Patents

Literature

35results about How to "Simple and flexible process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

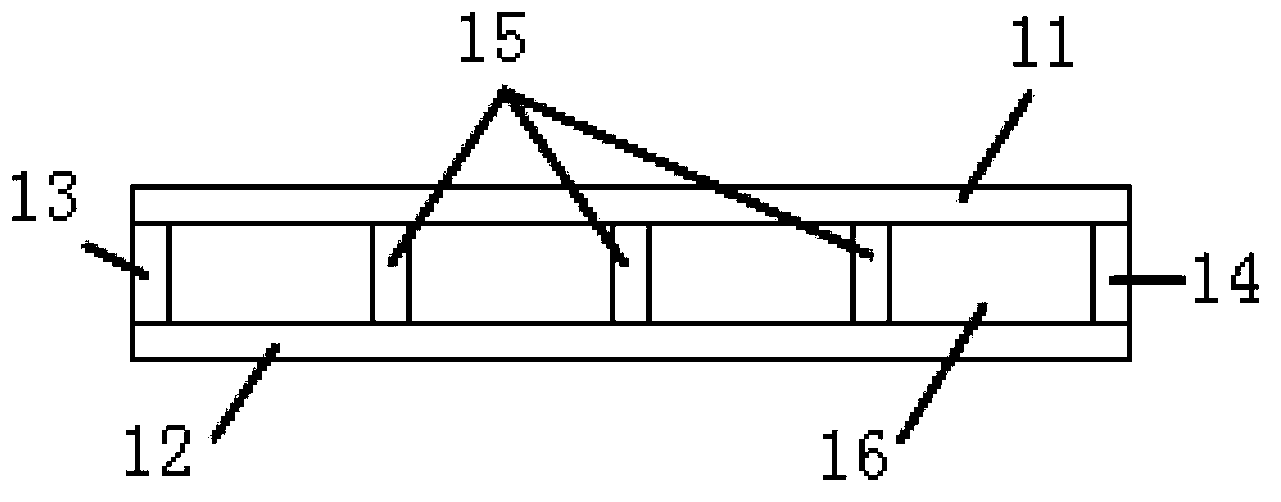

Ceramic flat membrane supporting body and production method thereof

ActiveCN103381338AImprove filtration efficiencyGuaranteed mechanical strengthSemi-permeable membranesSurface layerSlurry

