Method for preparing desulfurizer capable of absorbing catalytic cracking gas at high selection

A catalytic cracking gasoline, high-selectivity technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Reduce sulfur content and other issues to achieve the effect of avoiding secondary sulfide residues, avoiding secondary sulfide residues, and providing sulfur-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare catalyst of the present invention

[0040] (1) catalyst preparation: 100g silica sol (30wt% solid content), 33.3g aluminum sol (30wt% solid content), 146.9g zinc nitrate, 75.2g nickel nitrate and 19.1g copper nitrate were mixed for 10 minutes, then mixed Add 20g of citric acid to the solution, stir and reflux at 90°C for 6 hours to form a sol; evaporate at a constant temperature for 12 hours to form a xerogel; grind the xerogel into a fine powder, and roast at 500°C to obtain a powder catalyst;

[0041] (2) Catalyst molding: add 90ml of 3wt% dilute nitric acid solution to the powder obtained in step (1), mix it for 15 minutes, roll the ball into a 3mm ball in a granulator, dry at 120°C for 12 hours, and then dry at 500°C Roast for 3 hours;

[0042] (3) Hydrothermal treatment: put the spherical catalyst prepared in step (2) into a tubular reactor, raise the temperature to 500°C in the air under normal pressure, and then change the water vapor treatment at this t...

Embodiment 2

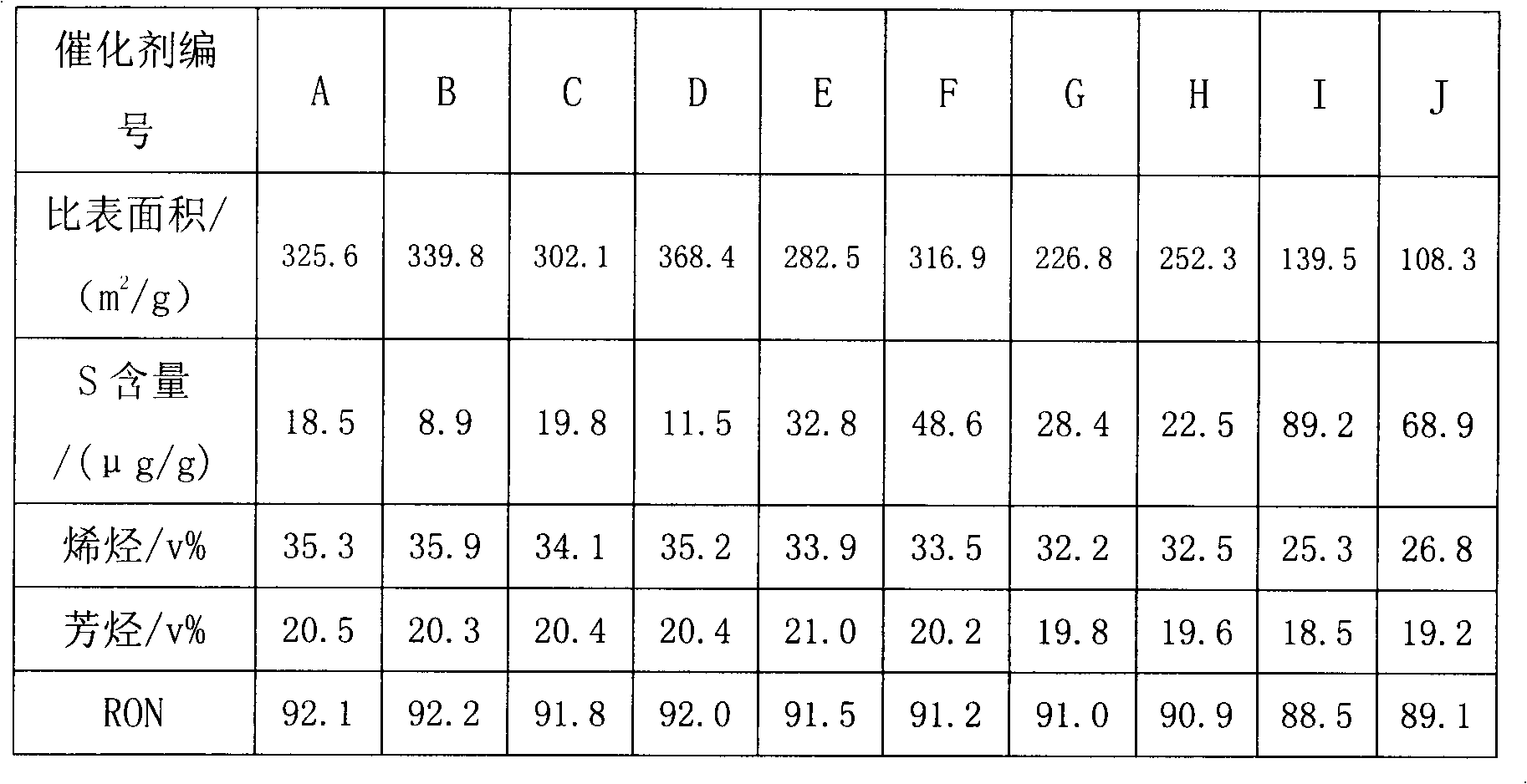

[0045] Prepare other several catalysts B-F by the method of embodiment 1, difference is to change active component and basic metal oxide type and content, be respectively B (nickel 15wt%, cobalt 5wt%, zinc oxide 40wt%, silicon aluminum oxide material content is the balance), C (nickel 6wt%, cobalt 12wt%, zinc oxide 40wt%, silicon aluminum oxide content is the balance), D (nickel 38wt%, cobalt 1wt%, manganese oxide 30wt%, silicon aluminum oxide material content is the balance), E (nickel 15wt%, copper 5wt%, calcium oxide 40wt%, silicon aluminum oxide content is the balance), F (nickel 15wt%, cobalt 5wt%, magnesium oxide 40wt%).

Embodiment 3

[0047] Catalyst G was prepared according to the method of Example 1, except that the carrier (zinc oxide 40wt%) modified by basic oxide was first prepared, and then the bimetallic active component (nickel 15wt%, cobalt 5wt%) was introduced by impregnation method, Carry out hydrothermal treatment by the method for step (3) then.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com