High-damping carbon nanotube/aluminum alloy composite material and preparation method thereof

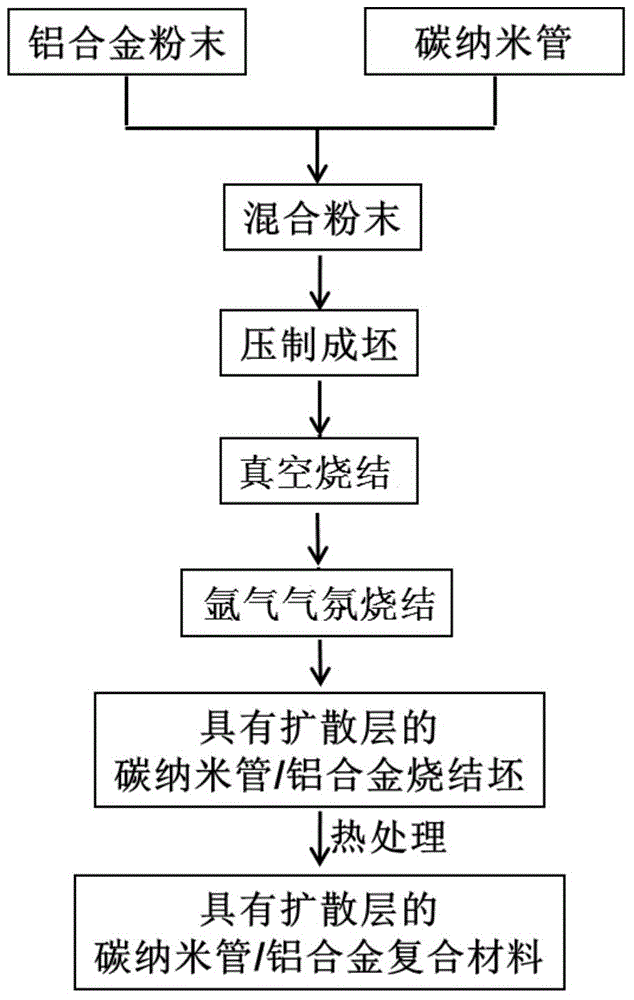

A technology of carbon nanotubes and composite materials, which is applied in the field of powder metallurgy preparation of high-damping carbon nanotubes/aluminum alloy composite materials, can solve the problem of changing the tensile strength and corrosion resistance of the alloy matrix, reducing the comprehensive performance of materials, and interfacial bonding plasticity Poor problems, to achieve the effect of easy preparation, good tensile strength, simple and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Mix carbon nanotubes with a diameter of 5-50nm and a length of 1-20μm with an aluminum alloy powder with a thickness of 0.1-2μm, a sheet diameter of 5-500μm, and a diameter-thickness ratio greater than 10 at a volume ratio of 2:98 Pressed evenly into a billet;

[0044] (2) Put the billet into the sintering furnace, vacuumize until the pressure in the sintering furnace is less than 2×10 -2 Pa, after the sintering furnace is heated to 614°C at a heating rate of 5°C / min, it is kept at 614°C for 20 minutes;

