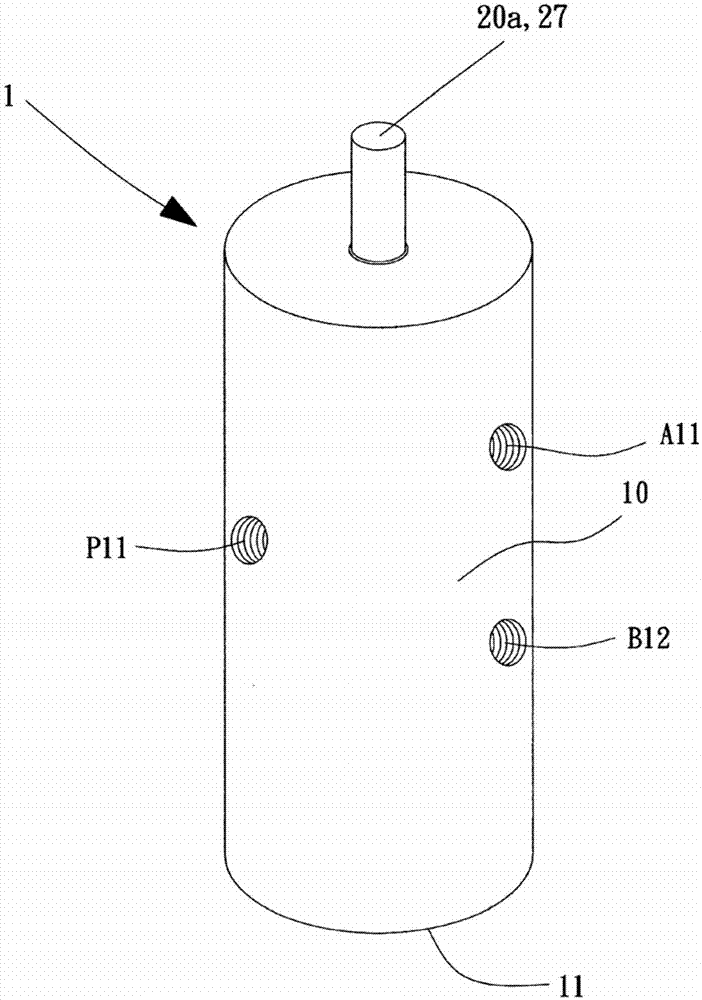

Rotary type hydraulic valve

InactiveCN106958551AControl flowSmall leakServomotor componentsMultiple way valvesPotential differenceInlet pressure

The invention relates to a rotary type hydraulic valve. The rotary type hydraulic valve comprises a valve body and a valve core rotationally and axially arranged in a rotating space of the valve body. When flowing into an oil inlet pressure balancing hole of the valve core from an oil inlet outer hole, hydraulic oil of an oil pressure source fills an annular groove of the oil inlet pressure balancing hole at any time and then flows into open inverted U-shaped grooves and open U-shaped grooves of a first working part and open inverted U-shaped grooves and open U-shaped grooves of a second working part, so that the upper force potential difference and the lower force potential difference of the valve core are symmetrically balanced; when all outer holes of the valve body communicate with all inner holes of the valve core, the hydraulic oil flows into a first oil return annular groove, a second oil return annular groove as well as the open U-shaped grooves and the open inverted U-shaped grooves of the first and second working parts; the pressure of the hydraulic oil acts on the inner wall of the valve body at any time; the compactness between the valve core and the valve body can be more precise; the inner leakage quantity of the hydraulic oil reaches the minimum; and in addition, the valve core can be suspended and kept balanced at any time and can be easily rotated with very small acting force so that the direction of a shaft part can be changed, the flow rate of the hydraulic oil is controlled, the hydraulic oil smoothly flows in the predetermined direction, and the predetermined action of an actuator is controlled.

Owner:郑瑞源

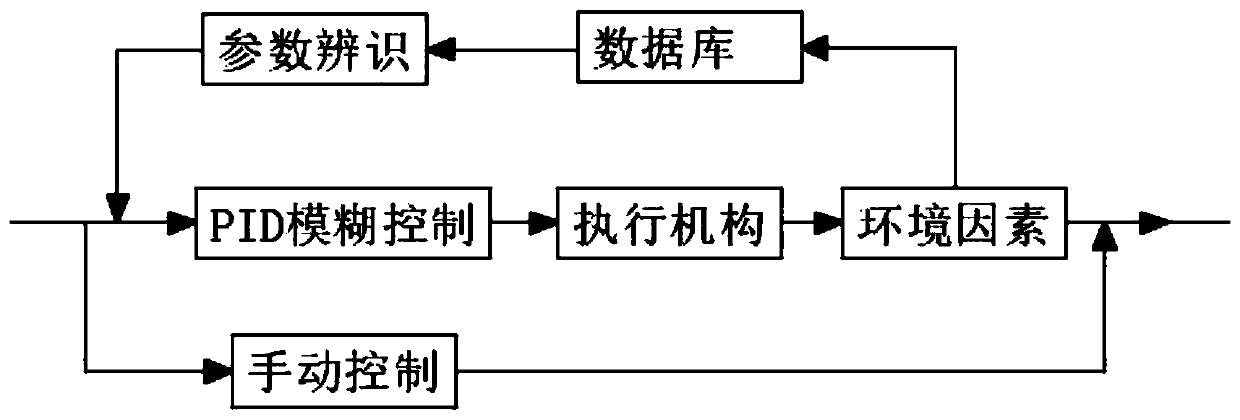

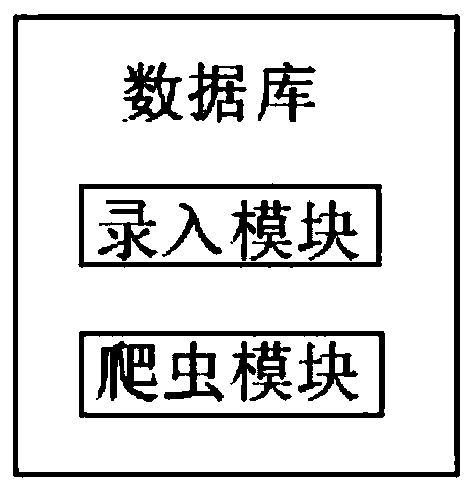

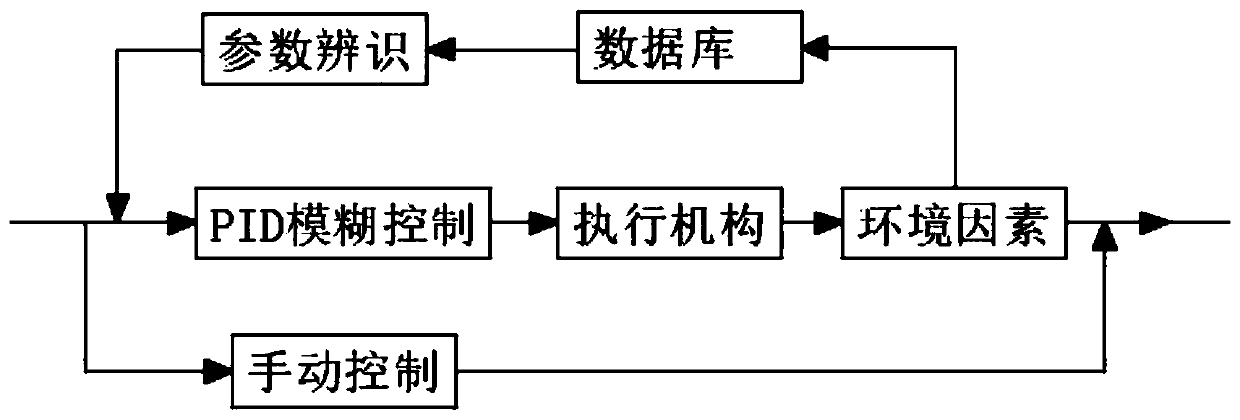

Numerical control machining process parameter self-adaptive control method

InactiveCN111176110AEasy to controlQuality improvementControllers with particular characteristicsNumerical controlControl engineering

The invention discloses a numerical control machining process parameter self-adaptive control method. A numerical control machine tool three-dimensional simplified model is established based on a machining process self-adaptive parameter database, multiple modes are adopted for conversion control, and self-adaptive control over machining process parameters is achieved in the mode of combining PIDfuzzy controller control with manual control. According to the numerical control machining process parameter self-adaptive control method, the control of the PID fuzzy controller becomes more and moreaccurate and closer to reality, the PID fuzzy control method is adopted and the machining process parameter self-adaptive control method is realized, the full-load operation of the device can be guaranteed under the premise that the machining precision is met, and the energy-saving and environment-friendly efficiency is achieved; meanwhile, the parameter control method is improved, rapid compensation can be conducted on changes of internal characteristics of the system and external disturbance influences, it is guaranteed that the whole machining process is smooth and stable and it is guaranteed that the quality of machined products is more ideal.

