Method for manufacturing grating micro-lens array through strain modulation self-assembly, and product

A microlens array and self-assembly technology, which is applied in the field of optical instruments, can solve the problems of complex, bulky and expensive optical spectrometers, and achieve the effect of simple and flexible process flow, simple steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

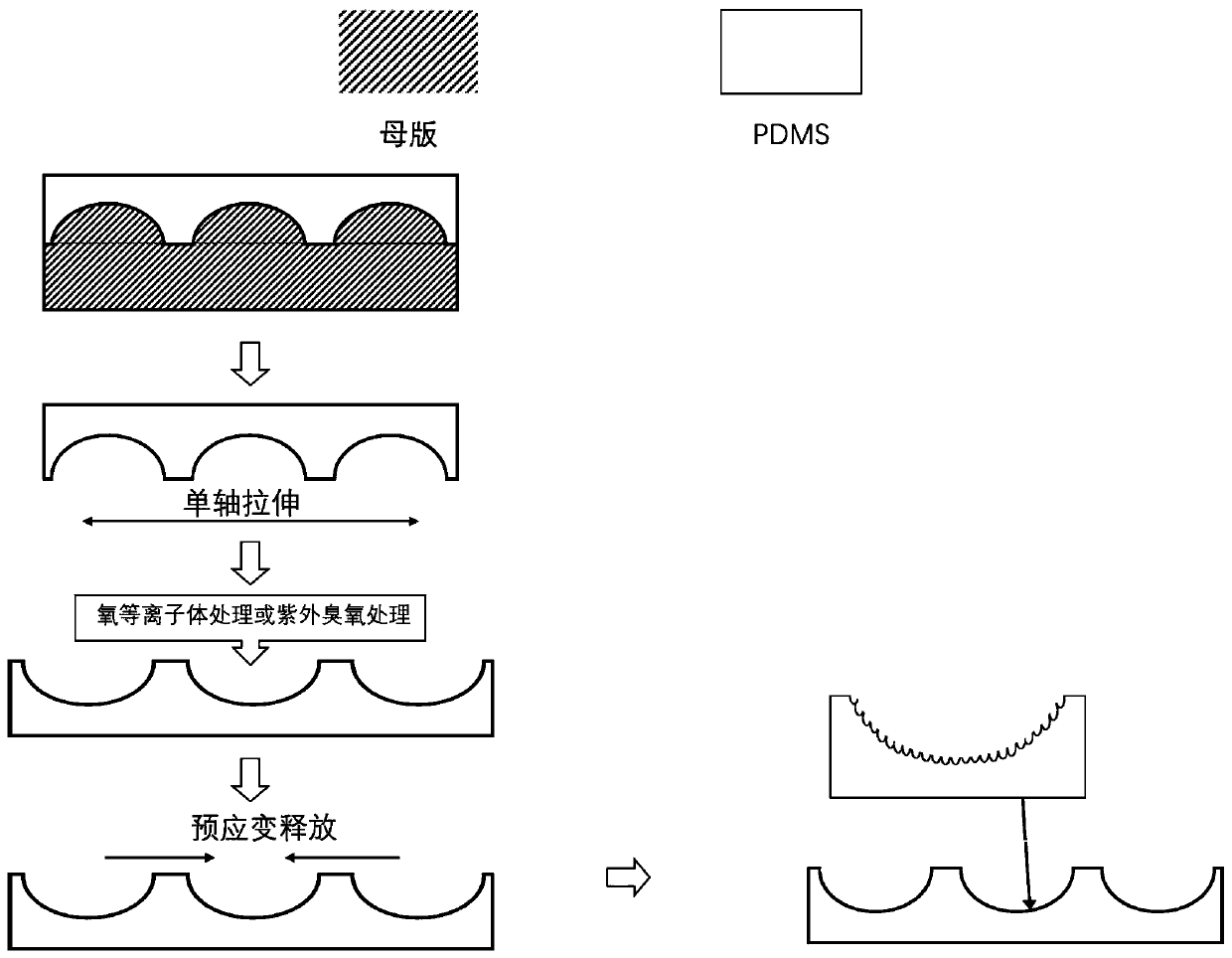

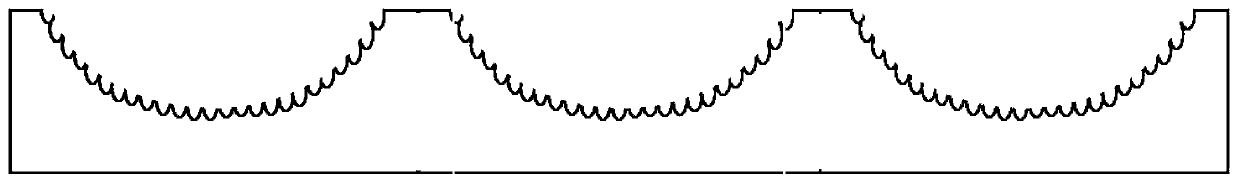

[0018] The first embodiment of the present invention provides a method for fabricating a grating microlens array using strain-modulated self-assembly, see Figure 1-2 , which includes the following processes:

[0019] Step 1, take a positive microlens array as a master plate, and use PDMS material (polydimethylsiloxane) to copy a negative microlens array mold.

[0020] Step 2, fix the prepared negative microlens array mold on a fixture that can be stretched uniaxially to realize the pre-stretching of the negative microlens array mold, and use an ion beam etching machine for the negative microlens array mold Oxygen plasma treatment or ultraviolet ozone treatment forms a layer of silicon dioxide-like hard film.

[0021] Step 3, the pre-stretching of the negative microlens array mold is released, and due to the difference in Young’s modulus be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com