Environment-friendly and energy-saving protective agent for coating surface of positive unformed plate and coating production method employing environment-friendly and energy-saving protective agent

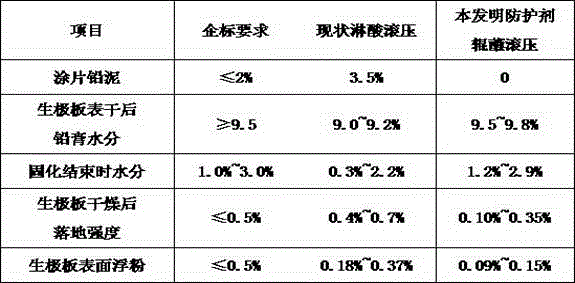

A technology of surface protective agent and production method, applied in lead-acid battery electrodes and other directions, can solve the problems of inability to fully utilize, high surface dry temperature, secondary pollution manufacturing cost, etc., so as to suppress the generation of surface cracks and surface floating powder. , The effect of inhibiting surface floating powder and reducing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] According to the percentage by weight, the particles are 0.5% of nano-fumed silica of 7-40 nm, 0.3% of 60% polytetrafluoroethylene emulsion, 0.6% of carboxymethyl cellulose, 0.4% of carboxy cellulose, and 2.5-3.5mm length polyester Fiber 0.20%, concentrated sulfuric acid 25%, distilled water 73%.

[0048] Production steps:

[0049] (1) Using a high-speed shear separation mixer, add nano fumed silica to distilled water, and stir continuously for 30 to 60 minutes to prepare a 20% nano fumed silica mother liquor; add distilled water to concentrated sulfuric acid, and fully stir to prepare it at 25°C Density 1.40g / cm 3 dilute sulfuric acid solution;

[0050](2) In the speed-adjustable mixer, according to the proportion of the components, add the remaining distilled water, 60% polytetrafluoroethylene emulsion, carboxymethyl cellulose, carboxy cellulose, polyester fiber for initial stirring, and the stirring speed is 100 Turn / min, stirring time 10min; after stirring, dilut...

Embodiment 2

[0053] 0.8% by weight of nano fumed silica, 0.1% of 60% polytetrafluoroethylene emulsion, 1.5% of carboxymethyl cellulose, 0.2% of carboxy cellulose, 0.05% of polyester fiber, 41% of concentrated sulfuric acid, 56.35% of distilled water .

[0054] Production steps:

[0055] (1) Using a high-speed shear separation mixer, add nano fumed silica to distilled water, and stir continuously for 30 to 60 minutes to prepare a 20% nano fumed silica mother liquor; add distilled water to concentrated sulfuric acid, and fully stir to prepare it at 25°C Density 1.40g / cm 3 dilute sulfuric acid solution;

[0056] (2) In the speed-adjustable mixer, according to the proportion of the components, add the remaining distilled water, 60% polytetrafluoroethylene emulsion, carboxymethyl cellulose, carboxy cellulose, polyester fiber for initial stirring, and the stirring speed is 200 rpm, stirring time 8min; after stirring, dilute sulfuric acid solution and nano fumed silica mother liquor were added...

Embodiment 3

[0059] Take 1.2% of nano fumed silica, 0.2% of 60% polytetrafluoroethylene emulsion, 1% of carboxymethyl cellulose, 0.3% of carboxy cellulose, 0.10% of polyester fiber, 30% of concentrated sulfuric acid, and 67.2% of distilled water by weight percentage .

[0060] Production steps:

[0061] (1) Using a high-speed shear separation mixer, add nano fumed silica to distilled water, and stir continuously for 30 to 60 minutes to prepare a 20% nano fumed silica mother liquor; add distilled water to concentrated sulfuric acid, and fully stir to prepare it at 25°C Density 1.40g / cm 3 dilute sulfuric acid solution;

[0062] (2) In the speed-adjustable mixer, according to the proportion of the components, add the remaining distilled water, 60% polytetrafluoroethylene emulsion, carboxymethyl cellulose, carboxy cellulose, polyester fiber for initial stirring, and the stirring speed is 300 RPM, stirring time 5min; after stirring, add dilute sulfuric acid solution and nano fumed silica mot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com