Small-size impeller and five-axis milling method thereof

A milling processing, small size technology, applied in the direction of metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of poor gear quality, high processing cost, low efficiency, etc., to ensure feasibility, good quality of finished products, and high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0073] Example:

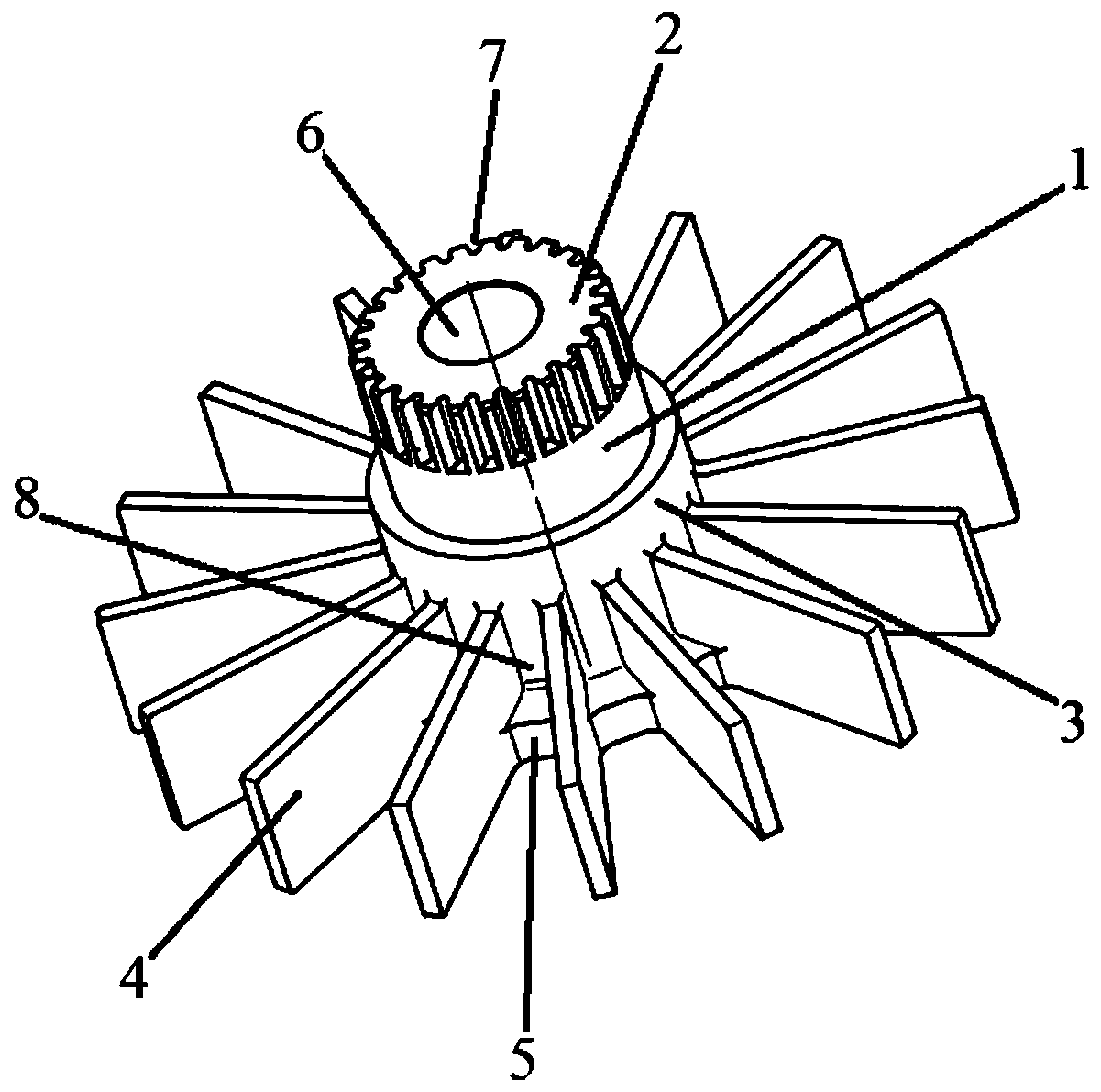

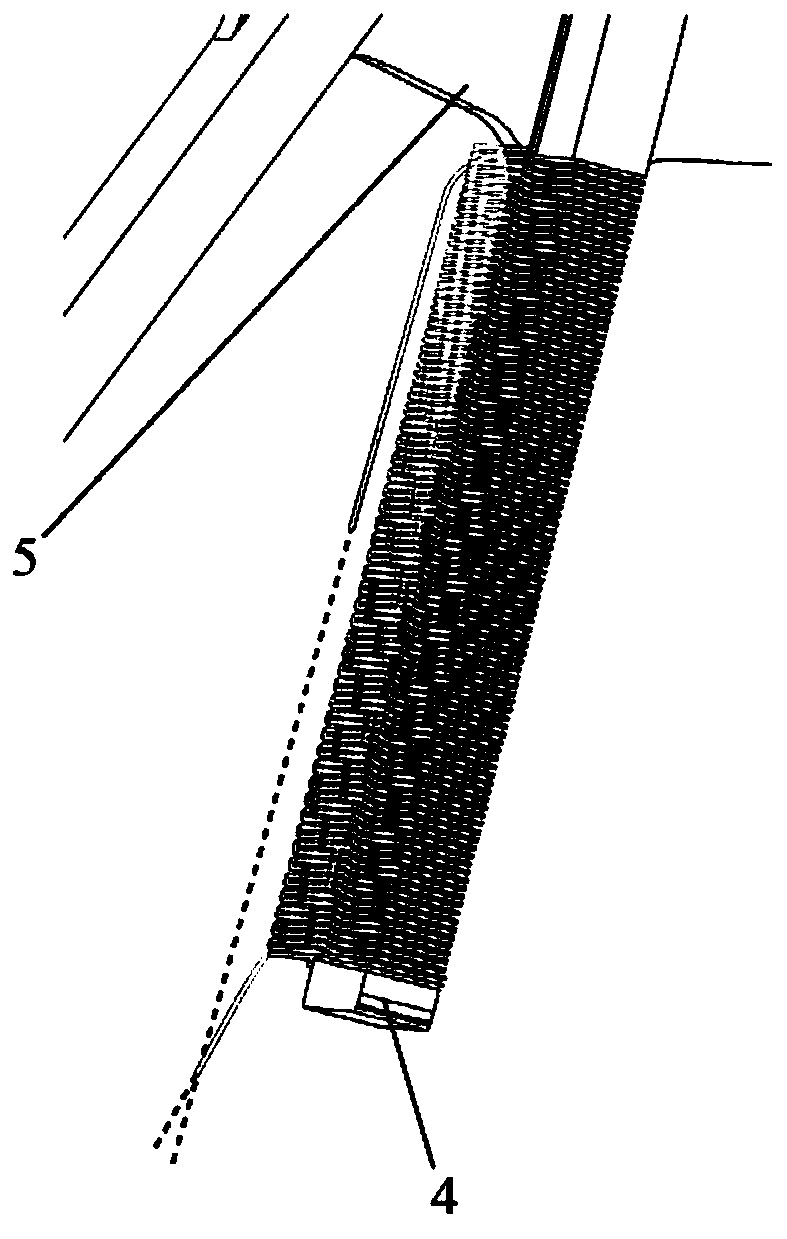

[0074] like figure 1 A small-sized impeller shown includes a main shaft 1, a gear 2 arranged on the top of the main shaft 1, a sleeve 3 sleeved outside the main shaft 1, and a plurality of blades 4 evenly arranged on the side of the sleeve 3 along the circumferential direction. A reinforcing rib 