Conical arc plate drilling clamp tool

A drilling jig and arc-shaped plate technology, which is applied in the direction of drilling/drilling equipment, clamping, positioning devices, etc., can solve the problems that the machining accuracy of each hole of the conical arc-shaped plate cannot be satisfied at the same time, and achieve the goal of meeting the machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

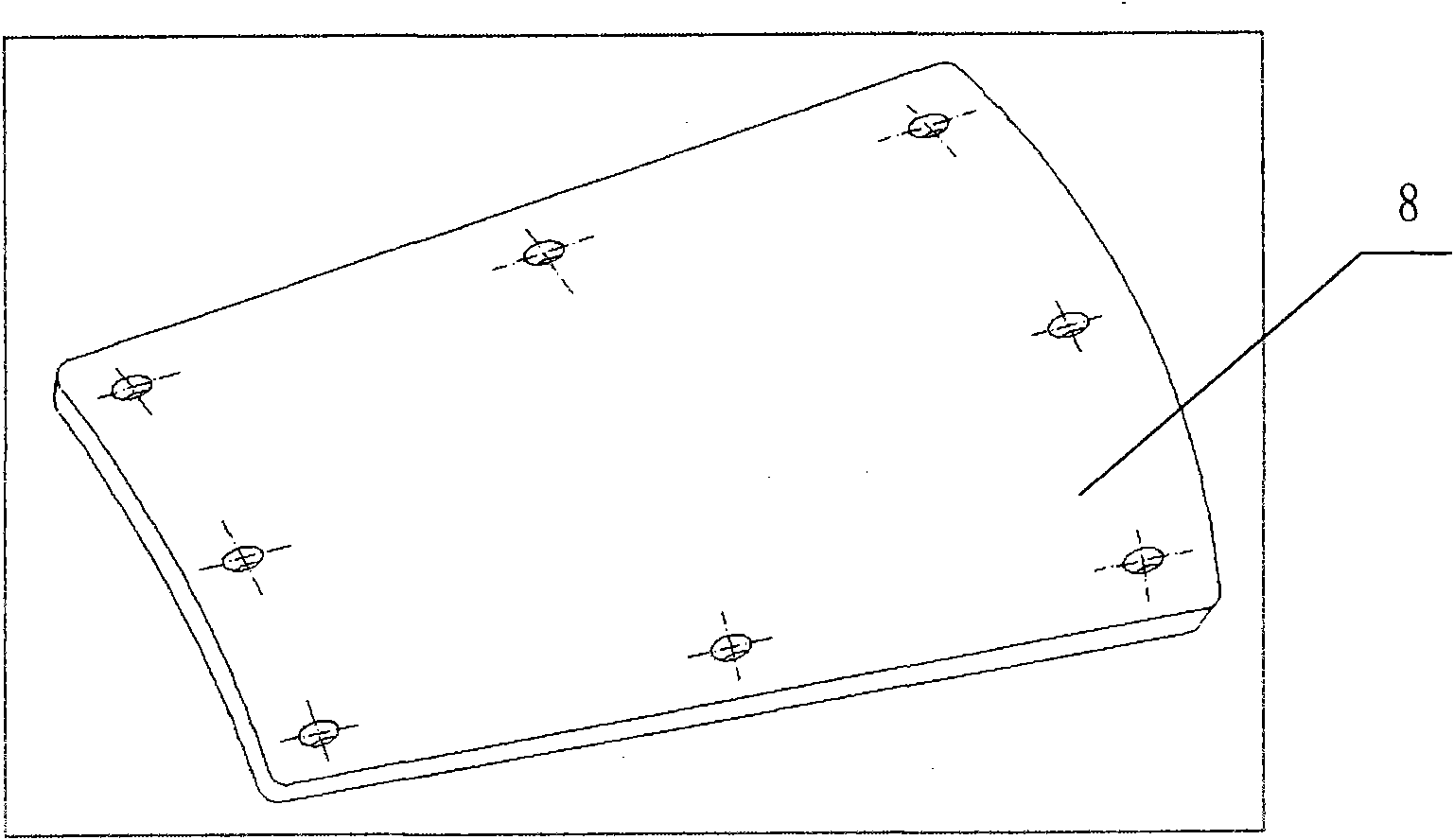

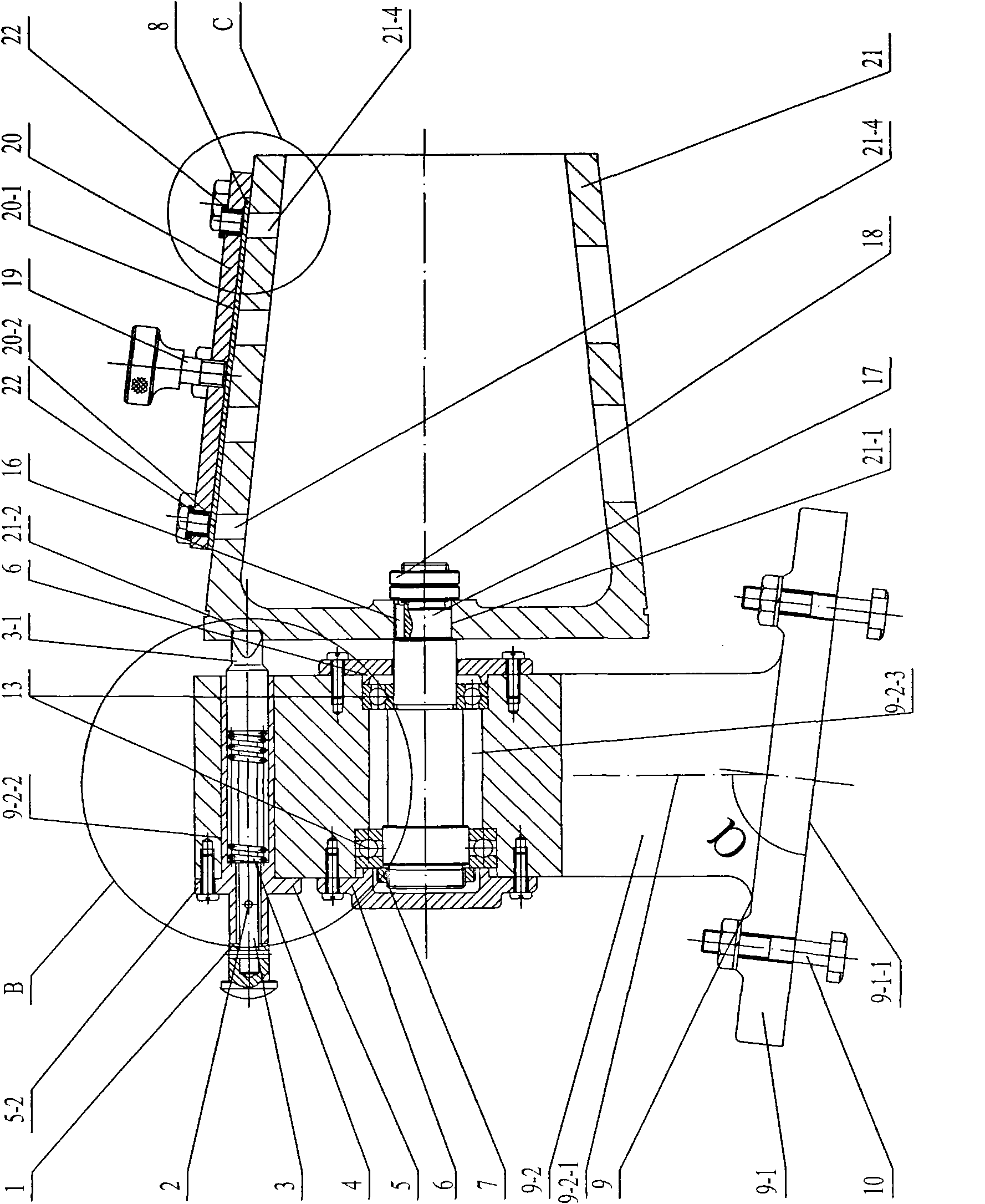

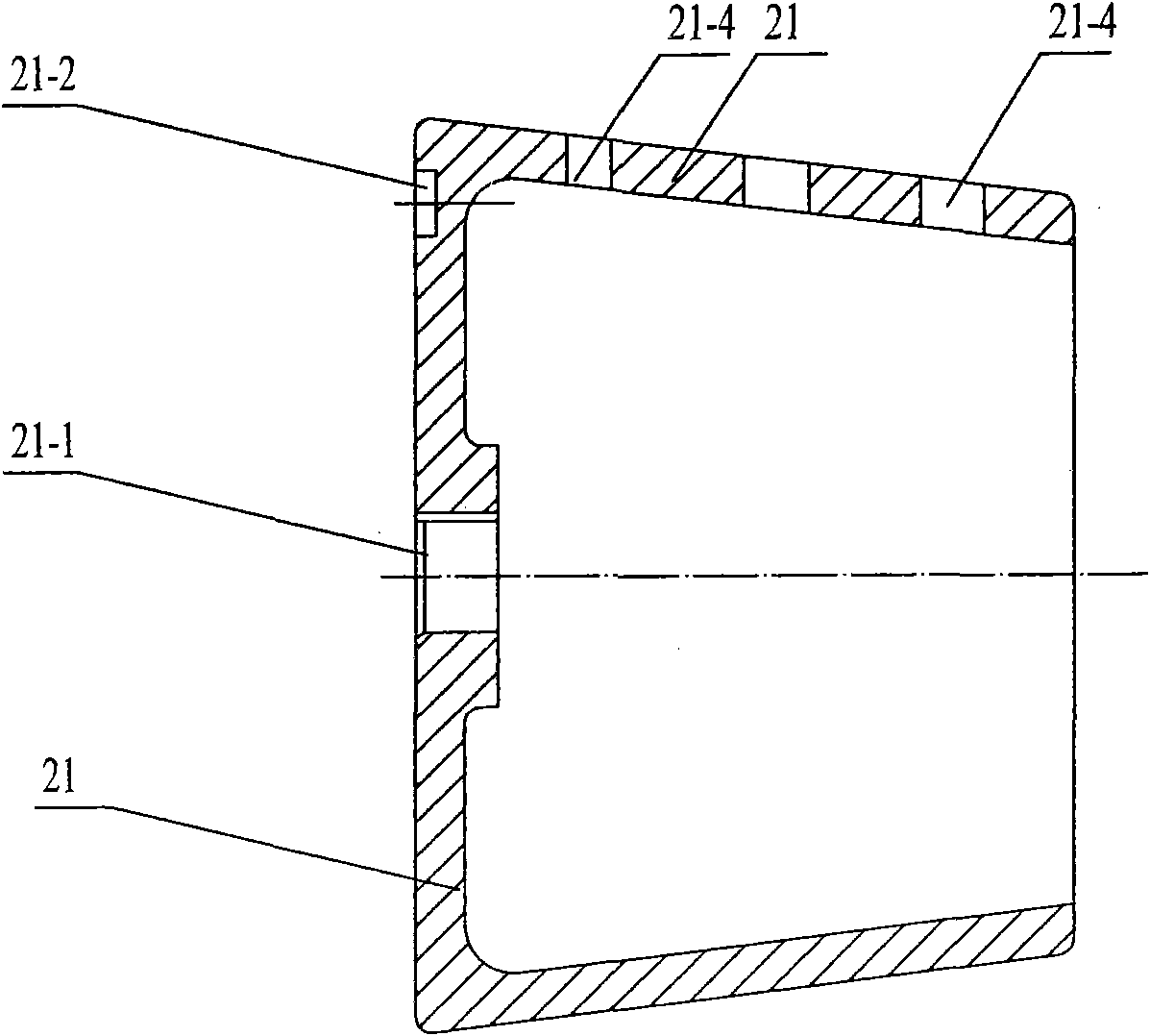

[0014] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, the tapered arc-shaped plate drilling jig tooling of this embodiment includes a pin handle 1, a latch 2, a positioning pin 3, a spring 4, a positioning pin cylinder 5, a first round nut 7, a placenta 9, a key 16, Step rotating shaft 17, second round nut 18, arc plate drilling mold 20, cone 21, two sealing covers 6 and two bearings 13, said placenta 9 is made of base 9-1 and base 9-1 It is composed of an integral upper body 9-2, and the acute angle α formed between the vertical line 9-2-1 of the upper body 9-2 and the bottom plane 9-1-1 of the base 9-1 is 83°. On the upper body 9-2, there are pin mounting holes 9-2-2 and shaft mounting holes 9-2-3 successively from top to bottom, and the pin mounting holes 9-2-2 and shaft mounting holes 9-2-3 are all along the Open in the horizontal direction, the center of the positioning pin cylinder 5 has a stepped hole 5-1, the positioning pin...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 2 The present embodiment will be described. The bearing 13 of the present embodiment is a single row radial ball bearing. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination Figure 5 Describe this embodiment, the arc plate jig 20 of this embodiment is a 45# steel arc plate jig or a T8A arc plate jig. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com