Owner:聊城市技师学院

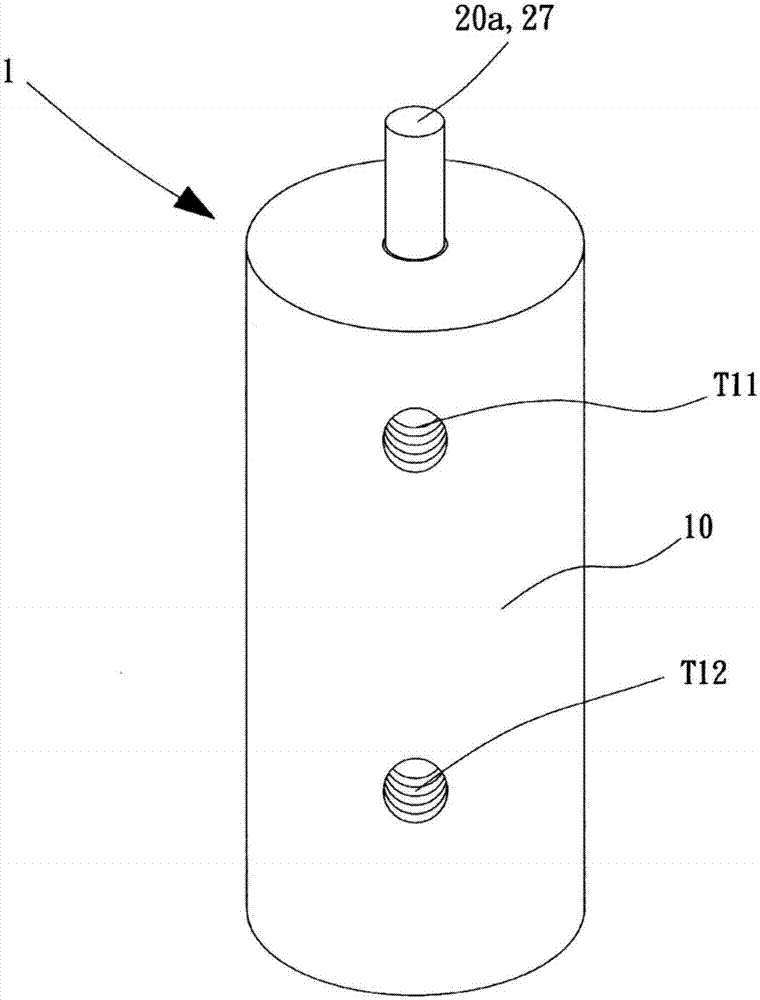

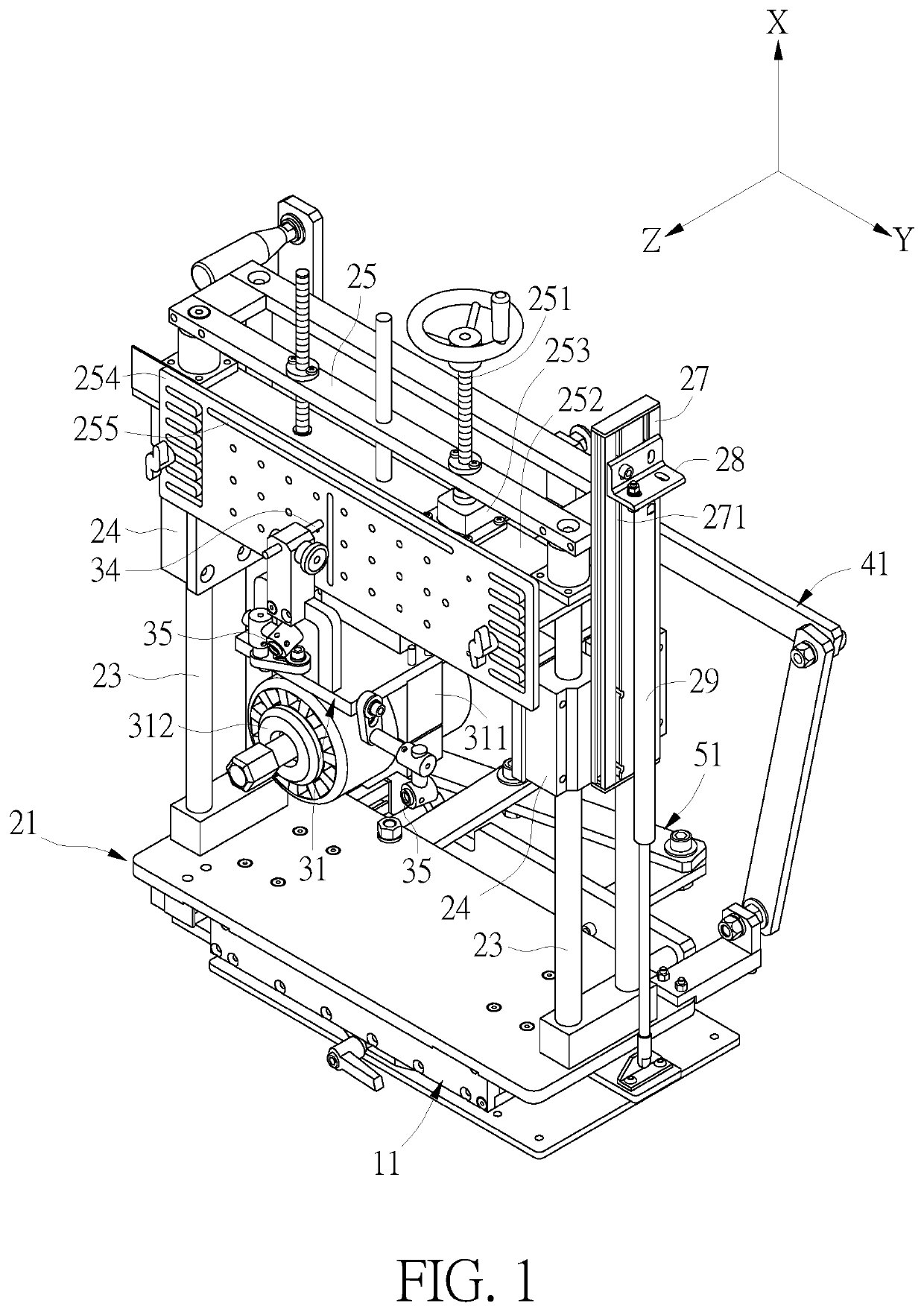

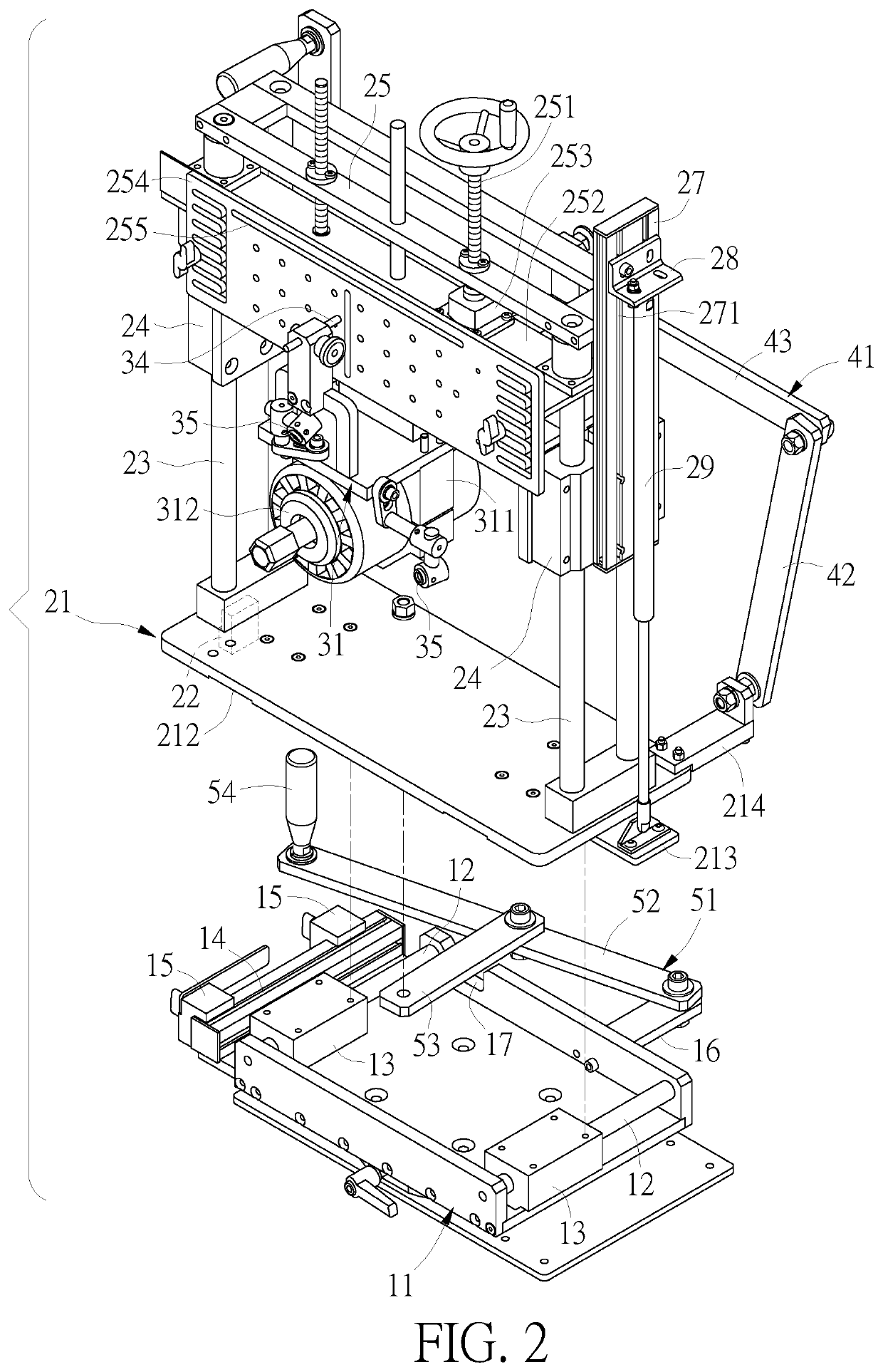

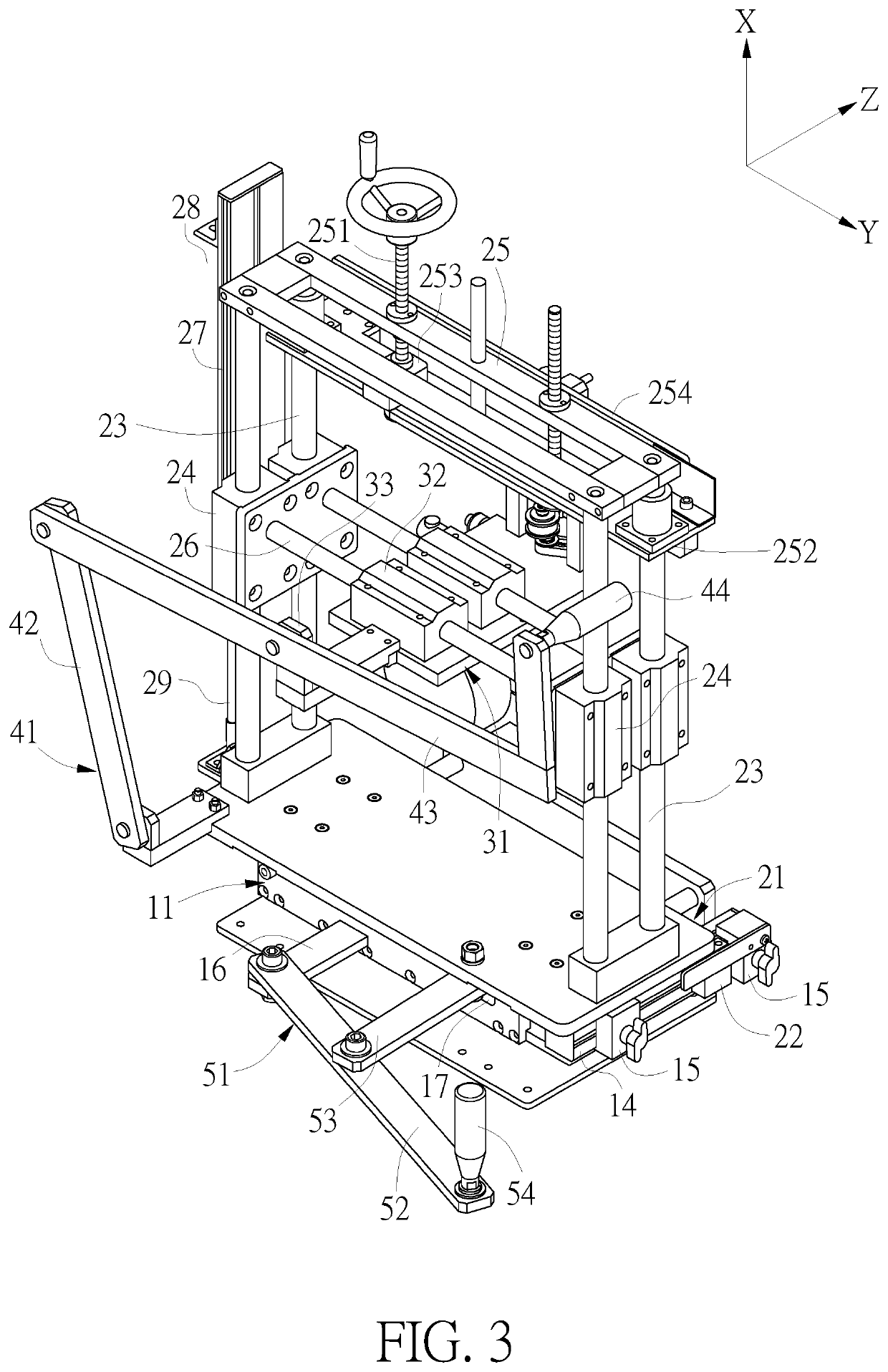

Carrier structure of woodworking machine spindle

InactiveUS20200086446A1Quickly calculateMachine accuracyTongue/grooves making apparatusMeasurement/indication equipmentsWoodworking machineWoodworking

A carrier structure of a woodworking machine spindle has a base and a sliding seat slidably disposed on the base. The sliding seat is moveable in a z-axis direction relative to the base. The sliding seat includes a carrier that is movable in an x-axis direction or in a y-axis direction. The sliding seat includes a position indicator for detecting and displaying the value of the movement of the carrier in the x-axis direction. The carrier includes a spindle. Two infrared aligners are disposed on two adjacent sides of the carrier. The two infrared aligners are spaced apart from each other at an angle of 90 degrees. The two infrared aligners cooperate with the position indicator to ensure the machining accuracy.

