A subcritical fluid continuous isobaric extraction and separation device system and extraction and separation process

A subcritical fluid, extraction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

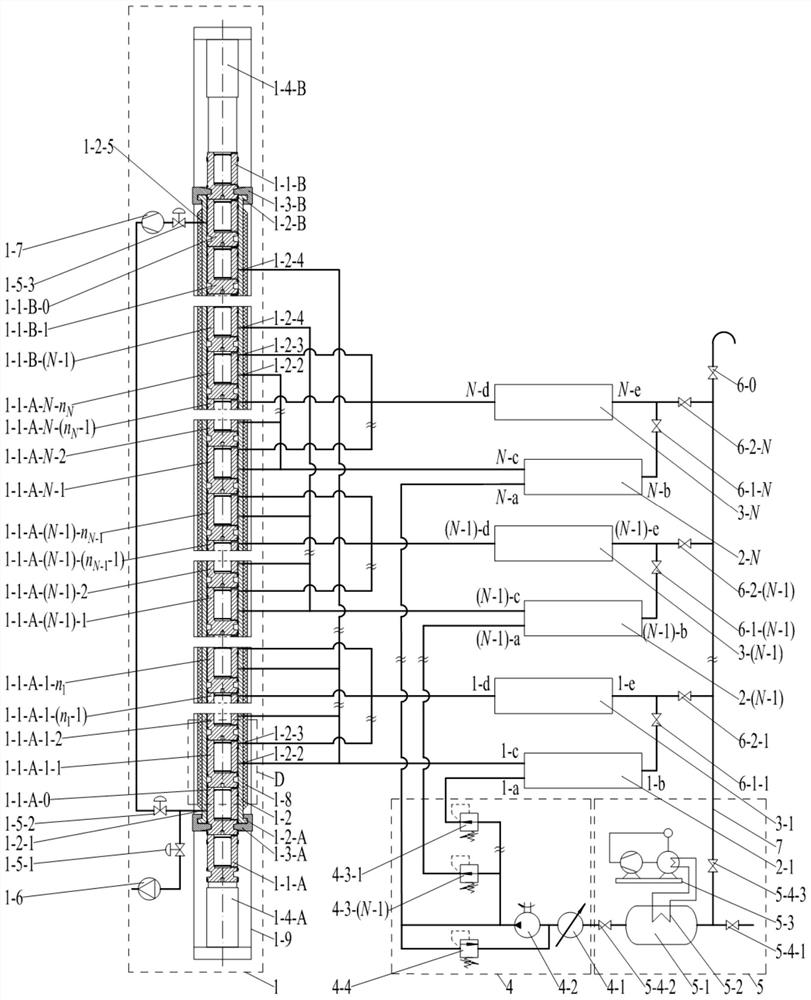

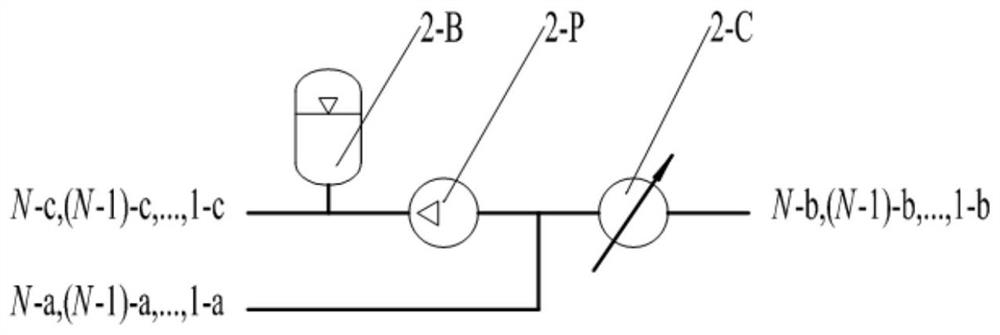

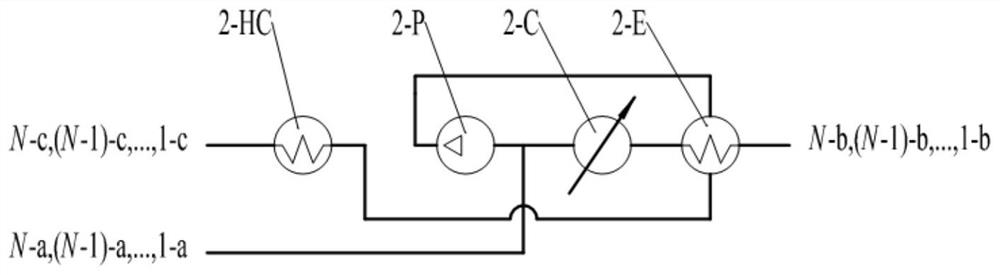

[0070] Embodiment 1: A subcritical fluid multi-stage continuous isobaric extraction and separation device system and process flow, such as figure 1 , figure 2 , Figure 6 , Figure 7 , Figure 11 shown.

[0071] A subcritical fluid multi-stage continuous isobaric extraction and separation device system consists of subcritical fluid medium source 5, pressurization subsystem 4, continuous extraction subsystem 1, first-stage separation subsystem 3-1,...,N-1 Stage separation subsystem 3-(N-1), N-stage separation subsystem 3-N, 1-stage pressurized cycle subsystem 2-1, ..., N-1 stage pressurized cycle subsystem 2-(N-1) Consists of an N-stage pressurized circulation subsystem 2-N, N is the total number of stages of step-by-step pressurization or extraction in the system, and N is greater than 2. The step-by-step extraction and step-by-step pressurization of subcritical fluids in the system of this embodiment coincide.

[0072] The subcritical fluid medium source 5 is composed ...

Embodiment 2

[0106] Embodiment 2: A subcritical fluid single-stage continuous isobaric extraction and separation device system and process flow, such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 7 , Figure 10 , Figure 11 shown.

[0107] A subcritical fluid single-stage continuous isobaric extraction and separation device system consists of a subcritical fluid medium source 5, a pressurized subsystem 4, a continuous extraction subsystem 1, and a first-stage separation subsystem 3-1, ..., N-1 fractions Ion system 3-(N-1), N-level separation subsystem 3-N and 1-level pressurized circulation subsystem 2-1, ..., N-1-level pressurized circulation subsystem 2-(N-1), N The stage pressurization circulation subsystem is composed of 2-N, N is the total number of stages of step-up pressurization or extraction in the system, N is greater than 2, the subcritical fluid extraction in the system of this embodiment and the Nth pressure stage of step-by-step pressurization coincide.

...

Embodiment 3

[0132] Embodiment 3: a subcritical fluid multi-stage continuous isobaric extraction and separation device system and process flow for supercritical fluid pre-extraction, such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 11 shown.

[0133] A subcritical fluid multi-stage continuous isobaric extraction and separation device system for supercritical fluid pre-extraction consists of subcritical fluid medium source 5, pressurization subsystem 4, continuous extraction subsystem 1, first-stage separation subsystem 3-1,... , N-1 stage separation subsystem 3-(N-1), N-stage separation subsystem 3-N and 1-stage pressurized cycle subsystem 2-1,..., N-1 stage pressurized cycle subsystem 2-( N-1), N-level pressurized circulation subsystem 2-N constitutes, N is the step-by-step pressurization or extraction total number of stages in the system, N is greater than 2, the supercritical fluid and the subcritical fluid in this embodiment syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com