Patents

Literature

36results about How to "Realize small batch production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

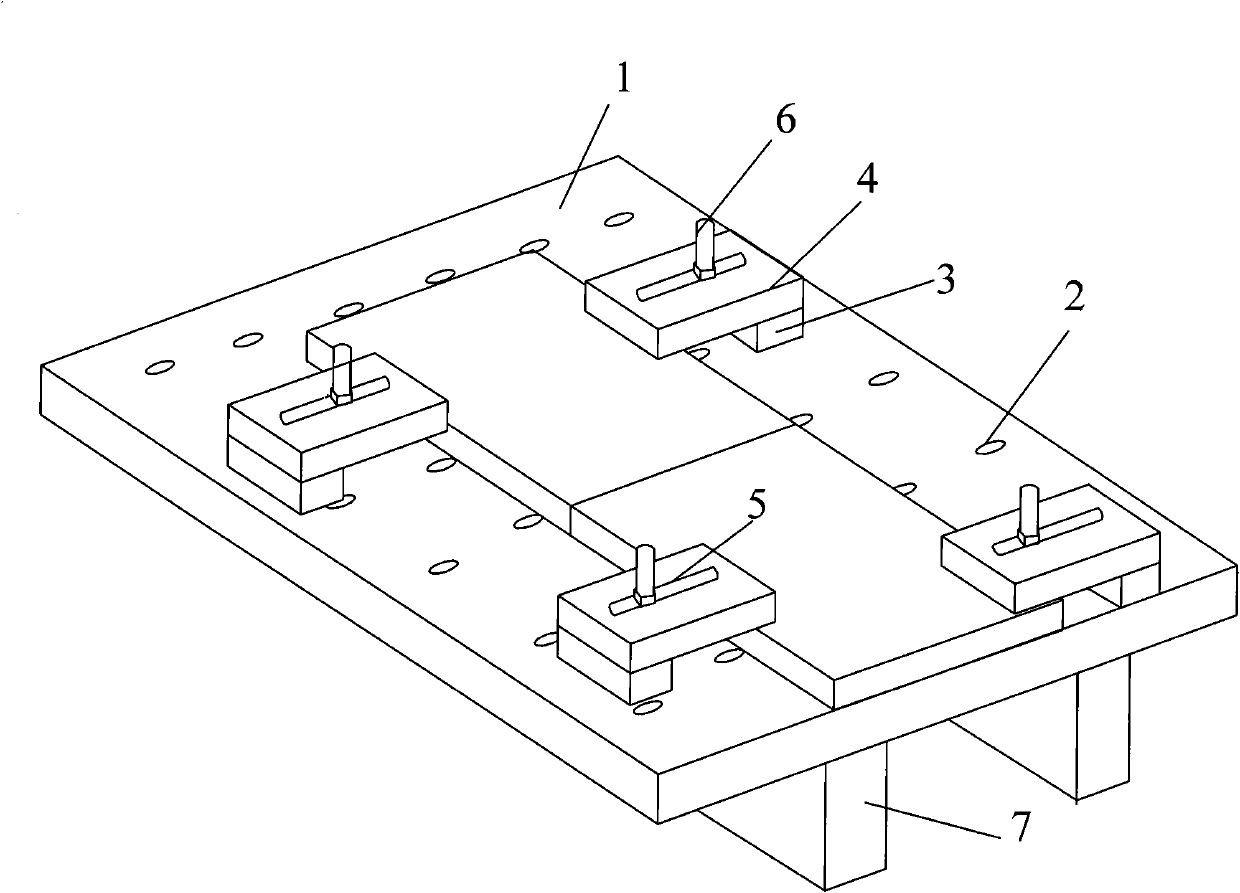

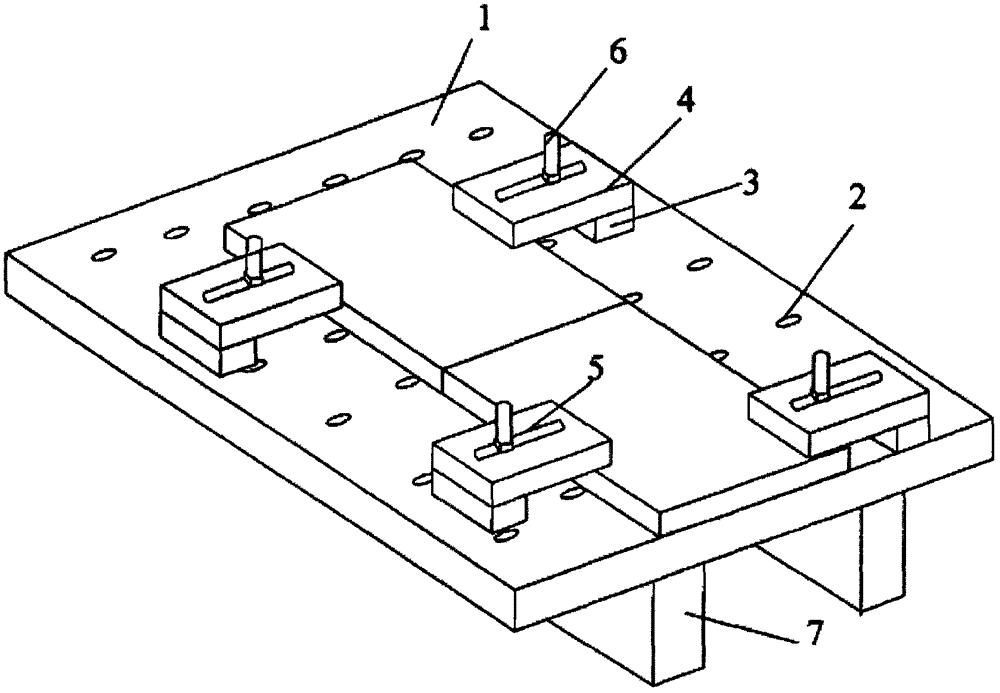

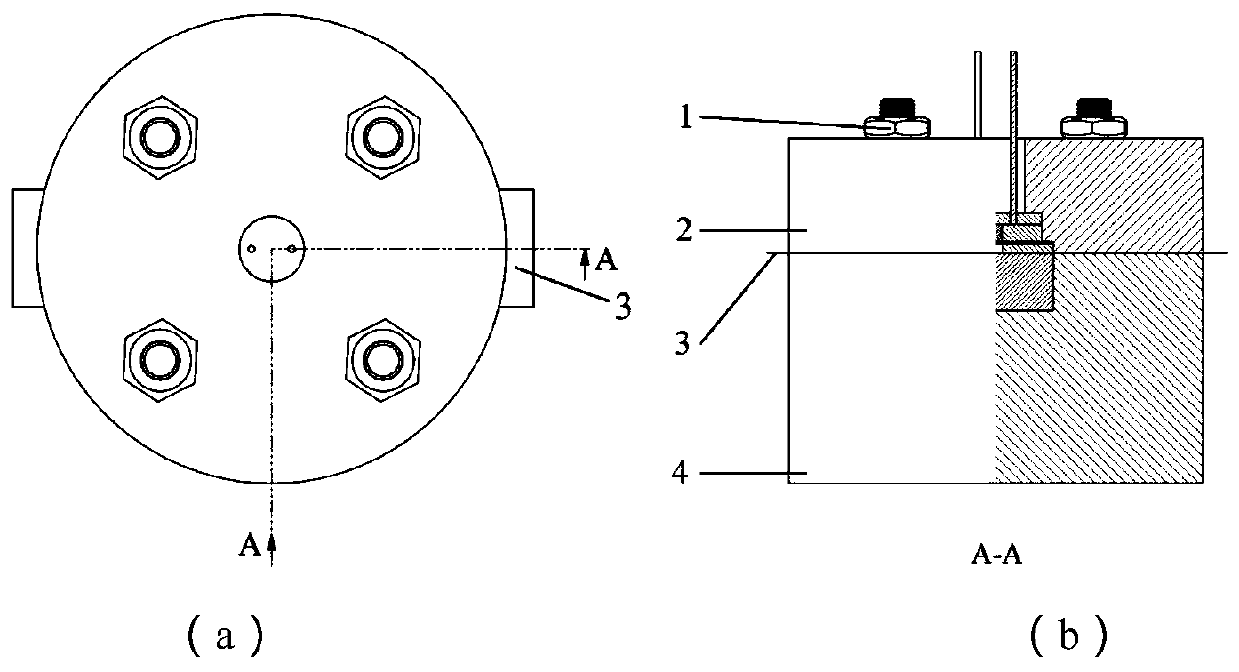

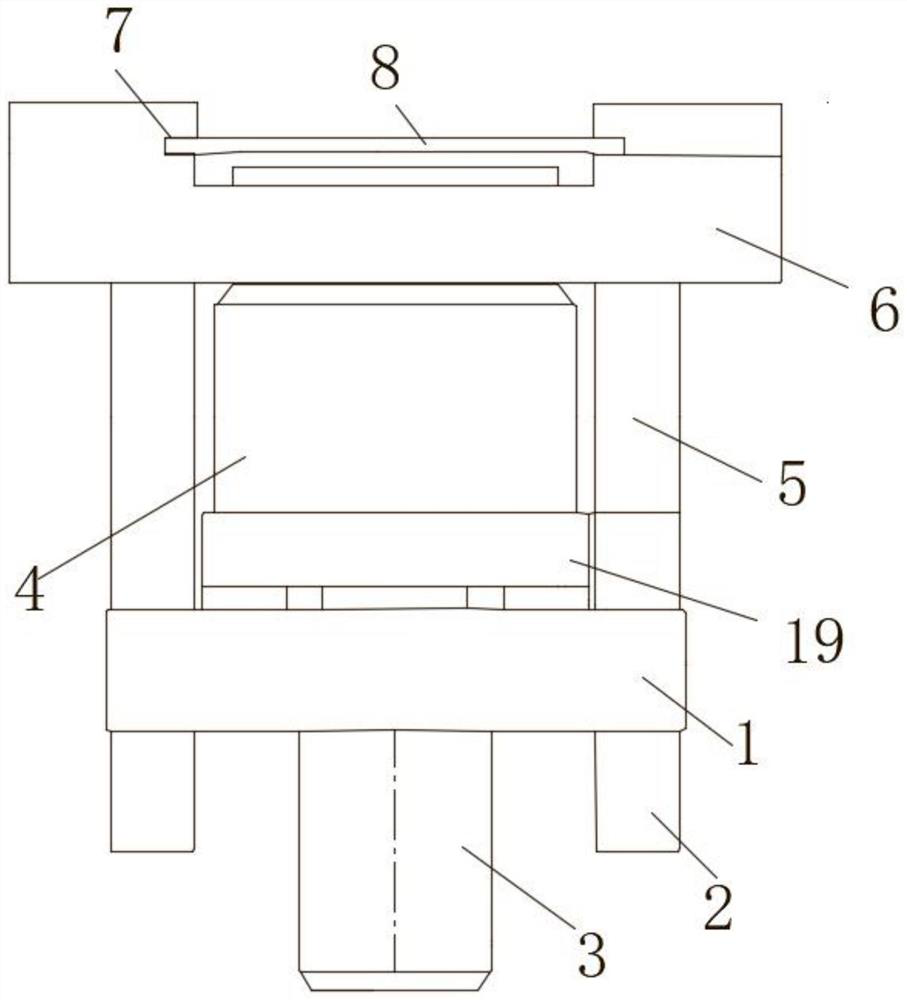

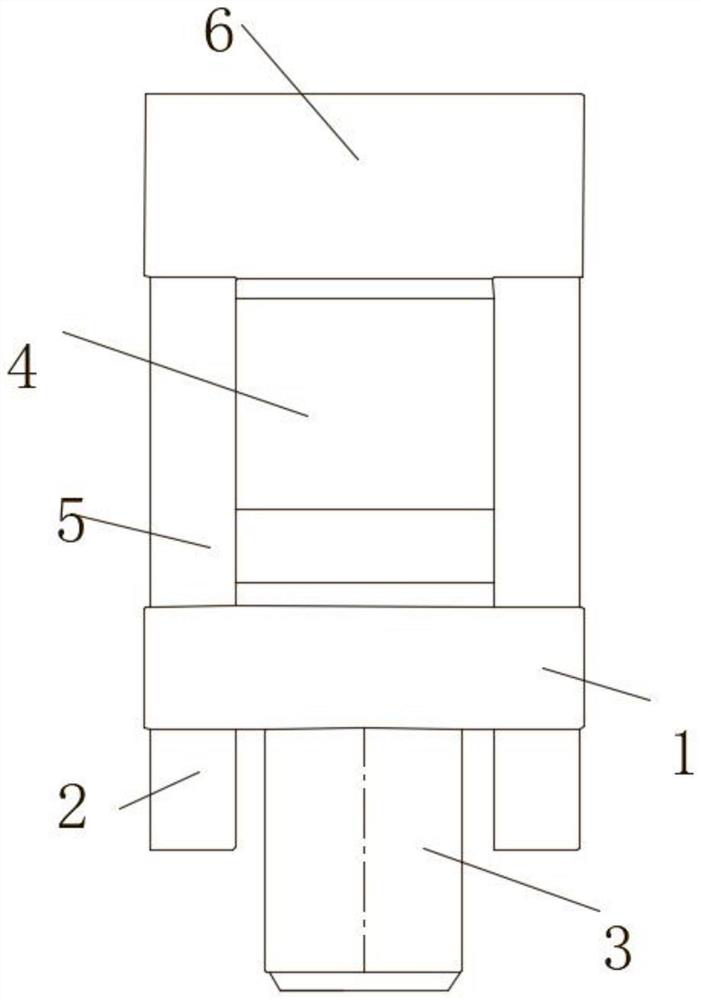

Clamp of vertical processing device

InactiveCN102019557ARealize small batch productionShorten the timePositioning apparatusMetal-working holdersMechanical engineeringEngineering

The invention discloses a clamp of a vertical processing device, including a loading table provided with at least two adjusting holes; at least two pressing plates provided with an adjusting channel and movably connected with the loading table by a nut. The clamp of the vertical processing device can simultaneously clamp a plurality of work pieces to be processed so as to implement small scale production and reduce time for exchanging cutters and installing the work piece each time, so that work efficiency is greatly improved. Additionally, position of the pressing plates is adjusted by a plurality of adjusting holes on the loading table so as to be suitable for the work pieces to be processed in different sizes, the pressing plates in the clamp vertically clamp the work pieces to be processed, compared with a flat nose clamp horizontally clamping the work pieces in the prior art, the clamp is not limited by shape of the work pieces to be processed, and has wider application range.