5 is provided between two adjacent blades 4, the main shaft 1, the gear 2 and the sleeve 3 are arranged coaxially, and the main shaft 1, the gear 2, the sleeve 3, the blade 4 and the reinforcing rib 5 are integrally formed.

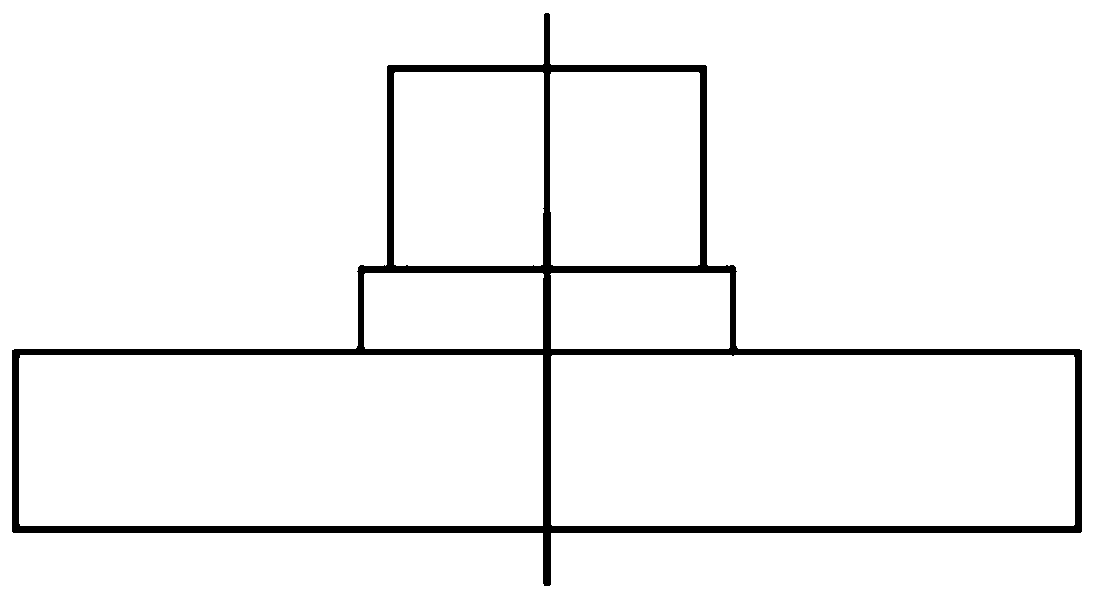

[0075] Wherein, the center of the main shaft 1 is provided with a main shaft through hole 6 along the axial direction. The outer diameter of the gear 2 is the same as that of the main shaft 1 . The outer surface of the top of the main shaft 1 is uniformly provided with a plurality of tooth grooves 7 along the circumferential direction, forming the gear 2 . The thickness of the rib 5 is smaller than the height of the blade 4 . The bottom surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com