Owner:HSU CHUN JEN

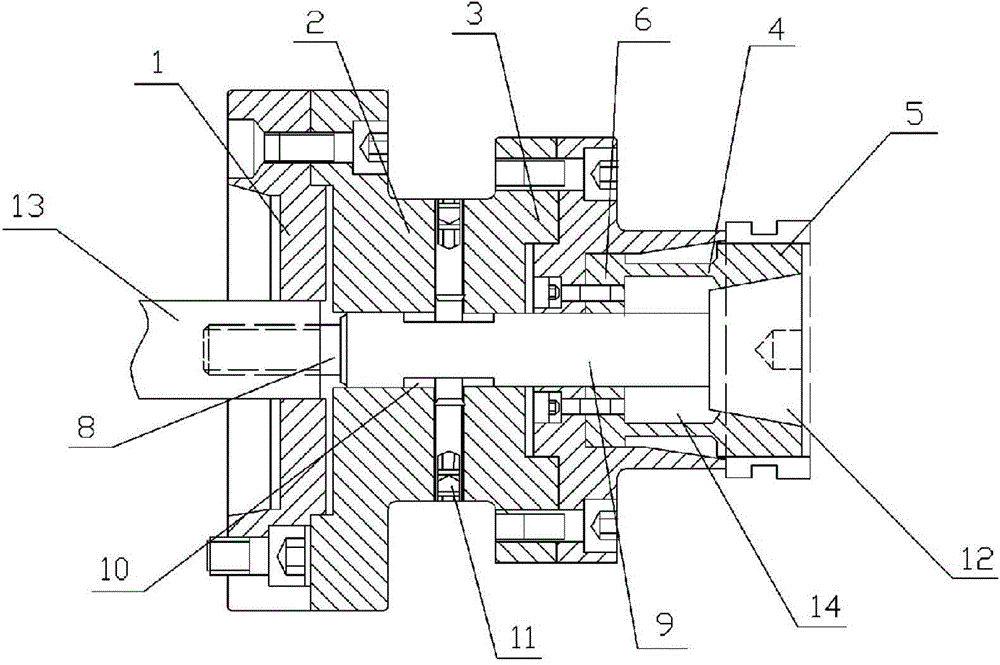

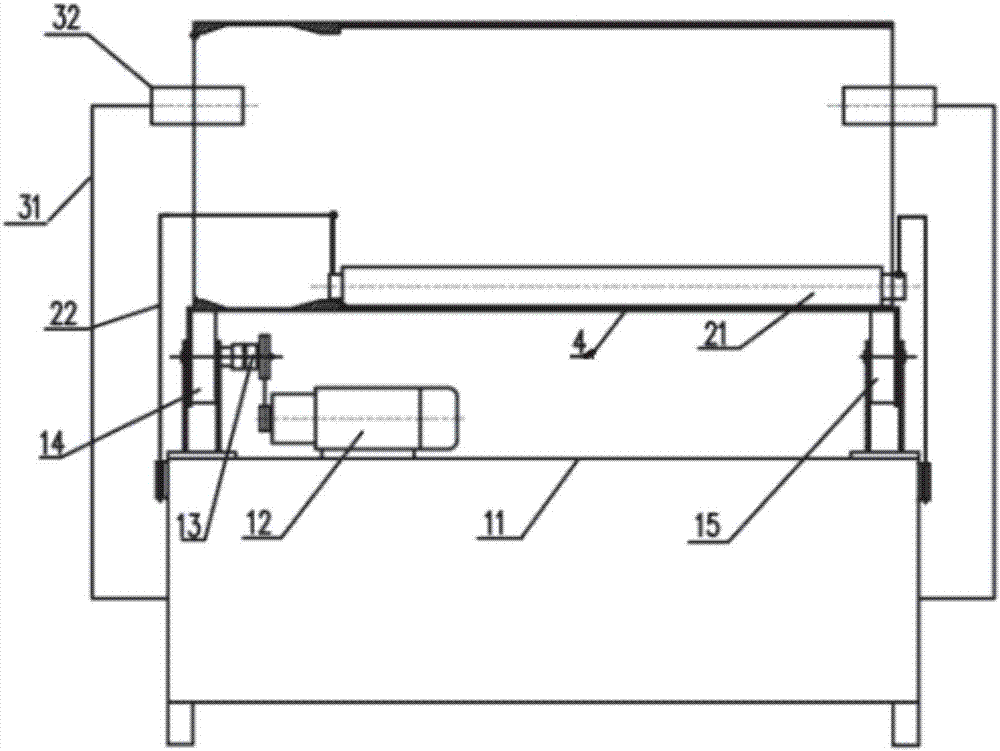

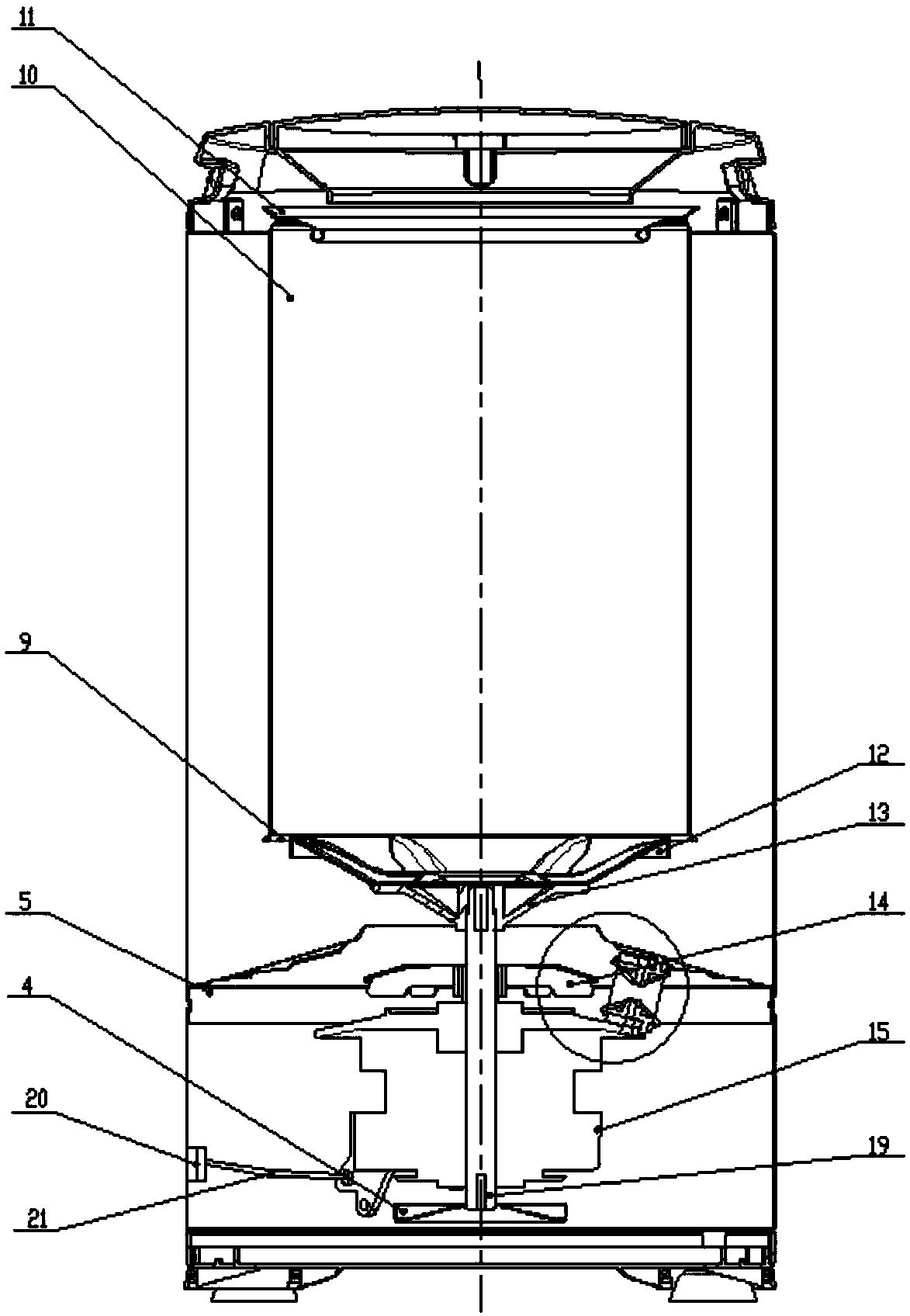

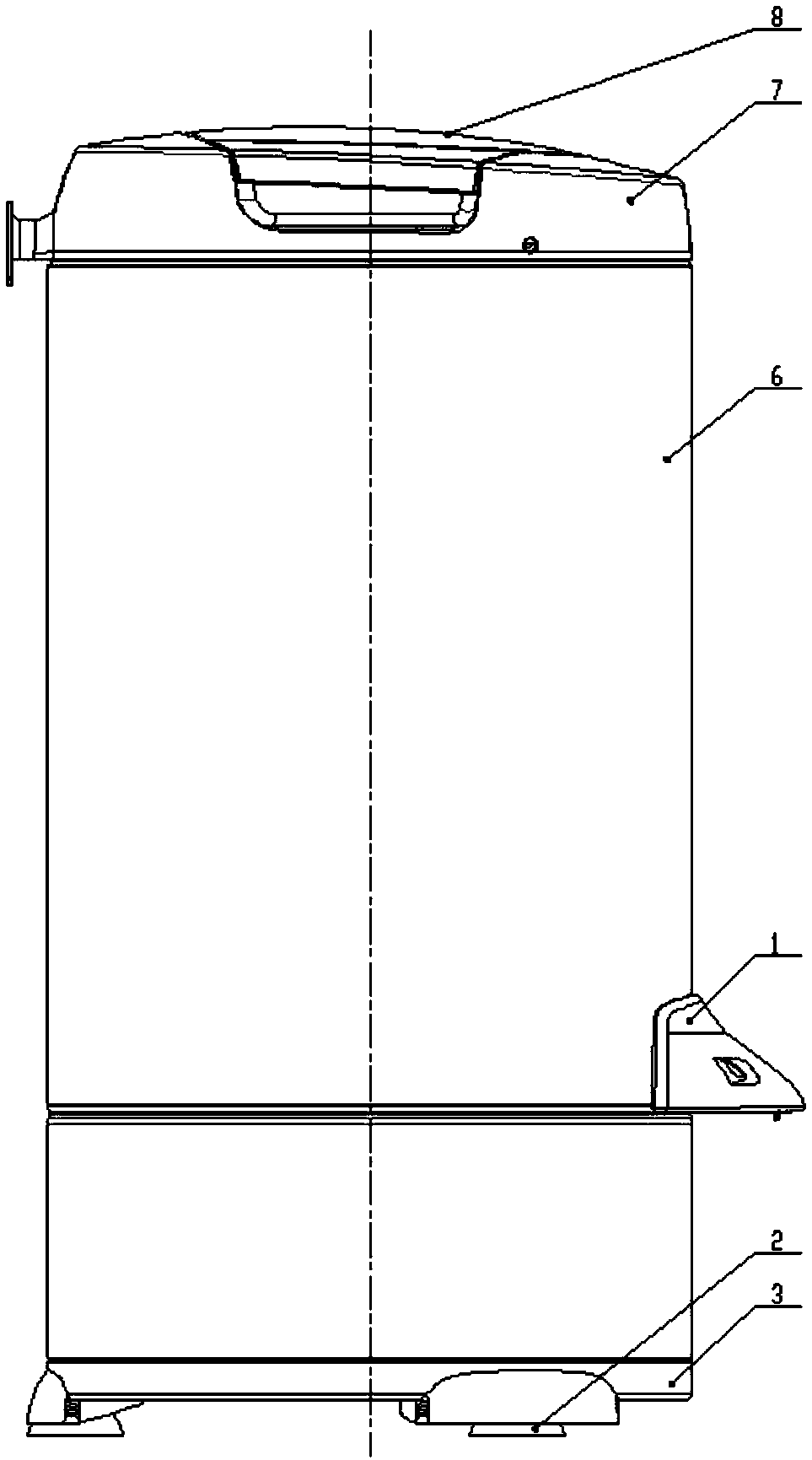

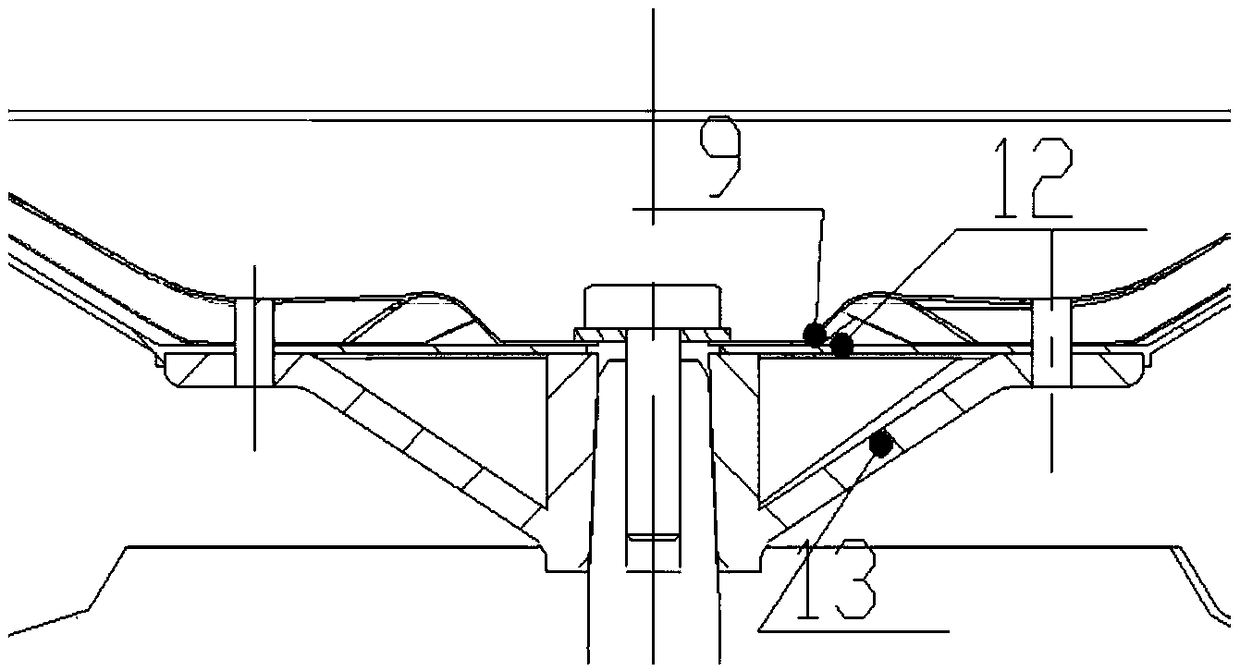

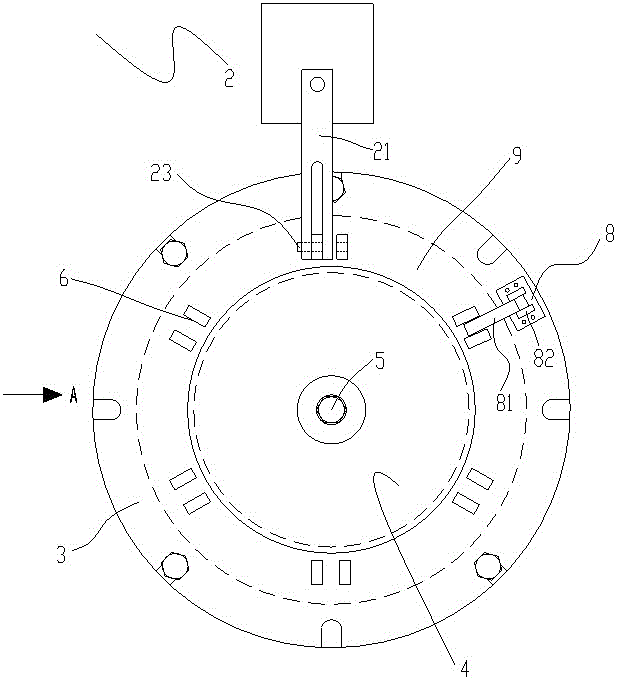

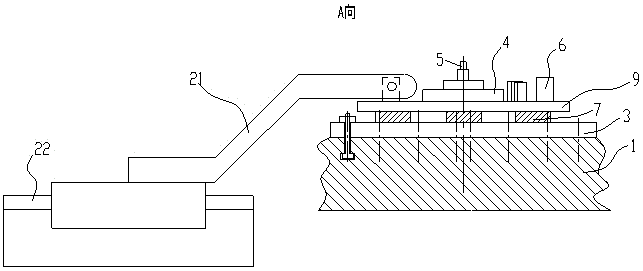

Dewatering machine

ActiveCN109099645AReduce vibrationReduce noiseDrying solid materials without heatPulp and paper industryFlange

The invention provides a dewatering machine which comprises an outer barrel, a motor and a dewatering barrel. The motor and the dewatering barrel are both sleeved with the outer barrel. An output shaft of the motor is fixedly connected with the bottom of the dewatering barrel through a flange. By adoption of the dewatering machine, the rotation speed can reach 2500-3000 r / min, and meanwhile, the dewatering machine is compact in structure, stable in running and low in noise.

Owner:HEFEI UNIV OF TECH

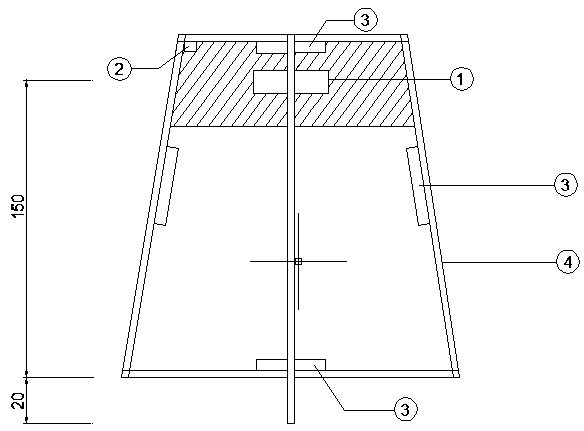

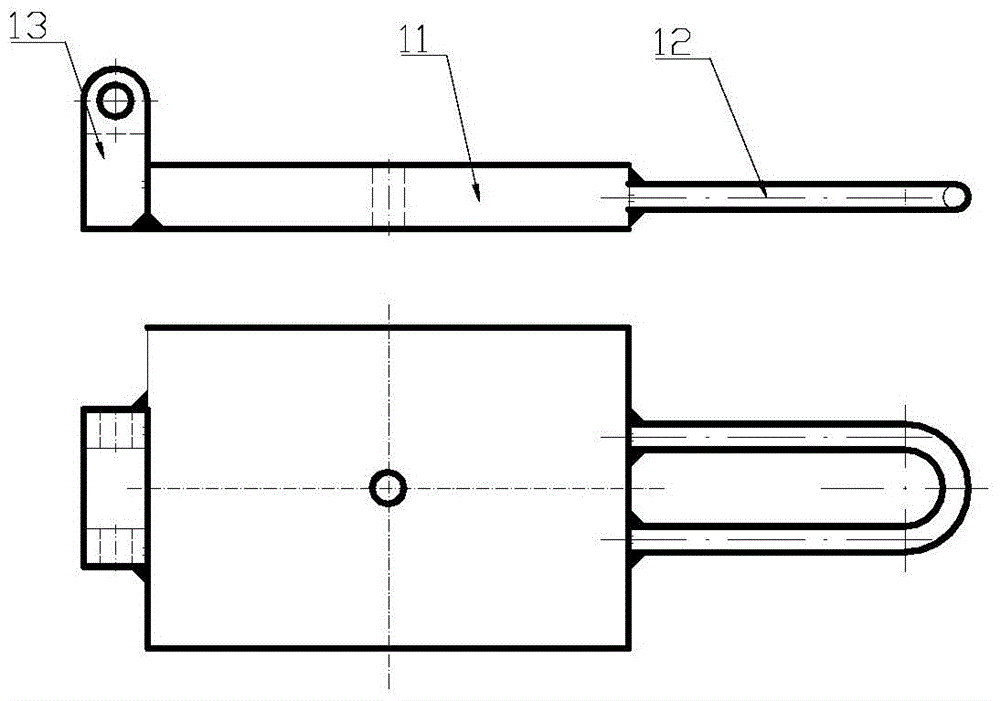

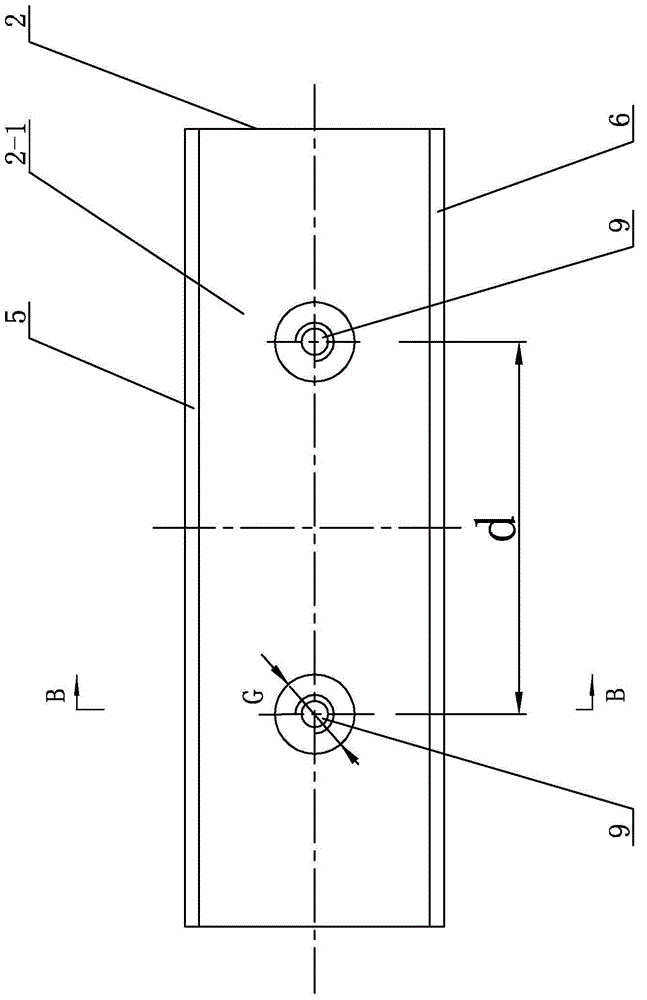

Special clamp for hinge seat pin hole of clutch pressure disc

ActiveCN106166684AMeet the machining accuracyStable pin hole performanceDrilling/boring measurement devicesMetal working apparatusClutchEngineering

The invention relates to a special clamp for a hinge seat pin hole of a clutch pressure disc. The special clamp comprises a machine tool rotation graduated table, a guiding device, a supporting frame, a pressing plate and a screw. The guiding device is arranged on one side of the machine tool rotation graduated table and used for enabling a hinge seat to perform positioning guiding, the machine tool rotation graduated table is provided with a T-shaped groove, the rotatable supporting frame is connected with the machine tool rotation graduated table through the screw in the T-shaped groove, the supporting frame is provided with a positioning boss, the clutch pressure disc is installed on the supporting frame through the positioning boss, and the pressing plate is installed on the upper portion of the clutch pressure disc and fastens the clutch pressure disc through the screw on the positioning boss. The guiding device can perform positioning guiding on a drill, the drilling precision is met well, and the hinge seat pin hole of the clutch pressure disc is stable in performance; the supporting frame performs graduated rotation on the clutch pressure disc, hole drilling and reaming can be finished simultaneously through one-time clamping, labor intensity is lowered, and production efficiency is improved.