Owner:SHENYANG CHENXUN SIMCOM TECH

Manufacturing method of large-sized cast steel part lost foam mold

InactiveCN103537623AReduce manufacturing costShorten the manufacturing cycleFoundry mouldsFoundry coresSurface finishingMaterials science

Owner:KOCEL GROUP +1

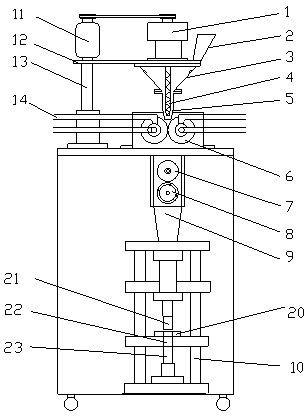

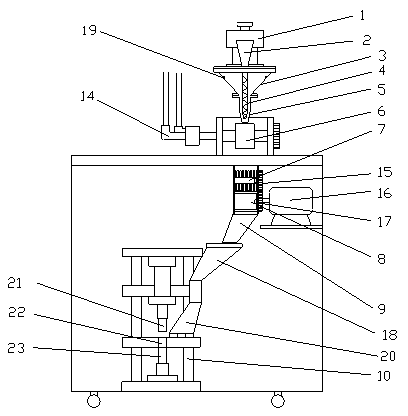

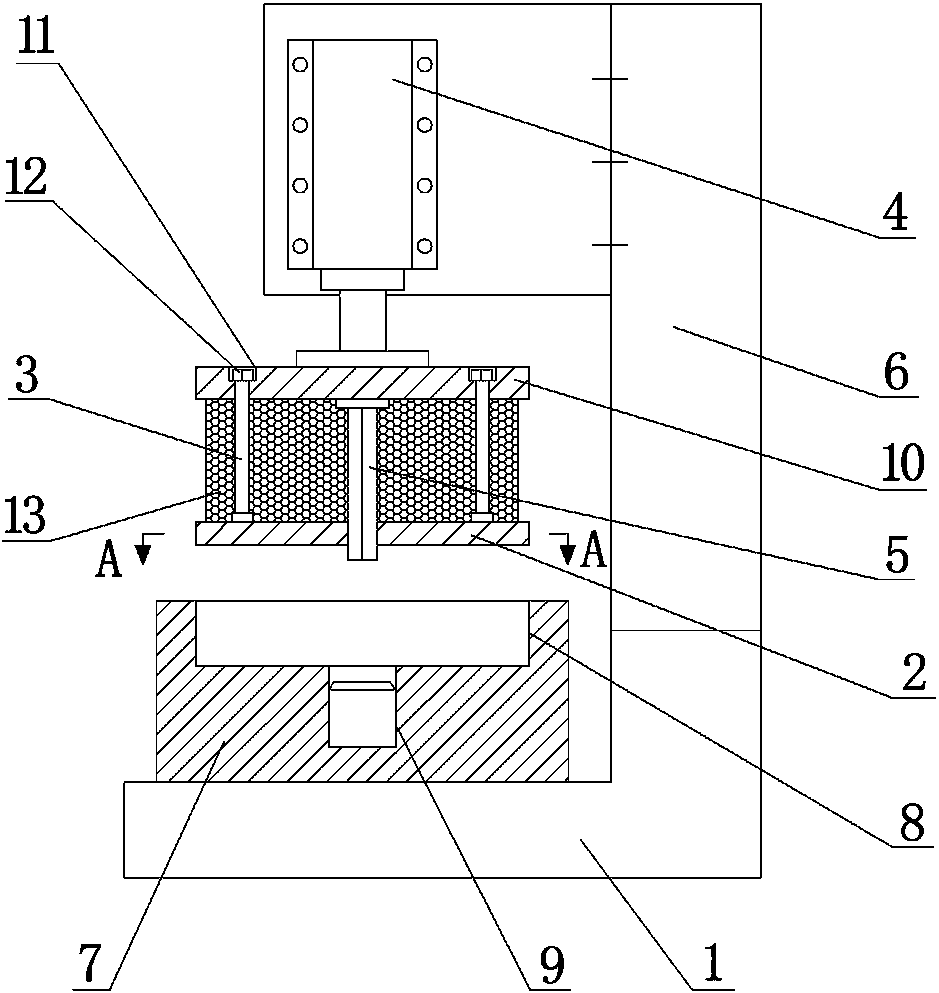

Pure powder granulation negotiable machine

ActiveCN104275822ARealize integrated productionIncrease productivityGrain treatmentsShaping pressEngineeringTableting

The invention provides a pure powder granulation negotiable machine and belongs to the field of medical instruments. The pure powder granulation negotiable machine comprises a feeding device, a roller pressing device, a granulating device and a negotiable device; the feeding device is located on the upper portion of the roller pressing device, and the granulating device is arranged between the roller pressing device and the negotiable device; the feeding device is provided with a feeding screw inside; the granulating device comprises a smashing mechanism and a granulating mechanism, and a discharging hopper is arranged below the granulating mechanism and is connected to the feeding port of the negotiable device. A radial blade and drum of the smashing mechanism are integrated as designed, a fixing bolt is arranged inside the drum, the end of the smashing mechanism is provided with the blade, the smashing dead corner is avoided, the integral production of granulating and negotiable is implemented, pure powder negotiable can be implemented, additives and water are omitted, and the producing efficiency can be improved effectively.