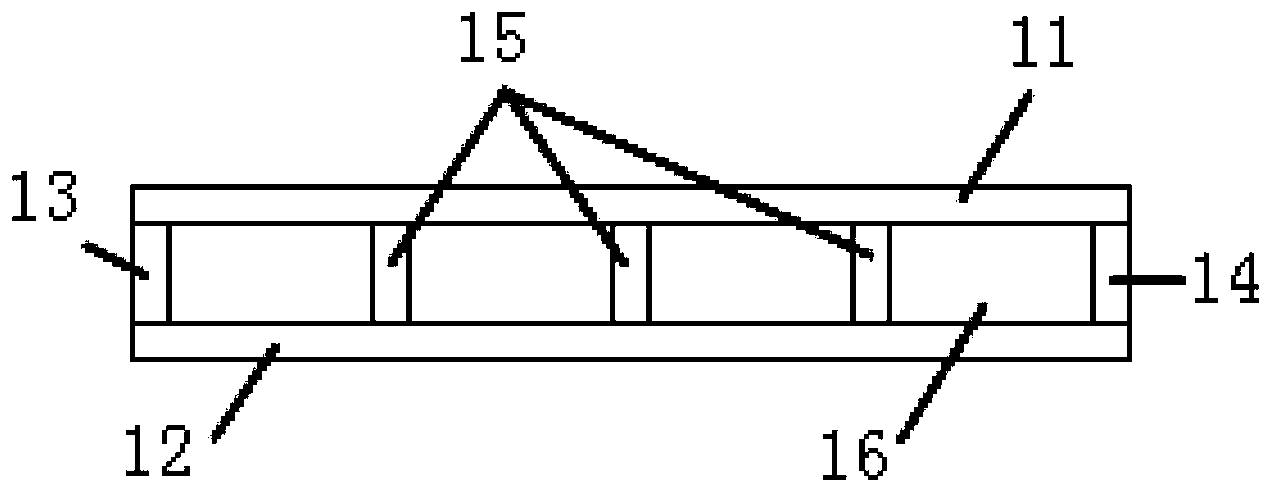

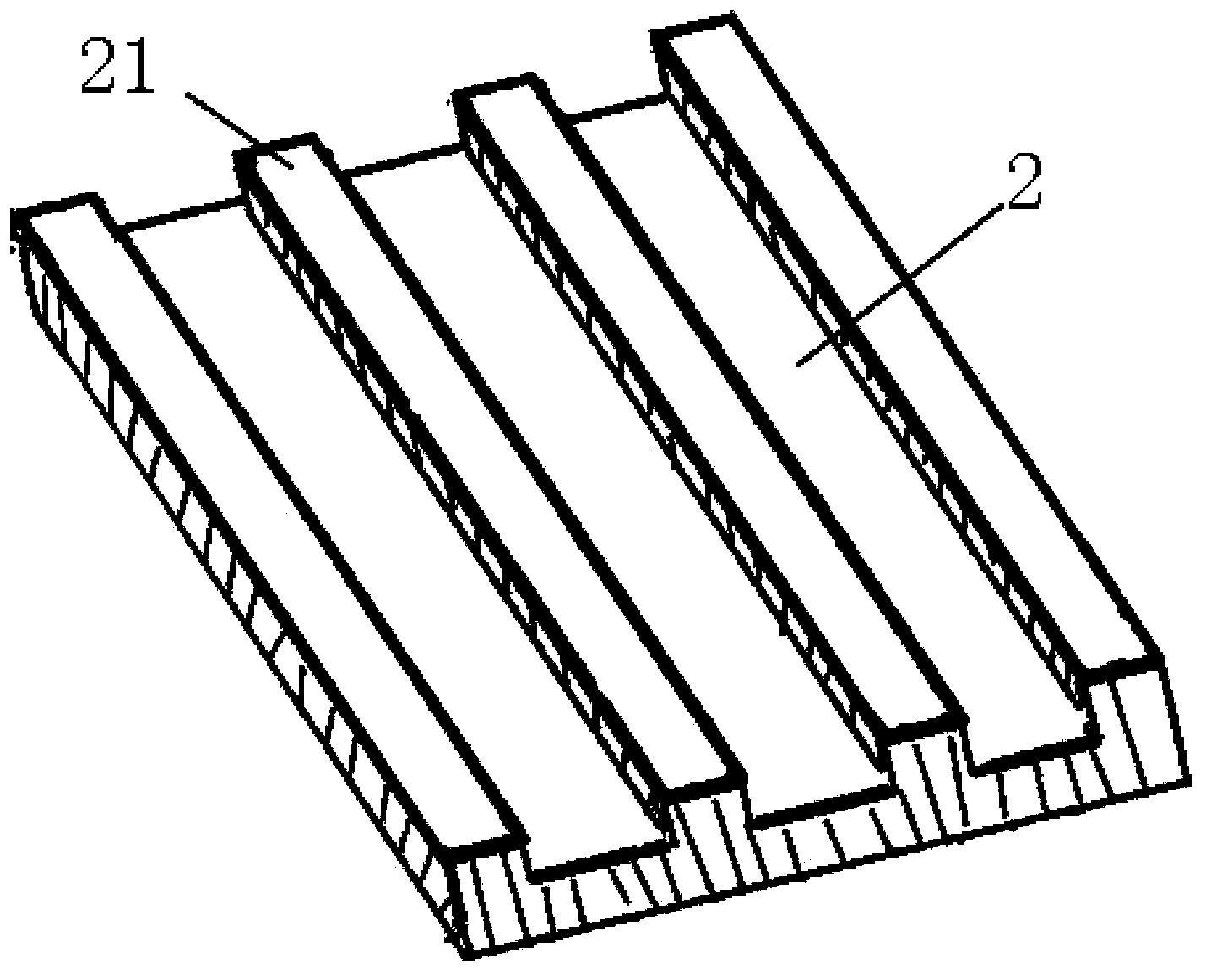

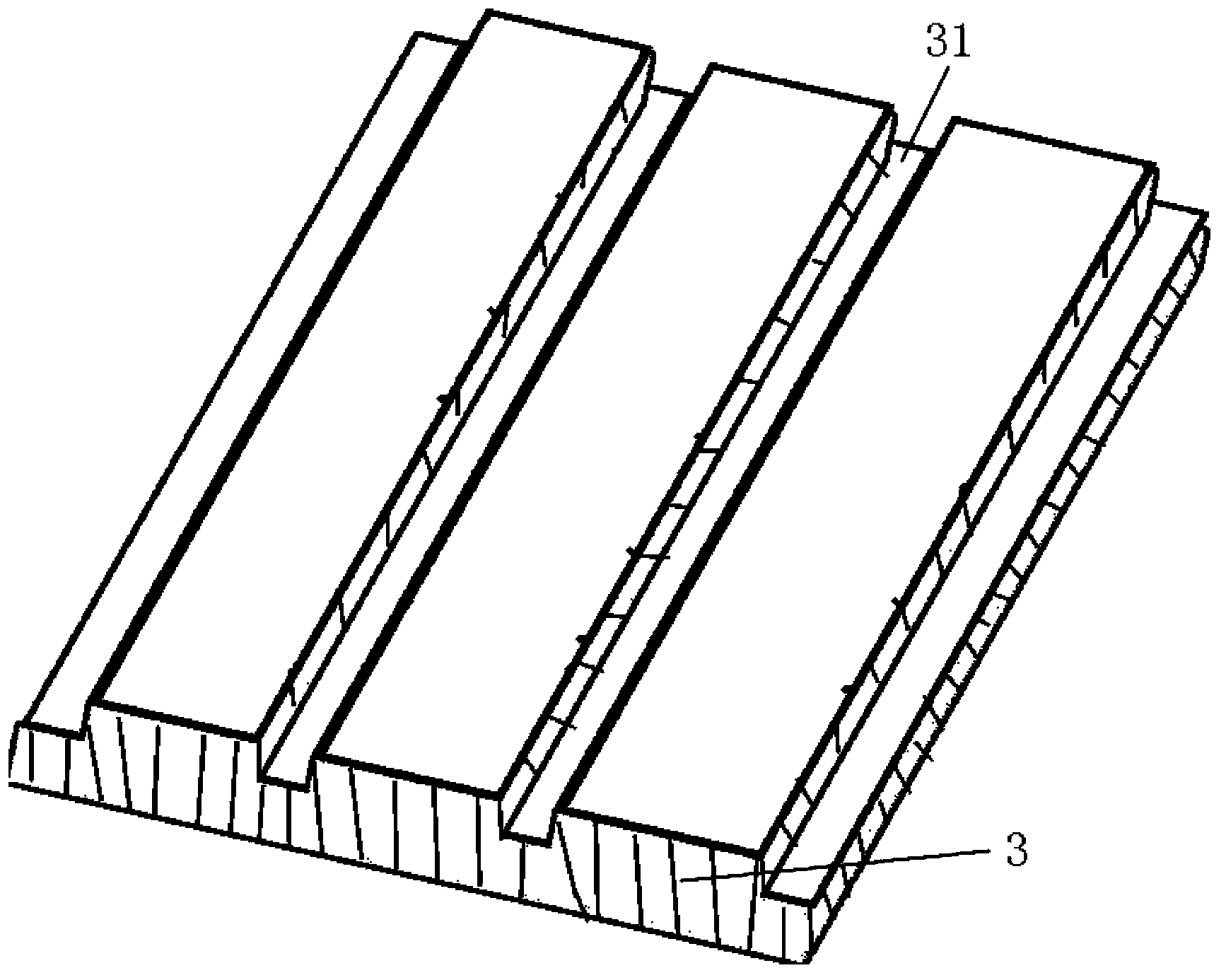

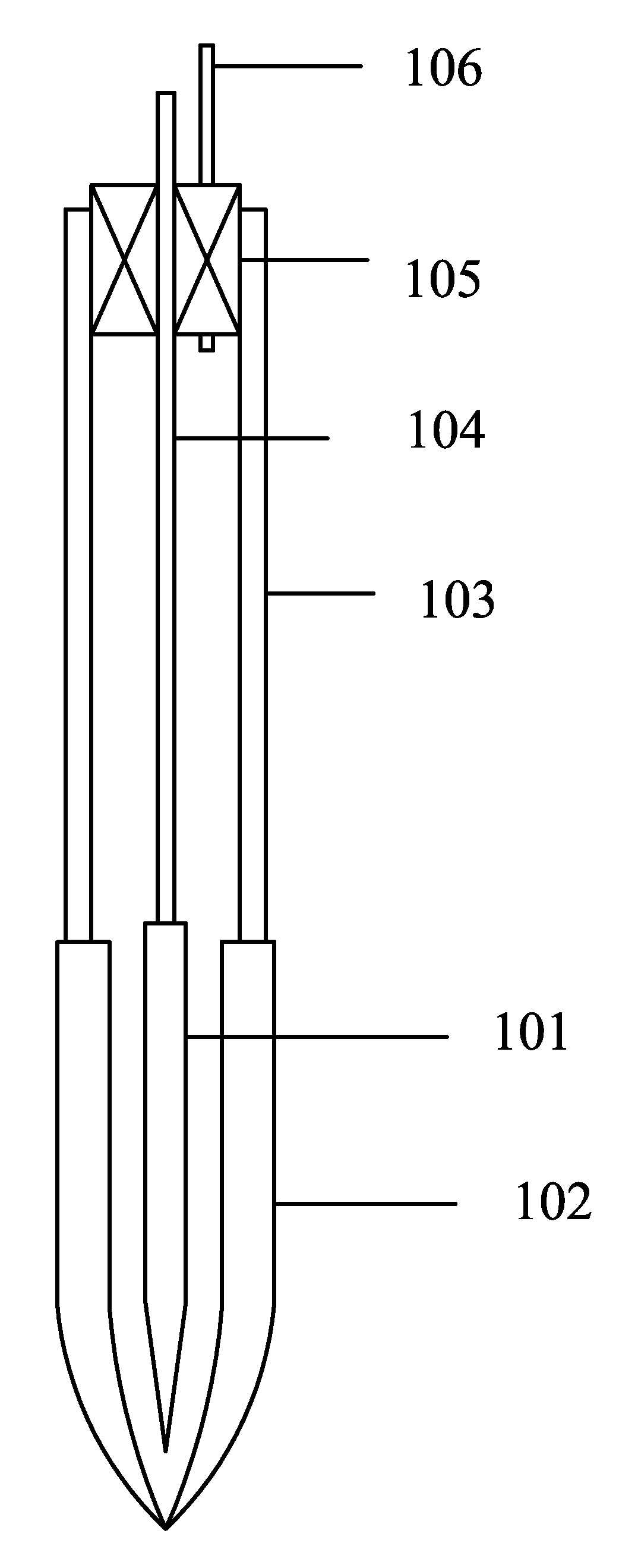

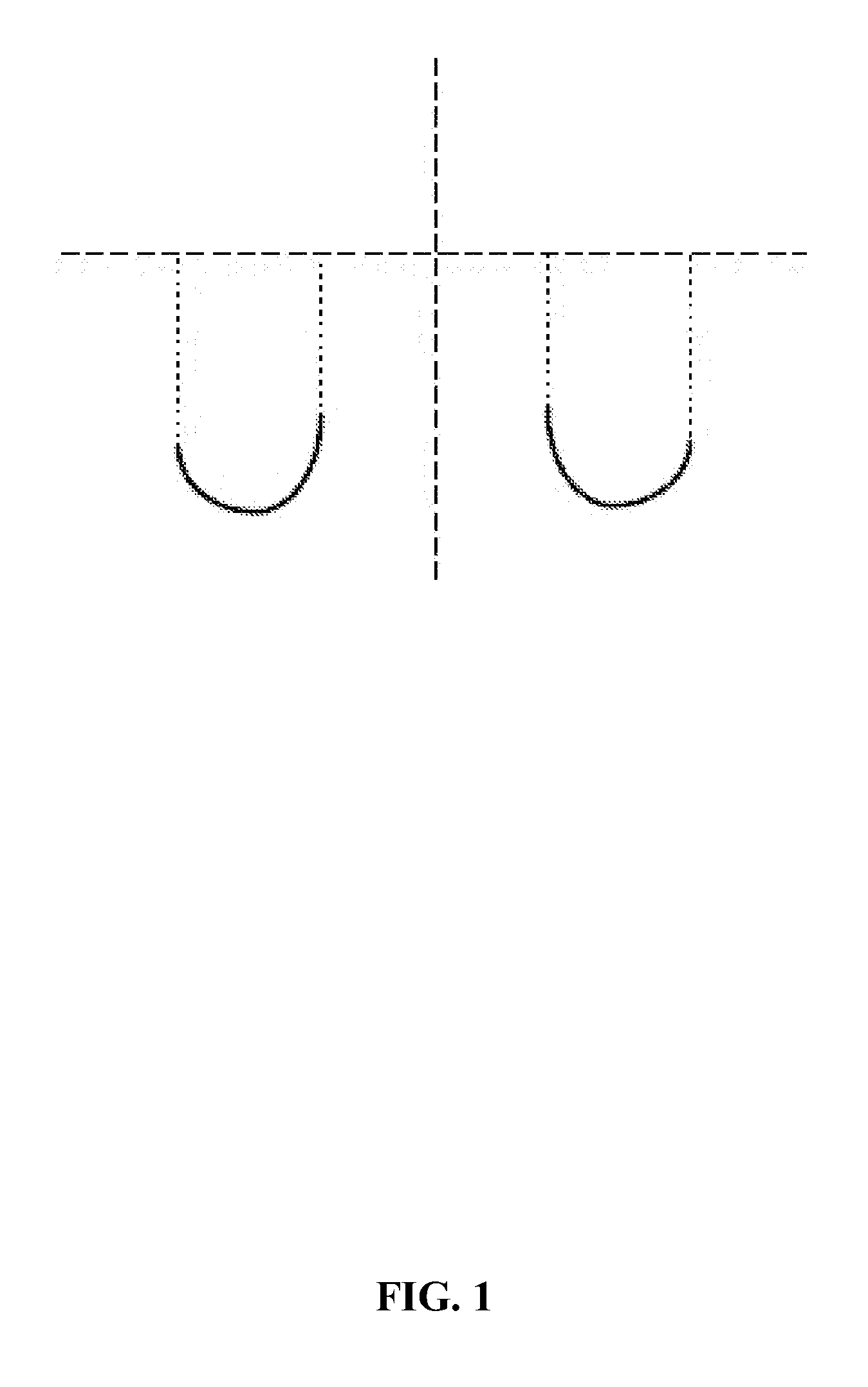

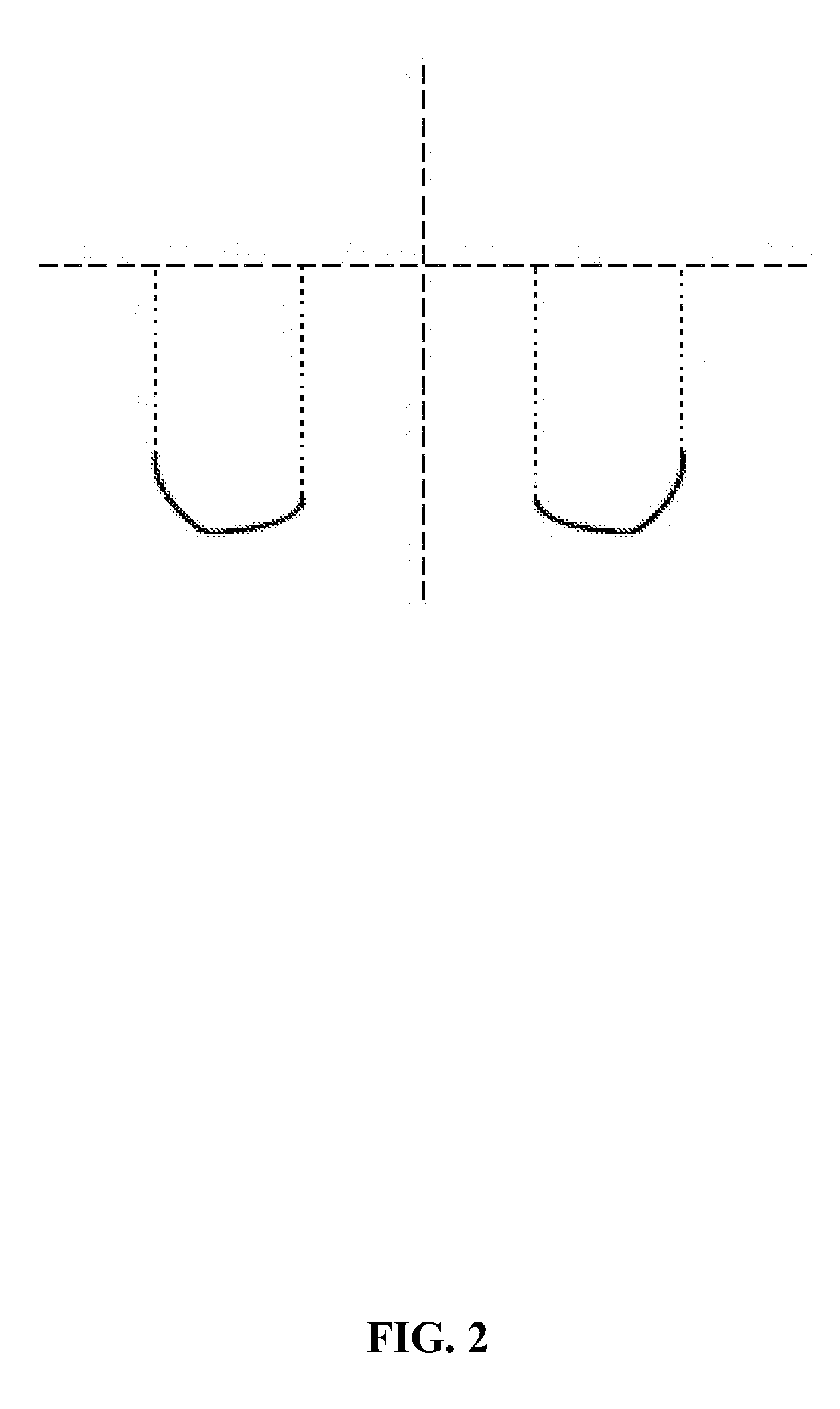

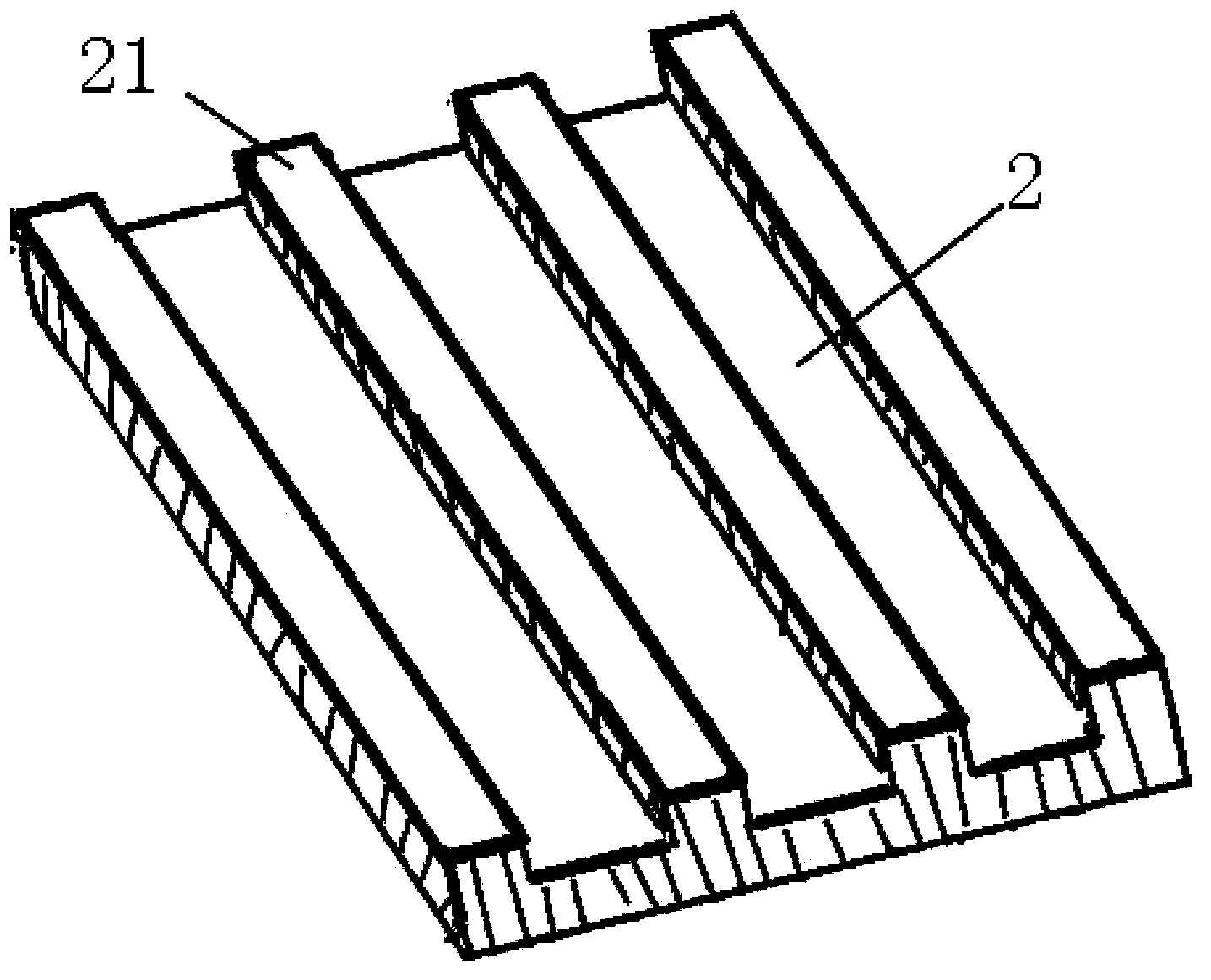

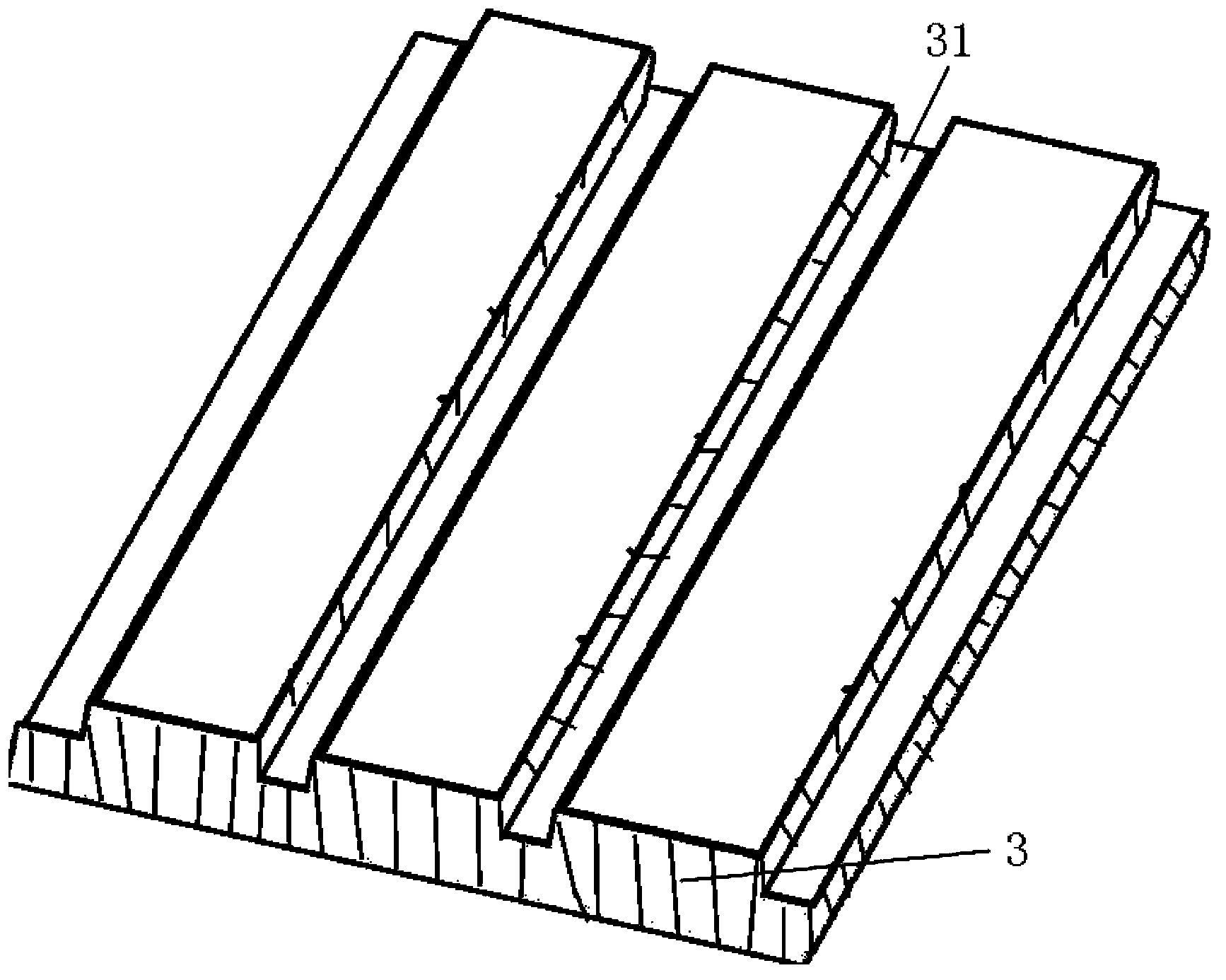

The invention discloses a ceramic flat membrane supporting body and a production method thereof. The ceramic flat membrane supporting body is formed by two layers of flat membranes, the left lateral wall, the right lateral wall and at least a supporting column; the two layers of flat membranes, the left lateral wall and the right lateral wall form into a flat-pipe-shaped structure; the supporting column is arranged between the two layers of flat membranes; the flat membranes which are in asymmetric structures comprise surface layers of sponge hole structures and internal layers of finger-shaped hole structures; separation selectivity, permeation flux and mechanical strength of the flat membranes are high. The production method of the ceramic flat membrane supporting body comprises preparing slurry, producing dies through a phase inversion method, forming through a die pressing method and sintering. The production technology is easy and flexible, the costs are low, the dies are cheap, the replacing is convenient, a plurality of assemblies in different sizes can be formed at one time, and the production efficiency is high.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

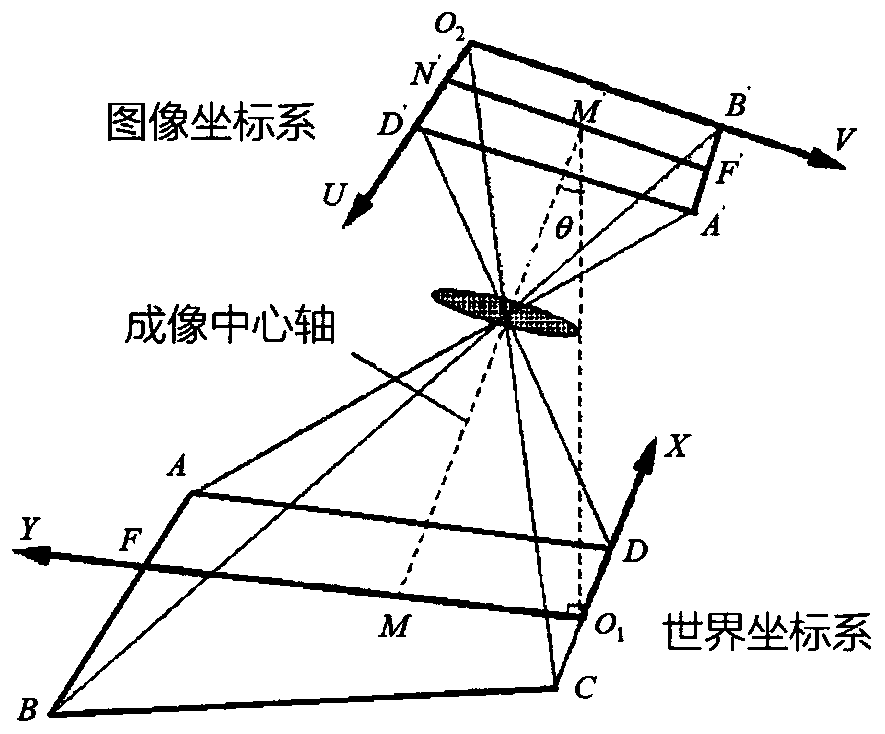

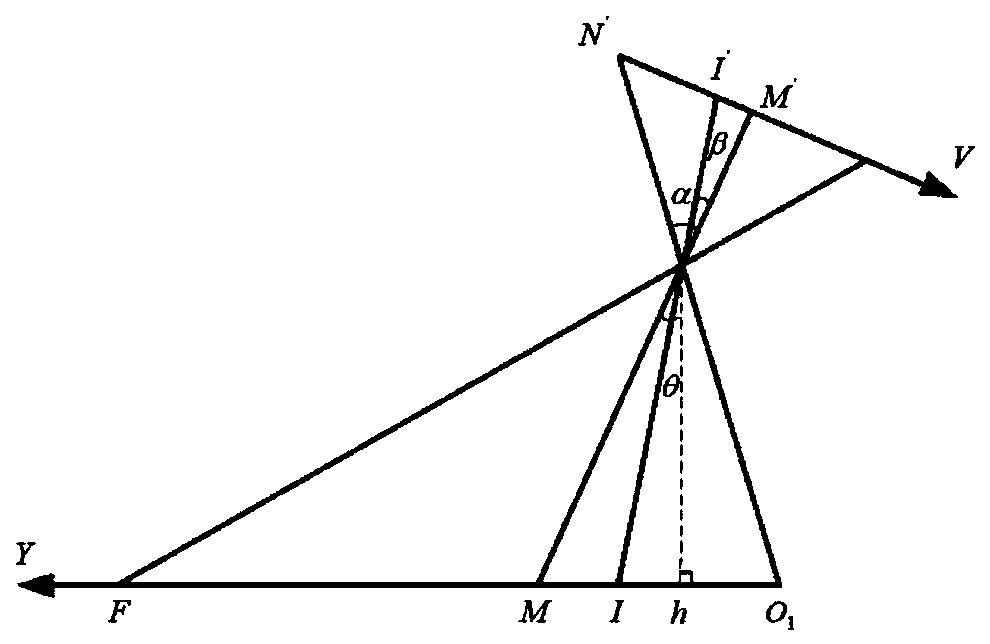

Automatic driving environment perception-oriented small sample in-loop learning system and method

ActiveCN110070139AIncrease the depth of informationImprove perceptionCharacter and pattern recognitionMachine learningSmall sampleAlgorithm

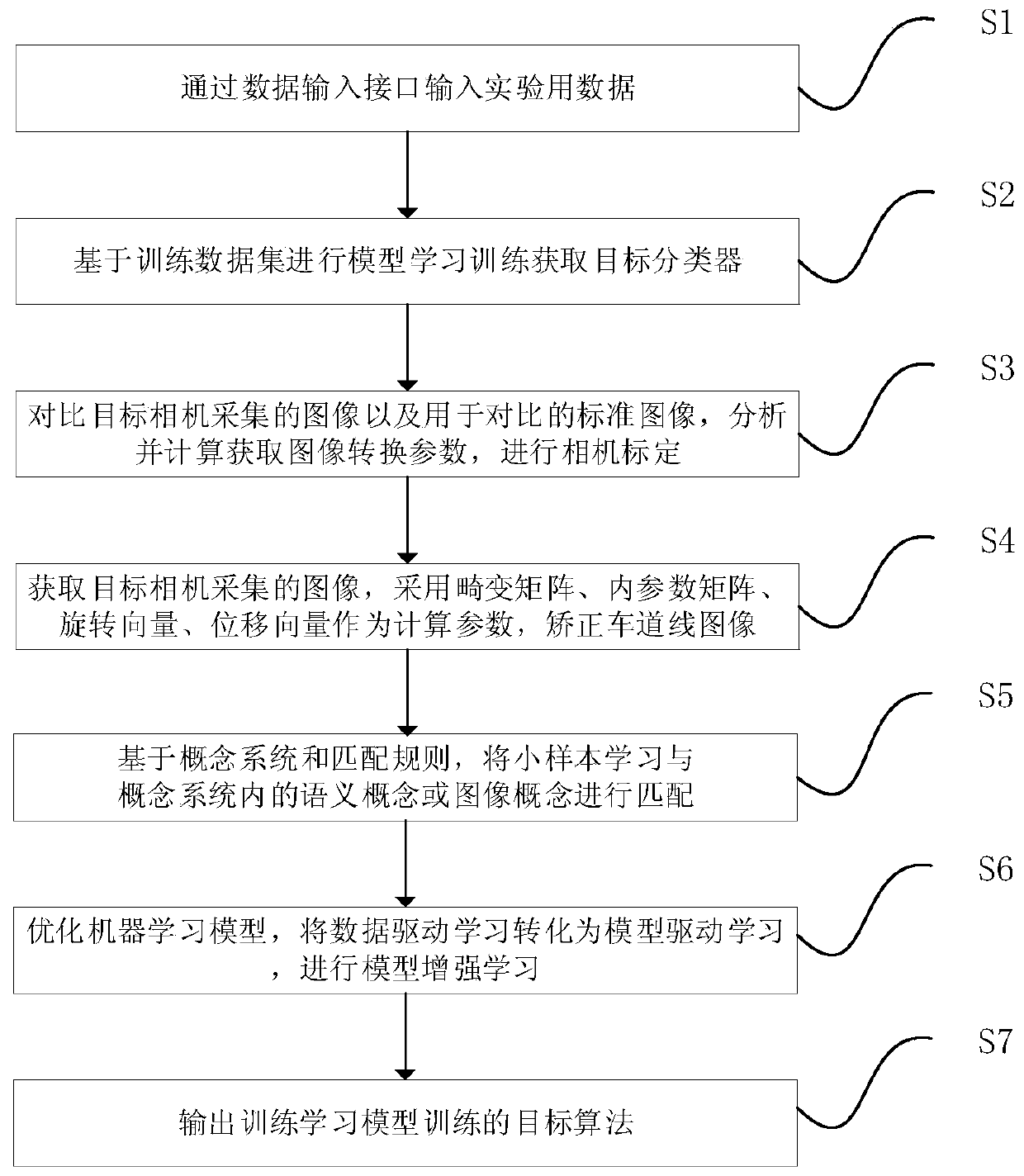

The invention relates to an automatic driving environment perception-oriented small sample in-loop learning system and method. Algorithm training is carried out on a target learning model based on a data training set to obtain a target detection algorithm; small sample training set training learning is carried out on the physical ECU module, and a target perception algorithm is obtained; target algorithm testing of the system is carried out through the obtained target perception algorithm. The system comprises a sample input module, an image acquisition module, an image display module, a physical ECU module and a result output module. According to the automatic driving environment perception-oriented small sample in-loop learning system and method, learning method based on small-scale datais provided, the arranged in-loop experiment simulation platform is matched with simulation software to solve the problem that large-scale data are difficult to obtain in real vehicle automatic driving environment perception algorithm development; the scene self-definition function is achieved, a large number of scene data which are difficult to achieve in actual situations are generated throughsimulation, and the experiment development safety is improved.

Owner:JILIN UNIV

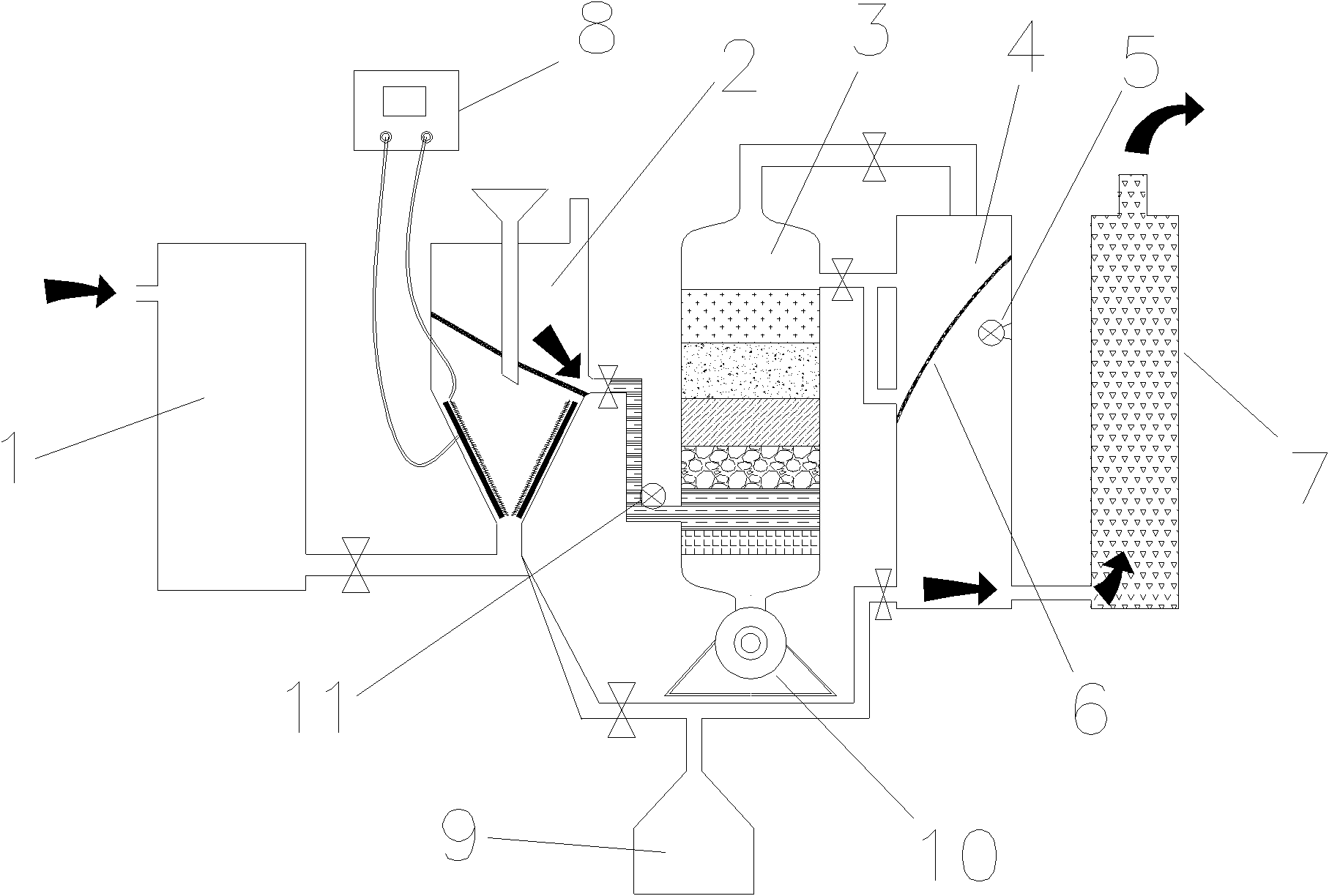

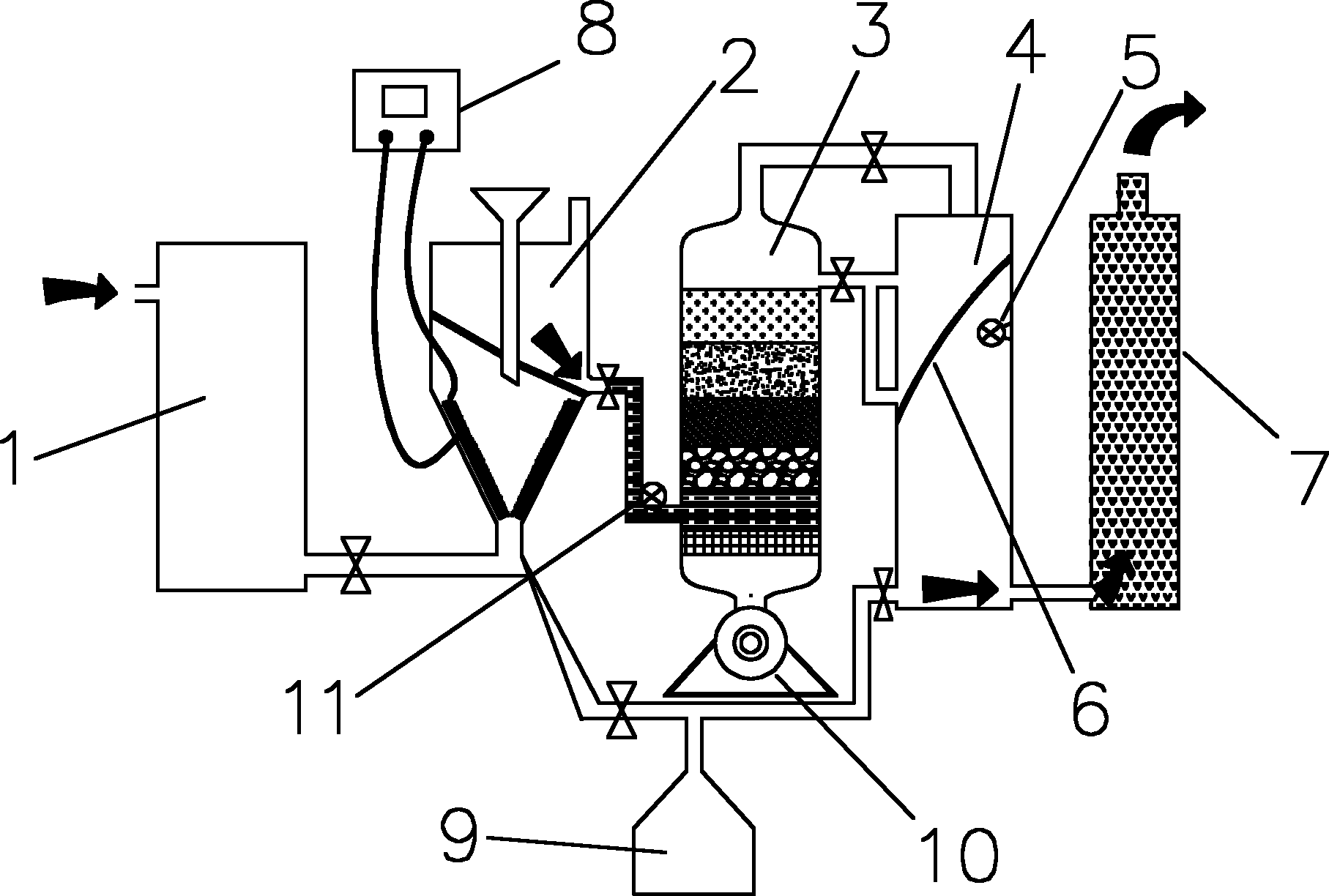

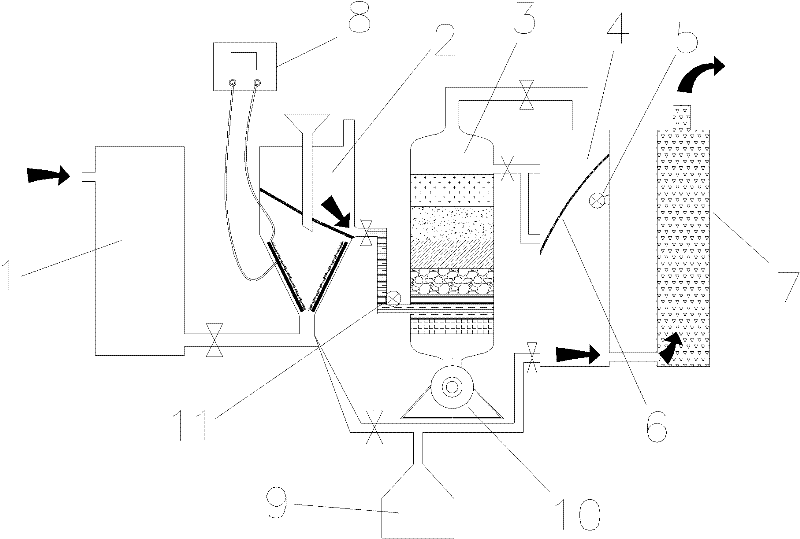

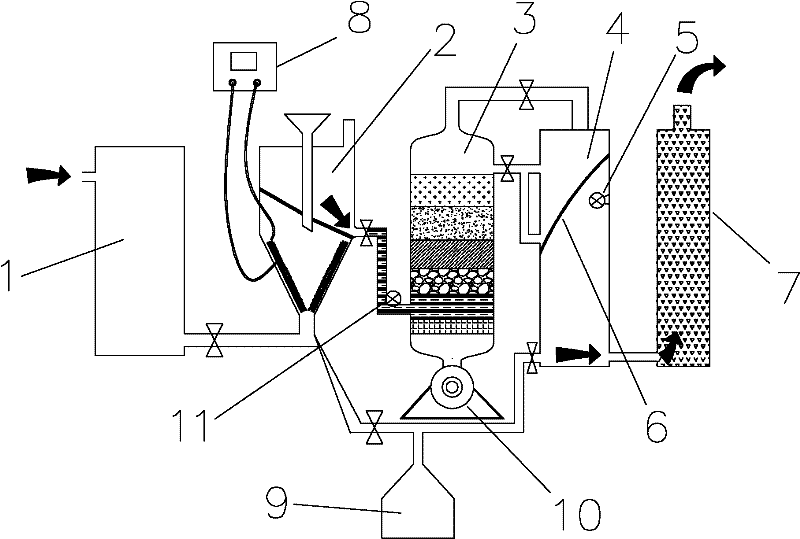

Device and method for processing restaurant wastewater

ActiveCN102145967AIncrease dissolved oxygenImprove the efficiency of degrading pollutantsMultistage water/sewage treatmentActivated sludgeElectrolysis

The invention discloses a device and a method for processing restaurant wastewater. A ferrallitic sheet is used as an anode and a graphite sheet is used as a cathode to carry out pulse direct current electrolysis on the restaurant wastewater so as to cause an electrocoagulation reaction; simultaneously ultrafine ozone bubbles are fed into an electrocoagulation reaction region to strengthen the electrocoagulation reaction, so that ferrous irons Fe2+ generated in the electrolysis process is rapidly converted into ferric irons Fe3+, the volume of flocculate becomes larger and the flocculate precipitates more efficiently to remove most of pollutants in the wastewater; sludge generated in the electrocoagulation process enters an activated sludge reactor and a sludge concentrating and extruding device; and clear water containing a little amount of organic matter enters an aeration-ozone-ultraviolet combined treatment degradation tank and a photocatalyst micro filtration membrane, and finally outflows through a fine porous sand filtering tank. The produced water can reach the primary standard in the industry. The processing method has high impact-load resistance. The outlet water quality is stable. In the engineering, consumables have long service life. Therefore, the processing cost of the restaurant wastewater can be greatly reduced.

