Manufacturing method of optical glass

A technology of optical glass and manufacturing method, which is applied in the direction of glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., which can solve the problems of easy safety accidents, lower product input-output ratio, and difficult operation, so as to reduce the labor intensity , Improve the input-output rate and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] The method of the present invention is used to produce 5 tons of optical glass with the same composition as the comparative example.

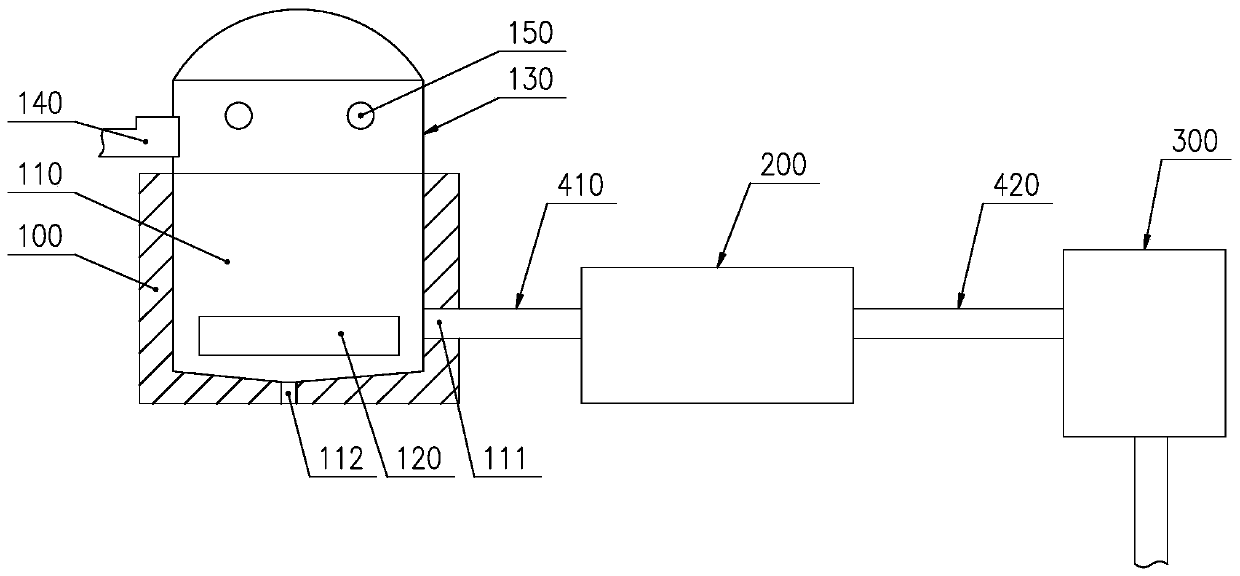

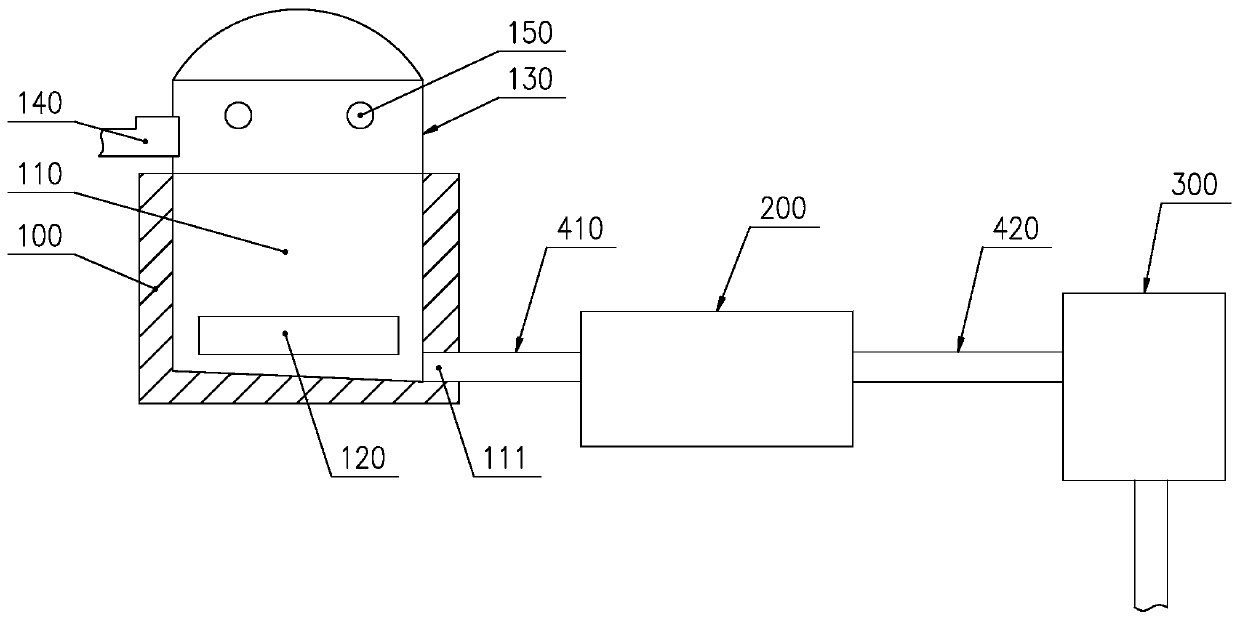

[0065] Choose figure 2 The optical glass manufacturing device shown is manufactured; the bottom surface of the melting chamber 110 of the melting pool 100 is an inclined surface, and the lower edge of the melting outlet 111 of the melting pool 100 is not higher than the inclined lower end of the bottom surface of the melting chamber 110.

[0066] The manufacturing process is as follows: 1) The glass material is continuously or intermittently poured into the melting chamber 110 from the feeding part 140, and the glass material is first burned in the atmosphere by the flame sprayed from the burner of the burner 150 and then melted into molten glass and flows into the melting chamber 110 , Then control the heating electrode 120 to heat the molten glass to keep the temperature of the molten glass at 1180°C to 1300°C; 2) send the molten glass to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com