Owner:升生健康科技(苏州)有限公司

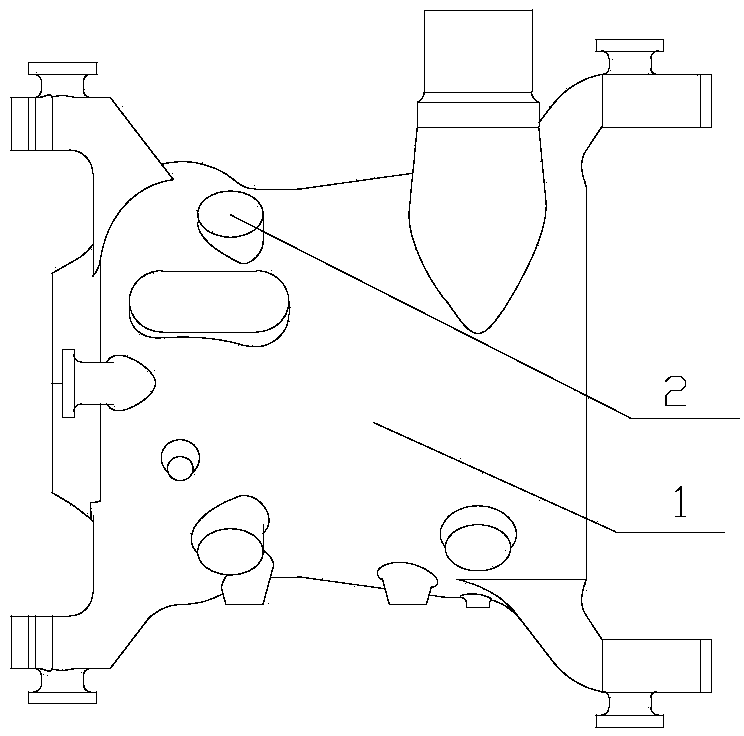

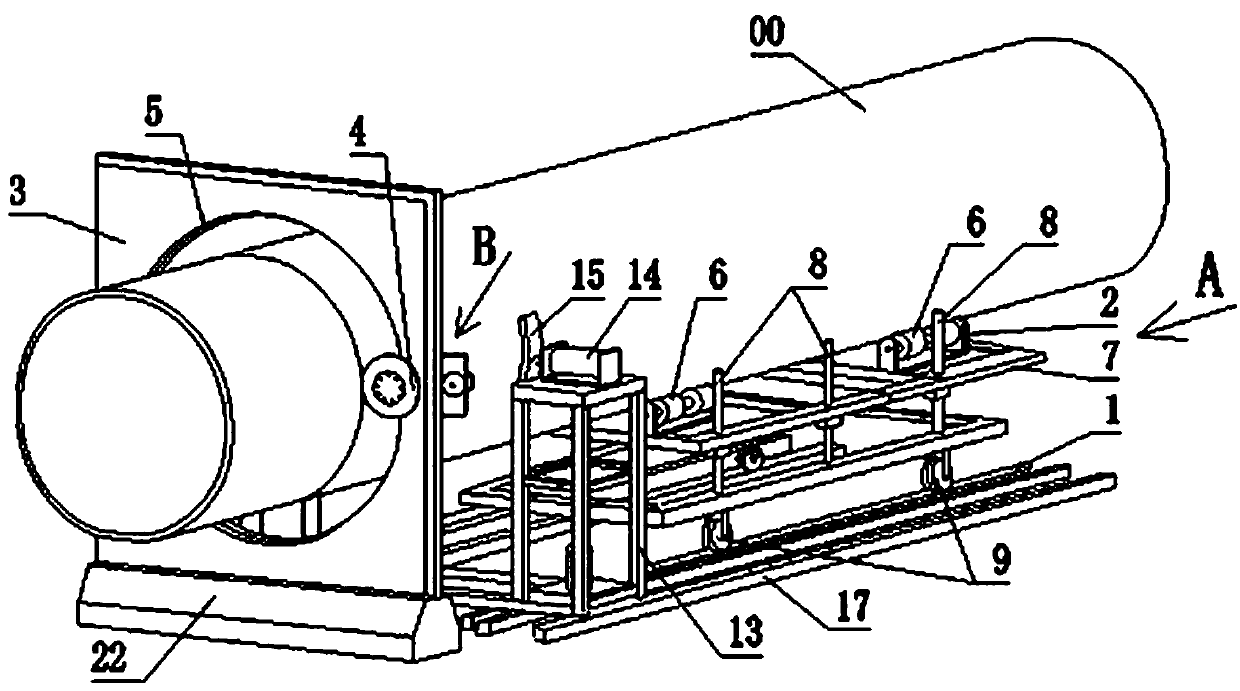

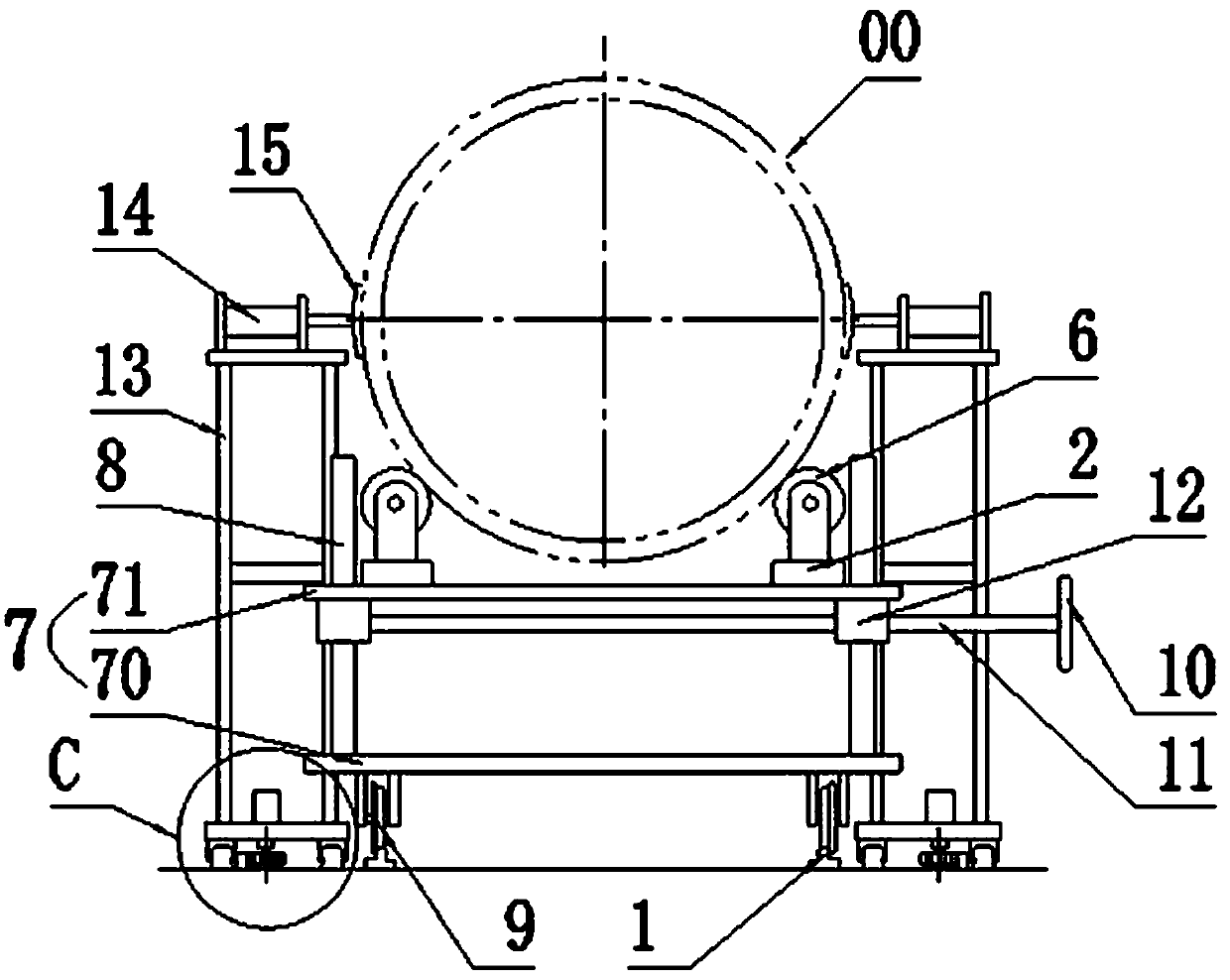

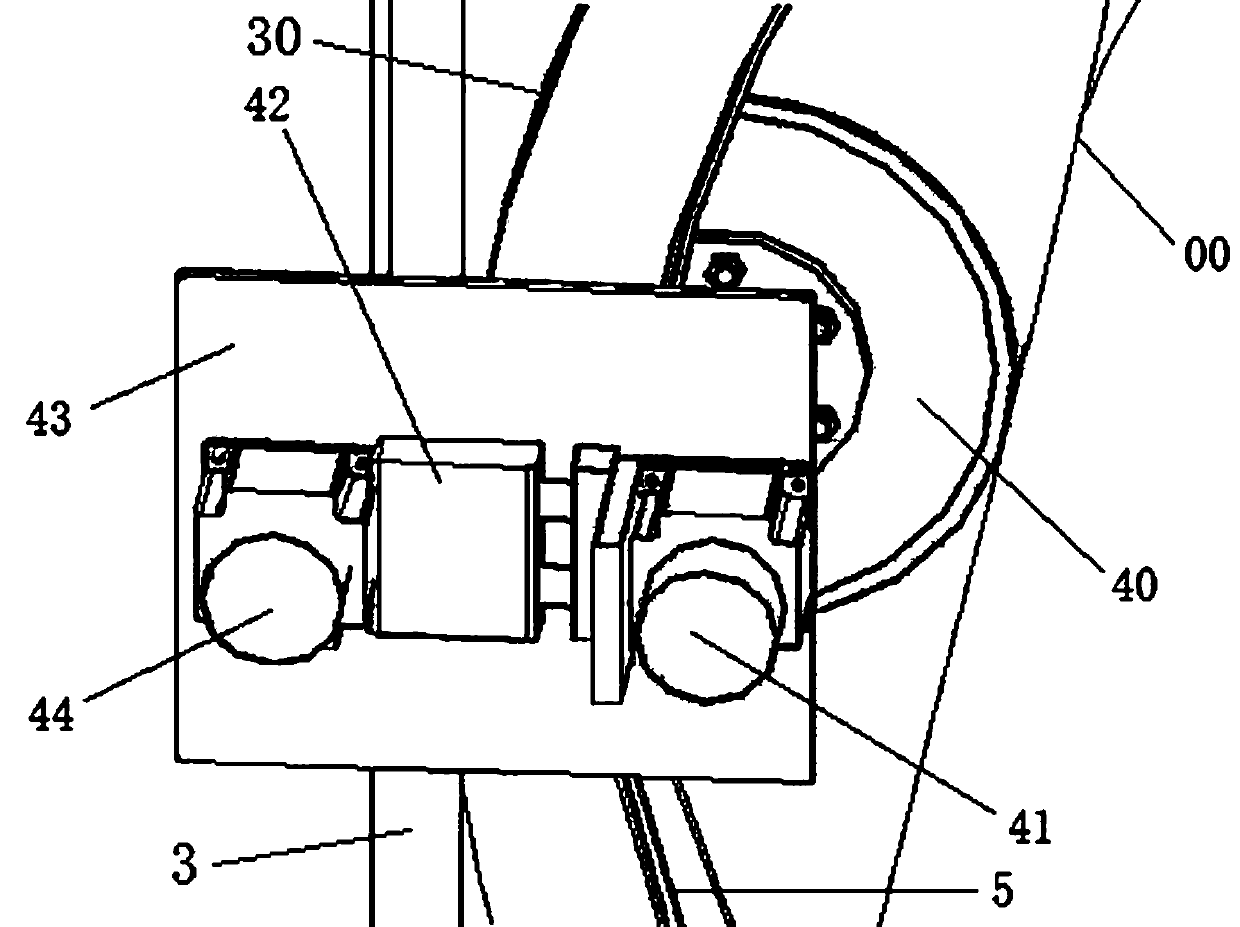

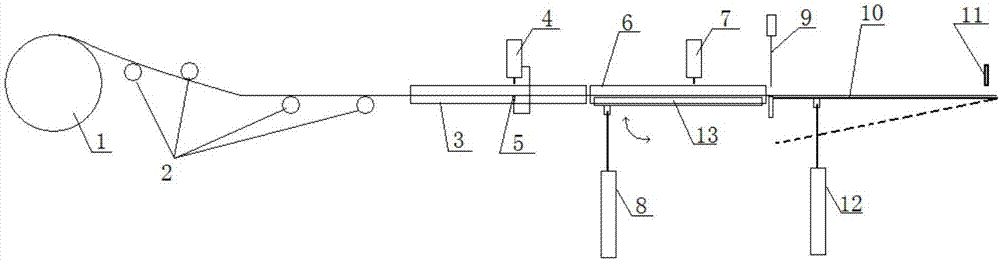

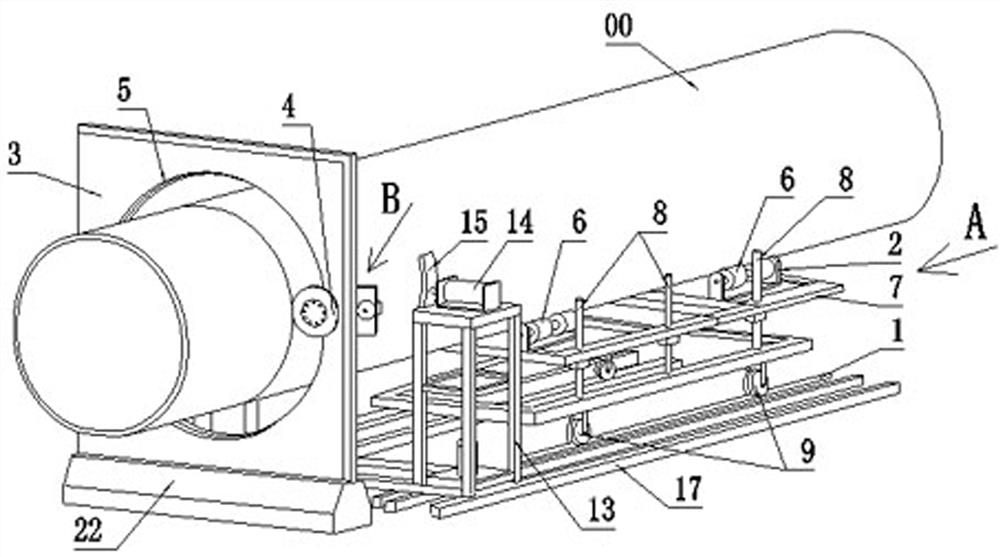

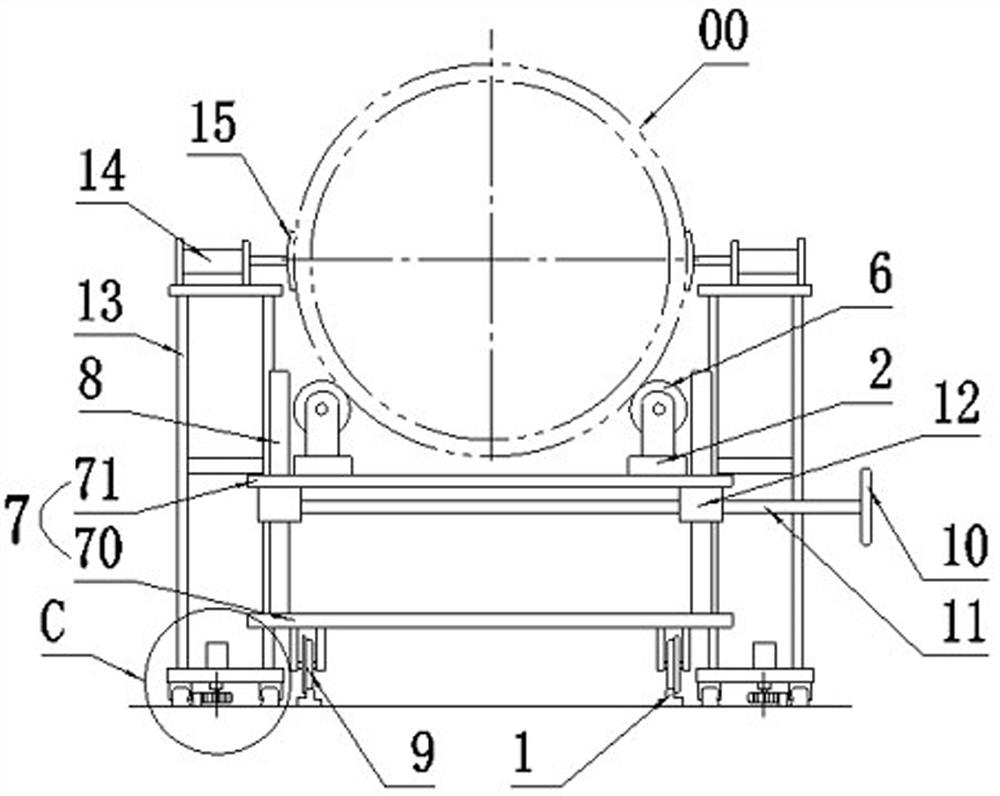

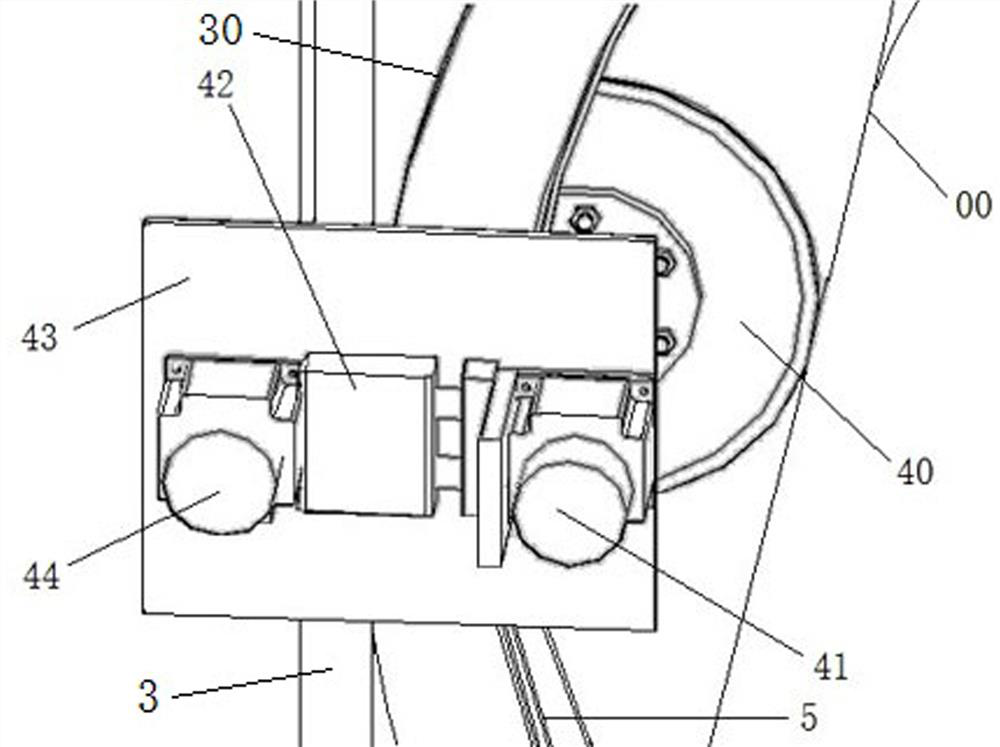

Offline cutting equipment for pipeline

ActiveCN110103272ARealize small batch productionReduce pup production costsMetal sawing devicesMetal working apparatusPortal frameCircular motion

The invention discloses offline cutting equipment for a pipeline, and belongs to the technical field of pipeline cutting equipment. The offline cutting equipment for the pipeline comprises a guide rail, a pipeline supporting bracket, a portal frame and a cutting saw; the pipeline supporting bracket is arranged on the guide rail, the guide rail and the pipeline supporting bracket are arranged on one side of the portal frame, the middle of the portal frame is provided with a circular hole used for allowing the pipeline to penetrate, a circular rail is arranged along the circular hole, and the cutting saw used for cutting the pipeline does circular motion along the circular rail; the pipeline is arranged on the pipeline supporting bracket, and a clamping device is arranged over the pipeline supporting bracket and used for clamping and fixing the pipeline; and the pipeline supporting bracket is connected with a lifting device and used for adjusting the height of the pipeline on the pipeline supporting bracket. The pipeline is erected on the pipeline supporting bracket, and the pipeline is adjusted to enable the central axis of the pipeline to coincide with the central line of the circular hole of the portal frame through the lifting device while the pipeline supporting bracket moves along the guide rail; and the pipeline is clamped and fixed through the clamping device, the cuttingsaw is started to do circular motion along the circular rail on the portal frame to cut the pipeline penetrating through the circular hole formed in the portal frame, and offline cutting of the pipeline is achieved.