Owner:TAIDEA TECH ZHONGSHAN

Methods for manufacturing optical fiber preform and methods for manufacturing optical fiber

ActiveUS20120324958A1Solve low manufacturing efficiencySmall additional bending lossGlass optical fibreGlass fibre drawing apparatusMicrowaveOxygen

A method for manufacturing an optical fiber preform, including: a) providing a lining tube as a substrate tube, and doping and depositing by a PCVD or an MCVD process; b) in the reacting gas of silicon tetrachloride and oxygen, introducing a fluorine-containing gas for fluorine doping, introducing germanium tetrachioride for germanium doping, ionizing the reacting gas in the lining tube through microwaves to form plasma, depositing the plasma on the inner wall of the lining tube in the form of glass; c) after the completion of deposition, processing the deposited lining tube into a solid core rod by melting contraction through an electric heating furnace; d) sleeving the solid core rod into a pure quartz glass jacketing tube and manufacturing the two into an optical fiber preform; and e) allowing the effective diameter d of the optical fiber preform to become between 95 and 205 mm.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

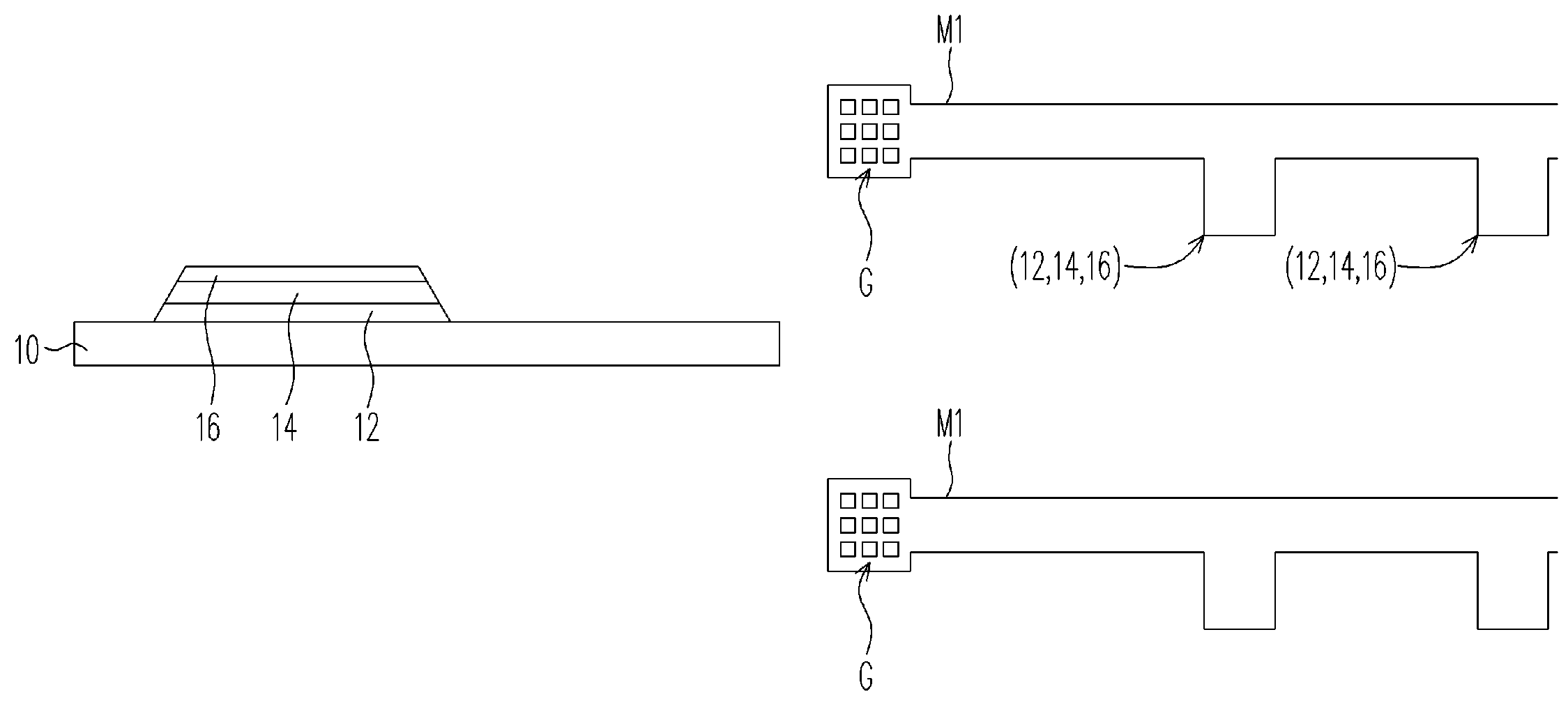

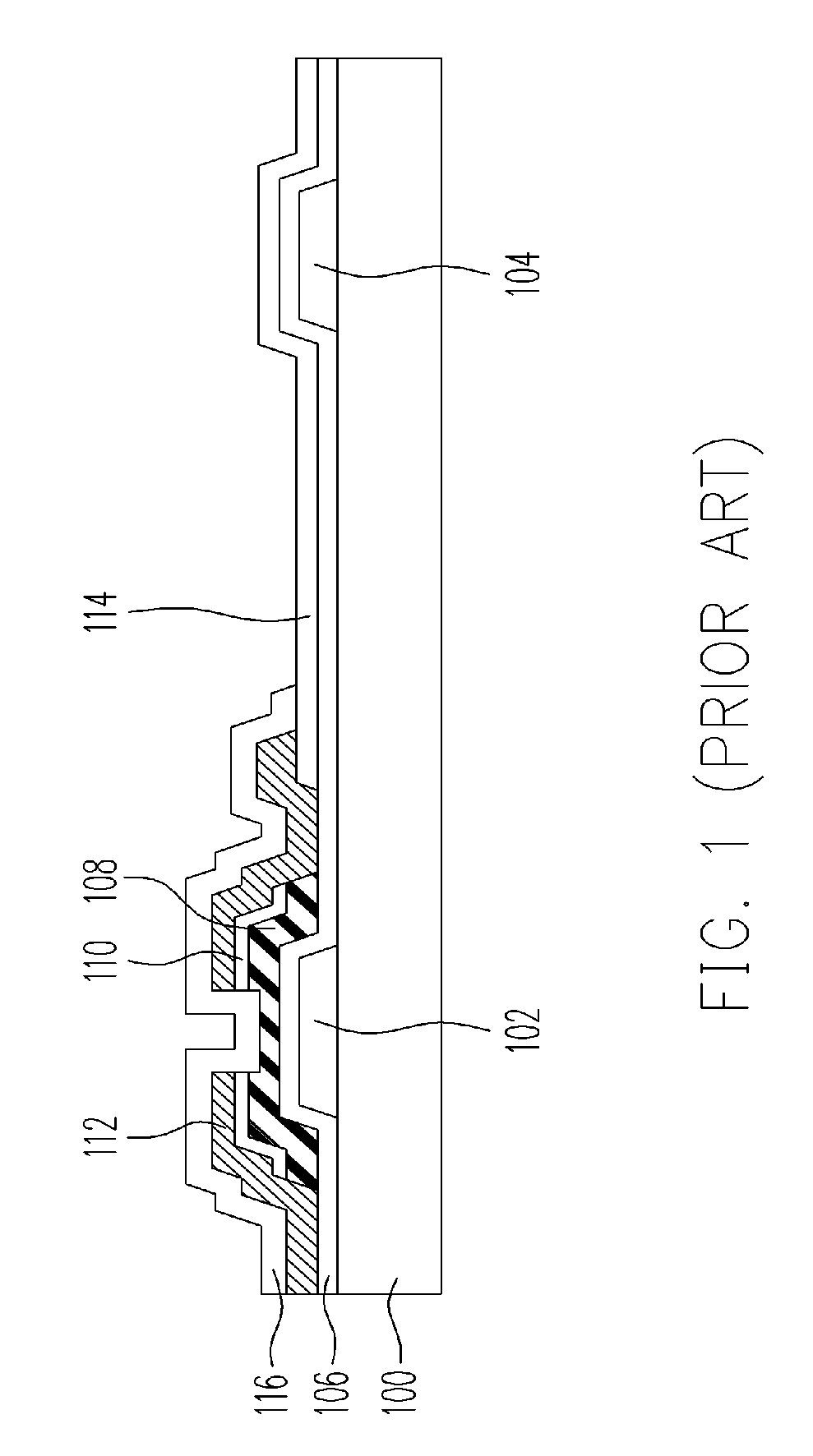

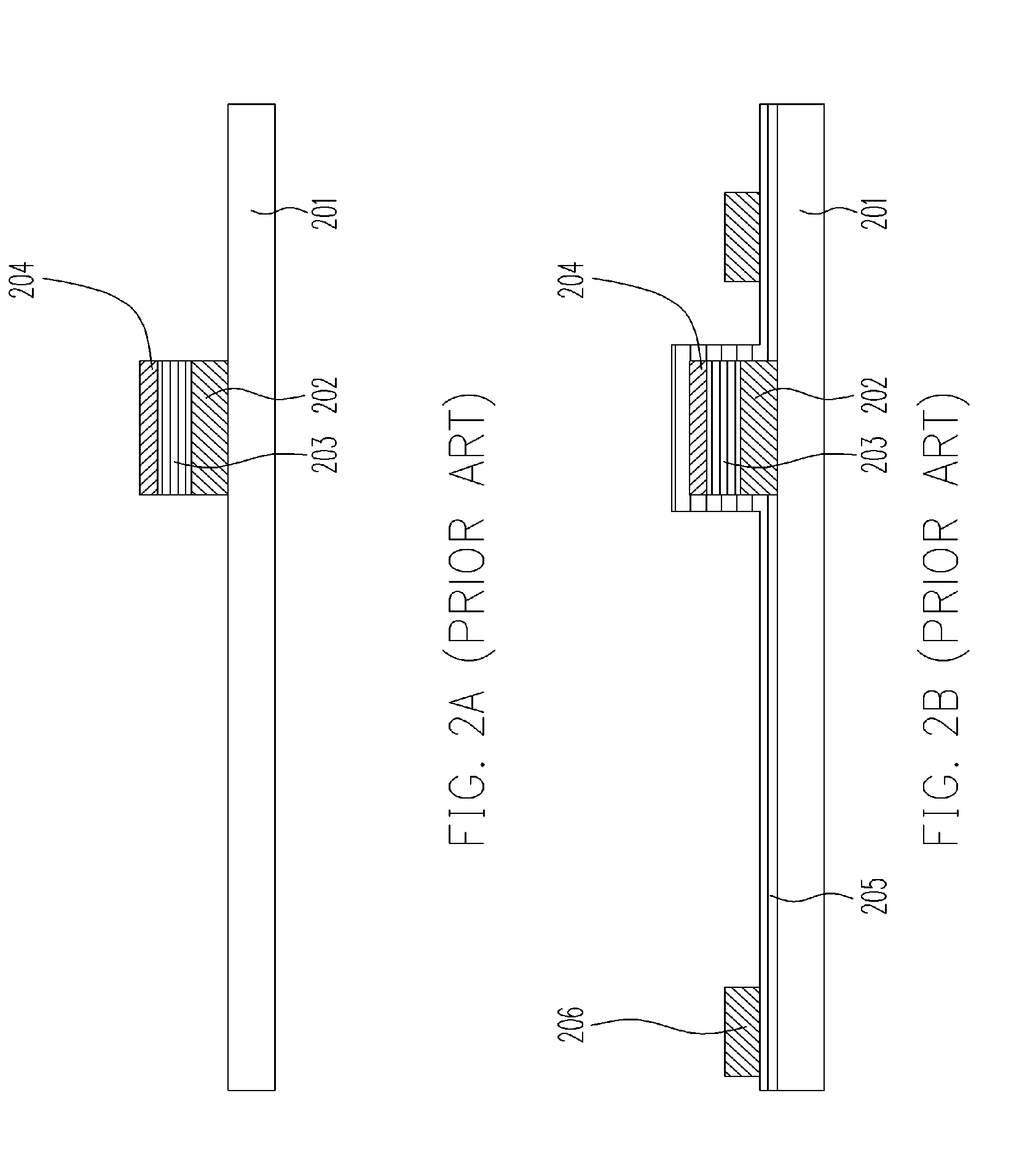

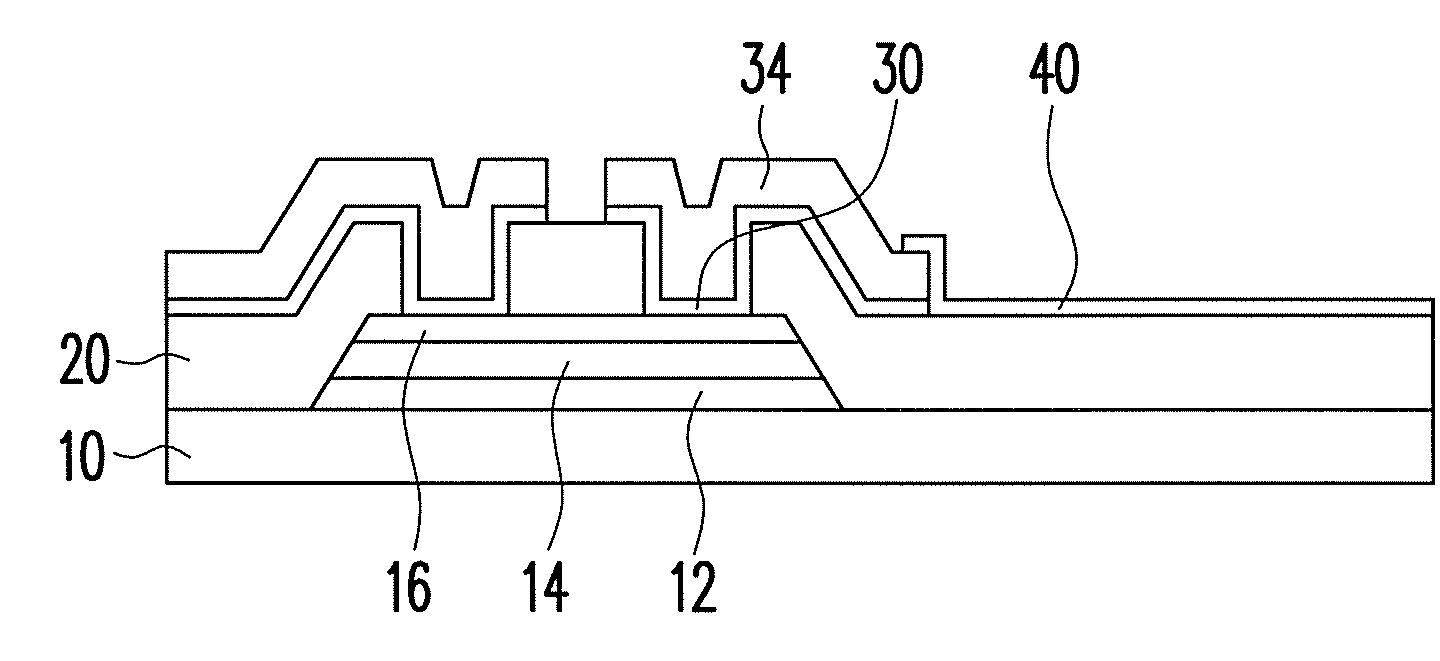

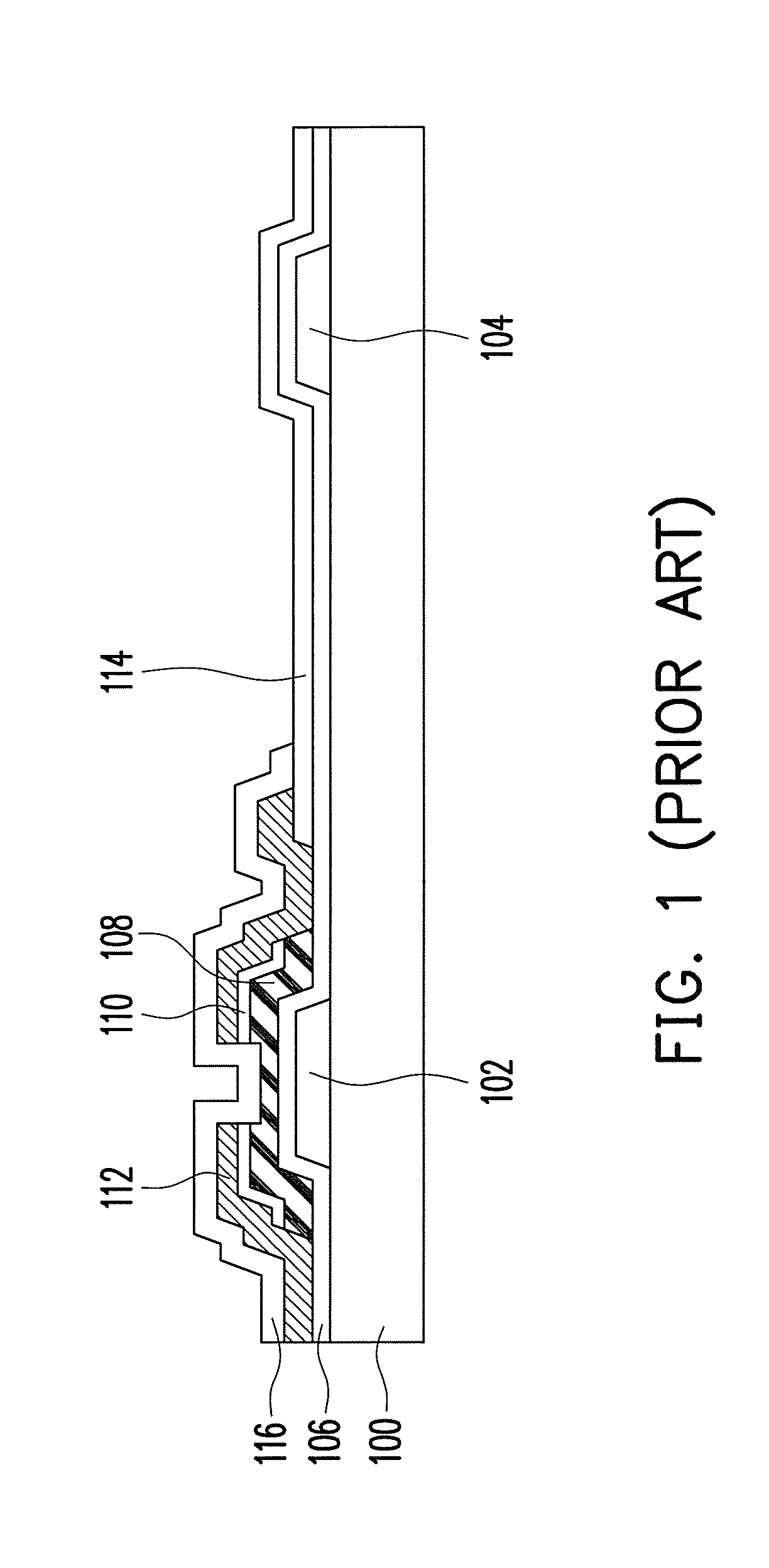

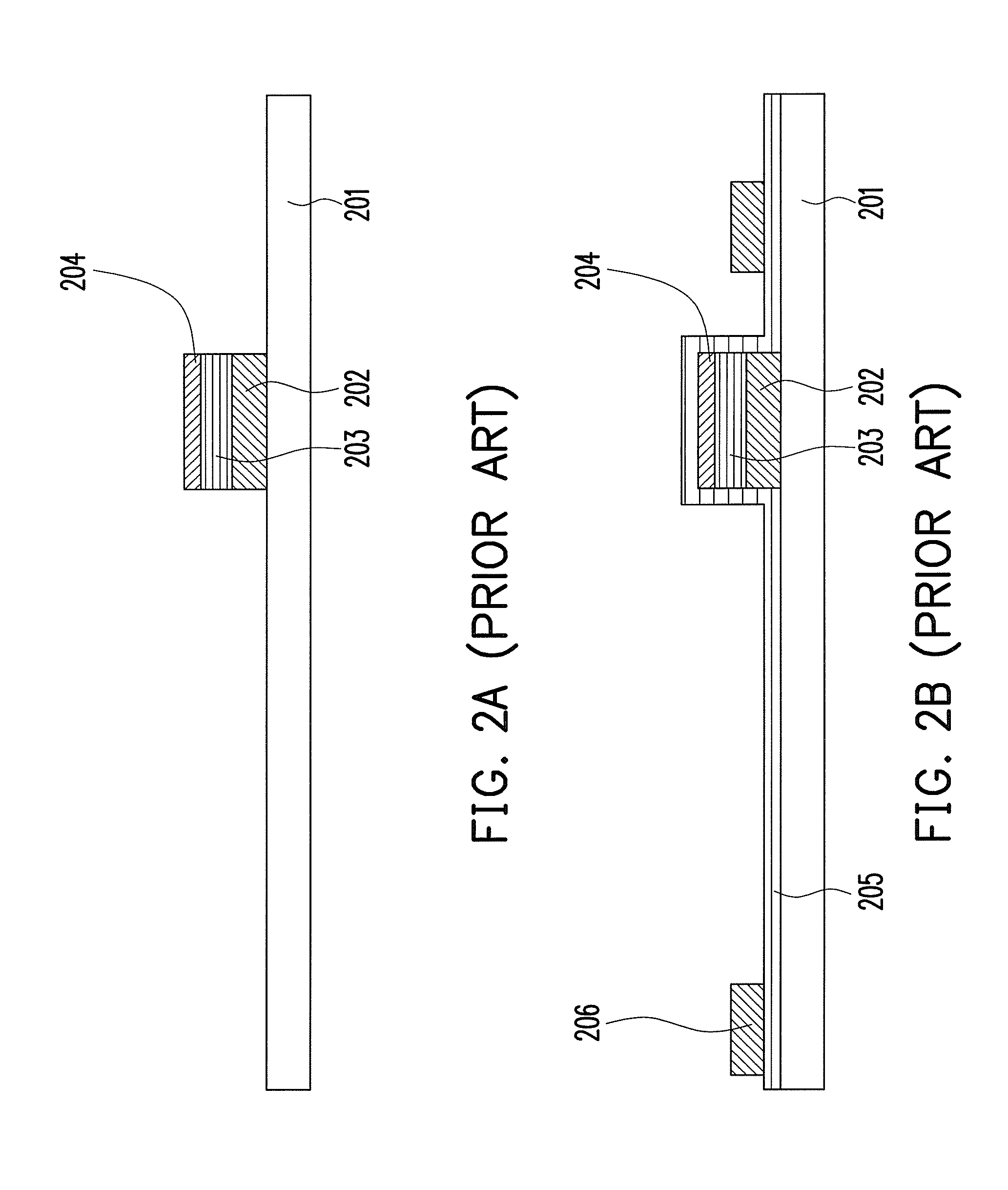

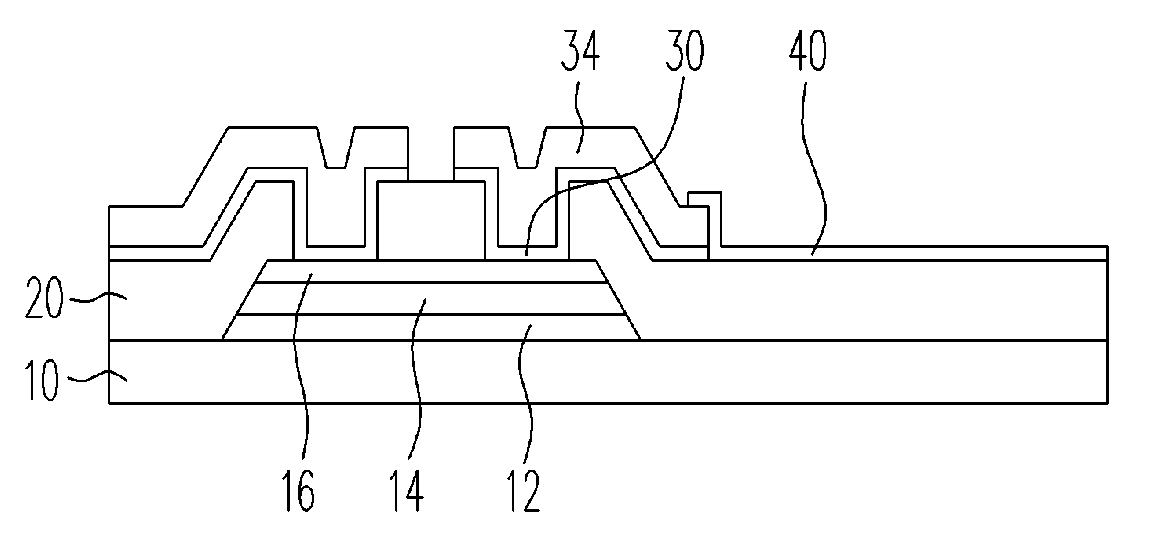

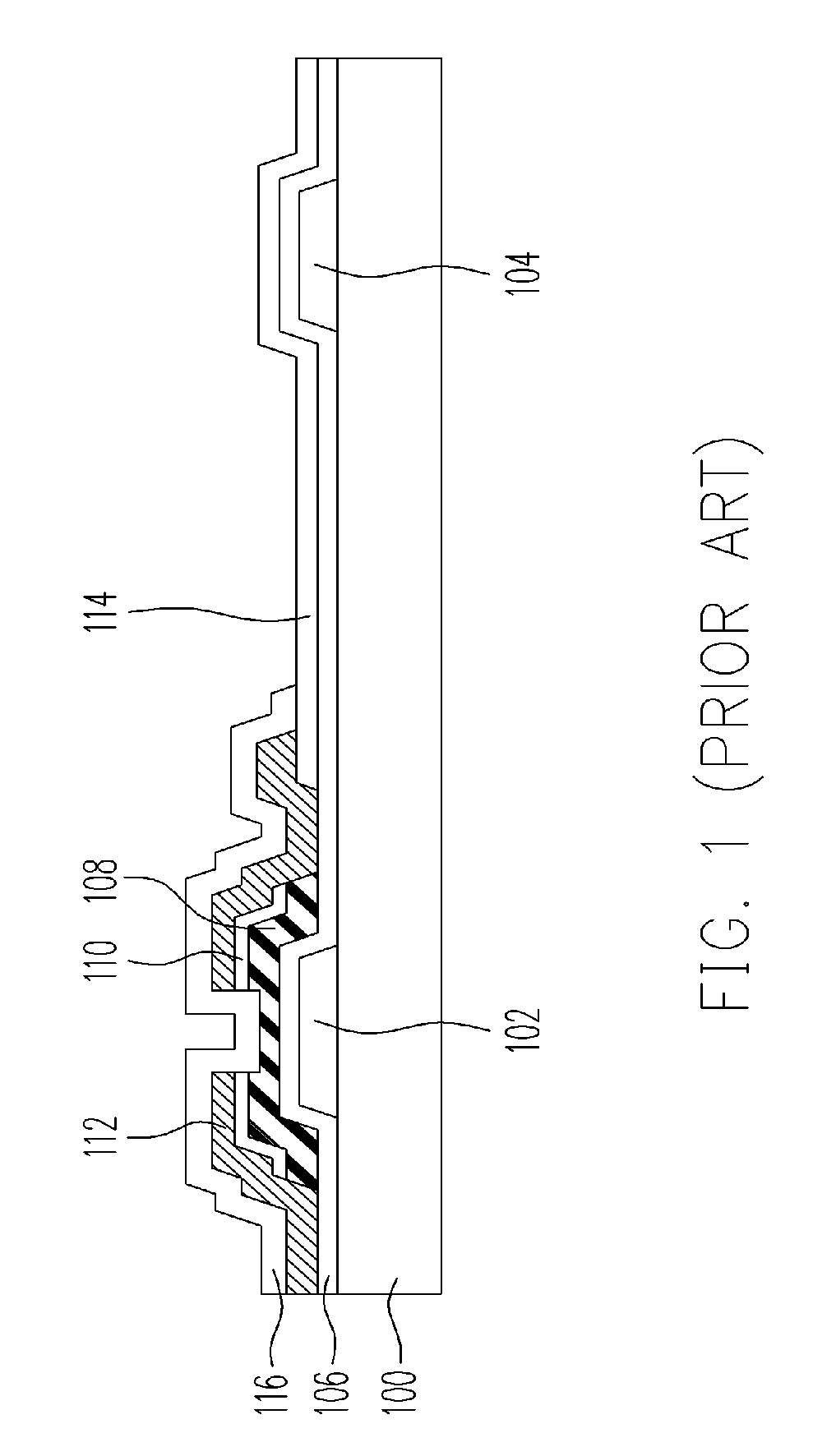

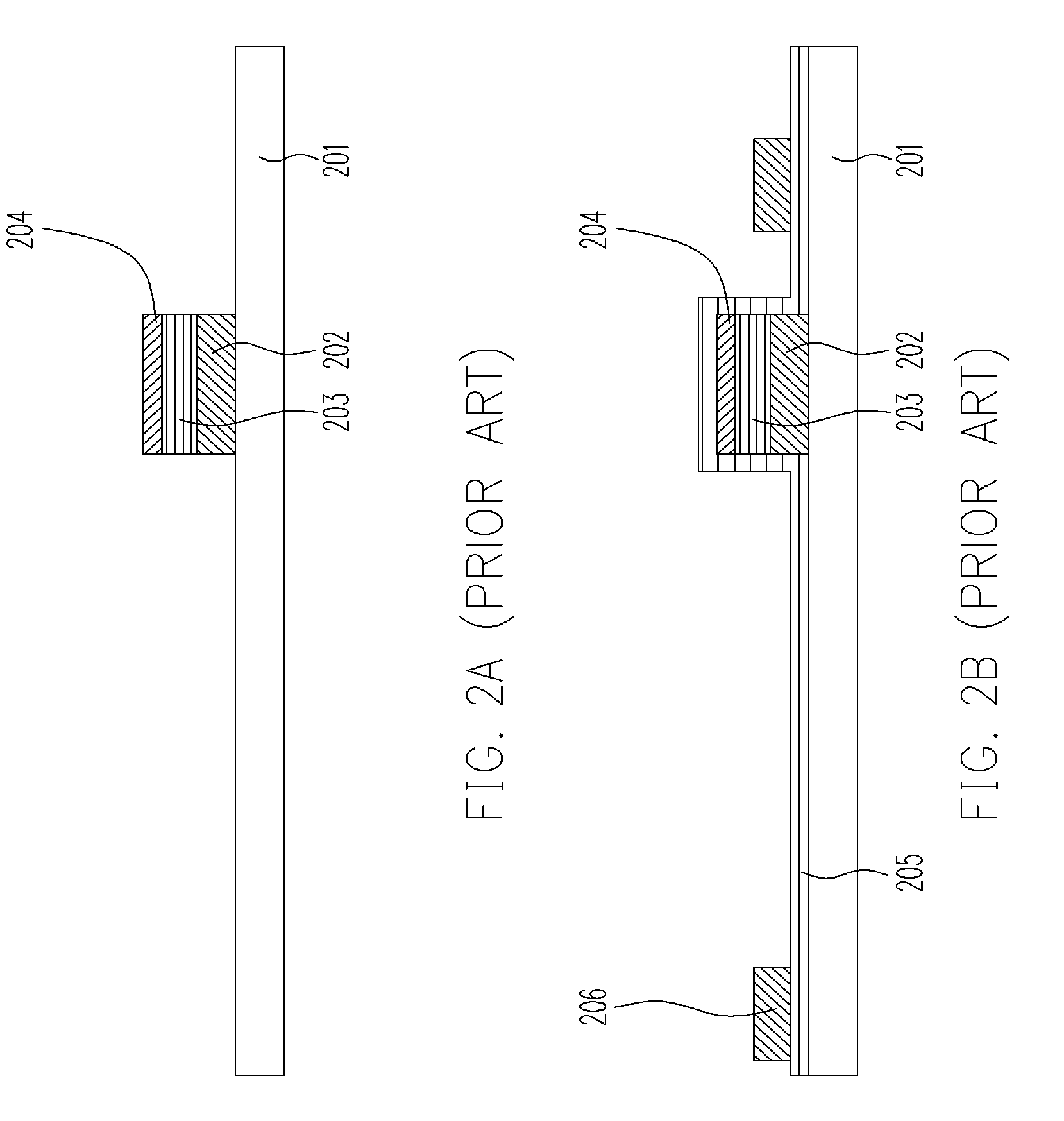

Structure of thin film transistor array and method for fabricating the same

InactiveUS20070161160A1Reduce manufacturing costSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSiliconTransistor

A substrate having a gate electrode layer, a gate insulating layer, and a silicon layer thereon is provided. These layers are patterned into a gate area, a gate line and a gate line wiring area. A passivation layer is formed on the entire substrate and patterned to form two contact holes in the passivation layer on the silicon layer at the gate area, and partions of the passivation layer at the gate line and at the gate line wiring areas are removed. An ion implanting layer and a metal layer are formed on the substrate and patterned to form a source region, a drain region, a data line, a data line wiring area and a second layer of the gate line wiring area. A pixel electrode is formed on the passivation layer and electrically coupled to the drain region. Therefore, the TFT array can be fabricated by only four masks.

Owner:IND TECH RES INST

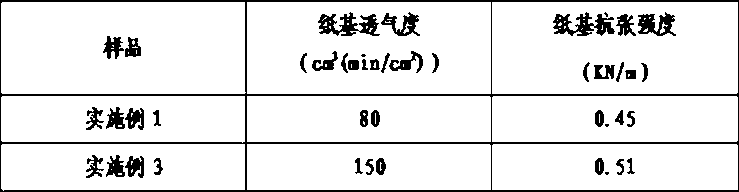

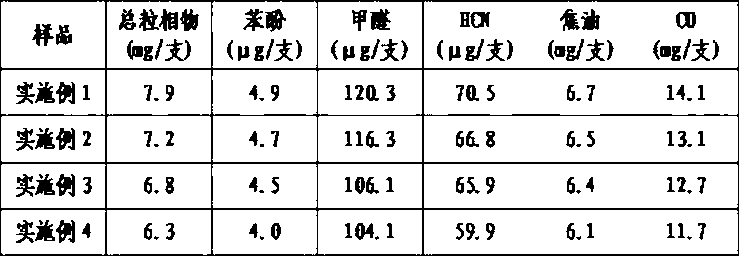

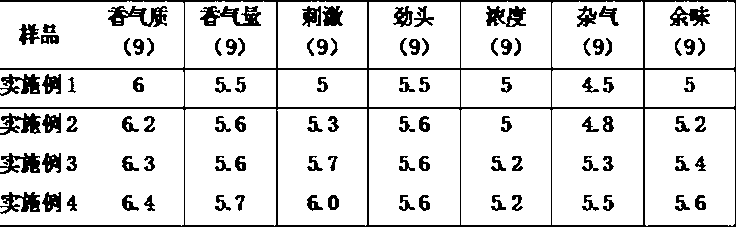

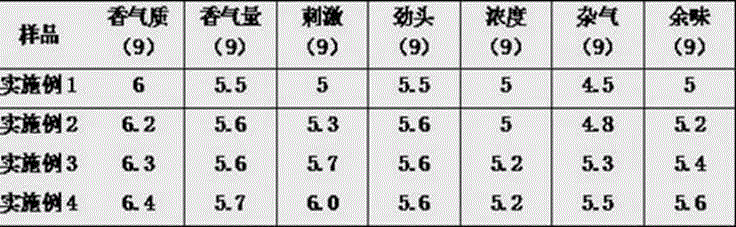

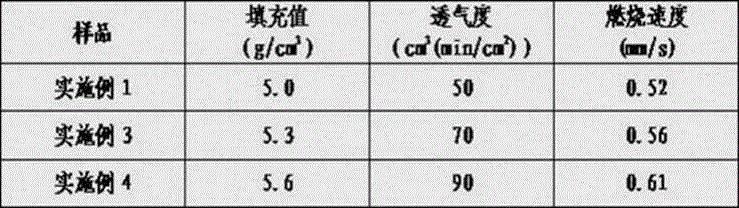

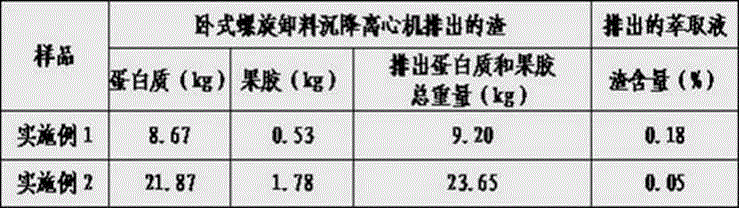

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

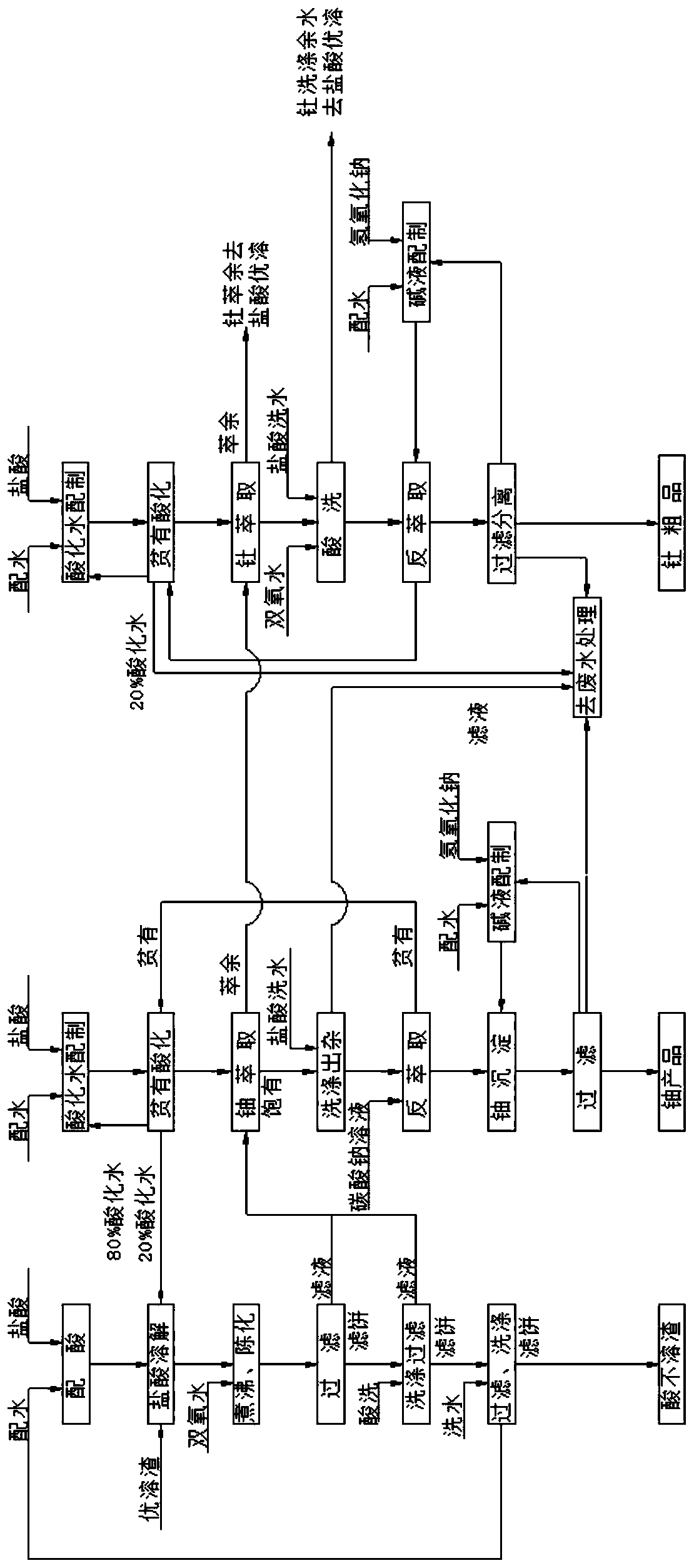

Method for smelting and separating uranium, thorium and rare earth from residual slag of processed monazite

ActiveCN111004920AReduce consumptionHigh recovery rateProcess efficiency improvementSlagWater chlorination

