Cold metal transition welding repairing method for wear or breakage of jet nozzle of universal pitot tube pump

A technology of cold metal transition and pitot tube pump, which is applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of nozzle failure, large eccentric vibration of rotating shell, and pitot tube pump damage, etc., and achieves short time consumption. , the effect of short repair time and high automation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

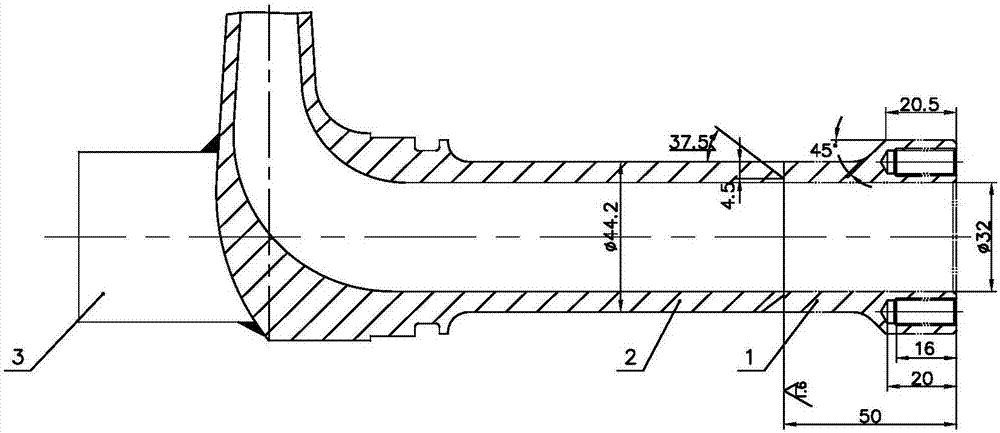

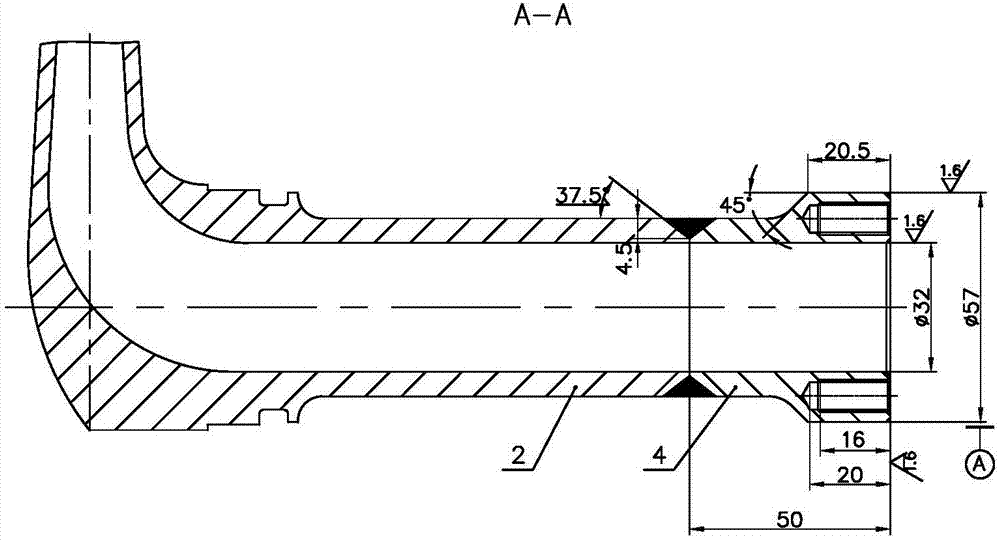

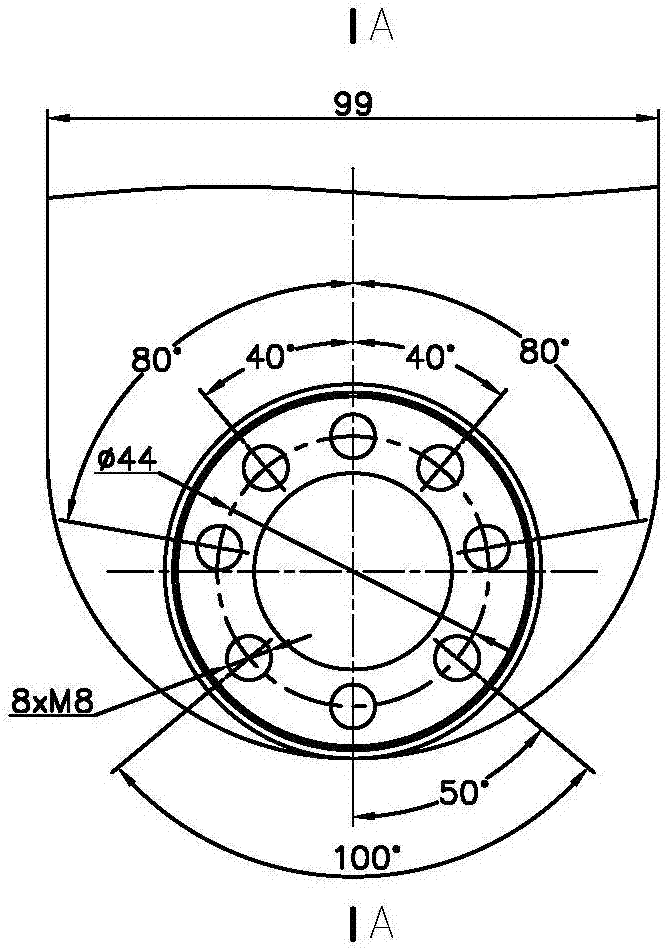

[0035] Such as Figure 1-Figure 3 As shown, in this embodiment, the general-purpose pitot tube pump nozzle wear or fracture cold metal transition welding repair method includes the following steps:

[0036] (1) According to the damage degree of the pitot tube nozzle, determine the repair plan of the nozzle.

[0037] (2) Find the machining reference (center) for the worn sealing ring, and make the tooling.

[0038] (3) if figure 1 As shown, one end of the Pitot tube nozzle body 2 is the damaged Pitot tube nozzle output end 1, and the other end of the Pitot tube nozzle body 2 is the subsequent processing tooling 3, which removes the damaged Pitot tube nozzle output end 1 and processes the welding groove;

[0039] (4) Make a new nozzle output end blank according to the survey drawing;

[0040] (5) Cooperate the output end of the new nozzle with the original shaft;

[0041] (6) if figure 2 As shown, one end of the pitot tube nozzle body 2 is welded to the nozzle output end 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com