Owner:HUACHUANG TIANYUAN IND DEVING

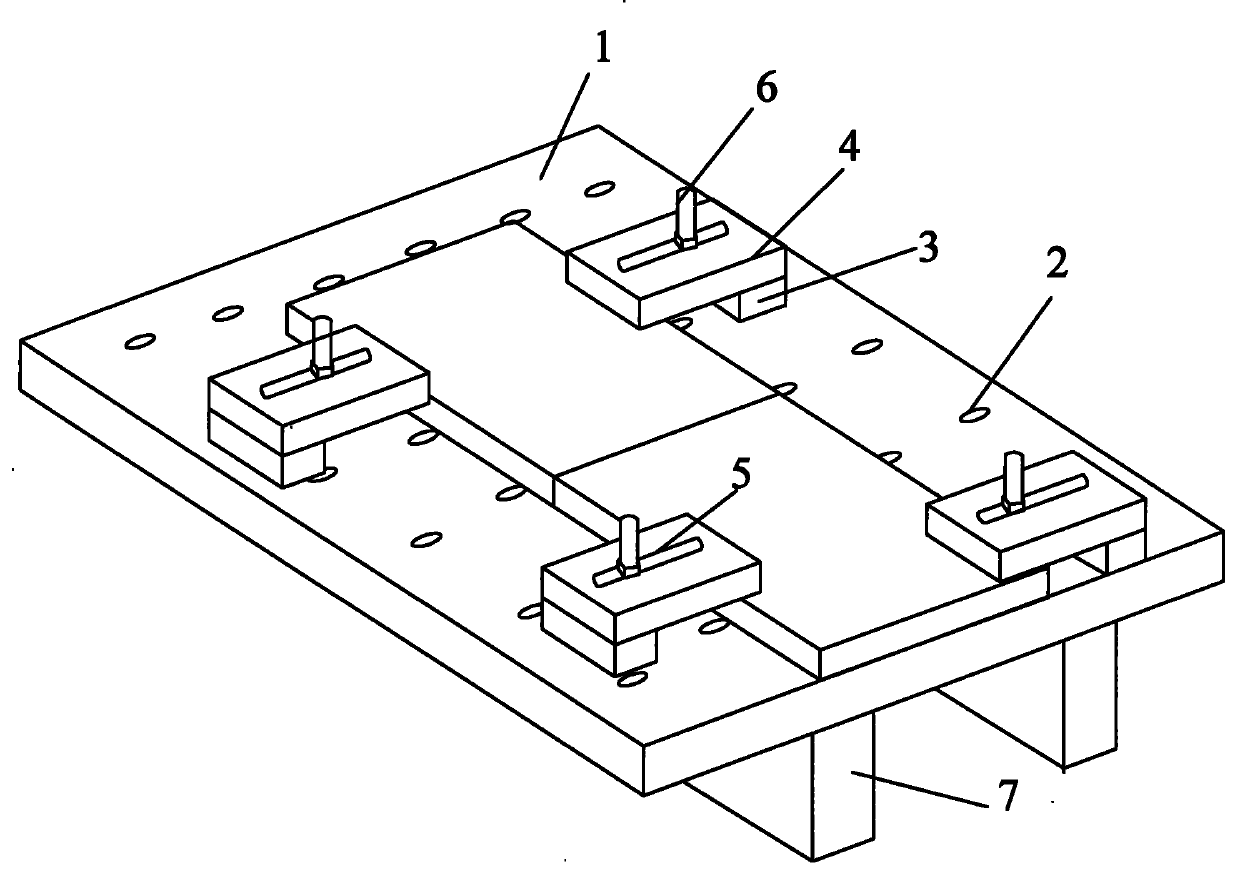

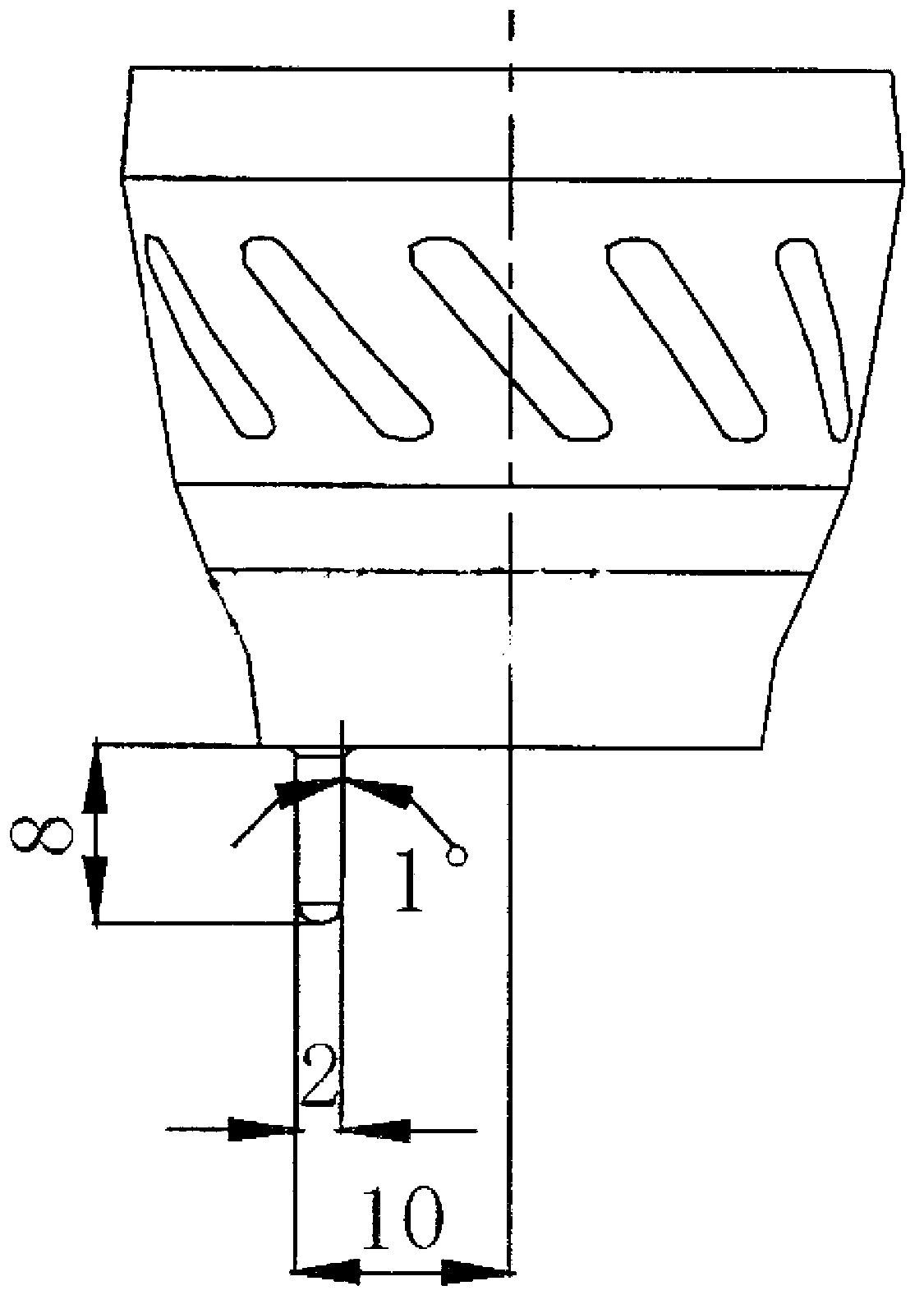

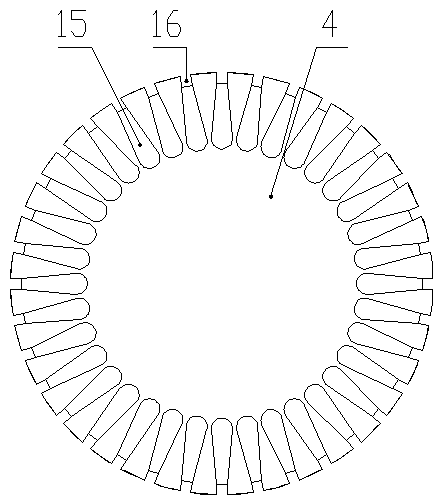

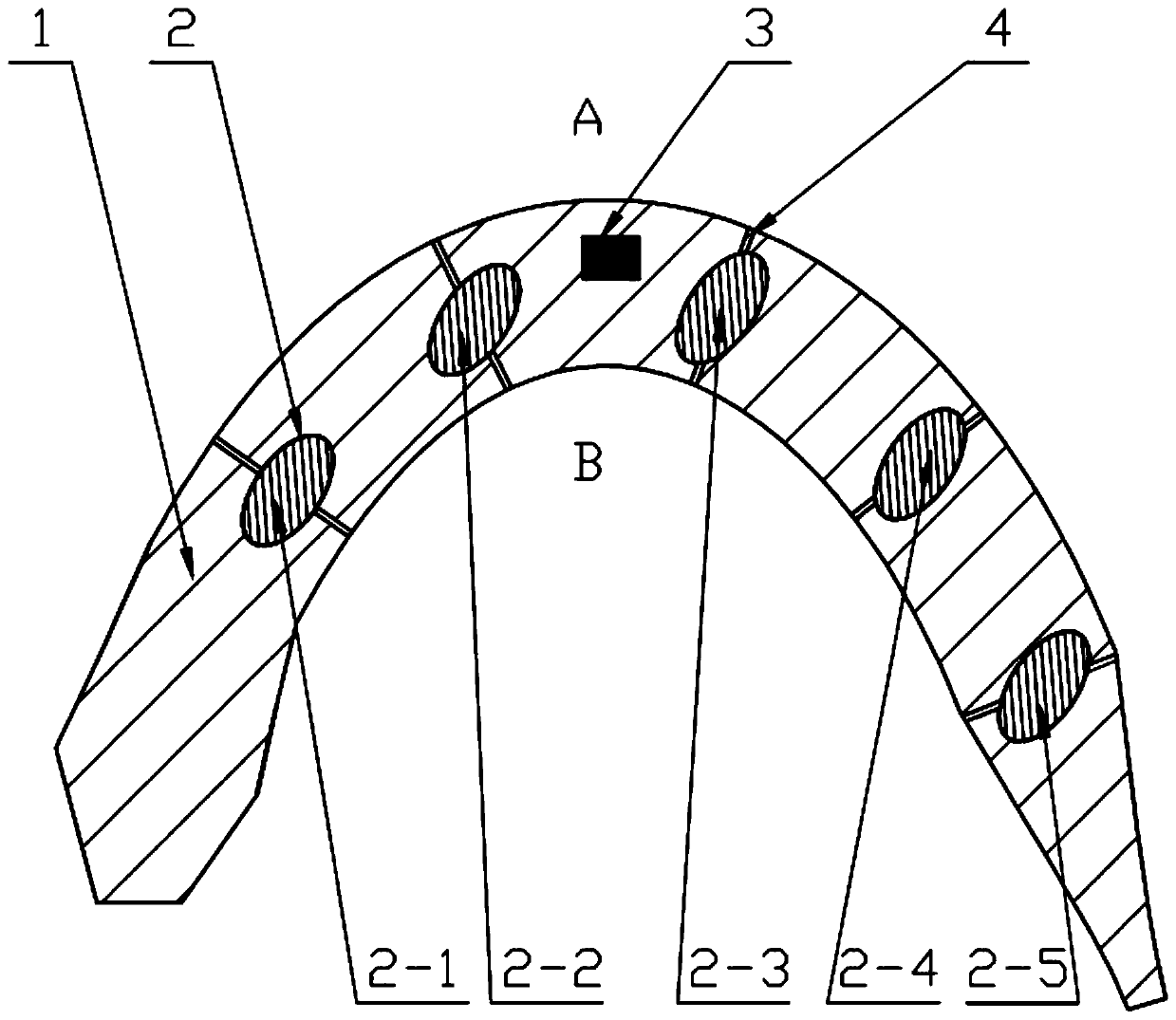

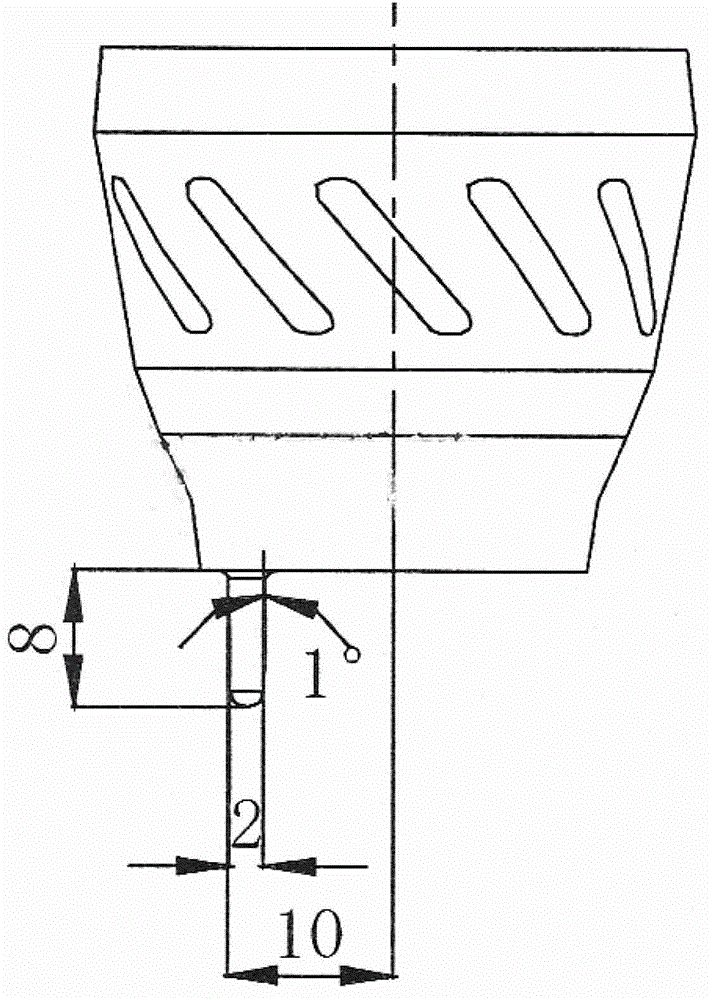

Molding method of three-layer-annular-wall two-layer-blade swirler precise casting

ActiveCN103317094ARealize small batch productionFilling the blank of molding technologyFoundry mouldsFoundry coresWaxCeramic molding

The invention relates to a molding method of a three-layer-annular-wall two-layer-blade swirler precise casting. The method is characterized in that the requirements of the molding method of the three-layer-annular-wall two-layer-blade swirler precise casting are that: a wax mold of the precise casting is prepared through a ring-in-ring forming method wherein a larger and a smaller ceramic molding cores are coated between an inner-layer wax mold and an outer-layer wax mold; blade through holes used for