Combination method of catalytic cracking production separation and hydrogen refining

A hydrorefining and catalytic cracking technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of large amount of absorbent, poor absorption effect, and high energy consumption of the absorption and stabilization system, achieving low investment, The effect of reducing energy consumption and improving absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

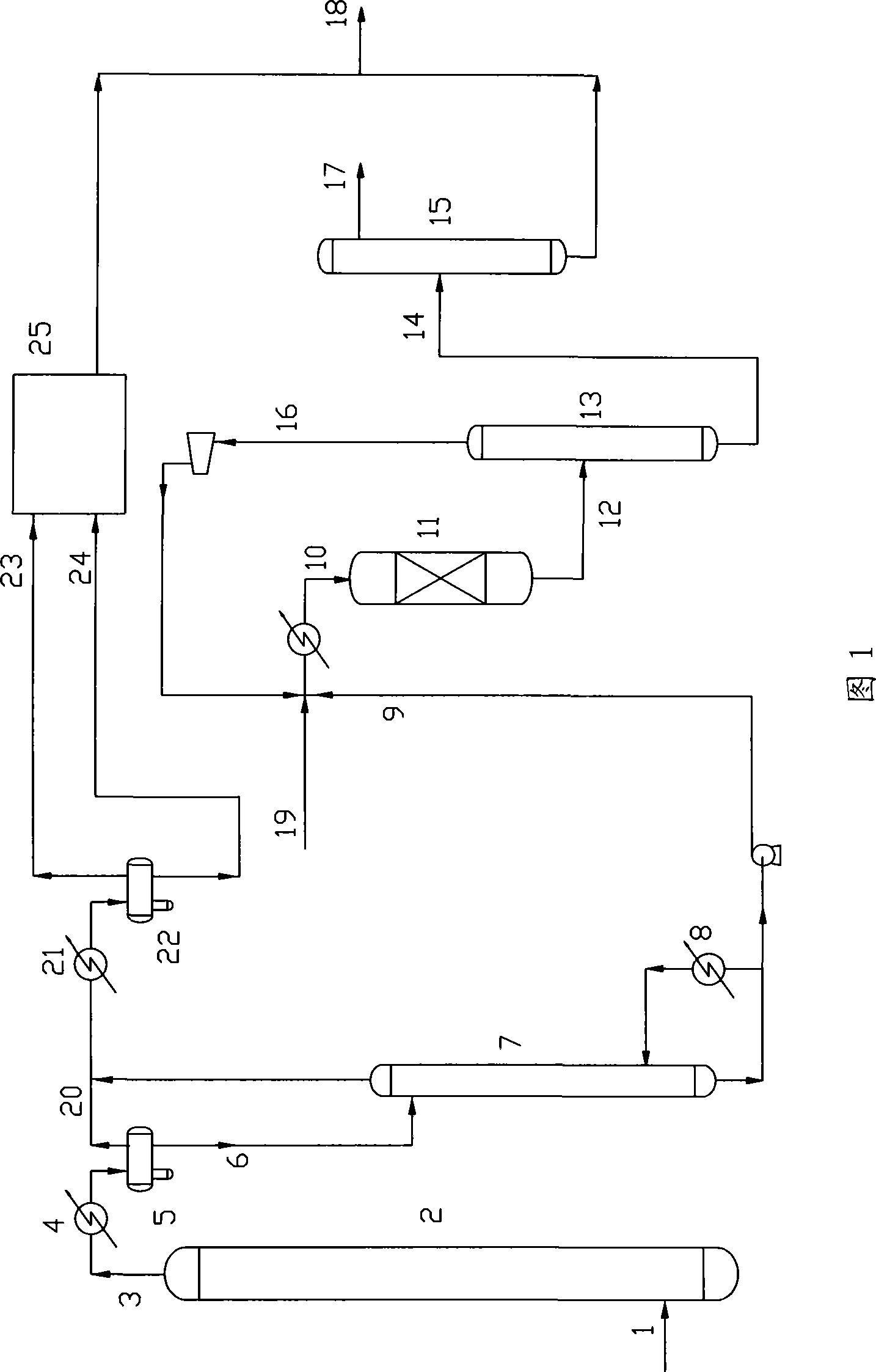

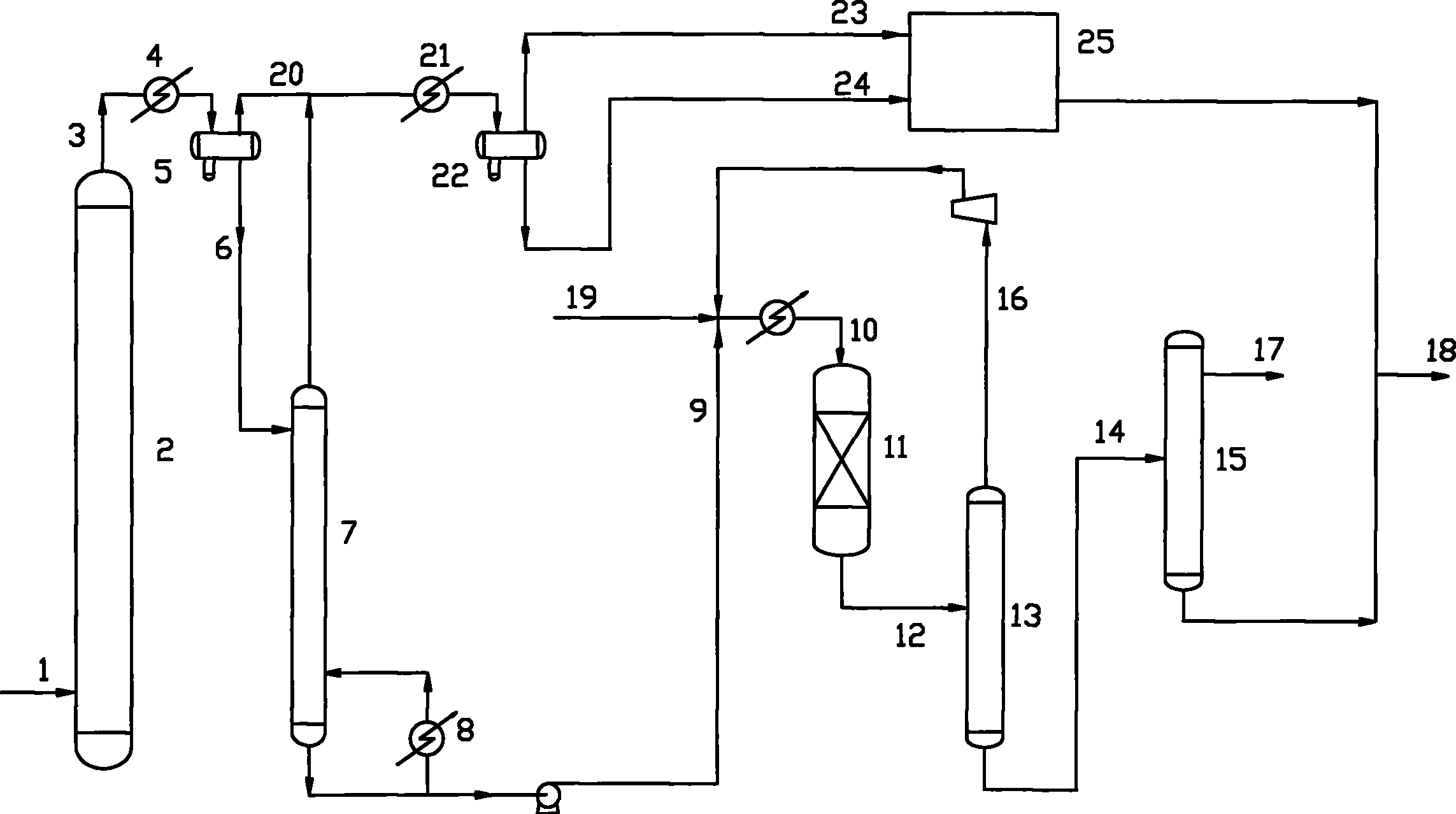

[0034] According to attached figure 1 The method provided by the present invention as shown, utilizes Aspen plus software to carry out simulation calculation to catalytic cracking fractionation absorption stable flow process, main operation condition: the oil and gas amount that enters main fractionation column is 309215kg / h, main fractionation column top heat exchanger 4 outlets The oil gas temperature is 70°C, the oil gas temperature at the outlet of the rich gas heat exchanger 21 is 40°C, and the 95% distillation temperature point of light gasoline is 165°C. The calculation results are shown in Table 1.

