Ceramic flat membrane supporting body and production method thereof

A flat membrane and support technology, applied in the field of ceramic flat membrane support and its preparation, can solve the problems of high production cost, unfavorable liquid penetration, low filtration efficiency, etc., and achieve low cost, simple and flexible process, and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

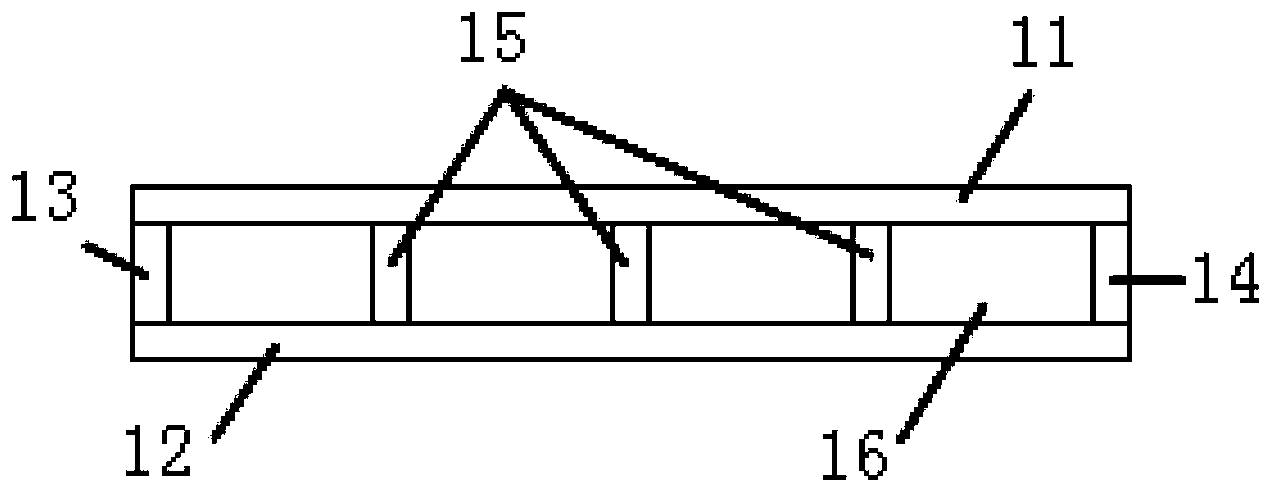

[0036] The binder polyethersulfone (PES) and the solvent N-methylpyrrolidone (NMP) were stirred and dissolved at 70 °C to obtain a transparent sol, the dispersant polyvinylpyrrolidone (PVP) was added, and the ceramic powder Al 2 O 3 (Particle size 0.5μm), stirring ball milling for 24 hours, vacuum defoaming for 2 hours to obtain a slurry, the slurry viscosity is between 10000 ~ 20000mPa·s; the raw material ratio is m(PES):m(NMP):m(Al 2 O 3 )=1:4:6, m(PVP): m(Al 2 O 3 ) = 1:100;

