Method for smelting and separating uranium, thorium and rare earth from residual slag of processed monazite

A technology of slag melting and stone optimization, which is applied in the field of smelting and separating uranium, thorium and rare earth, can solve the problems of easy emulsification of organic phase and low extraction capacity, and achieve the effect of improving recovery rate, simple and flexible process flow, and reducing the number of units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

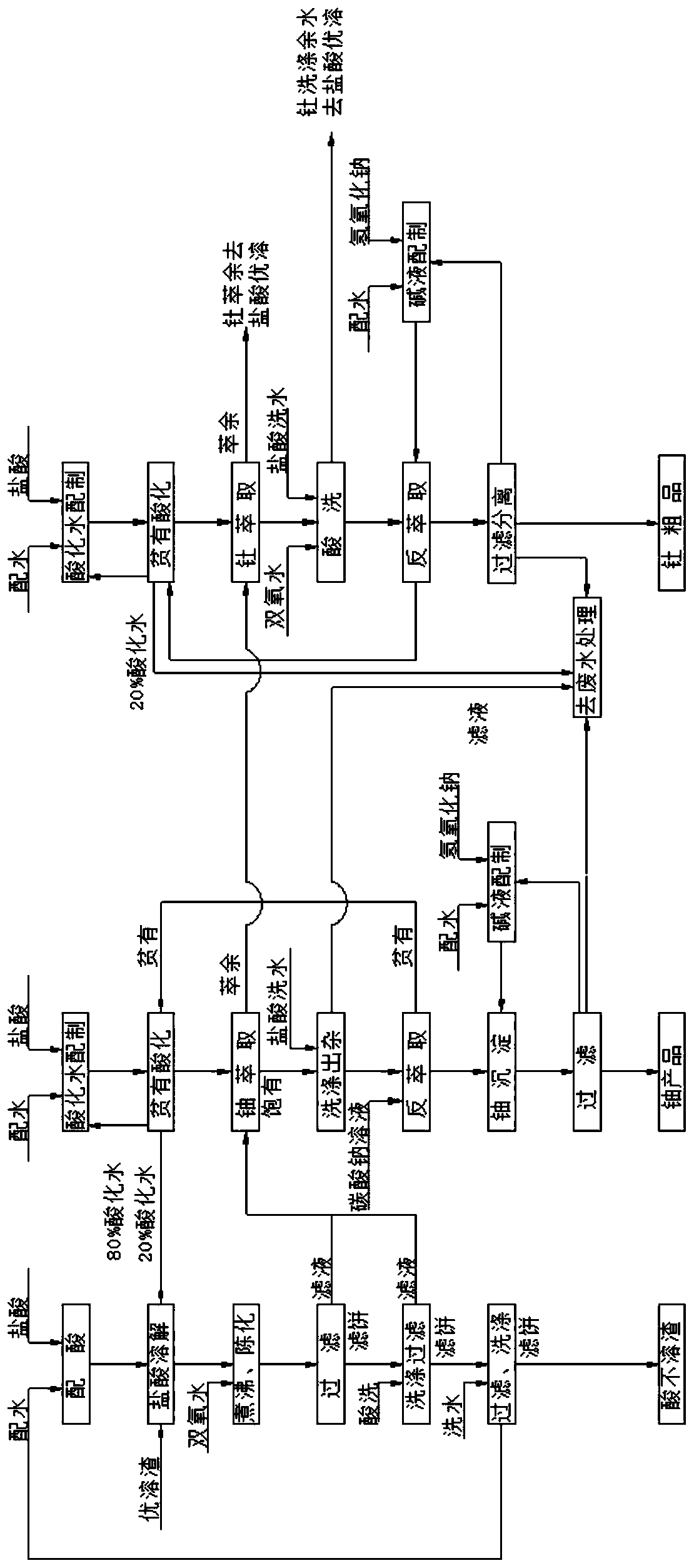

Image

Examples

Embodiment 1

[0055] Monazite excellent slag: U: 0.284%, ThO2 : 12.28%, REO: 11.36%, Fe: 0.83%.

[0056] Measure the 6mol / L HCl solution prepared in the dilute hydrochloric acid high-level metering tank and pour it into the dissolution tank, start stirring, heat and preheat, and when the temperature rises to 40°C, put monazite excellent slag into the dissolution tank, with a liquid-solid ratio of 1.5: 1. Warm and stir to dissolve, the reaction temperature is controlled at 92±2°C, the reaction time is 6h, and then boiled for 1.5h, the boiling temperature is 105±2°C. After boiling, stop heating, turn on the cooling water in the jacket of the reaction kettle to condense, when the temperature of the solution drops to 51°C, add 35.2% hydrogen peroxide at the rate of 0.050kg hydrogen peroxide / kg excellent molten slag, continue to keep warm for 12 hours, and siphon Extract the solution by means of supernatant liquid and inspection filter. The slurry after siphoning is washed by 3-stage countercur...

Embodiment 2

[0066] Monazite excellent slag: U: 0.164%, ThO 2 : 10.69%, REO: 10.48%, Fe: 1.06%.

[0067] Measure the 6mol / L HCl solution prepared in the dilute hydrochloric acid high-level metering tank and pour it into the dissolution tank, start stirring, heat and preheat, and when the temperature rises to 40°C, put monazite excellent slag into the dissolution tank, with a liquid-solid ratio of 1.5: 1. Warm and stir to dissolve, the reaction temperature is controlled at 85±2°C, the reaction time is 5h, and then boiled for 1.5h, the boiling temperature is 105±2°C. Stop heating after boiling, turn on the cooling water in the jacket of the reaction kettle to condense, when the temperature of the solution drops to 55°C, add 35.0% hydrogen peroxide at the rate of 0.050kg hydrogen peroxide / kg excellent molten slag, heat preservation and aging for 10h, use siphon Clear liquid and extract solution by means of inspection and filtration. The slurry after siphoning is washed by three-stage counte...

Embodiment 3

[0077] Monazite excellent slag: U: 0.301%, ThO 2 : 8.42%, REO: 9.98%, Fe: 0.96%.

[0078] Measure the 6mol / L HCl solution prepared in the dilute hydrochloric acid high-level metering tank and pour it into the dissolution tank, start stirring, heat and preheat, and when the temperature rises to 40°C, put monazite excellent slag into the dissolution tank, with a liquid-solid ratio of 1.5: 1. Heat and stir to dissolve, the reaction temperature is controlled at 90±2°C, the reaction time is 4h, and then boiled for 1.0h, the boiling temperature is 105±2°C. Stop heating after boiling, turn on the cooling water in the jacket of the reaction kettle to condense, when the temperature of the solution drops to 50°C, add 35.0% hydrogen peroxide at the rate of 0.050kg hydrogen peroxide / kg excellent molten slag, heat preservation and aging for 12h, and use siphon Clear liquid and extract solution by means of inspection and filtration. The slurry after siphoning is washed by three-stage coun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com