The invention provides a method for smelting and separating uranium, thorium and rare earth from residual slag of processed monazite. The residual slag of processed monazite is used as the raw material. The method comprises the following steps of performing hydrochloric acid complete dissolving, performing dissolving liquid aging, performing liquid-solid separation, extracting uranium by an amineextraction agent and performing extracting and enriching, extracting thorium from an acidic phosphorus-containing extraction agent and performing wastewater treatment. A raffinate phase obtained afterthorium extraction is returned to a monazite hydrochloric acid optimum solubilizing procedure to recover a rare earth chloride mixture, after extraction and separation, a single uranium product and athorium product are obtained through precipitation, and the recovery rate of resources such as uranium, thorium and rare earth is greater than 95%; and most of process water in the production processis directly returned to a system for cyclic utilization, a small amount of wastewater is recycled back to the system after comprehensive treatment, and zero drainage of the wastewater is realized. Bythe adoption of the technical scheme, the flow is simple and flexible, and large-scale production is achieved easily; the chemical material consumption is low, valuable resources such as rare earth,uranium and thorium can be efficiently recovered, and the resource recovery rate is increased; and the comprehensive treatment and environmental-friendly, efficient and clean production of the monazite resources are guaranteed.

Owner:湖南中核金原新材料有限责任公司

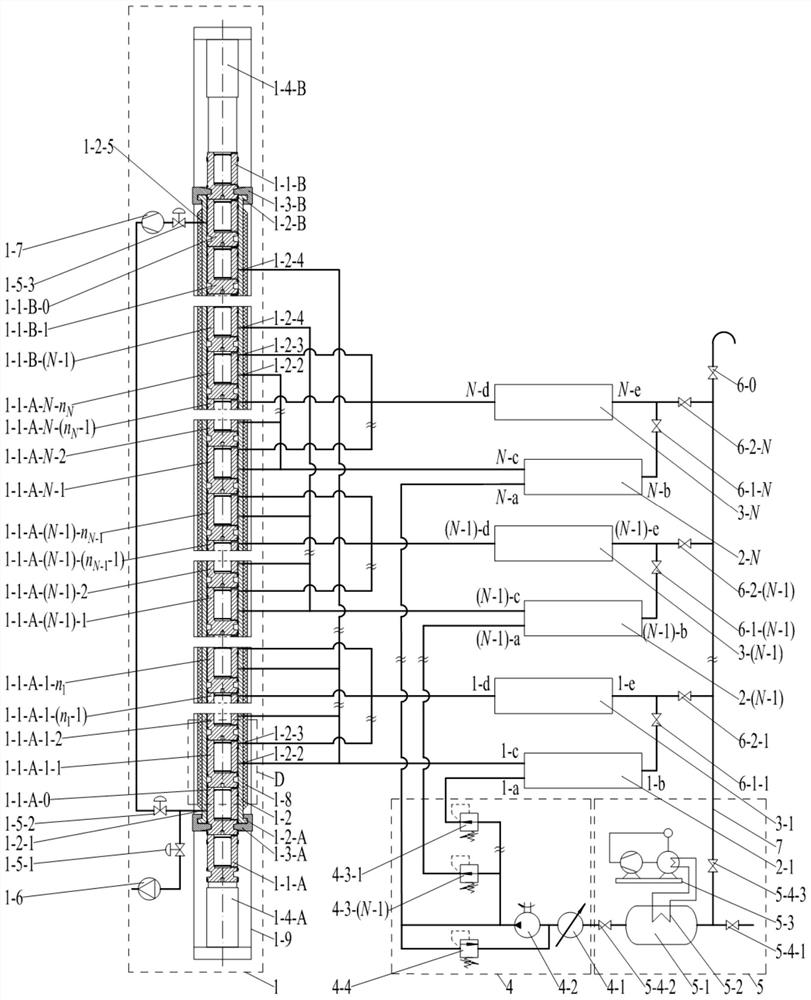

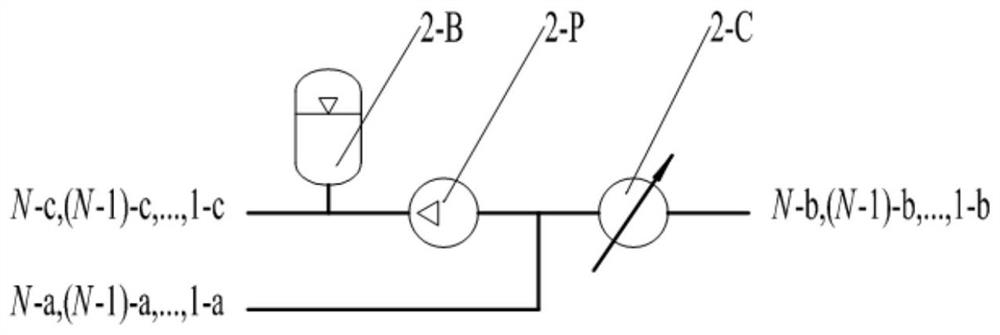

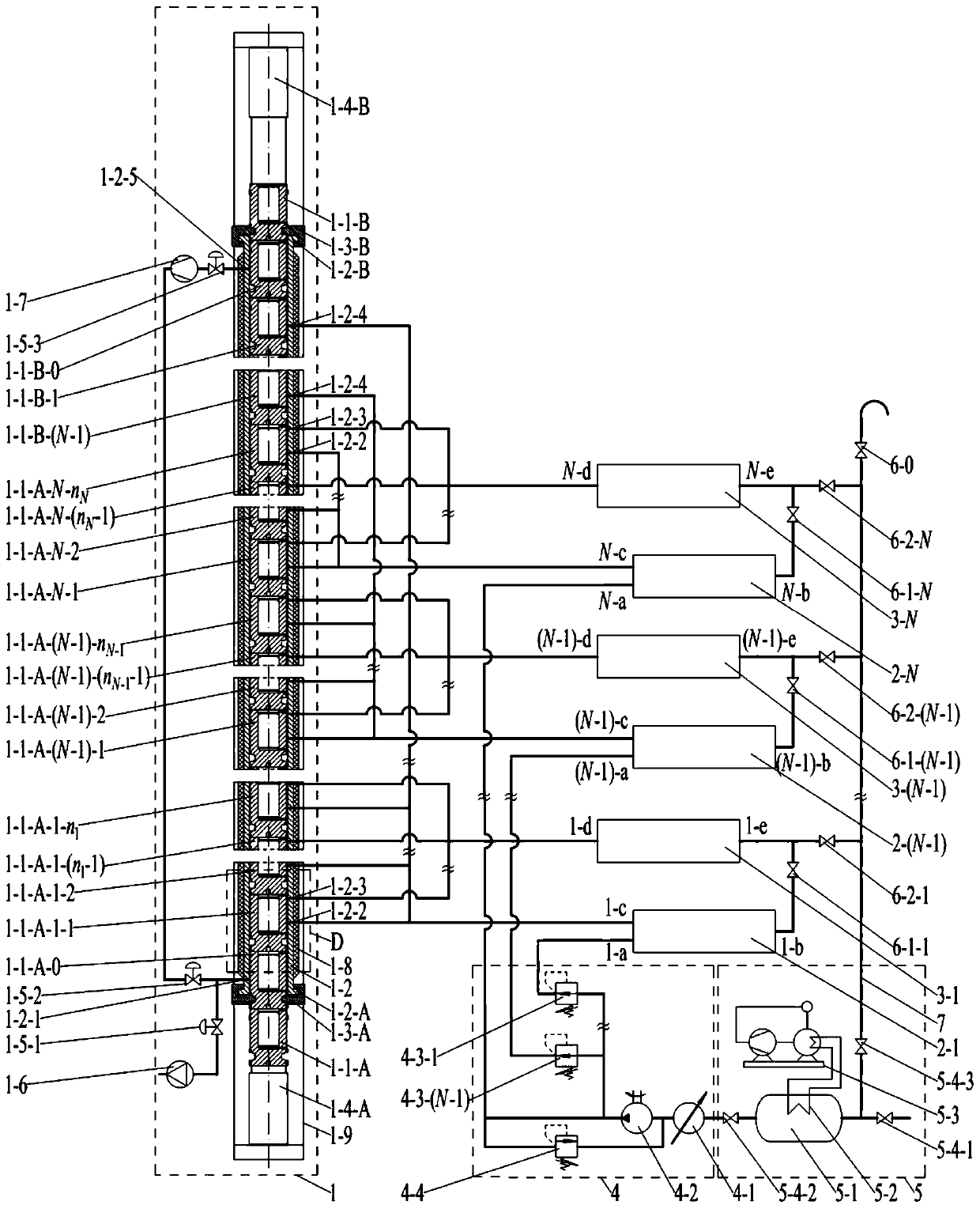

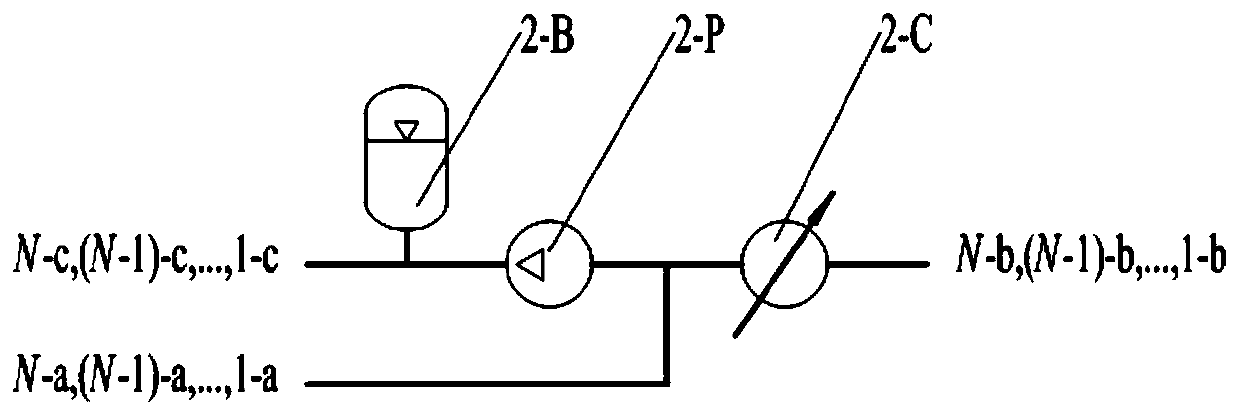

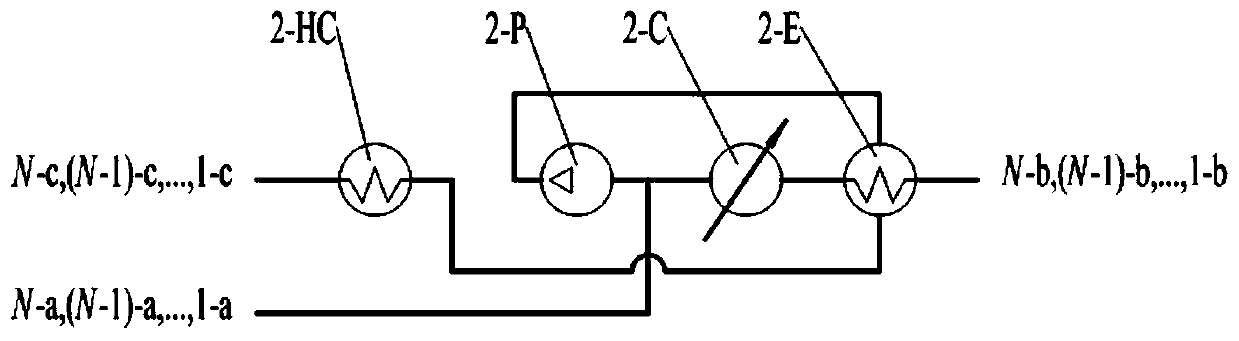

A subcritical fluid continuous isobaric extraction and separation device system and extraction and separation process

ActiveCN110152350BAchieve recyclingDiversity guaranteedSolid solvent extractionPhysical chemistryChemical separation

The invention relates to the field of chemical separation and bioengineering mechanical equipment, in particular to a subcritical fluid continuous isobaric extraction and separation device system and extraction and separation process, the device system consists of a subcritical fluid medium source, a pressurized subsystem, and a continuous extraction subsystem 1. The separation subsystem and the pressurization circulation subsystem are composed of the same step-by-step pressurization or step-by-step extraction stages of the continuous extraction subsystem. Applying the extraction and separation process implemented by this device system, through the systematic process operation, the extracted subcritical fluid or supercritical fluid in the silo after the extraction is completed enters the corresponding separation subsystem to start separation, and the discharge valve is opened periodically, Unload the extract separated by the separation subsystem. The technology device of the invention has high degree of automation, reliable operation, reasonable process flow of the device system, and realizes sub-extraction separation such as continuous subcritical fluid, energy saving and zero emission, excellent manufacturability, and excellent separation effect.

