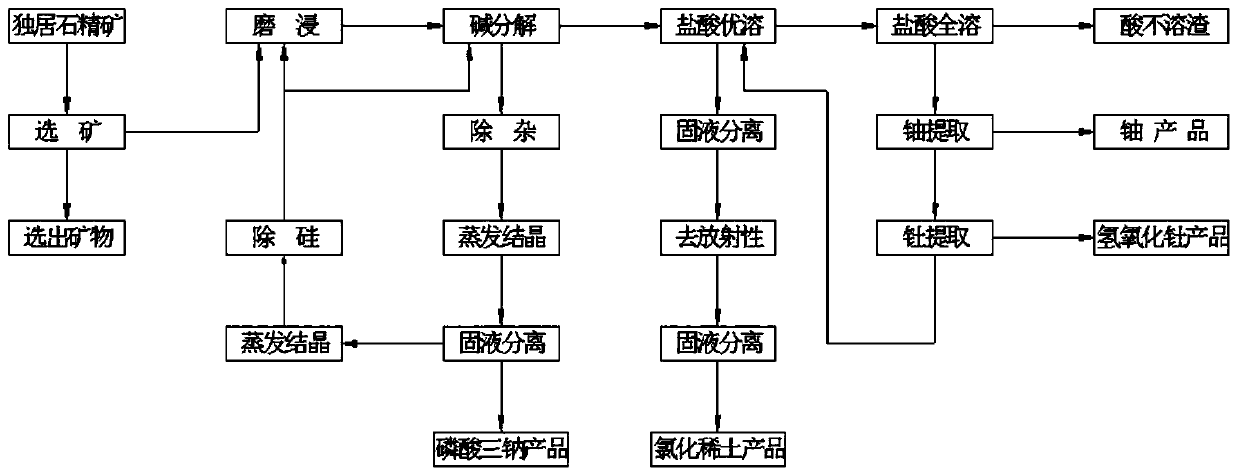

Process method for smelting and separating uranium, thorium and rare earth from monazite concentrate

A process method, ore concentrate technology, which is applied in the field of smelting and separating uranium, thorium and rare earth, and can solve problems such as endangering the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Monazite concentrate (REO: 52.61%, ThO 2 : 4.03%, CaO: 2.06%, TiO 2 :1.84%, ZrO 2 : 2.85%, SiO 2 : 2.73%, Fe 2 o 3 : 2.92%, U 3 o 8 : 1.14%), after unpacking, it is transported to the monazite silo by the belt conveyor system, and then discharged through the outlet of the lower part of the silo and sent into the 50% to 60% sodium hydroxide solution in the stirring slurry tank, according to 1 times The ratio of the volume to the weight of the pulp is used for pulping and uniform mixing. The pulp is pumped into the bead mill through the rubber tube. Under normal pressure or micro pressure, after grinding, the pulp with a particle size of -320 mesh (accounting for more than 99.5%) is classified by the built-in The device is classified and discharged from the mill.

[0069] Pump the slurry with a particle size of 320 mesh (accounting for more than 99.5%) into the permanent magnet magnetic separator. The magnetic separation strength of the magnetic separator is 1.2T; ...

Embodiment 2

[0085] Monazite concentrate (REO: 50.82%, ThO 2 : 4.29%, CaO: 2.63%, TiO 2 :2.82%, ZrO 2 : 6.71%, SiO 2 : 3.46%, Fe 2 o 3 :3.09%, U 3 o 8 : 0.98%) After being unpacked, it is transported to the monazite silo by a belt conveyor system, and then discharged through the outlet at the lower part of the silo and sent into the 50% to 60% sodium hydroxide solution in the stirring slurry tank, according to 1 times The ratio of the volume to the weight of the pulp is used for pulping and uniform mixing. The pulp is pumped into the bead mill through the rubber tube. Under normal pressure or micro pressure, after grinding, the pulp with a particle size of -320 mesh (accounting for more than 99.5%) is passed through the built-in classification device. Classification is carried out and discharged from the mill.

[0086] Pump the slurry with a particle size of 320 mesh (accounting for more than 99.5%) into the permanent magnet magnetic separator. The magnetic separation strength of th...

Embodiment 3

[0102] Monazite concentrate (REO: 51.24%, ThO 2 : 4.01%, CaO: 2.01%, TiO 2 :2.28%, ZrO 2 : 2.79%, SiO 2 : 2.86%, Fe 2 o 3 : 2.87%, U 3 o 8 : 1.58%), after unpacking, it is transported to the monazite silo by the belt conveyor system, and then discharged through the outlet of the lower part of the silo and sent into the 50% to 60% sodium hydroxide solution in the stirring slurry tank, according to 1 times The ratio of the volume to the weight of the pulp is used for pulping and uniform mixing. The pulp is pumped into the bead mill through the rubber tube. Under normal pressure or micro pressure, after grinding, the pulp with a particle size of -320 mesh (accounting for more than 99.5%) is classified by the built-in The device is classified and discharged from the mill.

[0103] Pump the slurry with a particle size of 320 mesh (accounting for more than 99.5%) into the permanent magnet magnetic separator. The magnetic separation strength of the magnetic separator is 1.2T; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com