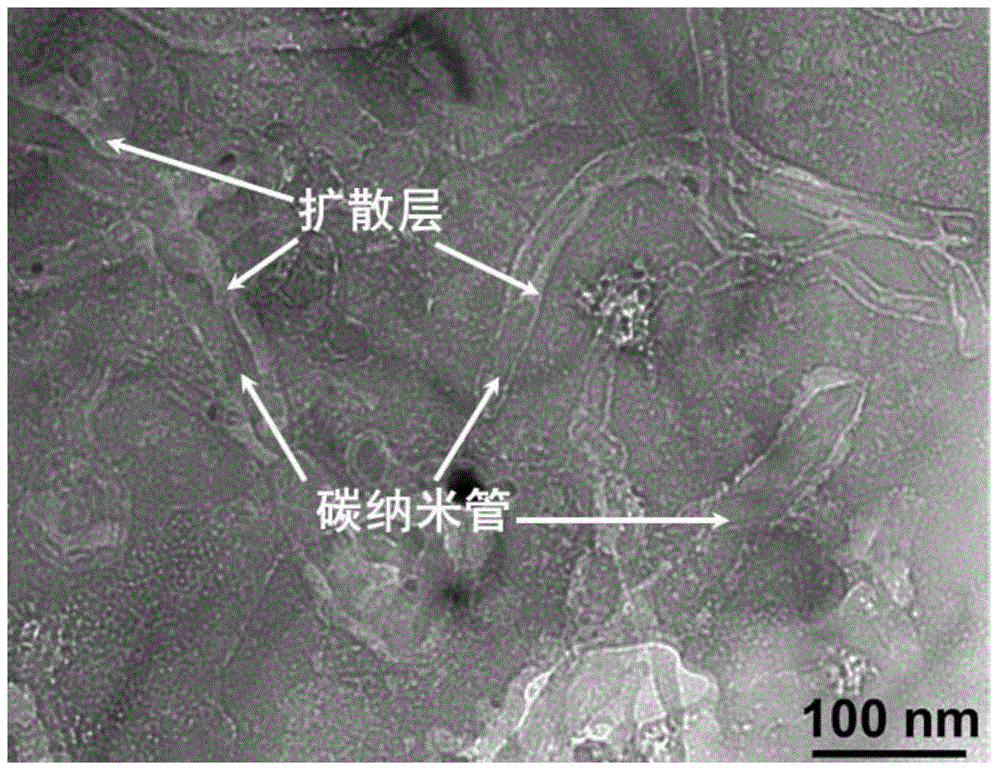

[0045] (3) Introduce argon gas into the sintering furnace so that the pressure of the argon gas in the sintering furnace is 0.1MPa, control the cooling rate of the sintering furnace temperature at 15°C / min to 527°C, and continue to keep warm at 527°C for 180min, control After cooling down to 430°C at a cooling rate of 15°C / min, control the cooling rate to 2°C / min and cool to room temperature to obtain a carbon nanotube / aluminum alloy sintered compact with a diffus...

Embodiment 2

[0050] (1) Mix carbon nanotubes with a diameter of 10-40nm and a length of 5-20μm with an aluminum alloy powder with a thickness of 0.1-2μm, a sheet diameter of 5-500μm, and a diameter-thickness ratio greater than 10 at a volume ratio of 10:90 Pressed evenly into a billet;

[0051] (2) Put the billet into the sintering furnace, vacuumize until the pressure in the sintering furnace is less than 2×10 -2 Pa, after the sintering furnace is heated to 614°C at a heating rate of 2°C / min, it is kept at 614°C for 5 minutes, cooled to 590°C at a rate of 10°C / min, and kept at 25 minutes;

[0052] (3) Introduce argon gas into the sintering furnace so that the pressure of the argon gas in the sintering furnace is 0.1MPa, control the cooling rate of the sintering furnace temperature at 5°C / min to 527°C, and continue to keep warm at 527°C for 180min, control After cooling down to 380°C at a cooling rate of 15°C / min, control the cooling rate to 5°C / min and cool to room temperature to obtain ...

Embodiment 3

[0057] (1) Mix carbon nanotubes with a diameter of 20-30nm and a length of 10-15μm with an aluminum alloy powder with a thickness of 0.1-2μm, a sheet diameter of 5-500μm, and a diameter-thickness ratio greater than 10 at a volume ratio of 0.5:99.5 Pressed evenly into a billet;

[0058] (2) Put the billet into the sintering furnace, vacuumize until the pressure in the sintering furnace is less than 2×10 -2 Pa, after the sintering furnace is heated up to 614°C at a heating rate of 2°C / min, it is kept at 614°C for 15 minutes, cooled to 558°C at a rate of 10°C / min, and then raised to 590°C at a rate of 5°C / min , continue to keep warm for 5 minutes;

[0059] (3) Introduce argon gas into the sintering furnace so that the pressure of the argon gas in the sintering furnace is 0.1MPa, control the temperature of the sintering furnace at a rate of 5°C / min to drop to 500°C, and continue to keep warm at 500°C for 300min. After cooling down to 420°C at a cooling rate of 10°C / min, control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com