Owner:SHANDONG UNIV +1

Process for increasing viscosity of kaolinite

InactiveCN101058218AIncrease viscosityQuality improvementClay mixing apparatusClay processing apparatusKaoliniteChina clay

The invention relates to a method on improving the porcelain clay viscosity. In proportion, it comprises China clay 100, intercalation urea 3-9, water content of China Clay within 1-5%, mixing them for 5-15 minutes to get the mixed sample, sending the mixed sample into the sealed container, then the baker in 65-105deg.C for 2-6 hours to get the compound, breaking the compound in the speed of 1kg / 1h and mixing the compound with the broken agent for 5-10 minutes to get the final product. Using this method, it can improve the viscosity of the China Clay from around 68% to 72%-73. 8%.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Structure of thin film transistor array

InactiveUS20090090912A1Reduce manufacturing costSimple processSolid-state devicesSemiconductor devicesSiliconTransistor

A substrate having a gate electrode layer, a gate insulating layer, and a silicon layer thereon is provided. These layers are patterned into a gate area, a gate line and a gate line wiring area. A passivation layer is formed on the entire substrate and patterned to form two contact holes in the passivation layer on the silicon layer at the gate area, and partions of the passivation layer at the gate line and at the gate line wiring areas are removed. An ion implanting layer and a metal layer are formed on the substrate and patterned to form a source region, a drain region, a data line, a data line wiring area and a second layer of the gate line wiring area. A pixel electrode is formed on the passivation layer and electrically coupled to the drain region. Therefore, the TFT array can be fabricated by only four masks.

Owner:IND TECH RES INST

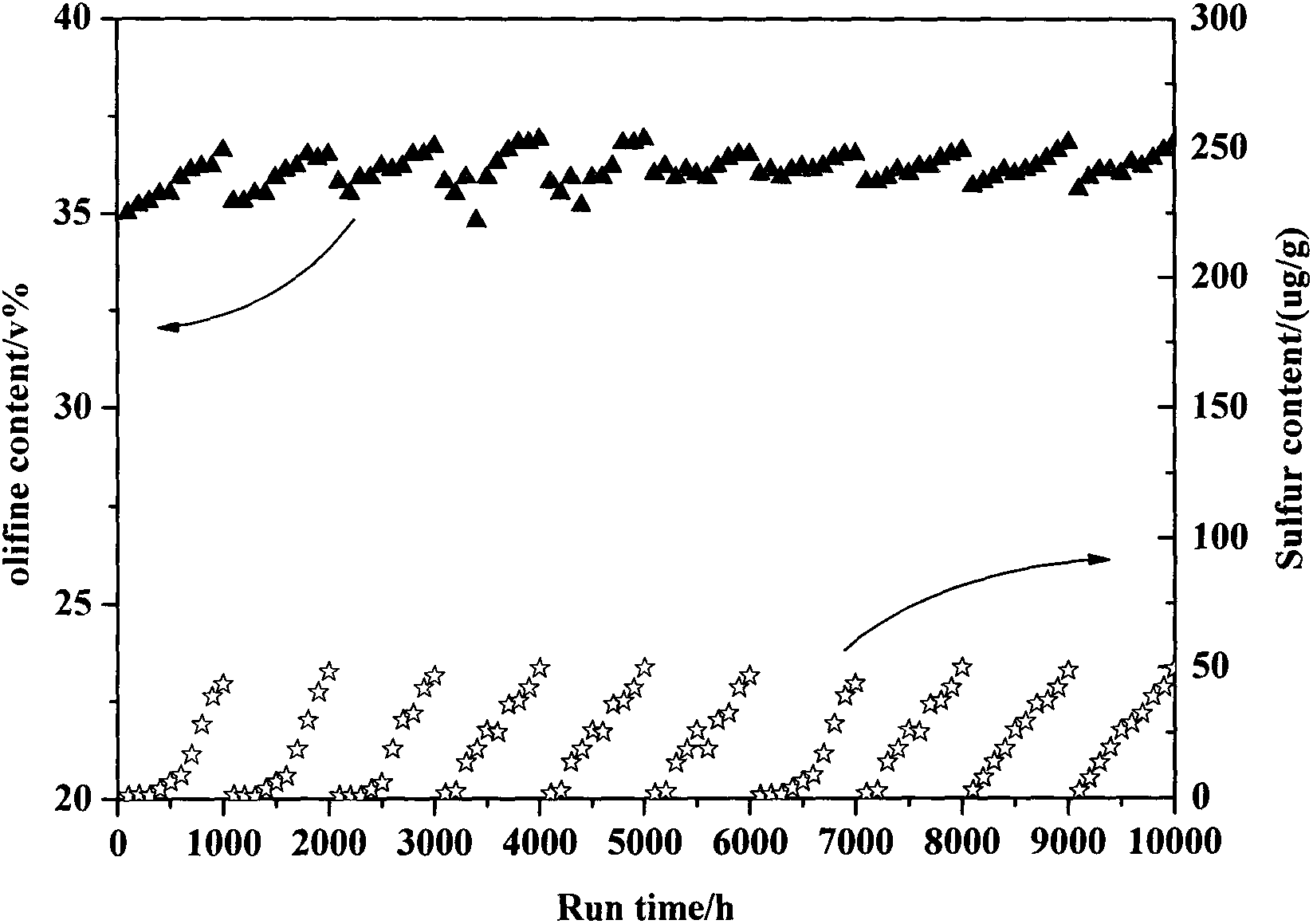

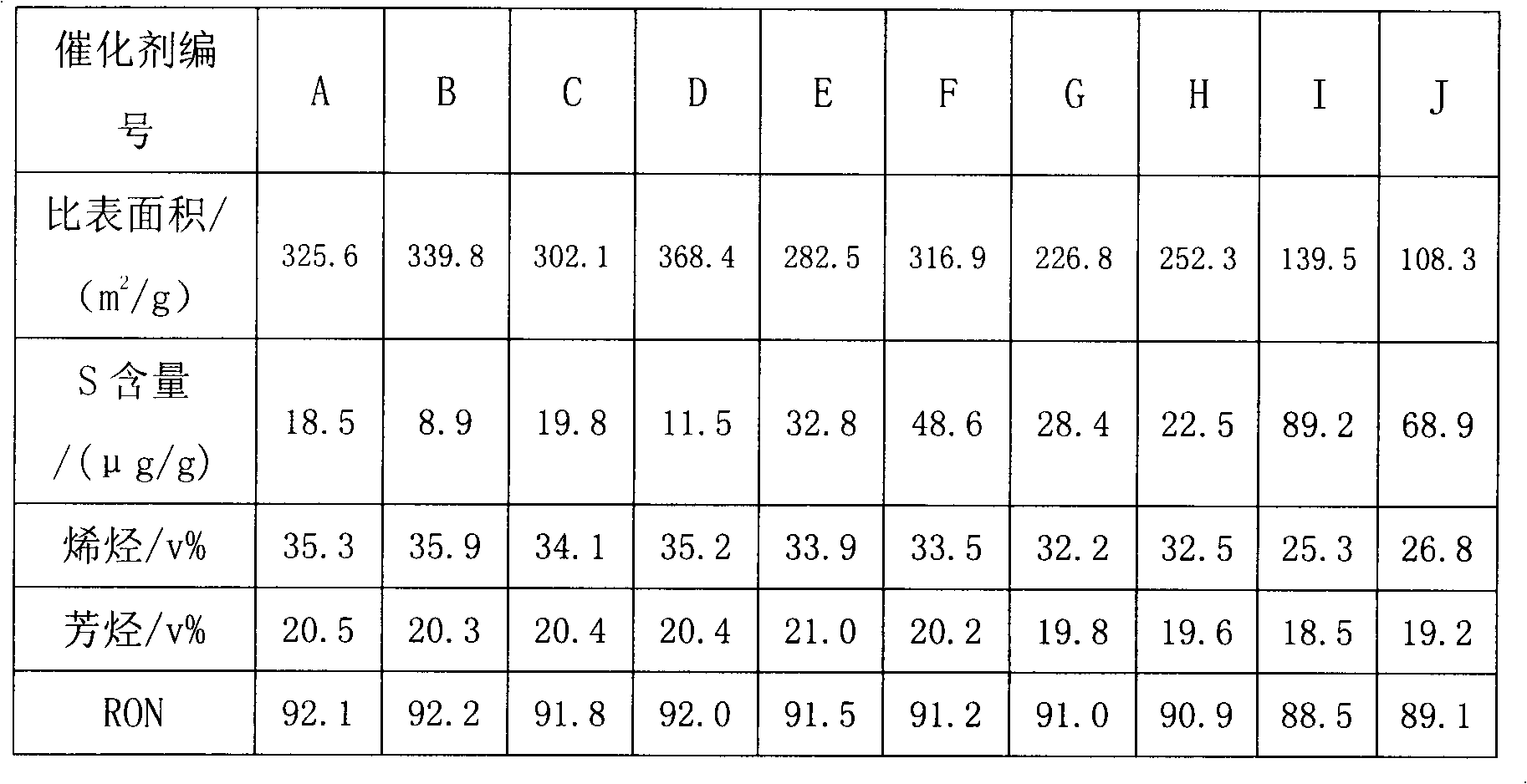

Method for preparing desulfurizer capable of absorbing catalytic cracking gas at high selection

ActiveCN102430412BSimple and flexible processReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsCobaltComposite oxide

The invention discloses a method for preparing desulfurizer capable of absorbing catalytic cracking gasoline at high selection, wherein catalyst is formed by loading the active components, such as nickel, cobalt and copper, on alkaline-metal modified silicon-aluminum composite carrier. The method for preparing the catalyst comprises two processes: the first process is to prepare the soluble precursor of each component and complexing agent as colloidal sol, dry, roast, form and process through hot water to obtain the catalyst; and the second process is to adopt the sol-gel method to prepare analkaline composite oxide carrier, then adopt a soaking method to introduce the first active component Ni and one of the second active components Co, Cu and Sn, finally process through the hot water to obtain the catalyst. The method has simple process, the large specific surface area of the catalyst is large, and the activity is stable. The method has advantages of high desulfurizing depth, good selection and little loss of octane value, so the method can be suitably applied to the desulfurization process of the catalytic cracking gasoline.

Owner:CHINA NAT OFFSHORE OIL CORP +2

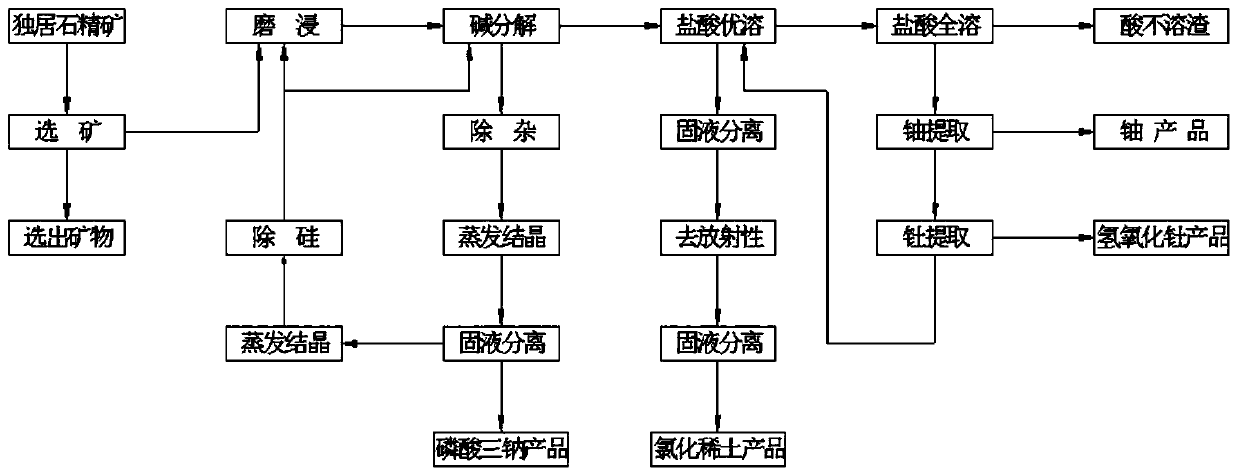

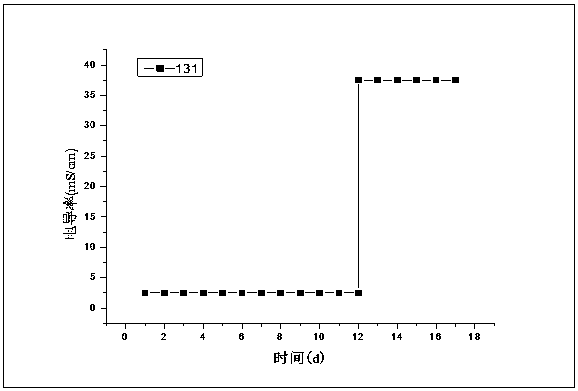

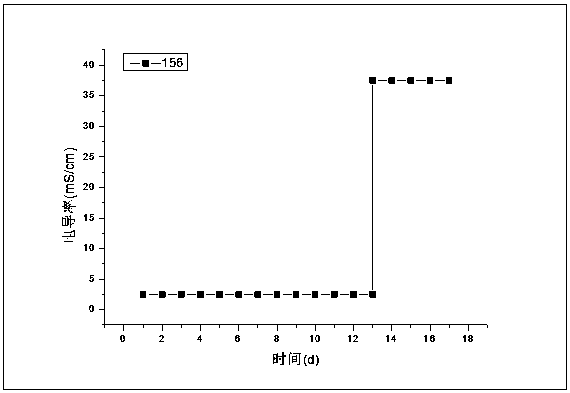

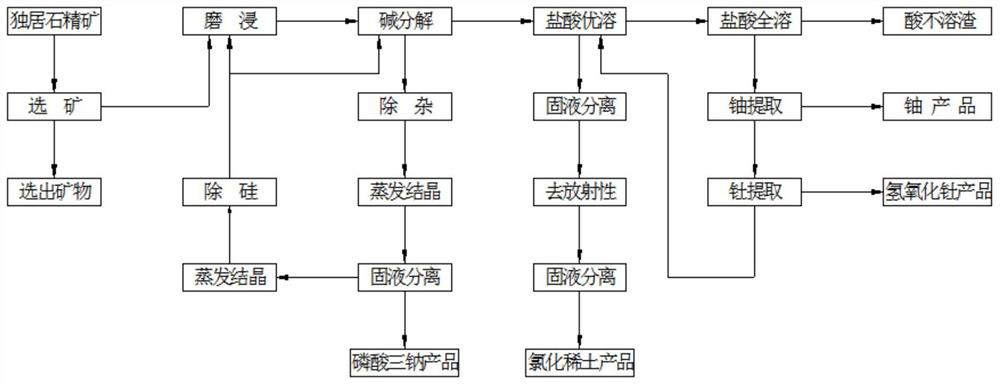

Process method for smelting and separating uranium, thorium and rare earth from monazite concentrate

ActiveCN111020242ASolve problems such as being abandonedHigh recovery rateRare earth metal chloridesRadium compoundsTrisodium phosphateMagnetic separation

The invention provides a process method for smelting and separating uranium, thorium and rare earth from monazite concentrate. The process method comprises the following steps that the monazite concentrate is used as a raw material, the steps of crushing by wet ball mill and iron removal by magnetic separation, alkali decomposition transformation, preparation of trisodium phosphate product, alkalicake adding hydrochloric acid for solubilization, preparation of rare earth chloride mixture product, adding hydrochloric acid to optimal solution slag for full dissolution, extraction of uranium byamines and preparation of uranium products, extraction of thorium by acidic phosphorus containing compounds and preparation of crude thorium products and wastewater treatment are adopted, and the recovery rate of valuable resources such as uranium, thorium, rare earth is greater than 95%. After the thorium is extracted, the raffinate water phase is returned to the optimal solution to recover the rare earth chloride mixture, most of the production process water is directly returned and recycled, and a small part of wastewater is returned to the system for utilization after comprehensive treatment, so that zero discharge of the wastewater is realized. The process is reliable, the chemical materials are common, and the consumption is low. The use of solitary stone resources is ensured for green, environmental protection, efficient and clean production, and the process method has obvious social benefits and economic benefits.

Owner:湖南中核金原新材料有限责任公司

Ceramic flat membrane supporting body and production method thereof

ActiveCN103381338BImprove filtration efficiencyGuaranteed mechanical strengthSemi-permeable membranesSurface layerSlurry

The invention discloses a ceramic flat membrane supporting body and a production method thereof. The ceramic flat membrane supporting body is formed by two layers of flat membranes, the left lateral wall, the right lateral wall and at least a supporting column; the two layers of flat membranes, the left lateral wall and the right lateral wall form into a flat-pipe-shaped structure; the supporting column is arranged between the two layers of flat membranes; the flat membranes which are in asymmetric structures comprise surface layers of sponge hole structures and internal layers of finger-shaped hole structures; separation selectivity, permeation flux and mechanical strength of the flat membranes are high. The production method of the ceramic flat membrane supporting body comprises preparing slurry, producing dies through a phase inversion method, forming through a die pressing method and sintering. The production technology is easy and flexible, the costs are low, the dies are cheap, the replacing is convenient, a plurality of assemblies in different sizes can be formed at one time, and the production efficiency is high.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

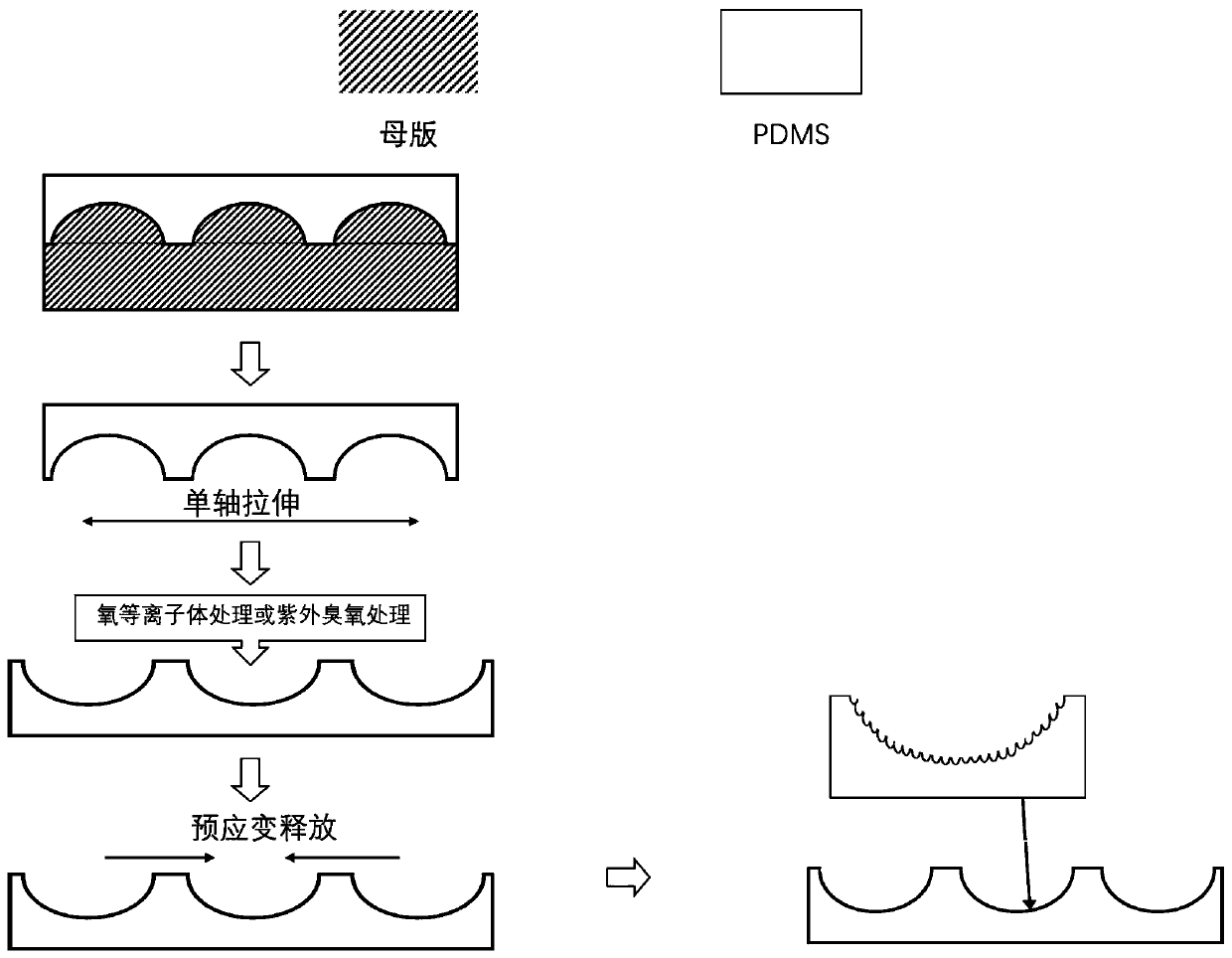

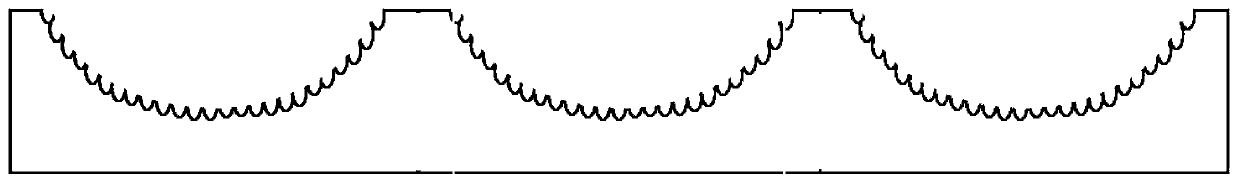

Method for manufacturing grating micro-lens array through strain modulation self-assembly, and product

The invention provides a method for manufacturing a grating micro-lens array through strain modulation self-assembly, and a product. The method comprises: copying a negative micro-lens array mold froma positive micro-lens array mother set by utilizing a PDMS; carrying out uniaxial pre-stretching on the negative micro-lens array mold; forming a silicon dioxide-like hard film on the surface of thePDMS negative micro lens array subjected to pre-stretching treatment; and after the pre-stretching of the negative micro-lens array is relieved, forming a grating microstructure on the surface of thenegative micro-lens array then, and obtaining the self-assembled negative focal length GMA. And the prepared negative focal length GMA is used as a mold for copying, so that the positive focal lengthGMA can be prepared. The method has the advantages of simple steps, no need of complex equipment and low cost; and, compared with manufacturing of a traditional grating / micro lens array, the method has the advantages of being simple and flexible in technological process, short in manufacturing time and low in cost, and is advantageous in that the negative focal length GMA and the positive focal length GMA can be manufactured by copying different mother set micro lens arrays according to different requirements in the manufacturing process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