Owner:山东理工远航教育服务有限公司

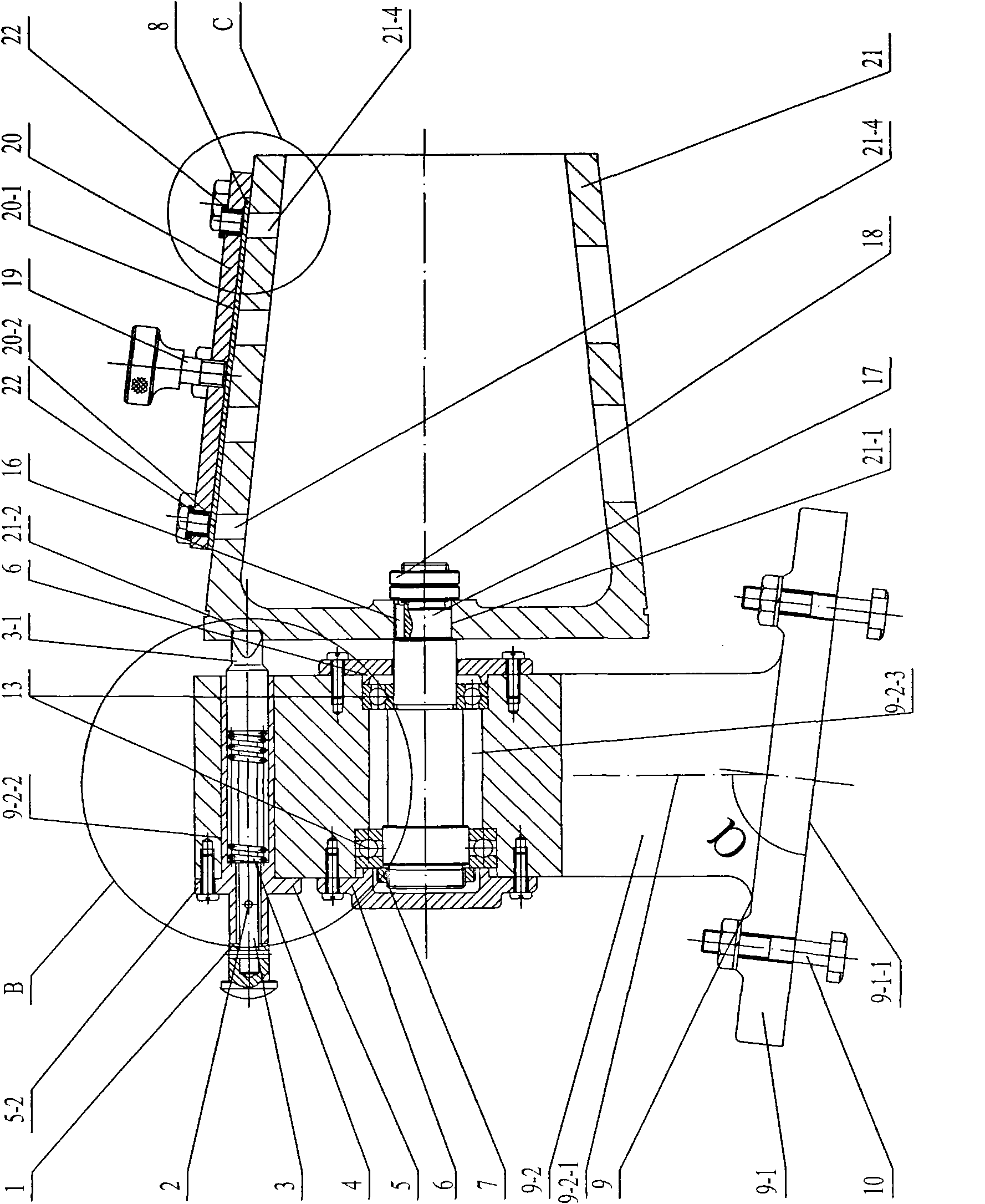

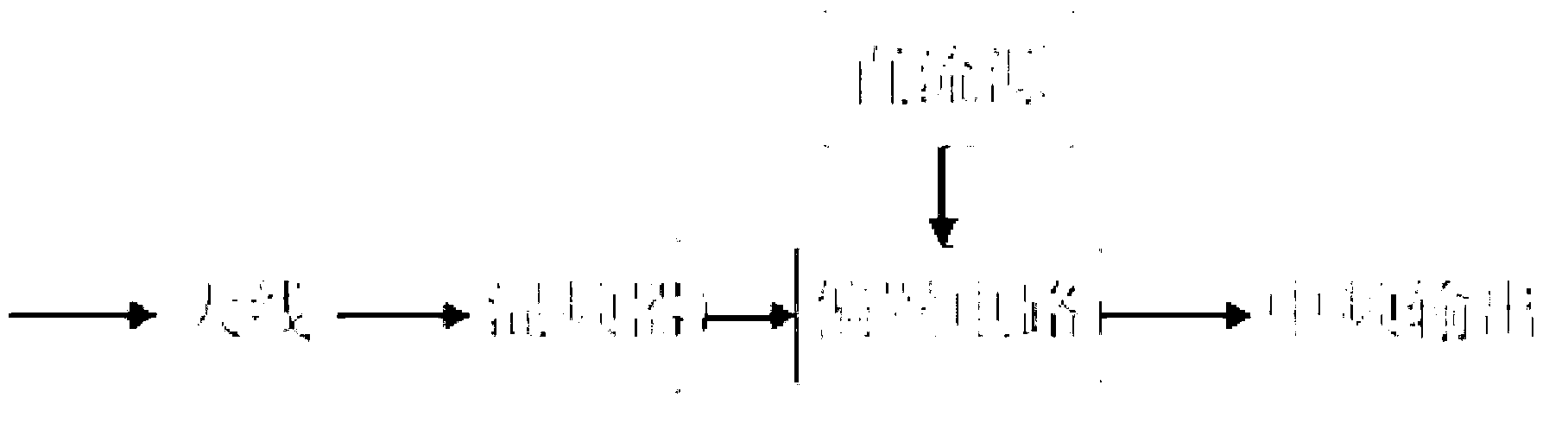

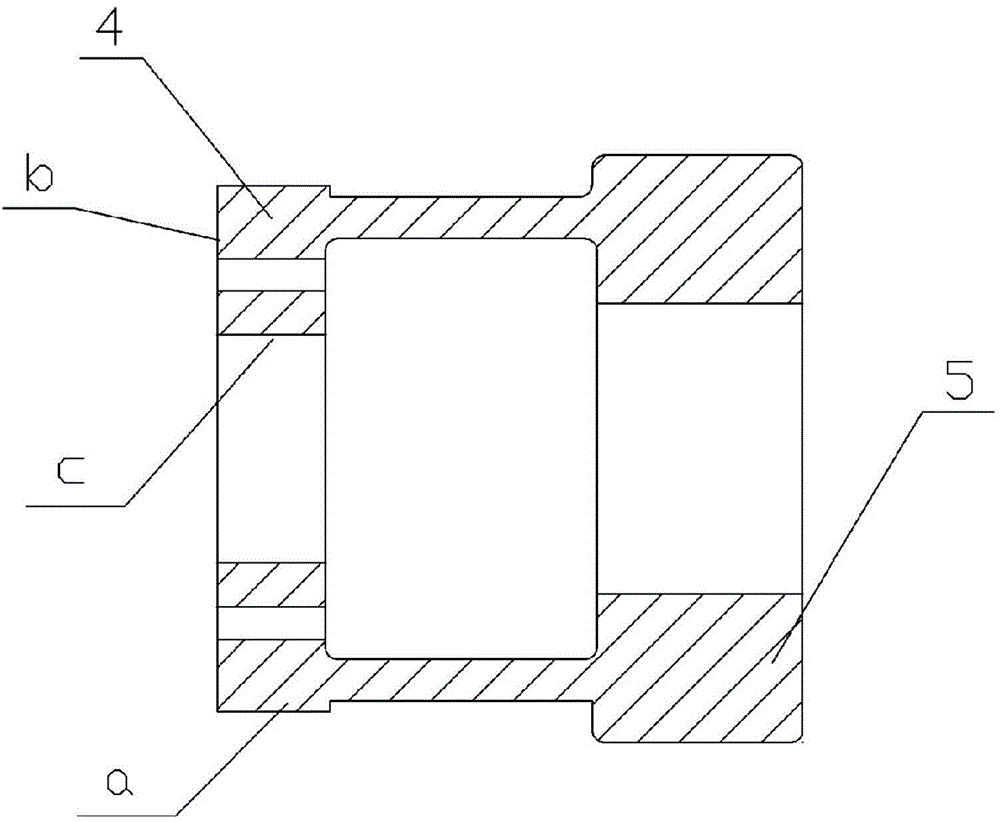

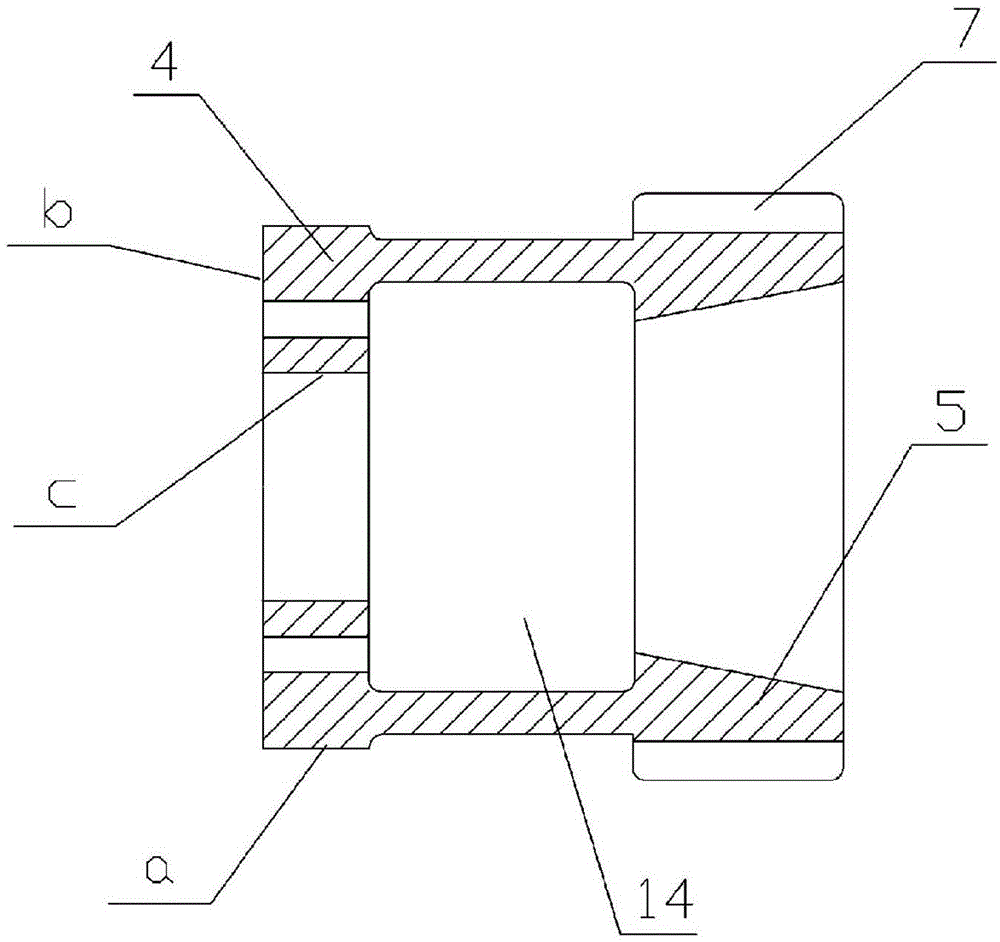

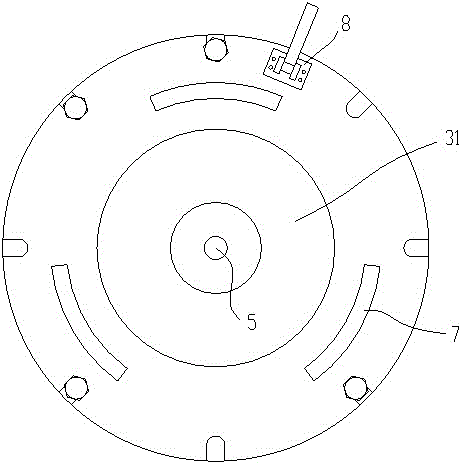

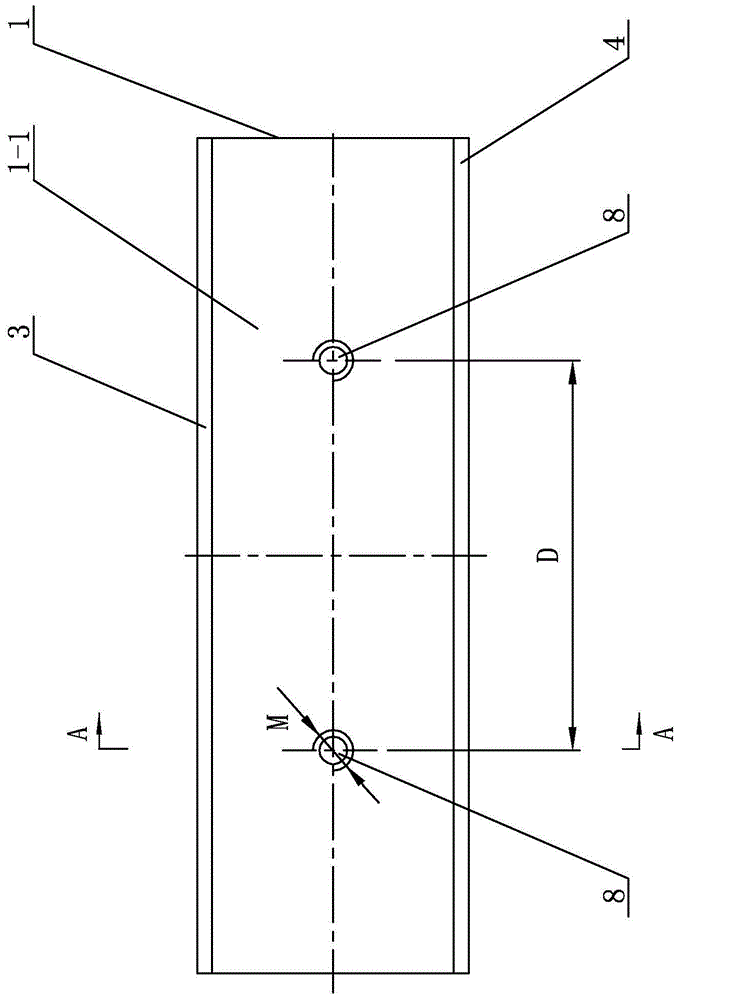

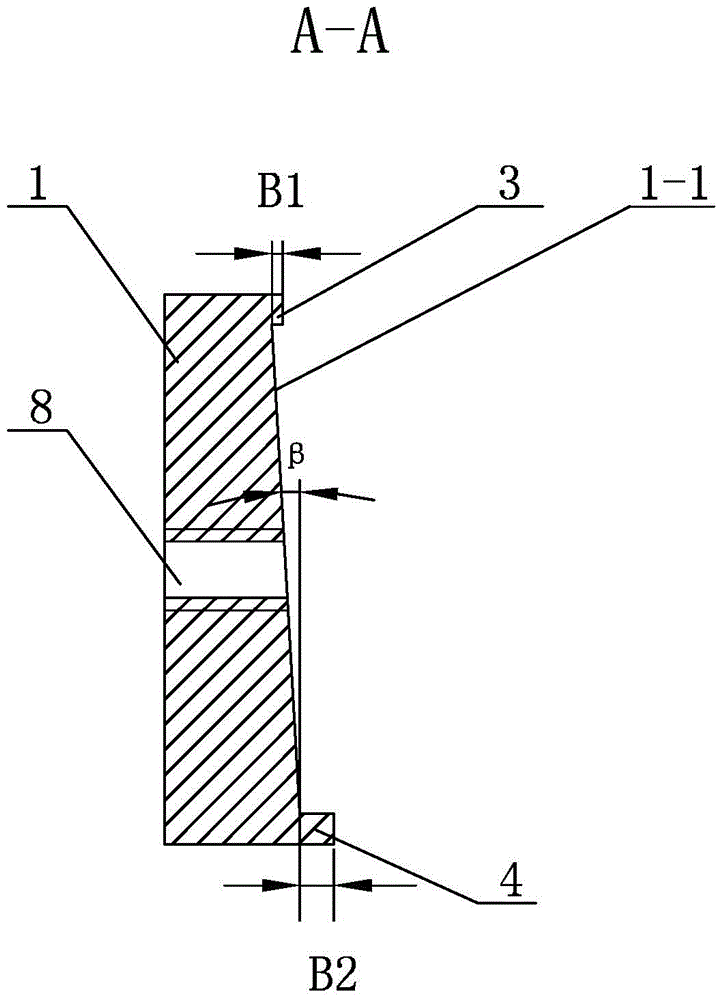

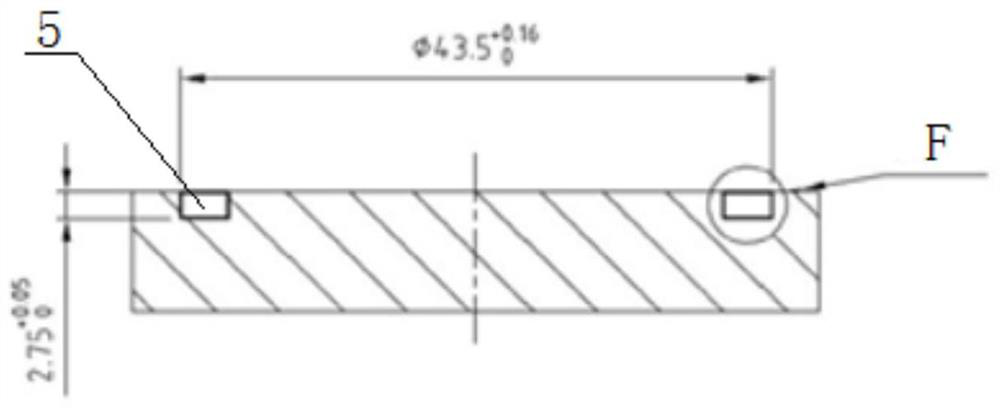

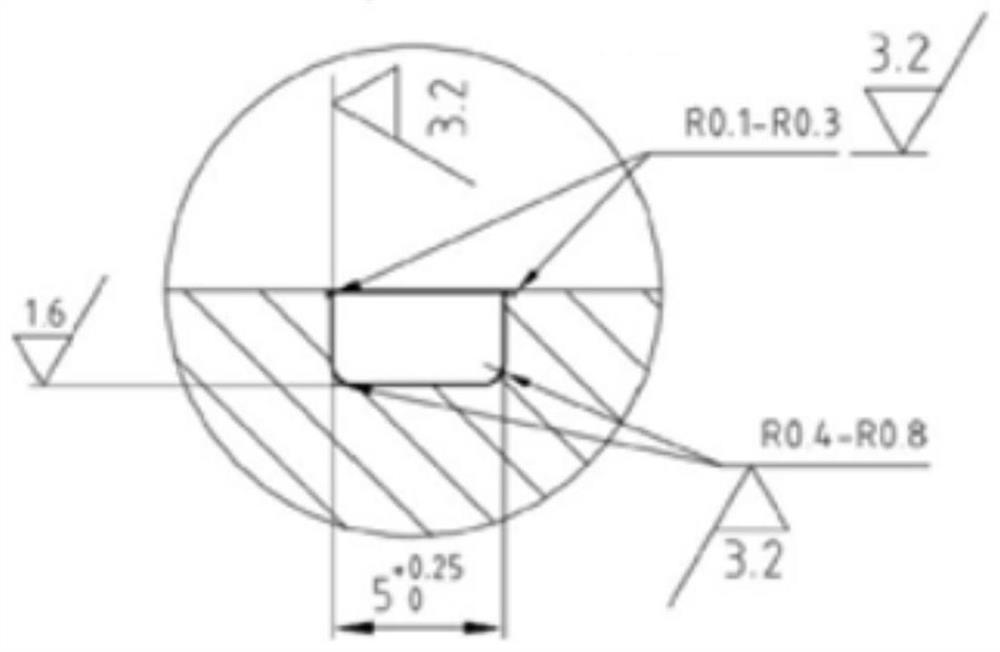

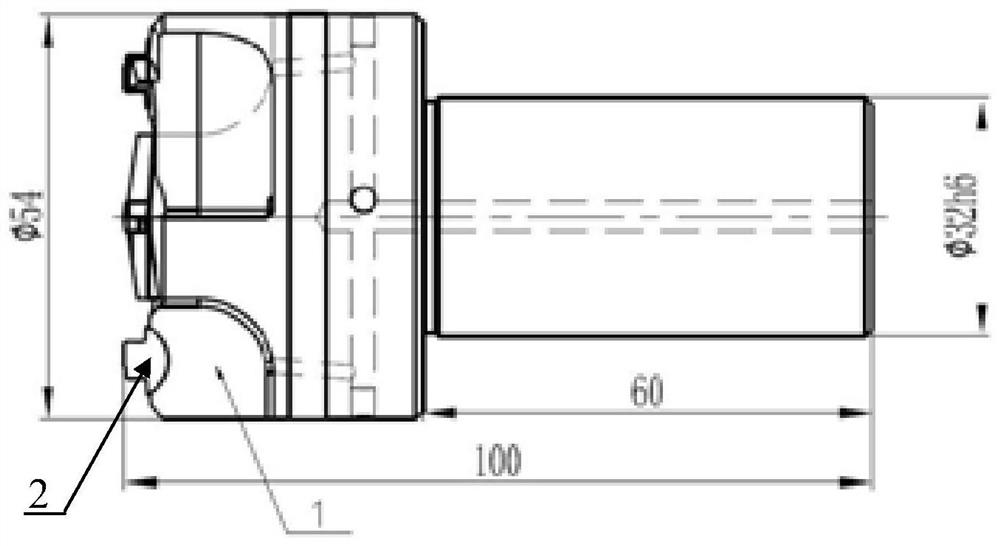

Drill jig structure for drilling plate-shaped metal component

The invention relates to a drill jig structure for drilling a plate-shaped metal component. The drill jig structure comprises a drill jig plate assembly 1, a bottom plate assembly 2, a positioning plate 3, a pin a 4, a drill sleeve 5, a screw 6 and a pin b 7. The special drill jig structure is designed, the structure is simple, and the requirement for machining precision of a plate-shaped metal component hole is met. The requirements of various machine types in a plate-shaped metal component workshop are met, the labor intensity of workers is relieved, and the production efficiency is improved.

Owner:HARBIN

Precise inner hexagon machining lathe for valve element of pressure valve and machining process of precise inner hexagon machining lathe

ActiveCN112846775APrecisionThe amount of deformation is easy to controlOther manufacturing equipments/toolsMachined surfaceEngineering

The invention discloses a precise inner hexagon machining lathe for a valve element of a pressure valve and a machining process of the precise inner hexagon machining lathe. The precise inner hexagon machining lathe comprises an equipment base, a moving device is arranged on the left side of the top of the equipment base, a height adjusting mechanism is arranged on the right side of the top of the equipment base, a transverse moving mechanism is arranged on the top of the left side of the height adjusting mechanism, and a broaching tool adjusting mechanism is arranged at the bottom of the transverse moving mechanism. In actual use, lathe machining is adopted, a 120-degree-angle tool is customized, a main shaft is locked, and movement of a tool turret in the Z direction is utilized, so that one angle in a hexagon can be broached, the rest five angles are machined in sequence after the main shaft uniformly rotates by 60 degrees, and therefore, by means of the machining mode, the broaching amount each time is about 0.05 mm, the machining precision of the hexagon can be met, the machined surface is flat and smooth, no stamping stress is generated, the deformation of the size of the inner hexagon after heat treatment can be controlled more easily, circulation of parts is reduced, and the machining efficiency is improved.

Owner:WUXI YINGBEI PRECISION BEARING

Material shifting equipment for machining heavy truck brake drum