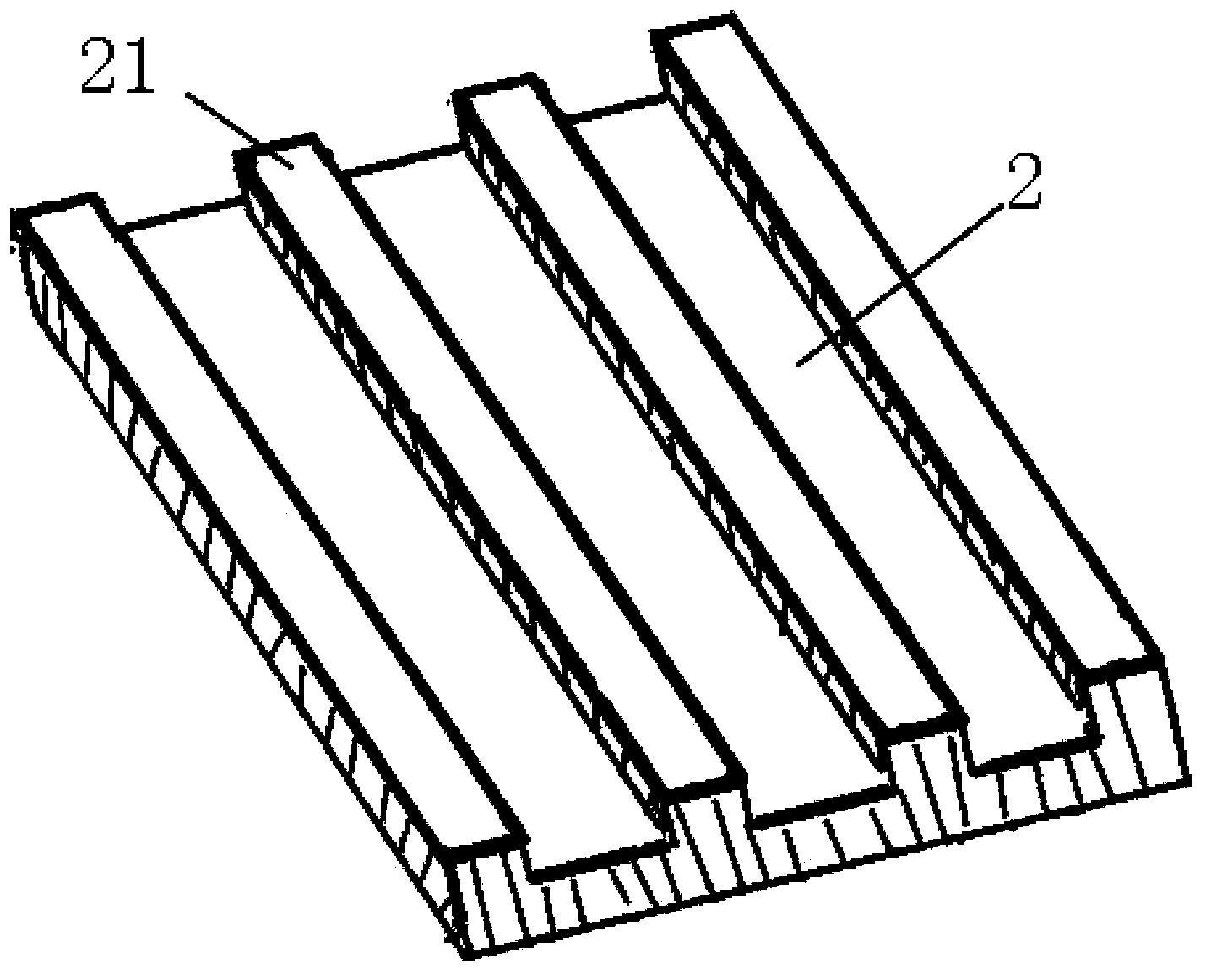

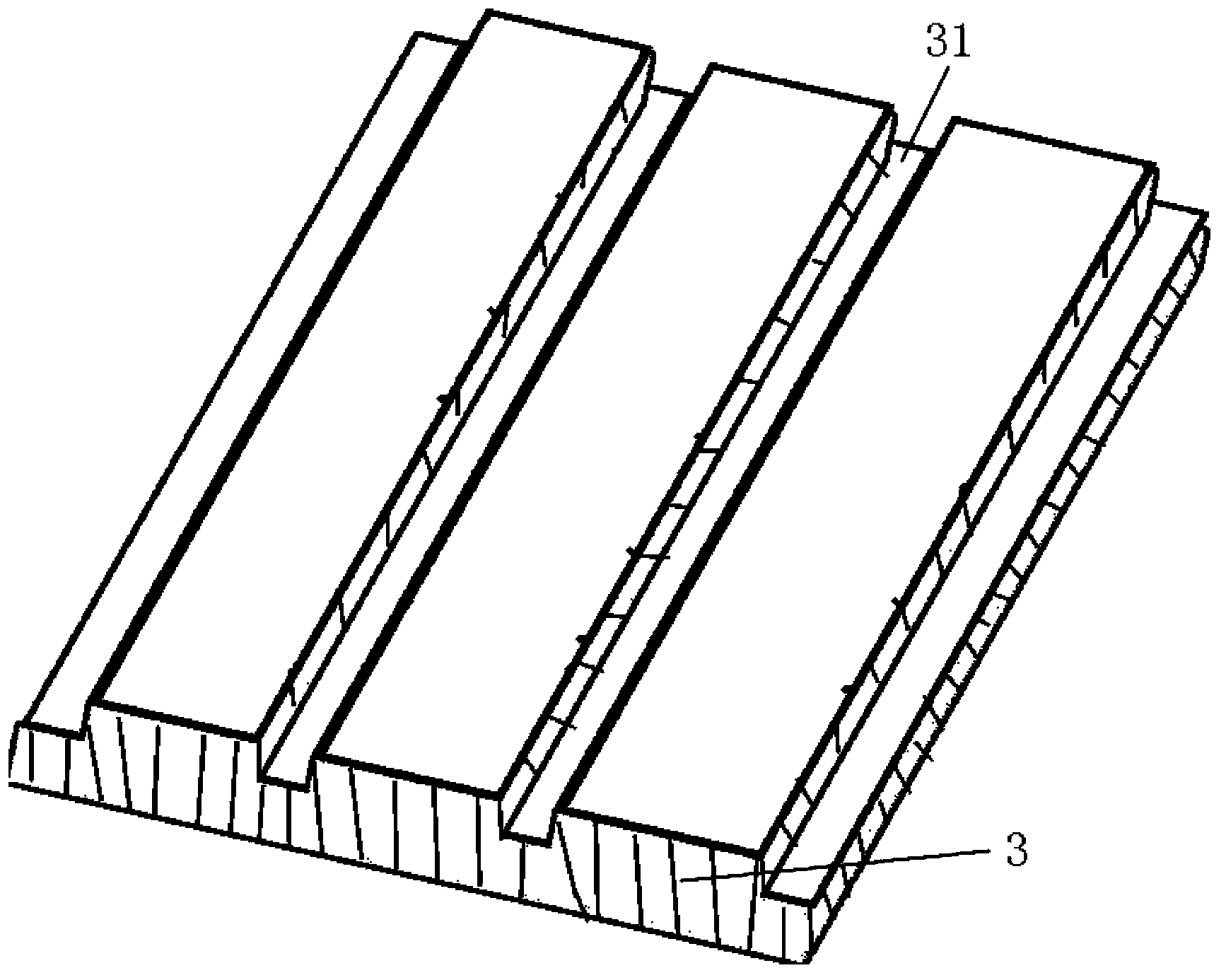

[0037] use image 3 The glass template plate shown is scraped at a temperature of 30°C and a thickness of 3mm. The template plate is quickly immersed in water to cure for 0.5h, and dried after the phase inversion is complete to obtain a half-edge membrane with protrusions;

[0038] Prepare an aqueous solution of 8wt.% polyvinyl alcohol (PVA), take two identical half-edge films, pre-coat a layer of PVA solution on one side of the protruding part, and then stick them together and press them tightly...

Embodiment 2

[0044] The binder polysulfone (PSF) and solvent dimethylacetamide (DMAC) were dissolved by heating and stirring, and then ceramic powder yttria-stabilized zirconia (YSZ, particle size 0.2μm), dispersant PVP, and stirring ball milled for 24h were added. , vacuum defoaming for 6h to obtain slurry, the viscosity of the slurry is between 10000~20000mPa·s; the ratio of raw materials is m(PSF):m(DMAC):m(YSZ)=1:5:8, m(PVP): m(YSZ)=1:100.

[0045] Using a silicone template plate to scrape the film, the temperature of the scraping film is 15 °C, the thickness of the scraping film is 5 mm, after scraping the film, let it stand in the air for 3 minutes, quickly immerse the template plate in water to cure for 2 hours, and dry it after the phase inversion is complete. Outgoing half membrane;

[0046] Prepare 8 wt.% PVA aqueous solution, take two identical half-edge films, pre-coat a layer of PVA solution on one side of the protruding part, and then relatively adhere and press tightly, and...

Embodiment 3

[0050] Select polyethersulfone (PES) as binder, N-methylpyrrolidone (NMP) as solvent, polyvinylpyrrolidone (PVP) as dispersant, alumina (Al 2 O 3 , particle size 1 μm) and titanium oxide (TiO 2 , particle size 50nm) mixed uniformly in a mass ratio of 6:1 as a ceramic powder. m(PES):m(NMP):m(ceramic powder)=1:5:6, m(PVP):m(ceramic powder)=1:120.

[0051] When the green body is sintered, the temperature is raised to 450°C at 1°C / min, held for 3 hours, and heated to 1150°C at 2°C / min, held for 5 hours. Other conditions are the same as in Example 1. The ceramic flat membrane support prepared in this example has a porosity of 60%, an average pore diameter of 100 nm, a compressive strength of 22 MPa, and a pure water flux of 12 m under a pressure of 0.1 MPa. 3 / (m 2 h).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com