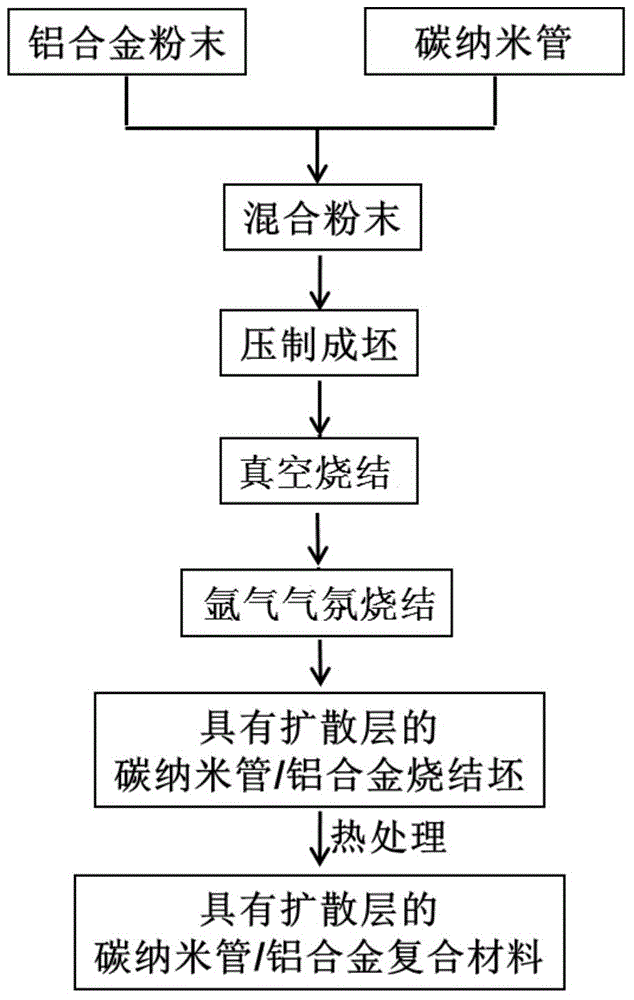

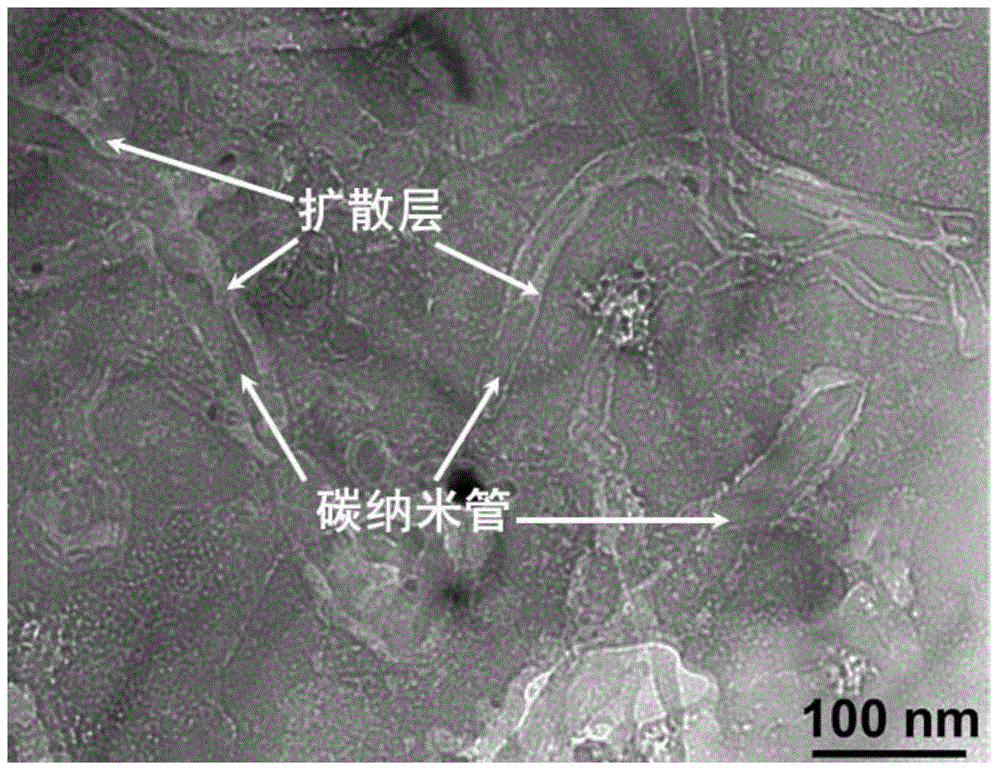

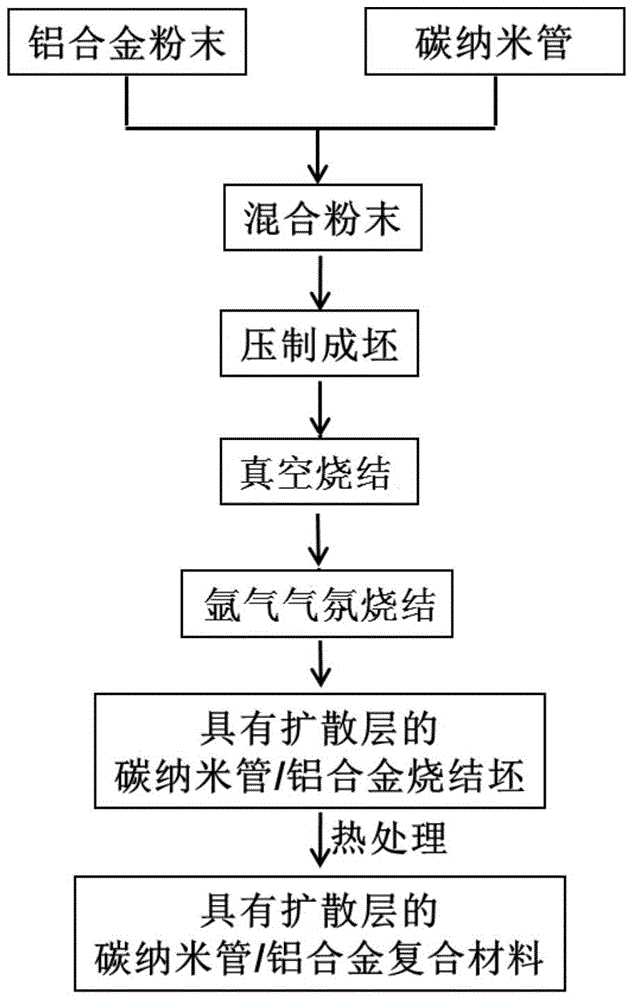

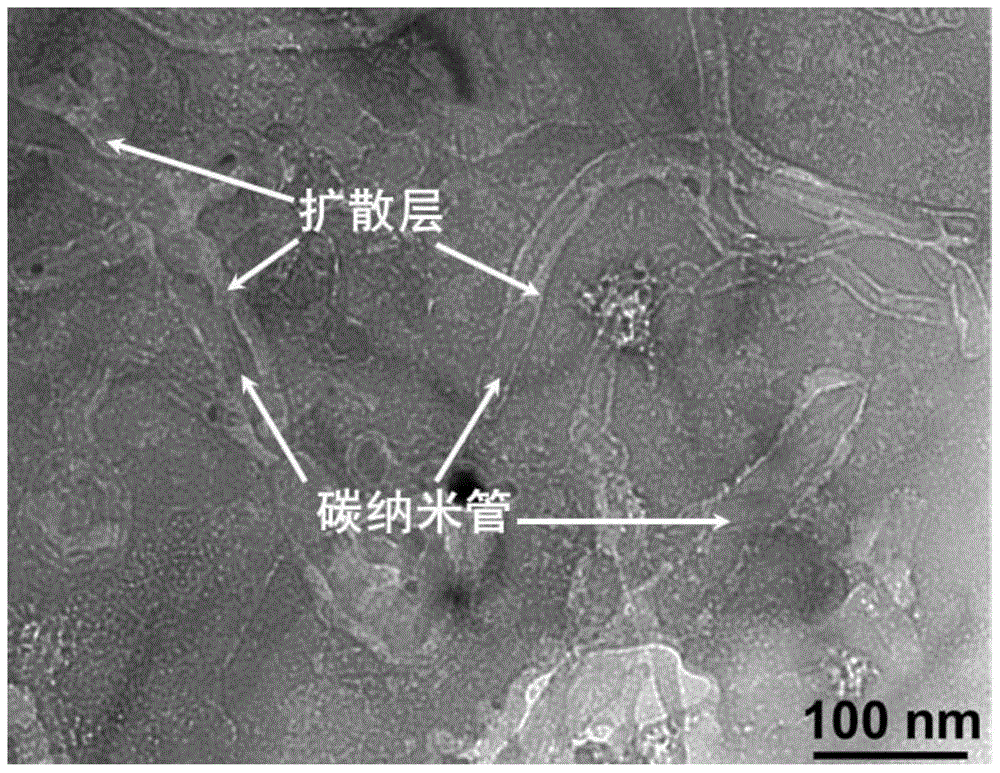

High-damping carbon nanotube/aluminum alloy composite material and preparation method thereof

The invention provides a high-damping carbon nanotube / aluminum alloy composite material. The carbon nanotubes are uniformly distributed in an aluminum alloy matrix, the outer surface of the carbon nanotubes is coated with a diffusion layer, the diffusion layer extends from the outer surface of the carbon nanotubes to the aluminum alloy matrix; the diffusion layer has a microstructure different from the aluminum alloy matrix, and a micro surface is formed between the diffusion layer and the aluminum alloy matrix; and the damping factor of the high-damping carbon nanotube / aluminum alloy composite material is 0.005-0.0011. According to the high-damping carbon nanotube / aluminum alloy composite material prepared by the invention, because the diffusion layer is formed outside the carbon nanotubes, the interfacial potential between the carbon nanotubes and the alloy matrix can be obviously reduced, and interface bonding is coordinated and intensified. Therefore, the prepared composite material has ideal plasticity and damping properties, and the like.