The invention relates to the technical field of heavy truck brake drum machining, in particular to material shifting equipment for machining a heavy truck brake drum. The material shifting equipment for machining the heavy truck brake drum comprises a feeding mechanism, a guiding mechanism, a work box, an overturning mechanism, a compressing mechanism, discharging mechanisms, a straight-line movement mechanism and a controller. The guiding mechanism is arranged between the feeding mechanism and the overturning mechanism. The work box is rotatably arranged on the overturning mechanism. The compressing mechanism is installed on the work box, and the output end of the compressing mechanism is located inside the work box. The discharging mechanisms are arranged on two sides of the overturningmechanism. The input end of the straight-line movement mechanism is connected with the output end of the overturning mechanism. According to the scheme of the material shifting equipment for machiningthe heavy truck brake drum, the structure is more reliable, and the control accuracy is higher.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

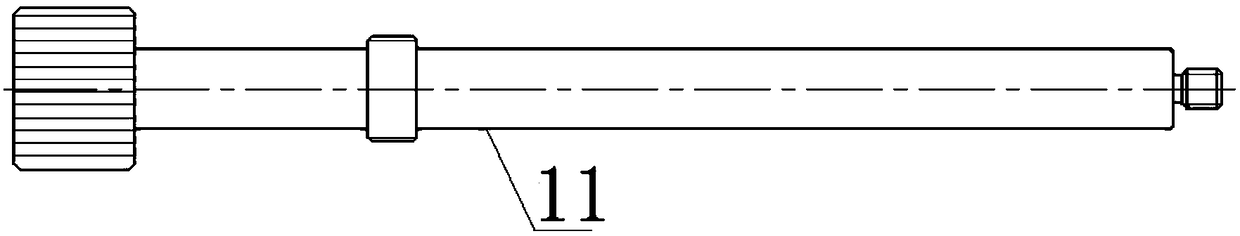

A combined honing tool and method

InactiveCN106737119BPrecisionMeet the needs of machining super long holesHoning toolsEngineeringSerialization

The invention discloses a combined type honing tool. The combined type honing tool comprises a honing cutter rod, a honing cutter and a rotary knob. A cutter handle is arranged at the tail of the honing cutter rod. The rotary knob is arranged on the honing cutter rod, and scales are arranged on the outer surface of the rotary knob. Threads are formed in the outer surface of one end of the honing cutter rod and the inner surface of one end of the honing cutter correspondingly. The honing cutter rod and the honing cutter are connected through the threads. A honing cutter frame is provided with a square hole. The surface of the honing cutter is designed to be a taper with a circular arc. A taper matching the taper of the horning cutter is designed for the honing cutter rod. The outer surface of the honing cutter is fastened to the honing cutter frame through an O-shaped ring. When a super-long deep-hole product is machined, the standardized honing cutter and the honing cutter rod are connected through the threads for splicing lengthening. The combined type honing tool has the advantages that the requirements of universalization, serialization and special conditions during product machining can be met. The invention further discloses a combined type honing method.

Owner:WUHAN HANGDA AERO SCI & TECH DEV

Special fixture for milling inclined planes of symmetric V-shaped parts with holes

InactiveCN106141724ASimple structureEasy to operatePositioning apparatusMetal-working holdersEngineeringProcessing cost

