Simple preparation method for anode support of solid oxide fuel cell

A technology of anode support and solid oxide, which is applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effects of fast molding, small batch production, and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

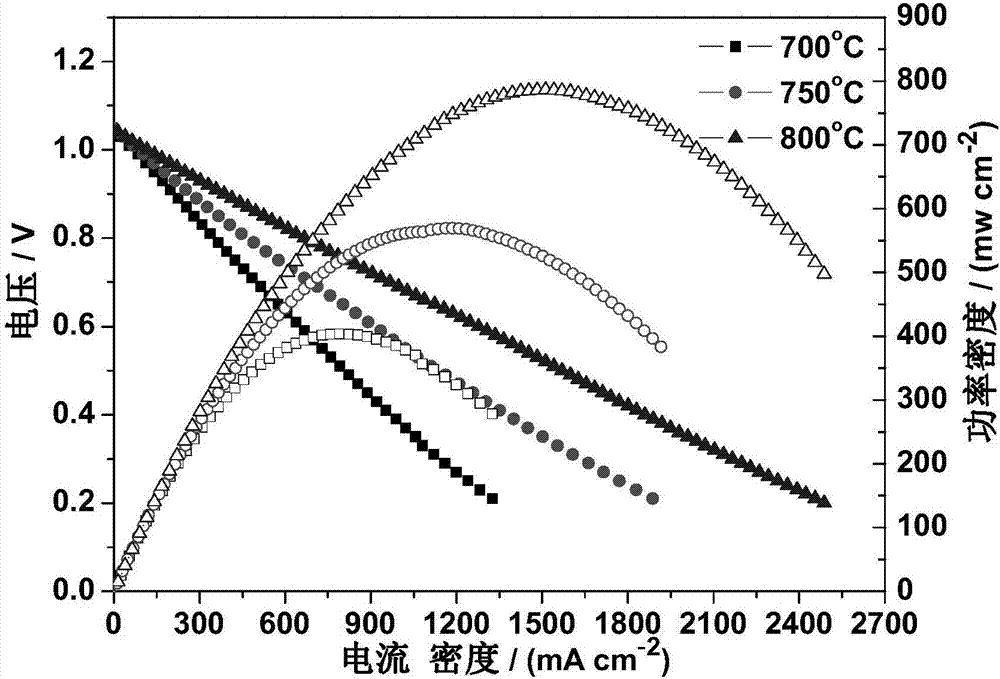

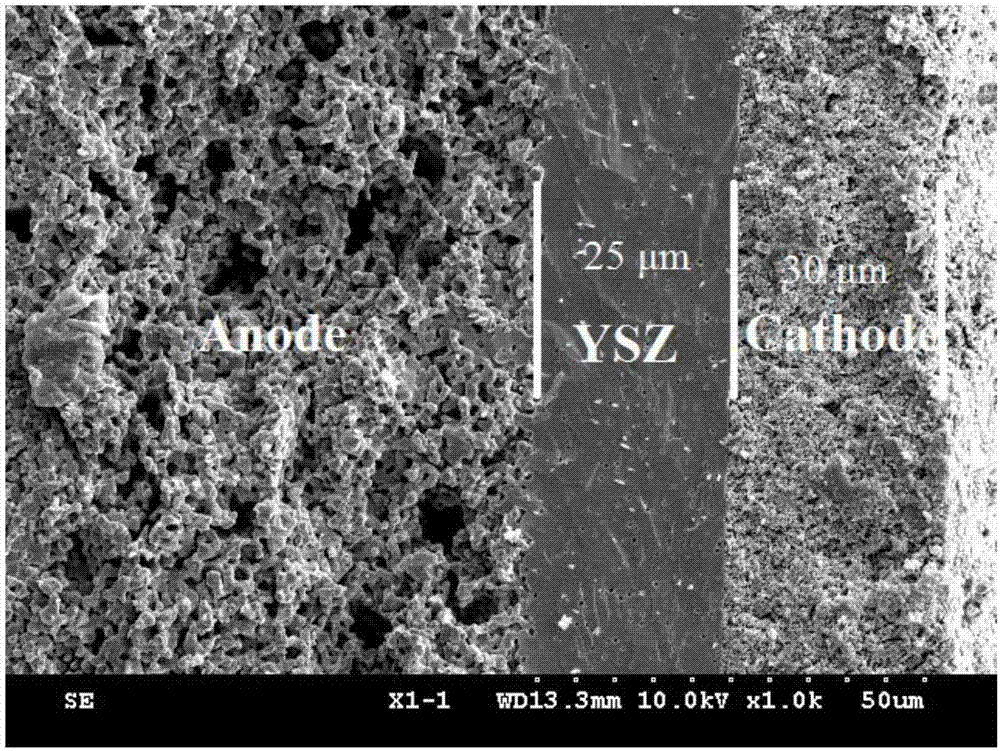

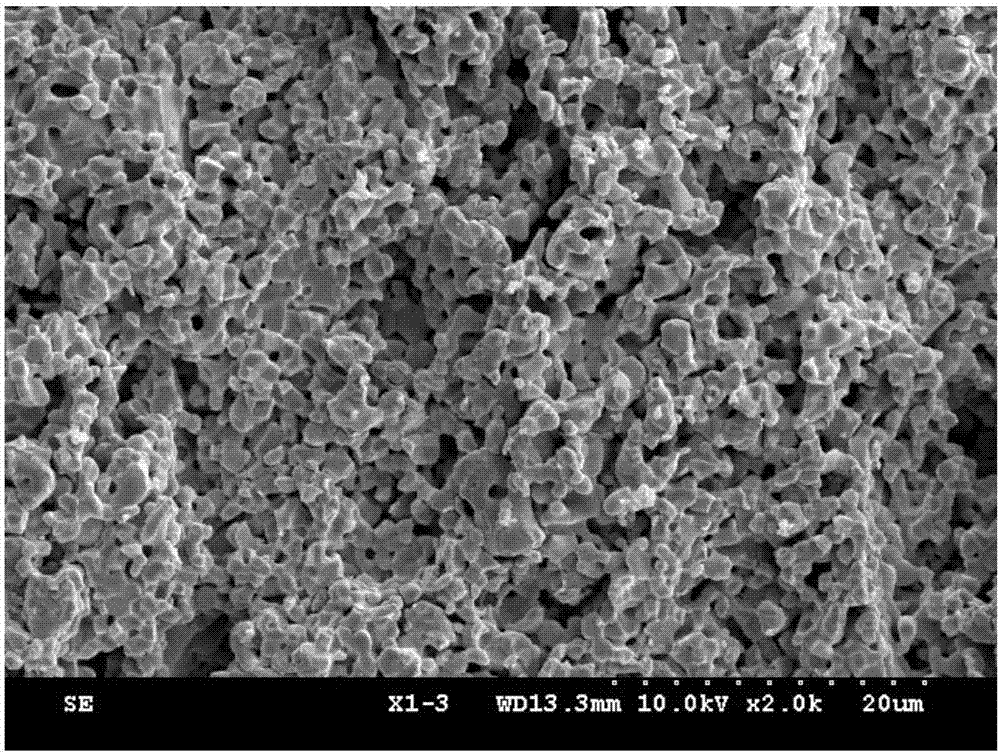

[0030] Such as Figure 1-Figure 3 As shown, the simple preparation method of a solid oxide fuel cell anode support described in this specific embodiment adopts the following method steps:

[0031] Step 1: slurry preparation, the steps adopted are as follows:

[0032] 1) Nickel oxide (NiO), 8mol% yttrium oxide stabilized zirconia (YSZ), graphite powder and organic additives are ball milled and mixed for 3-4h to form a suspension slurry; wherein: the weight ratio of NiO and YSZ is 1:1;

[0033] II) the organic additive in the step I is polyvinyl butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and dehydrated alcohol;

[0034] III) Nickel oxide, 8mol% yttria-stabilized zirconia, graphite powder, polyvinyl butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethanol in the suspension slurry The weight percentage is 16-18%: 16-18%: 2-4%: 5-8%: 1.5-2%: 3-4%: 3-4%: 45-47%;

[0035] IV) During preparation, during the high-speed ball mi...

specific Embodiment approach 1

[0045] Such as Figure 1-Figure 2 As shown, the preparation method of the porous anode support body of the solid oxide fuel cell of the present invention adopts the following method steps:

[0046] Step 1: Slurry preparation:

[0047] Nickel oxide (NiO), 8mol% yttrium oxide stabilized zirconia (YSZ) (NiO and YSZ weight ratio 1:1), graphite powder and organic additive ball milling mixed for 3h to form a suspension slurry; the organic additive is polyvinyl alcohol Butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethanol; the nickel oxide, 8mol% yttria-stabilized zirconia, graphite powder, polyvinyl butyral, three The weight percentages of ethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethanol are 18%: 18%: 4%: 5%: 1.5%: 3%: 3%: 47%. By vacuuming, the slurry is placed in a vacuum rotator to reduce the pressure to -2MPa, and the air bubbles in the slurry are removed to obtain a stable and uniform anode slurry.

[0048] Step ...

specific Embodiment 2

[0054] The preparation method of the porous anode support body of the solid oxide fuel cell of the present invention adopts the following method steps:

[0055] Step 1: Slurry preparation:

[0056] Nickel oxide (NiO), 8mol% yttria-stabilized zirconia (YSZ) (NiO and YSZ weight ratio 1:1), graphite powder and organic additive ball milling mixed for 4h to form a suspension slurry; the organic additive is polyvinyl alcohol Butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethanol; the nickel oxide, 8mol% yttria-stabilized zirconia, graphite powder, polyvinyl butyral, three The weight percent of ethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethanol is 16%: 16%: 2%: 5%: 1.5%: 3%: 3%: 45%. By vacuuming, the slurry is placed in a vacuum rotator to reduce the pressure to -2MPa, and the air bubbles in the slurry are removed to obtain a stable and uniform anode slurry.

[0057] Step 2: Squeegee forming:

[0058] First, paste two se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com