Owner:CRRC QINGDAO SIFANG CO LTD +1

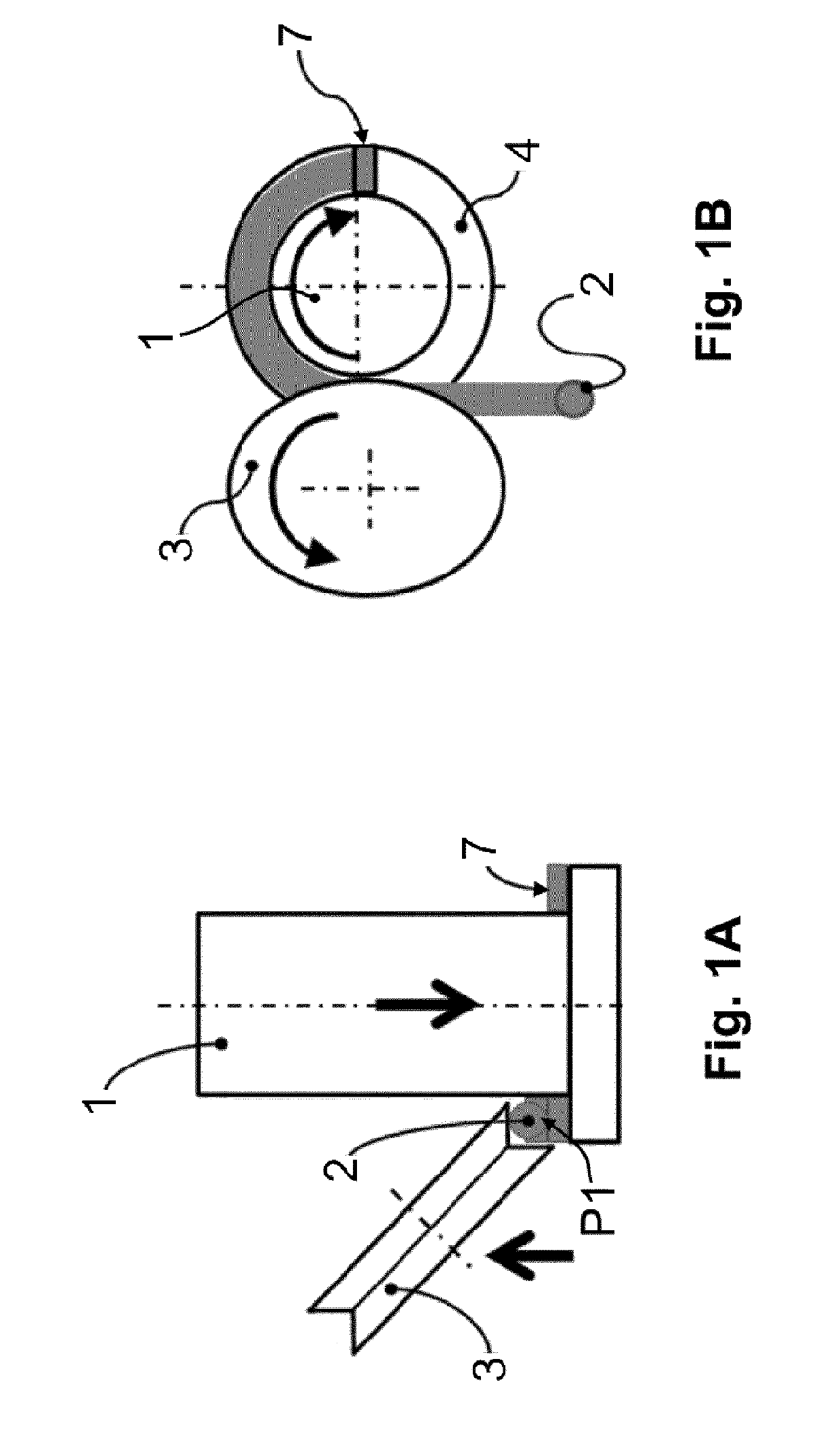

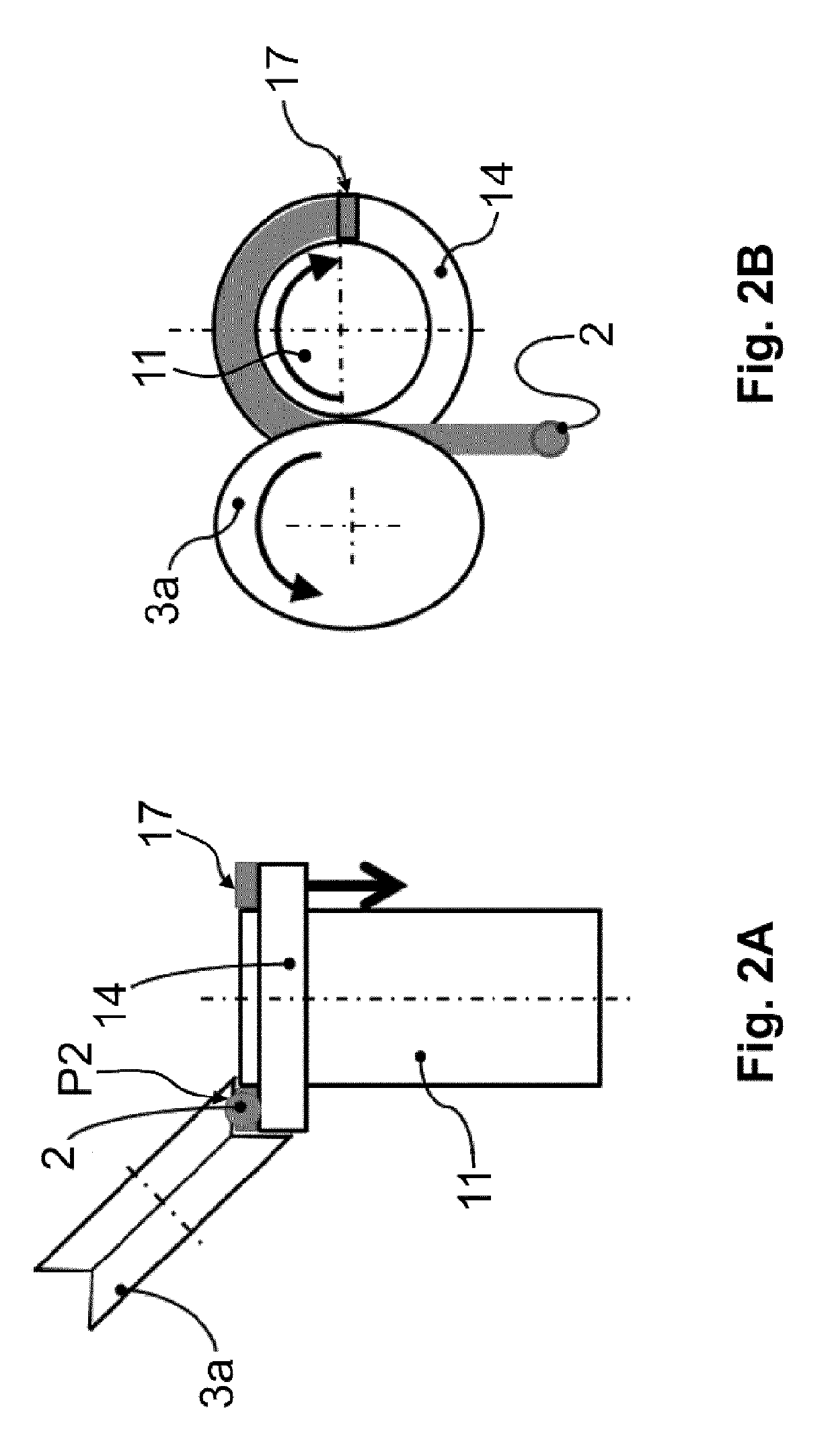

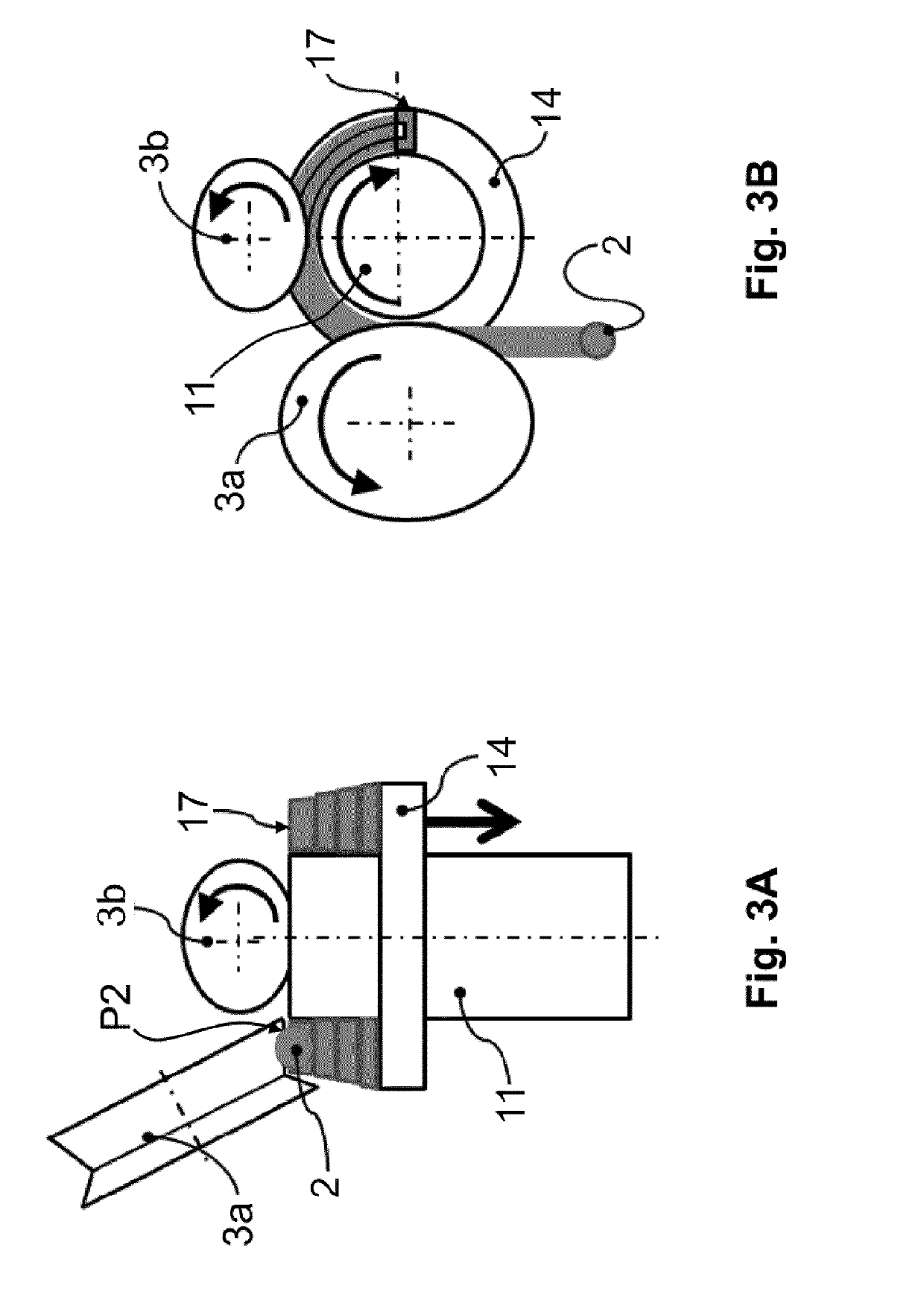

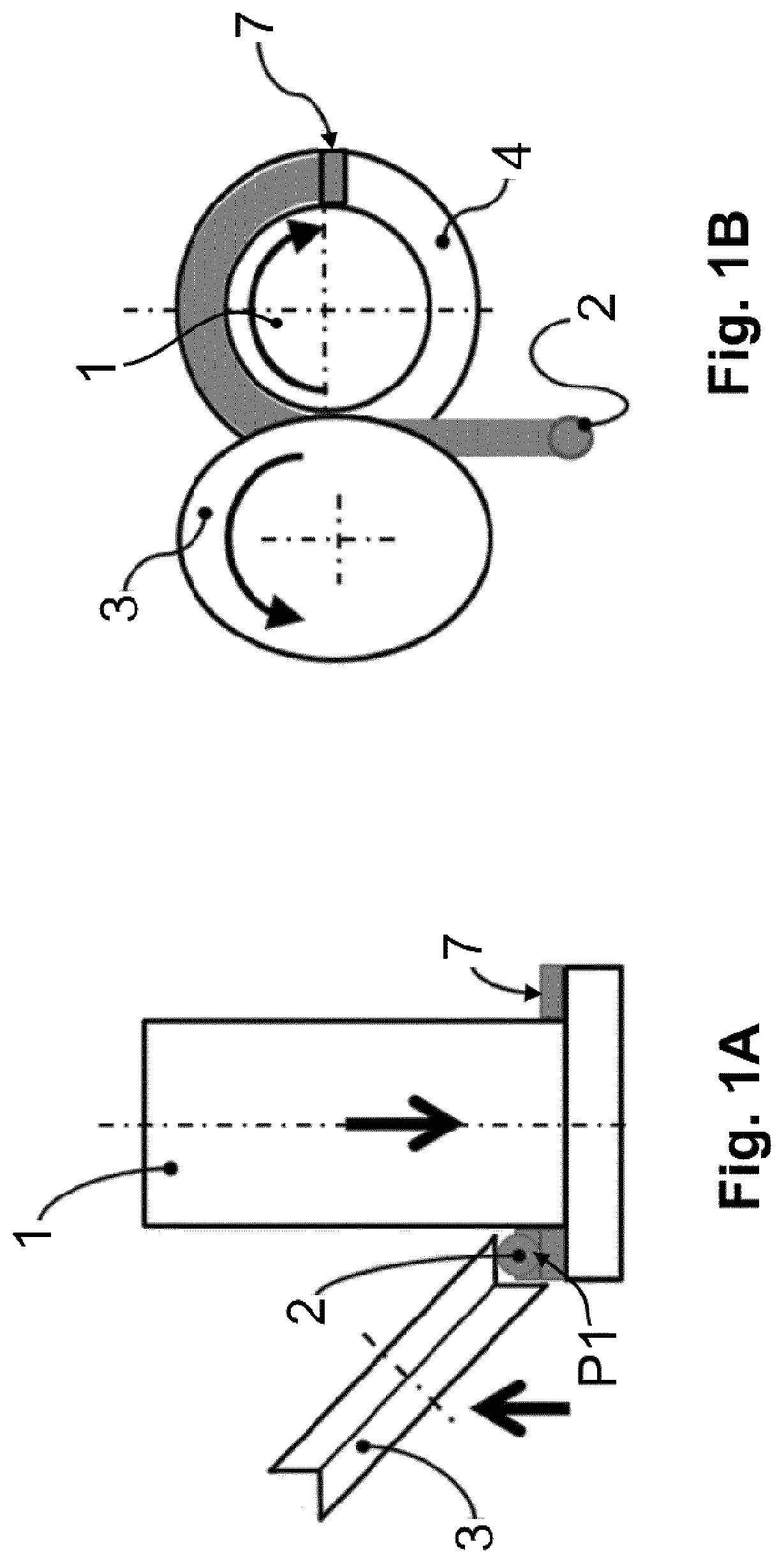

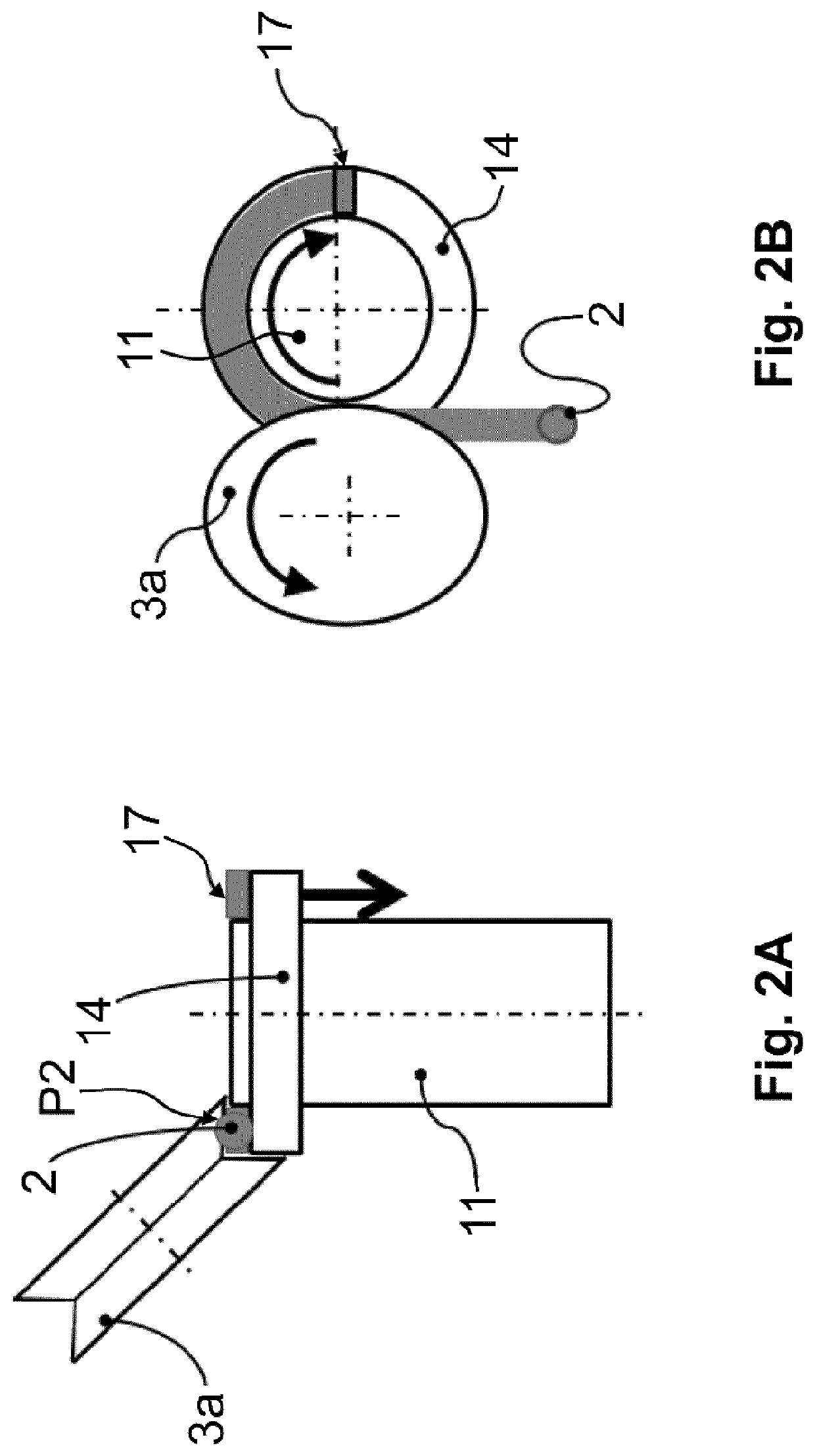

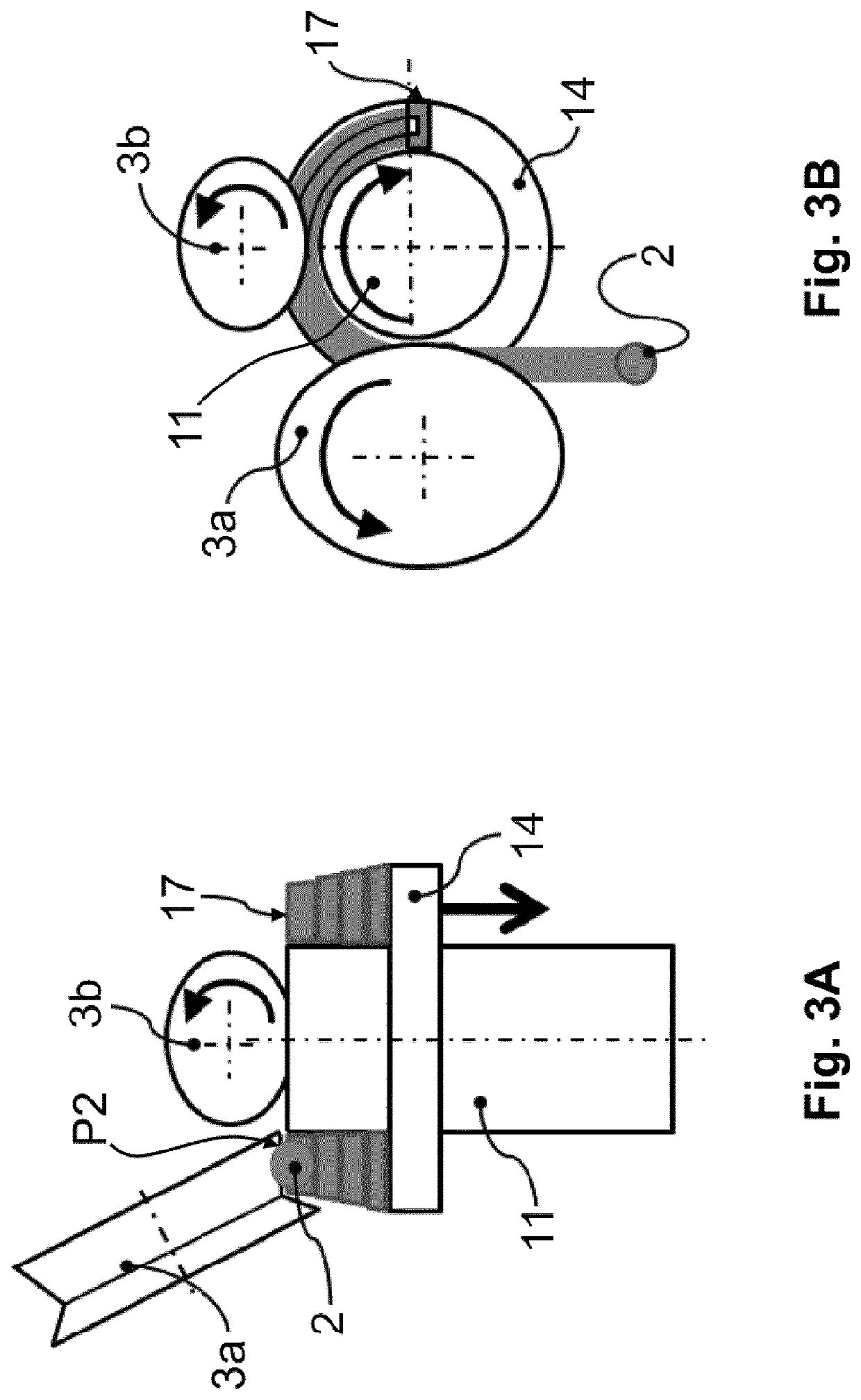

Method and device for producing a winding element

ActiveUS20190333697A1Produced economicallySimple and flexible manufacturing processManufacturing dynamo-electric machinesInductances/transformers/magnets manufactureCopper wireFill factor

The invention provides a method and a device for producing a winding element from a supplied wire, in particular from a round copper wire, said method and device allowing the economical and flexible production of a winding element which, when subsequently used in the field of electrical engineering as a coil or inductor fitted in a stator, ensures the highest possible groove filling factor. For this purpose, the wire is wound to a three-dimensional shape and the cross section of the wire is changed simultaneously, as a result of which separate method steps and therefore tool arrangements for three-dimensional winding of the wire as well as the change of the cross-section of the wire can advantageously be dispensed with.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Subcritical fluid continuous constant-pressure extraction and separation device system, and extraction and separation technology thereof

ActiveCN110152350AAchieve recyclingDiversity guaranteedSolid solvent extractionSeparation technologyChemical separation

The invention relates to the field of chemical separation and bioengineering mechanical devices, and especially relates to a subcritical fluid continuous constant-pressure extraction and separation device system, and an extraction and separation technology thereof. The device system comprises a subcritical fluid medium source, a pressurization subsystem, a continuous extraction subsystem, a separation subsystem having the same step-by-step extraction or extraction stage number with the continuous extraction subsystem, and a pressurized circulation subsystem. The extraction and separation technology enforced by applying the extraction and separation system is operated to make a subcritical fluid or supercritical fluid in a bunker enter the corresponding separation subsystem after the completion of extraction in order to separate, and a discharge valve is periodically opened to discharge the extract separated by the separation subsystem. The device system and the technology have the advantages of high automation degree and reliable running of a device, reasonable process flow, realization of subcritical fluid continuous constant-pressure extraction and separation, energy saving, zeroemission, excellent processability and excellent separation effect.

Owner:SHANDONG UNIV +1

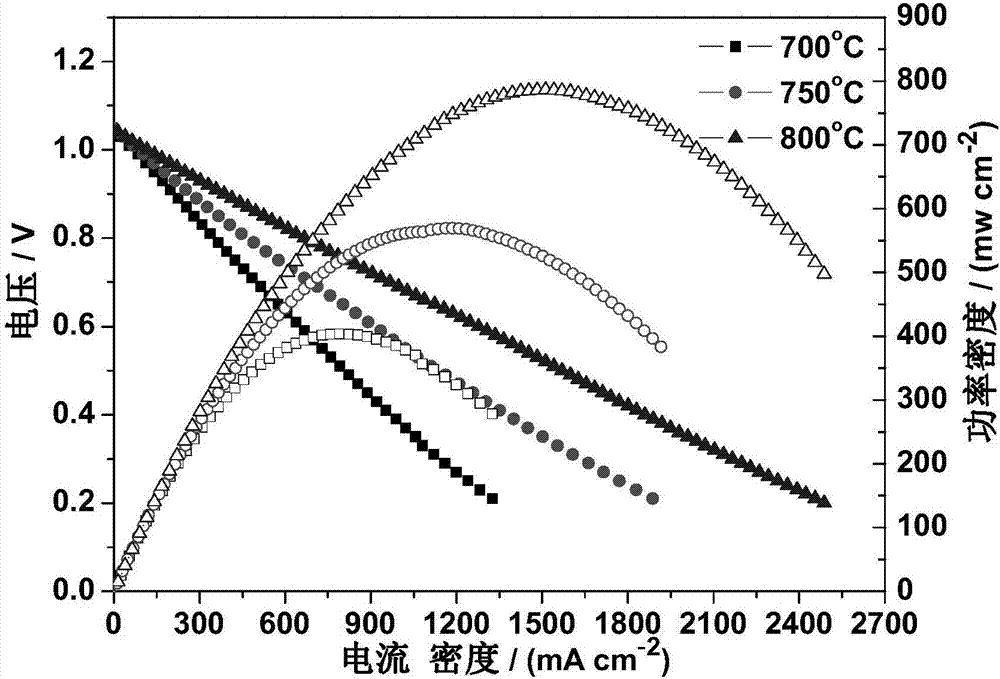

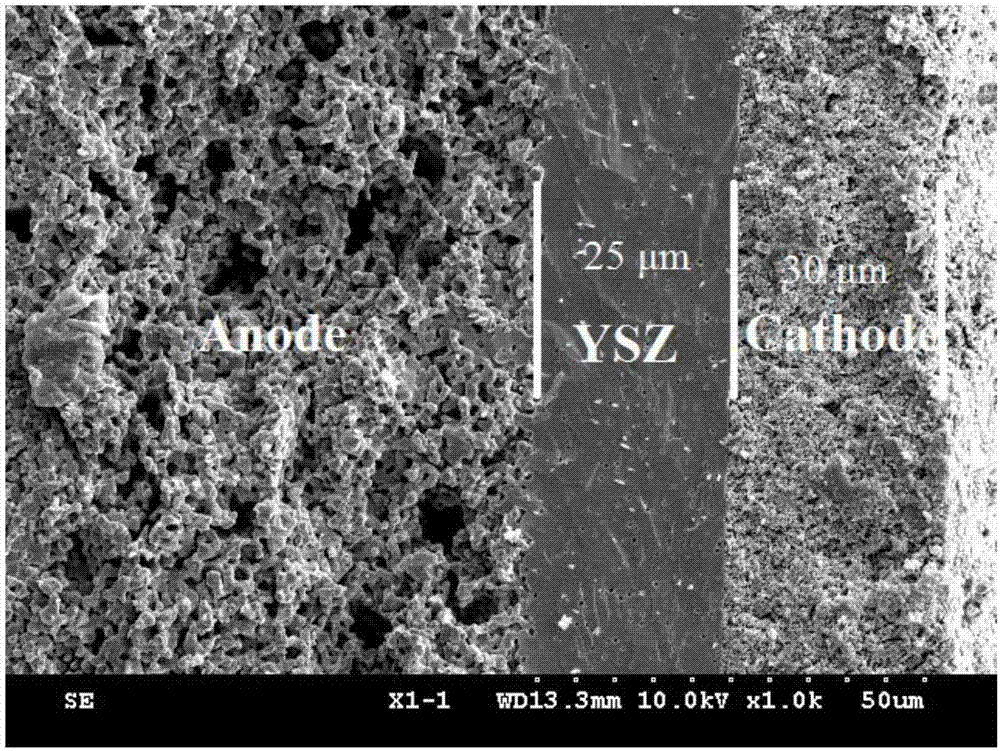

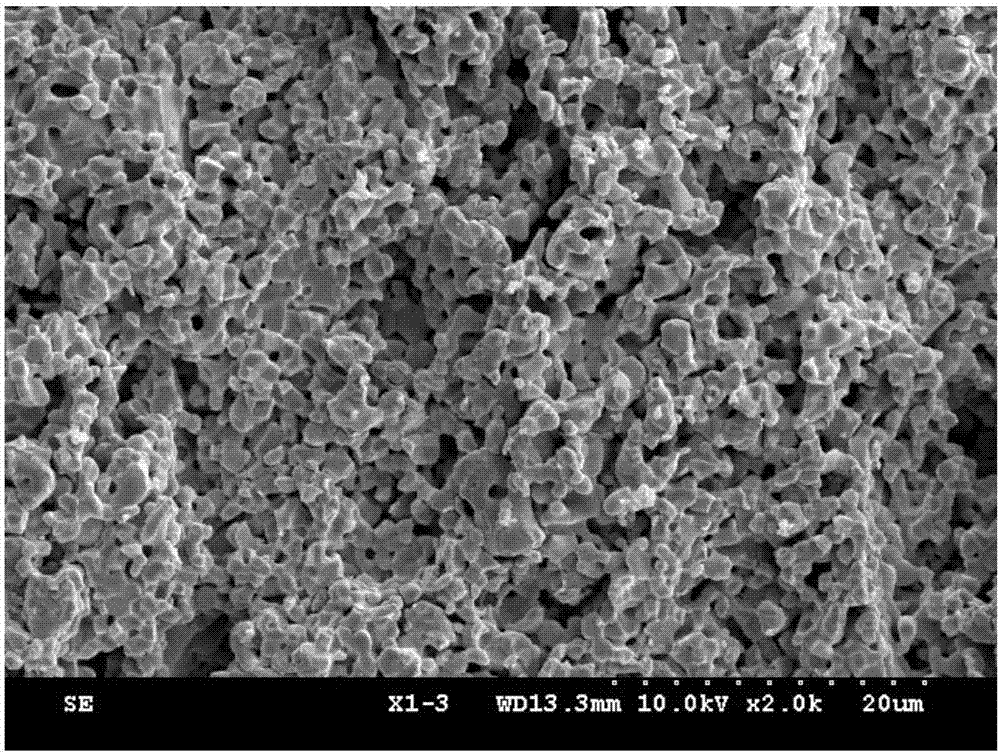

Simple preparation method for anode support of solid oxide fuel cell

InactiveCN107275657AHigh green strengthImprove toughnessFinal product manufactureFuel cellsPolyvinyl butyralPolyethylene glycol

The invention relates to the technical field of preparation of a solid oxide fuel cell and specifically relates to a simple preparation method for an anode support of the solid oxide fuel cell. The method comprises the following steps: 1) preparing a sizing agent: ball-milling and mixing NiO and YSZ at a weight ratio of 1:1, graphite powder and an organic additive for 3-4h, thereby forming a suspending sizing agent, wherein the organic additive includes polyvinyl butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethyl alcohol and the weight percent ratio of NiO to YSZ to graphite powder to polyvinyl butyral to triethanolamine to polyethylene glycol to di-n-octyl phthalate to absolute ethyl alcohol is (16-18%):(16-18%):(2-4%):(5-8%):(1.5-2%):(3-4%):(3-4%):(45-47%); 2) molding by adopting a scraper: pouring the anode sizing agent onto a glass plate, using the scraper for uniformly and smoothly filling the sizing agent into a glass carrier area between the adhesive tapes and molding; and 3) sintering under a high temperature. The method has the advantages of fast molding, simple and convenient operation, capability of realizing small scale production, and the like.

Owner:云南探源者科技股份有限公司

Method for fabricating structure of thin film transistor array

InactiveUS7537973B2Reduce manufacturing costSimple processSolid-state devicesSemiconductor/solid-state device manufacturingSiliconMetal

Owner:IND TECH RES INST

A method for manufacturing high-quality functional paper-making reconstituted tobacco leaves

ActiveCN103251125BLow lignin contentReduce releaseTobacco preparationPapermakingMacromolecular Substances

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

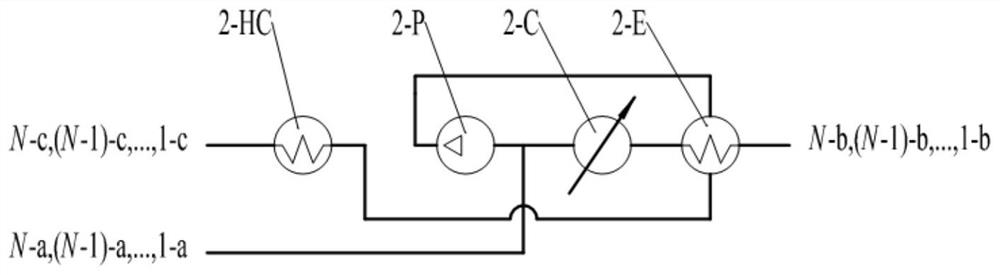

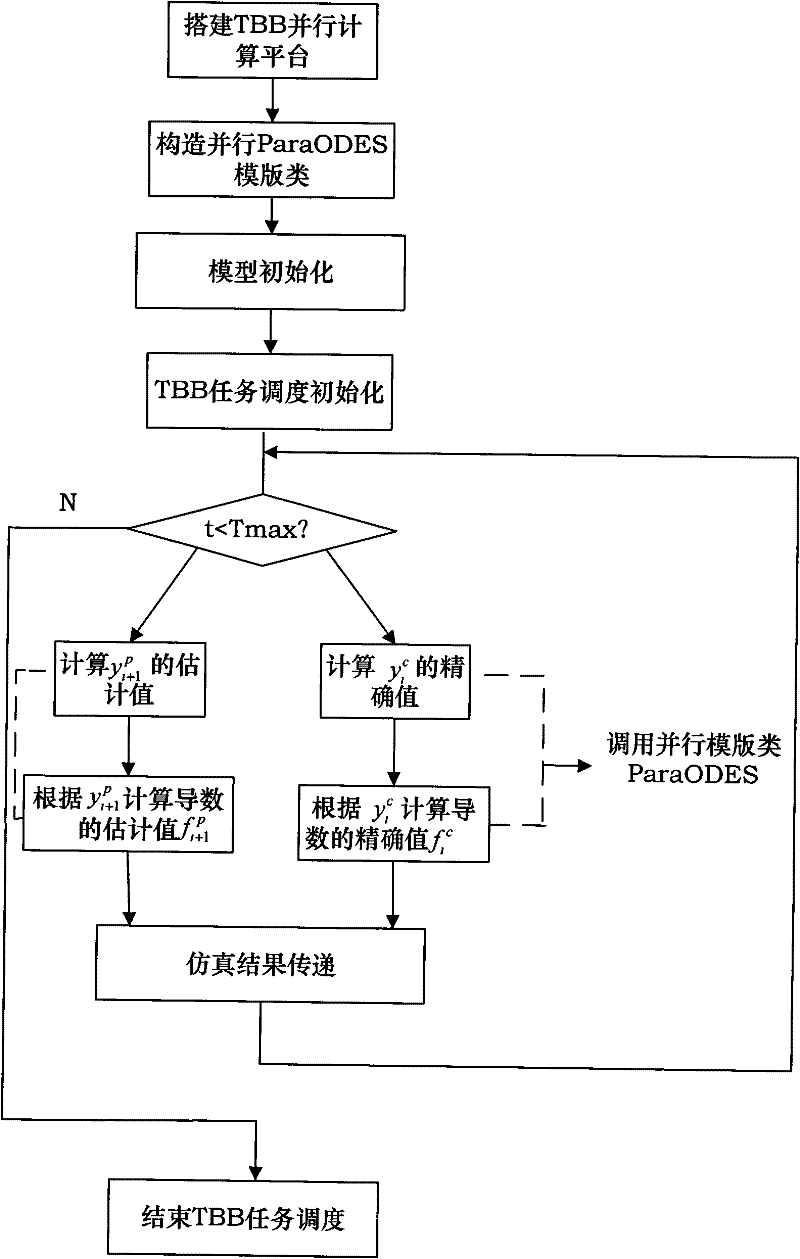

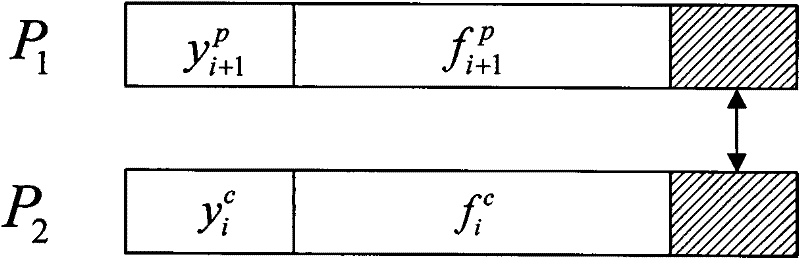

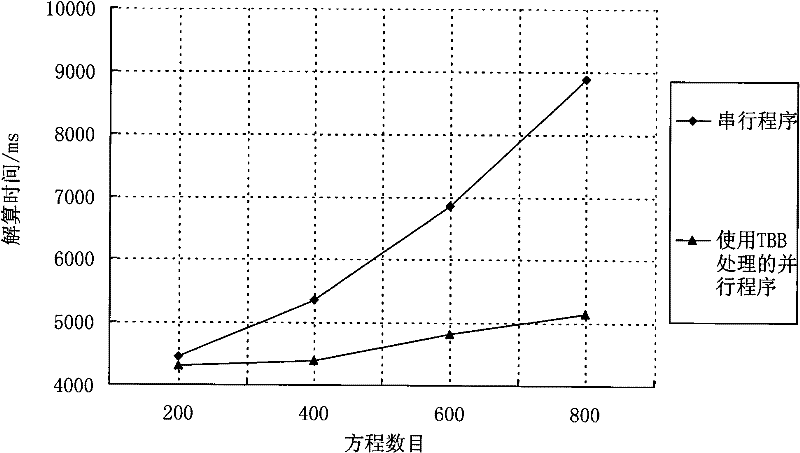

Multi-core parallel method for continuous system simulation based on TBB threading building blocks

InactiveCN101639788BHigh speedMeet real-time requirementsMultiprogramming arrangementsSpecial data processing applicationsMulticore architectureParallel computing

The invention discloses a multi-core parallel method for continuous system simulation based on TBB threading building blocks. The method mainly comprises the following steps: step 1, building a TBB parallel computing platform; step 2, constructing a parallel ParaODES template catalog; step 3, carrying out model initialization; step 4, initializing TBB task scheduling; step 5, judging a simulationtime scope; step 6, calling the parallel ParaODES template; step 7, transferring a simulation result; and step 8, ending TBB task scheduling. The method can realize parallelization processing for continuous system simulation by TBB, improve the simulation calculating speed, meet the requirement of simulation real-time property, and shorten the simulation research period; by parallelization processing with the TBB, the method has simple and flexible process, easy operation and good expansibility; and the TBB adopts a multi-core architecture, which conforms to the development direction from thecurrent parallel technology to a multi-core platform.

