Special clamp for hinge seat pin hole of clutch pressure disc

A special fixture and clutch technology, used in clamping, manufacturing tools, drilling/drilling equipment, etc., can solve the problems that fixtures cannot meet processing requirements, reduce production efficiency, and affect production rhythm, so as to improve production efficiency and reduce The effect of labor intensity and stable performance of pin holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

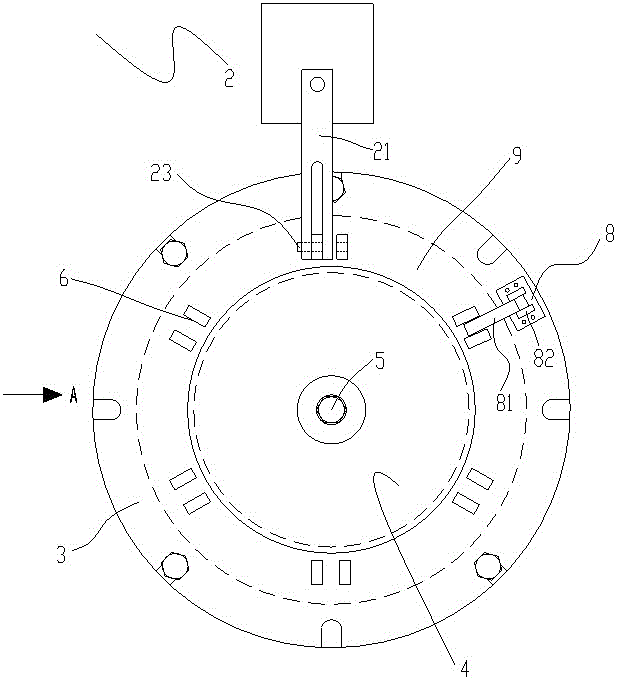

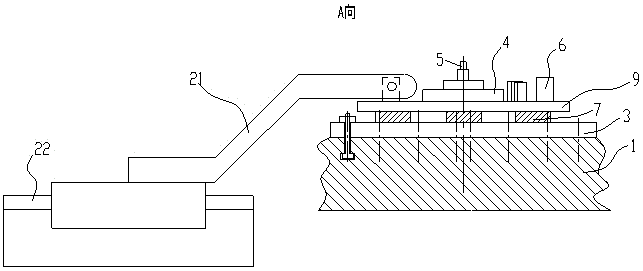

[0019] like Figure 1-3 As shown, a special fixture for the pin hole of the hinge seat of the clutch pressure plate, including: a rotary indexing table 1 of the machine tool, a guide device 2, a support frame 3, a pressure plate 4 and a screw rod 5, and the guide device 2 is arranged on the rotary indexing table of the machine tool. One side of the workbench 1 is used for positioning and guiding the hinge seat 6 on the clutch pressure plate 9. The guide device 2 includes a pair of guide arms 21 and a guide rail 22 for the clutch pressure plate 9 hinge seat 6 to guide. The guide arm 21 is arranged on the guide rail 22 and can move back and forth, and the guide arm 21 is provided with a guide hole 23 .

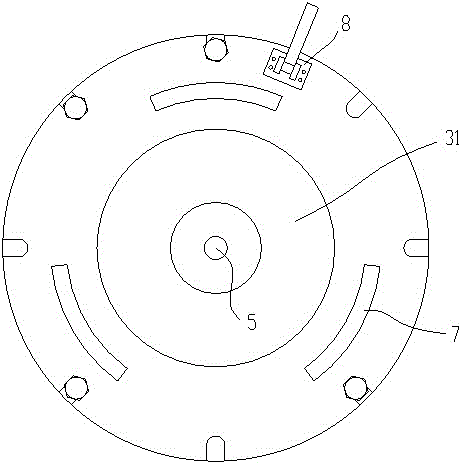

[0020] The rotary indexing table 1 of the machine tool is provided with a T-shaped slot, and the rotatable support frame 3 is connected with the rotary indexing table 1 of the machine tool through the screws arranged in the T-shaped slot. The support frame 3 is provided with Po...

Embodiment 2

[0022] On the basis of Embodiment 1, the special fixture of the present invention also includes a pre-positioning device 8, and the pre-positioning device 8 is fixed on the support frame 3 for when the clutch pressure plate 9 is installed on the When supporting the frame 3, the clutch pressure plate 9 is pre-positioned. The pre-positioning device 8 includes a positioning rod 81 and a connecting frame 82, the positioning rod 81 is movably connected to the connecting frame 82, and the positioning rod 81 is installed on the joint between two adjacent hinge seat units of the clutch pressure plate. within the void.

[0023] like Figure 4 As shown, the processing process of using the special fixture of the present invention to process the pin holes of the clutch pressure plate hinge seat is as follows: first use the drilling guide device 2 to position and guide the clutch pressure plate hinge seat, and after the drill bit 10 performs the drilling process on the hinge seat , the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com