The invention discloses a special fixture for milling inclined planes of symmetric V-shaped parts with holes, relates to the special fixture for milling the inclined planes and aims at solving the problems that high processing cost, difficulty in clamping and aligning and inaccuracy in locating are caused due to the fact that no special fixture is used for milling the inclined planes of the symmetric V-shaped parts with holes. A first fixture body and a second fixture body are rectangular respectively; one end face of the first fixture body is a first inclined plane; both a first stopping edge and a second stopping edge are located on the first inclined plane; the first stopping edge is fixedly connected to the upper part of the first inclined plane; the second stopping edge is fixedly connected to the lower part of the first inclined plane; two through holes are formed in the first inclined plane; one end face of the second fixture body is a second inclined plane; both a third stopping edge and a fourth stopping edge are located on the second inclined plane; the third stopping edge is fixedly connected to the upper part of the second inclined plane; the fourth stopping edge is fixedly connected to the lower part of the second inclined plane; two counter bores are processed in the second inclined plane; and the diameters of two screws are identical with the apertures of the two counter bores. The special fixture disclosed by the invention is used for processing the symmetric V-shaped parts with holes.

Owner:HARBIN JIANCHENG GRP

One-time forming efficient PCD cutter for annular groove machining

InactiveCN111633254AStable processingMeet the designMilling cuttersWorkpiecesStructural engineeringKnife blades

The invention provides a one-time forming efficient PCD cutter for annular groove machining, and aims to solve the problem that a traditional annular groove machining scheme cannot meet the requirement of mass production. Two of four PCD forming blades on a cutter body are A-type blades, and the other two of the four PCD forming blades on the cutter body are B-type blades; the two A-type blades are distributed on the same straight line, and the two B-type blades are distributed on the same straight line; chip discharging grooves of the A-type blades are formed in the bottom surfaces of the A-type blades and positioned on one sides of inner diameter cutting edges, and penetrate through the inner diameter cutting edges; chip discharging grooves of the B-type blades are formed in the bottom surfaces of the B-type blades and positioned on one sides of outer diameter cutting edges, and penetrate through the outer diameter cutting edges; when bottom surface cutting edges of the A-type bladesand the B-type blades act simultaneously, a complete annular groove bottom shape can be machined; and the inclination angles of notch cutting edges of the A-type blades and the B-type blades are both2-5 degrees. According to the invention, the machining of an annular groove and corresponding fillets can be completely finished through one-time axial cutting, and the machining precision can be met.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com