Owner:BEIHANG UNIV

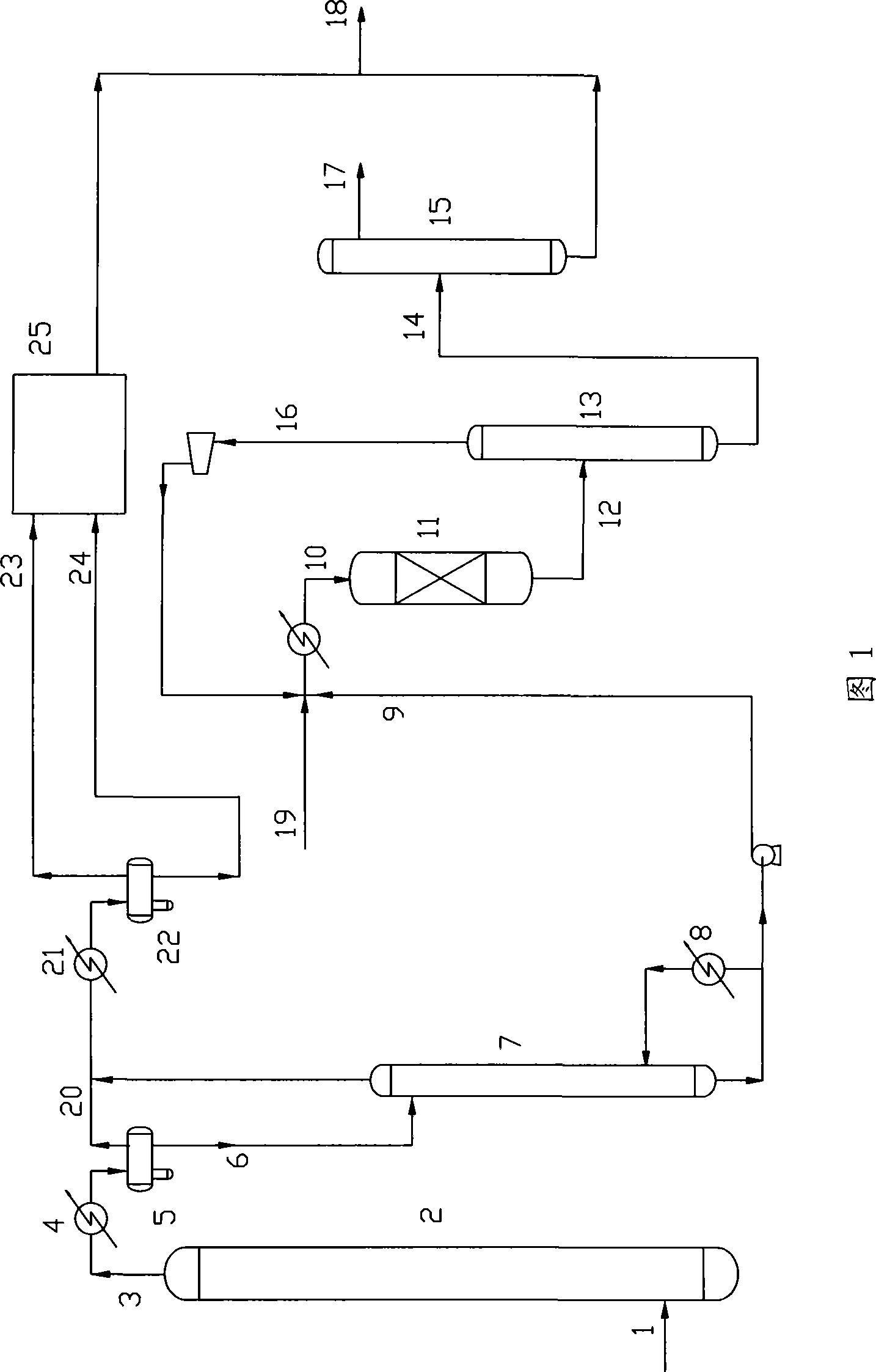

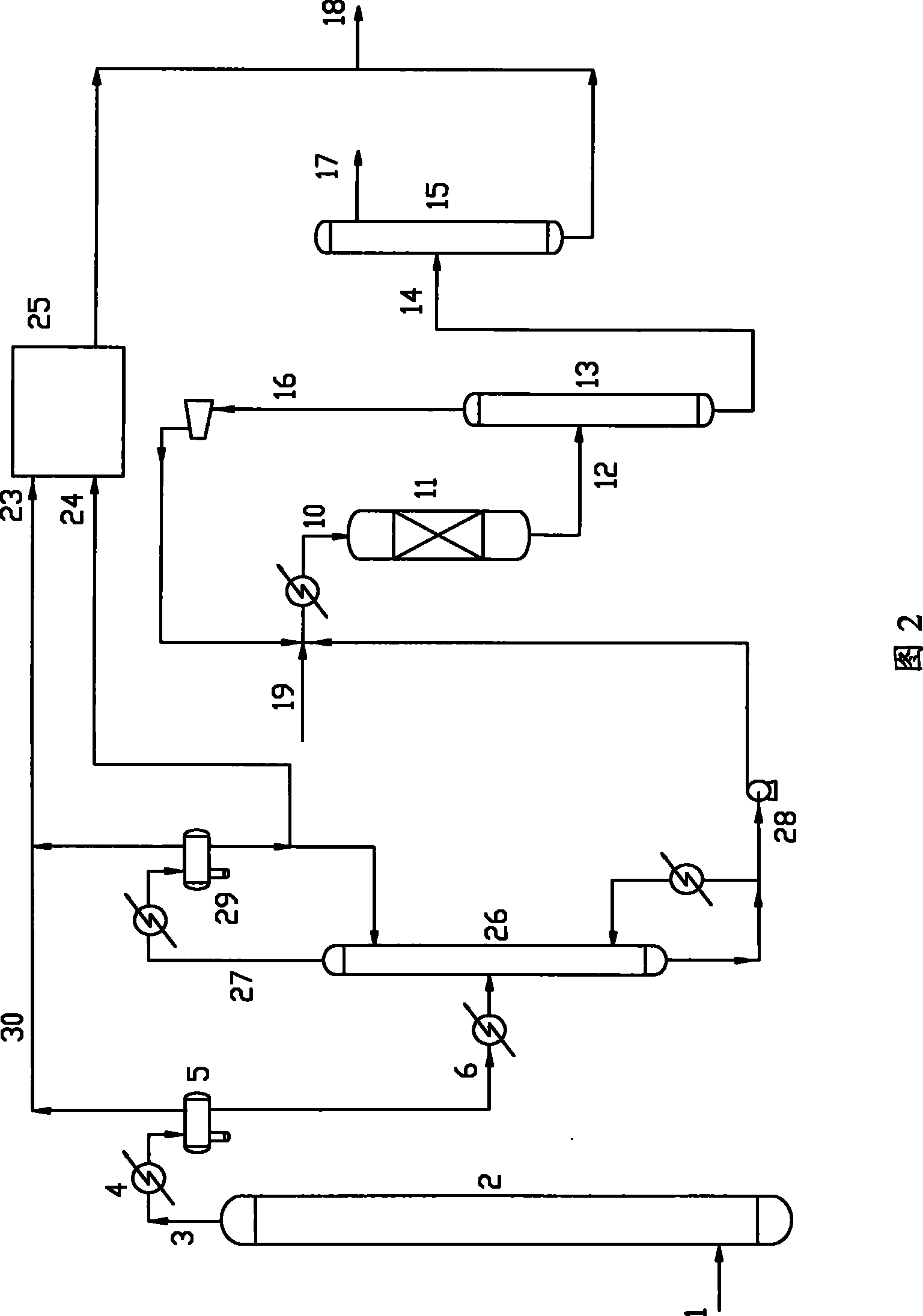

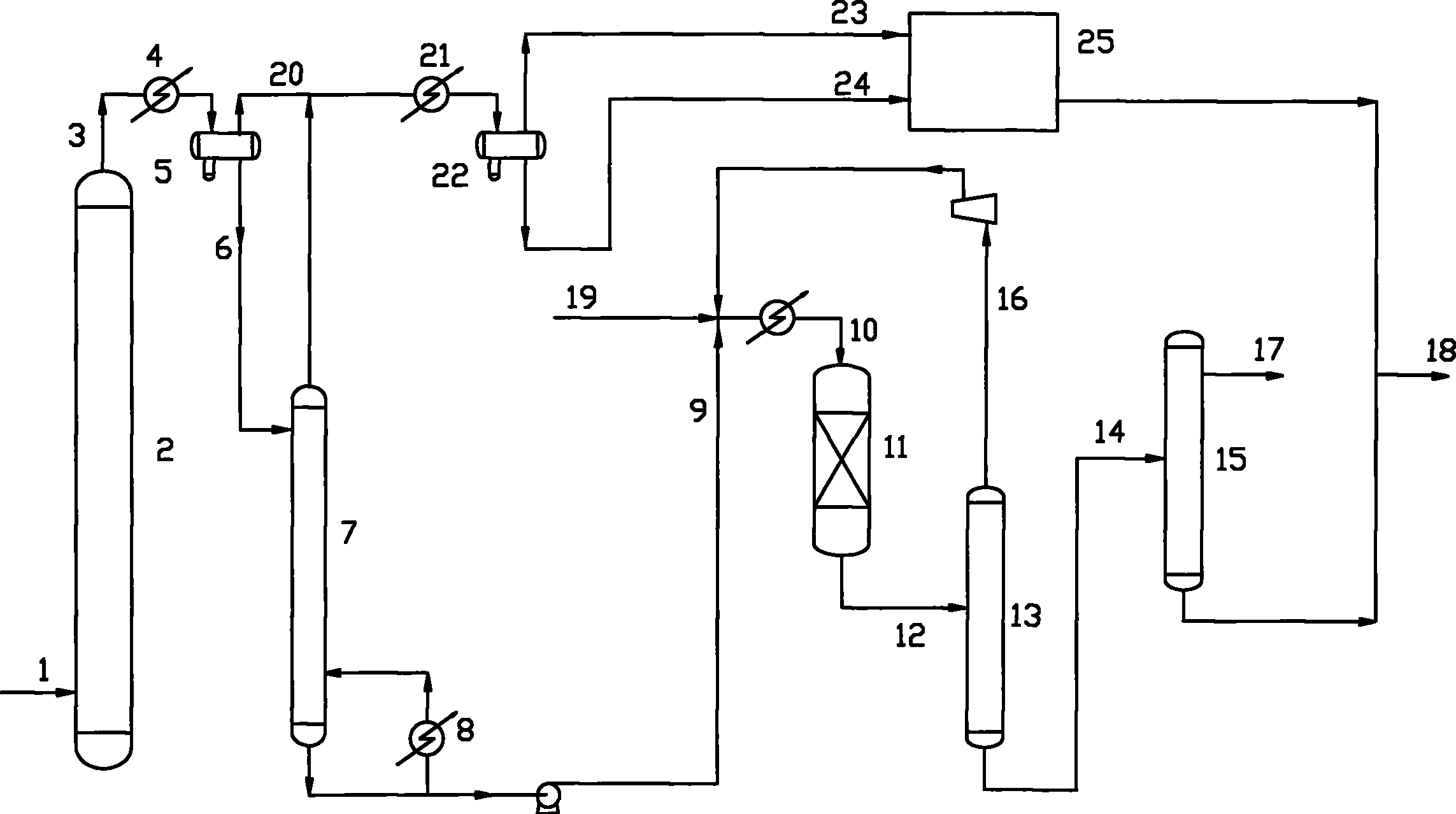

Combination method of catalytic cracking production separation and hydrogen refining

ActiveCN101294108BReduce liquid loadReduce saturationTreatment with hydrotreatment processesHydrogenation reactionCombined method

A combined method for separating and hydro-refining catalytic cracking product comprises the following steps: (1) introducing oil gas escaping from a settler of a catalytic cracking reaction system into a main fractionating tower, sequentially separating slurry oil, cycle oil, heavy diesel oil, diesel oil and overhead oil gas from bottom to top of the main fractionating tower, and feeding the overhead oil gas to an oil gas separation system to separate a fraction less than C4, light gasoline fraction and heavy gasoline fraction; (2) introducing the separated fraction less than C4 and the light gasoline fraction into an absorbing, stabilizing and refining system of the catalytic cracking device to obtain the product of the fraction less than C4 and the light gasoline product; and (3) introducing the separated heavy gasoline fraction into a hydrogenation reaction, contacting with a hydro-refining catalyst, and feeding hydrogen to carry out hydro-refining reaction to obtain heavy gasoline product. The method provided by the invention can produce clean gasoline and improve the absorption effect, and has the advantages of lowered energy consumption, simple and flexible flow, less investment and easy implementation.

Owner:CHINA PETROLEUM & CHEM CORP +1

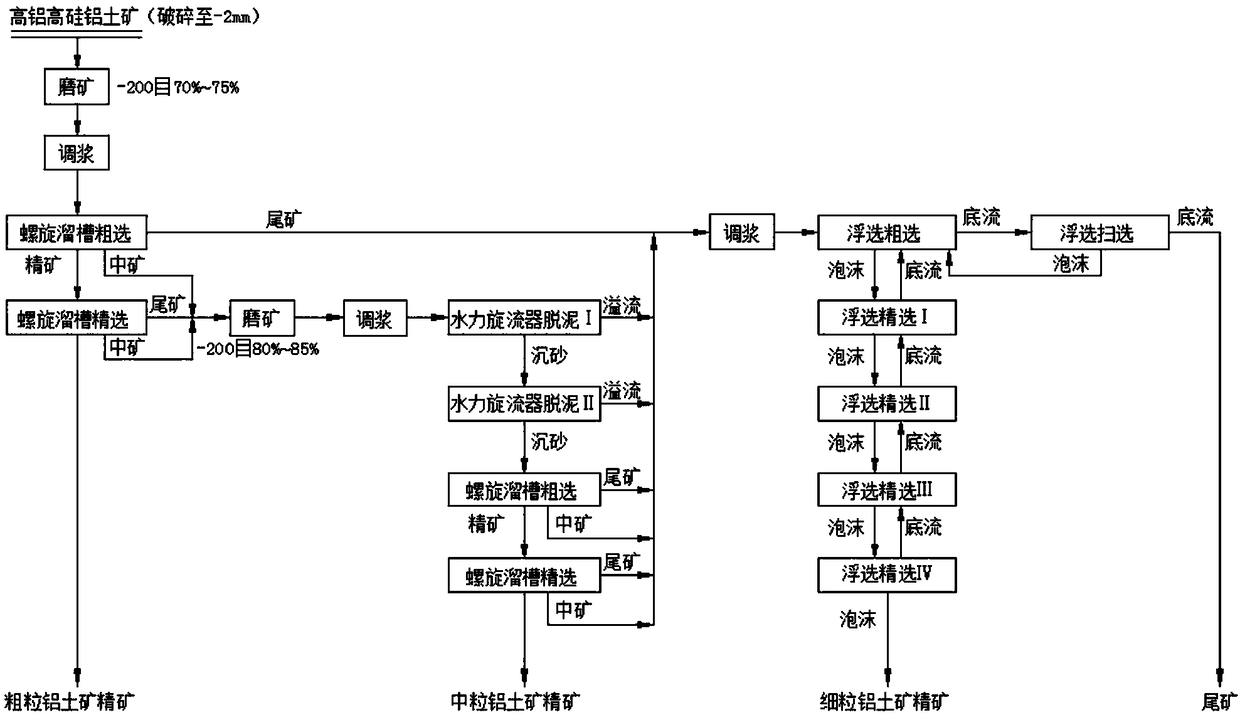

A kind of step-by-step desiliconization and upgrading method of high-aluminum and high-silicon bauxite

ActiveCN106902975BEmbodies the advantages of "being able to get it early"Reduce the amount of oreFlotationWet separationSlurryMaceral

The invention belongs to the technical field of mineral processing engineering and relates to a step-by-step desiliconizing and upgrading method for high-aluminum and high-silicon bauxite. The method comprises the steps that firstly, the high-aluminum and high-silicon bauxite is subjected to rough grinding, slurry mixing is conducted, a spiral chute is adopted to conduct the first step of desiliconizing, and coarse grain bauxite concentrate ores are obtained through roughing and concentrating; secondly, middlings in the first step are combined and reground, slurry mixing is conducted, the second step of desiliconizing is conducted through a hydraulic cyclone and the spiral chute in sequence, specifically, desliming is conducted through the hydraulic cyclone firstly, settled sand of slime is subjected to roughing and concentrating through the spiral chute, and medium grain bauxite concentrate ores are obtained; and thirdly, the middlings and tailings obtained in the first and second steps are combined and subjected to floatation desiliconizing, fine grain bauxite concentrate ores are obtained through a closed floatation process. By means of the step-by-step desiliconizing and upgrading method that the coarse grain ores are enriched in the spiral chute after rough grinding, after the middlings are reground, the medium grain ores are enriched in the hydraulic cyclone united with the spiral chute, and tailing fine slime flotation is conducted to enrich the fine grain ores, the bauxite concentrate ores of different grain grades are obtained by stages, so that the step-by-step desiliconizing and upgrading method has the advantages that drug consumption is low, the recovery rate is high, and desiliconizing is thorough.

Owner:KUNMING UNIV OF SCI & TECH

Method and device for producing a winding element

ActiveUS11335500B2Improve fill factorProduced economicallyManufacturing dynamo-electric machinesInductances/transformers/magnets manufactureWire rodCopper wire

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

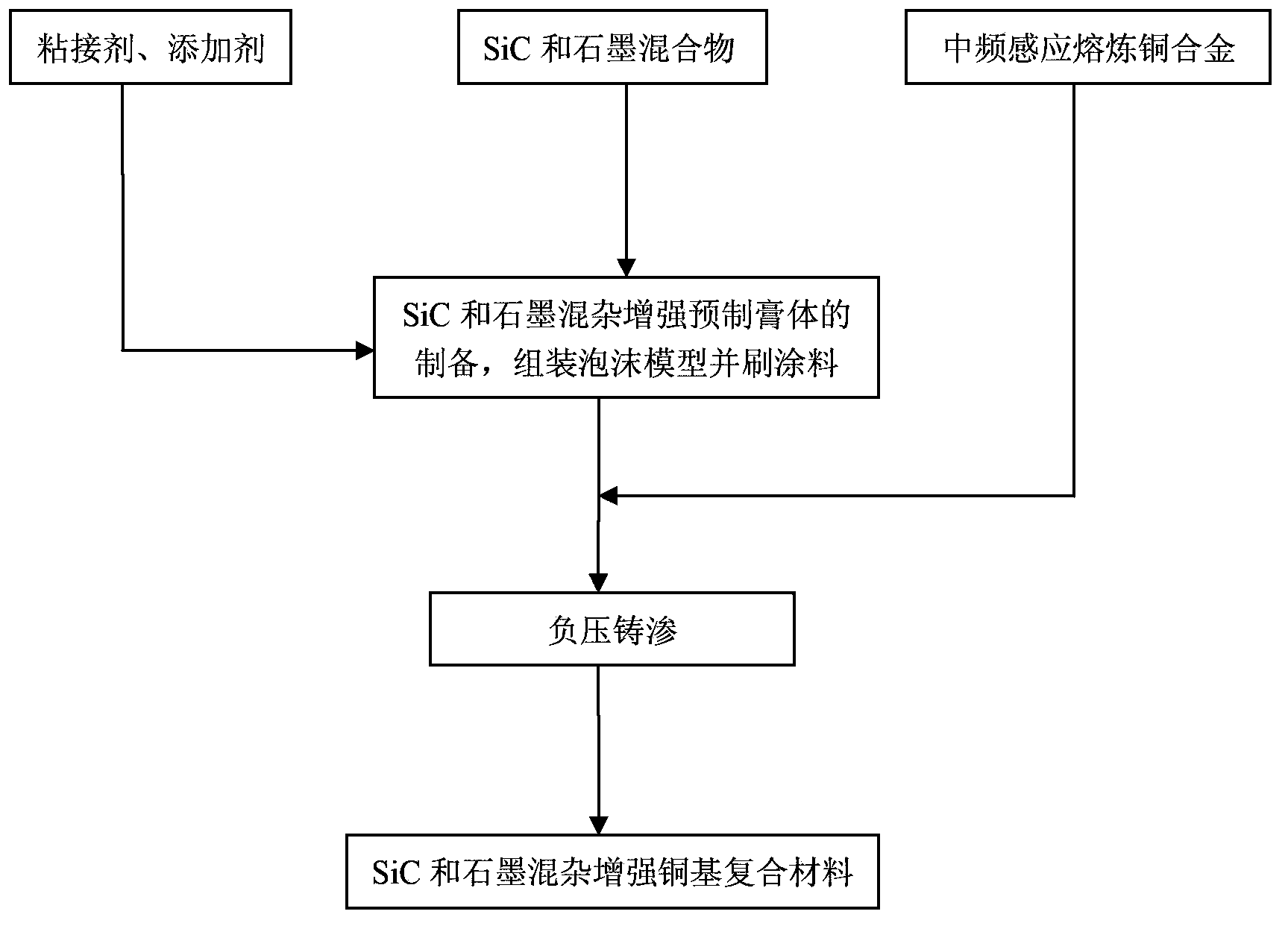

Preparation method for SiC and graphite hybrid reinforced copper-based surface composite material

InactiveCN102787253BIncreased Design FreedomSimple and flexible processFoundry mouldsMoulding machine componentsPhosphorSodium fluoride

Owner:XIAN UNIV OF TECH

Device and method for processing restaurant wastewater

ActiveCN102145967BIncrease dissolved oxygenImprove the efficiency of degrading pollutantsMultistage water/sewage treatmentActivated sludgeElectrolysis

Owner:TAIDEA TECH ZHONGSHAN

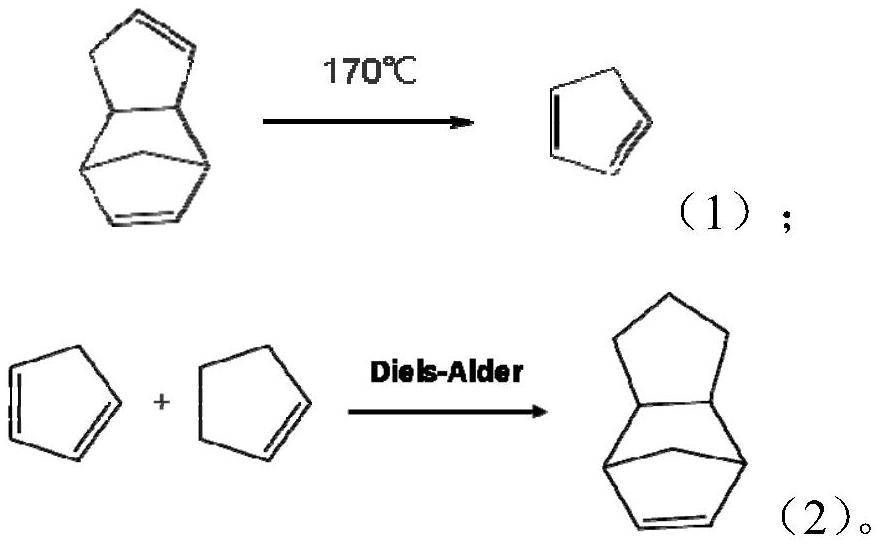

Synthesis method of polycyclic norbornene derivative

PendingCN114478156AExcellent optical propertiesImprove moisture resistanceHydrocarbons from unsaturated hydrocarbon additionHydrocarbon by depolymerisationPolymer sciencePolyolefin

The invention relates to C07C, in particular to a synthetic method of a polycyclic norbornene derivative. Comprising the following steps: heating dicyclopentadiene and cycloolefin to 190-260 DEG C in a reaction kettle under the protection of protective gas, carrying out heat preservation reaction for 1-5 hours, and then separating to obtain a light component, an intermediate component and a heavy component, and the intermediate component is a polycyclic norbornene derivative. The invention provides a preparation method of a polycyclic norbornene derivative. The polycyclic norbornene derivative can be used for preparing a high polymer material through a ring-opening metathesis reaction. The polycyclic norbornene derivative can be used for preparing a high-performance high polymer material which has excellent optical properties and moisture resistance and also has excellent chemical resistance of polyolefin and transparency and molding processability of amorphous resin.

Owner:广东华锦达新材科技有限公司

A kind of high damping carbon nanotube/aluminum alloy composite material and preparation method thereof

The invention provides a high-damping carbon nanotube / aluminum alloy composite material. The carbon nanotubes are uniformly distributed in an aluminum alloy matrix, the outer surface of the carbon nanotubes is coated with a diffusion layer, the diffusion layer extends from the outer surface of the carbon nanotubes to the aluminum alloy matrix; the diffusion layer has a microstructure different from the aluminum alloy matrix, and a micro surface is formed between the diffusion layer and the aluminum alloy matrix; and the damping factor of the high-damping carbon nanotube / aluminum alloy composite material is 0.005-0.0011. According to the high-damping carbon nanotube / aluminum alloy composite material prepared by the invention, because the diffusion layer is formed outside the carbon nanotubes, the interfacial potential between the carbon nanotubes and the alloy matrix can be obviously reduced, and interface bonding is coordinated and intensified. Therefore, the prepared composite material has ideal plasticity and damping properties, and the like.

Owner:CRRC QINGDAO SIFANG CO LTD +1

A kind of preparation technology of location blocking agent

ActiveCN105622856BReduce pollutionPrevent movementDrilling compositionMicroballoon preparationToluene diisocyanateAcrylonitrile

The invention discloses a preparation process of a positioning channeling blocking agent, and relates to the technical field of oil field development. The preparation process comprises the following steps: mixing ethanol, ethyl acetate, sodium lauryl sulfate, alkyl phenol polyoxyethylene (10) ether, ammonium persulfate, oxalic acid, furfuryl mercaptan, tripolycyanamide, formaldehyde, acrylonitrile and 2,6-toluene diisocyanate for reaction to obtain ammonium persulfate microcapsules; sequentially adding phenol and caustic soda into formaldehyde for reaction to generate phenolic resin; adding the ammonium persulfate microcapsules and the phenolic resin into a mixed solution of liquid acrylamide and tap water, and carrying out reaction at an ambient temperature of 80 DEG C to generate the positioning channeling blocking agent. The preparation process is simple, convenient, safe, and low in risk; by the preparation process, pollution of a plugging agent to a low-permeability layer can be reduced, movement of a gelatinized plugging agent in a stratum is avoided, and the plugging strength is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A process for smelting and separating uranium, thorium and rare earth from monazite concentrate

ActiveCN111020242BSolve problems such as being abandonedHigh recovery rateRare earth metal chloridesRadium compoundsPhosphoric acidWater chlorination

The invention provides a process method for smelting and separating uranium, thorium and rare earth from monazite concentrate, using monazite concentrate as raw material, adopting wet bead mill crushing, magnetic separation to remove iron, alkali decomposition transformation, trisodium phosphate Product preparation, alkali cake plus hydrochloric acid excellent solution, rare earth chloride mixture product preparation, high-quality molten slag plus hydrochloric acid full solution, amine extraction and extraction of uranium and uranium product preparation, acidic phosphorus-containing extraction of thorium and crude thorium product preparation, waste water Treatment and other steps make the recovery rate of uranium, thorium, rare earth and other valuable resources greater than 95%. After extracting thorium, the raffinate water phase is returned to the excellent solution to recover the rare earth chloride mixture. Most of the production process water is directly returned for recycling, and a small part of the wastewater is returned to the system for utilization after comprehensive treatment to achieve zero discharge of wastewater. The invention has reliable process technology, common chemical materials and low consumption. Guaranteeing the use of monazite resources in a green, efficient and clean production has obvious social and economic benefits.

Owner:湖南中核金原新材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com