Embodiment 2

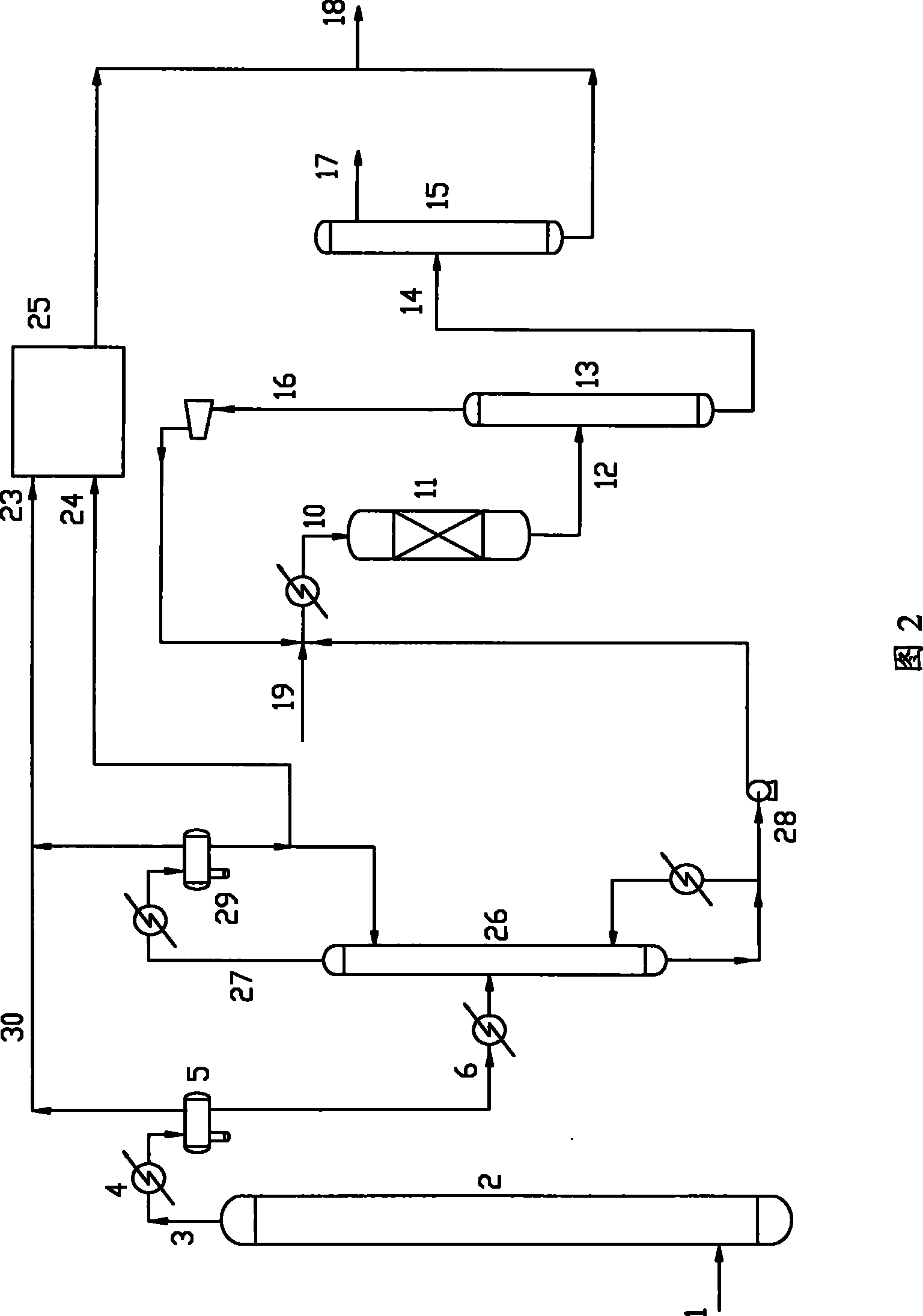

[0036] According to attached figure 2 The method provided by the present invention as shown, utilizes Aspen plus software to simulate and calculate the catalytic cracking fractionation absorption stable process, the main operating conditions: the amount of oil and gas entering the main fractionation tower is 309215kg / h, and the condensation temperature at the top of the gasoline fractionation tower is 40 °C , the temperature at the bottom of the tower is 180°C, the reflux ratio is 1.2, and the distillation temperature of 95% of light gasoline is 150°C. The calculation results are shown in Table 1.

Embodiment 3

[0041] The crude gasoline A produced by the catalytic cracking unit is cut into light and heavy gasoline fractions, the cut point is 96°C, and the heavy gasoline fraction is hydrofined. The hydrofinishing catalyst is the catalyst of Changling Refinery and Chemical General Plant of China Petroleum and Chemical Corporation. The RSDS-1 catalyst produced by the factory. The light gasoline fraction is washed with alkali to remove mercaptans, and then the light and heavy fractions are mixed into refined gasoline products. The properties of raw material A heavy gasoline fraction are shown in Table 2, the hydrogenation reaction conditions and reaction results are shown in Table 3, and the properties of raw material A and the mixed gasoline product are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com