forming blades are provided on the periphery of the ceramic mold cores; a key-shaped boss is designed on the end face of the molding core; positioning is carried out in a key-shaped positioning recess provided on the wax mold, such that positions and angles of two layers of blades can be controlled. With the method, the molding of the three-layer-annular-wall two-layer-blade swirler precise casting is realized. According to the invention, with the ring-in-ring wax mold forming method wherein the larger and the smaller ceramic molding cores are coated between the inner-layer wax mold and the outer-layer wax mold, a blank in molding technology of a multilayer-annular-wall multi-blade swirler precise casting is filled up, and swirler precise casting small-batch production is realized. Also, great economic benefit is provided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

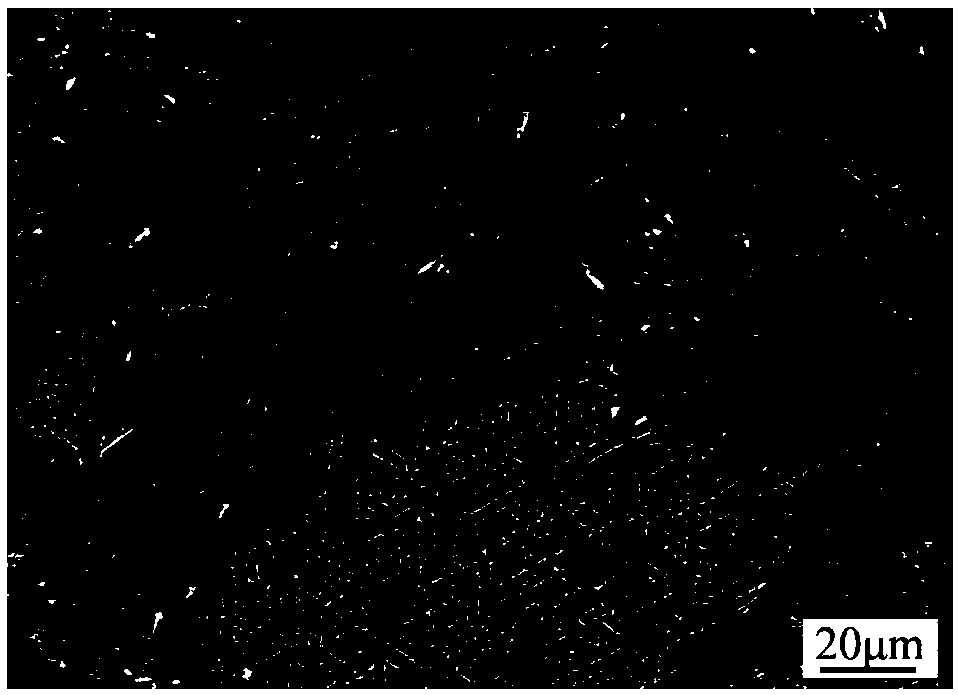

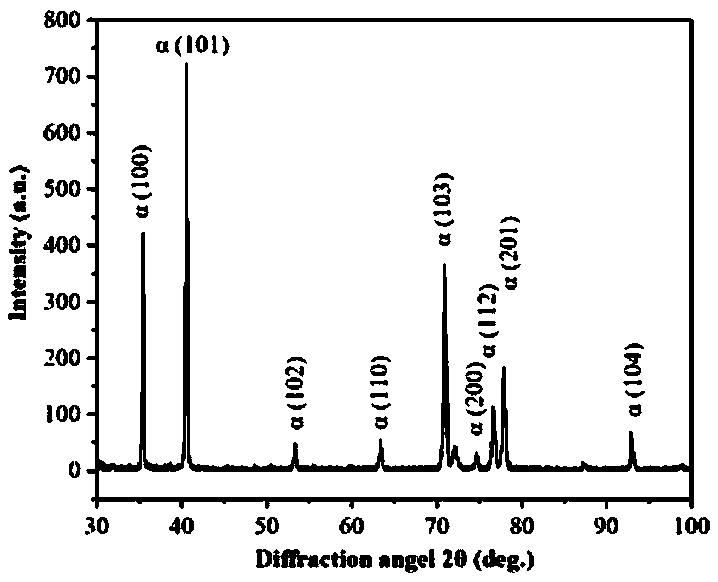

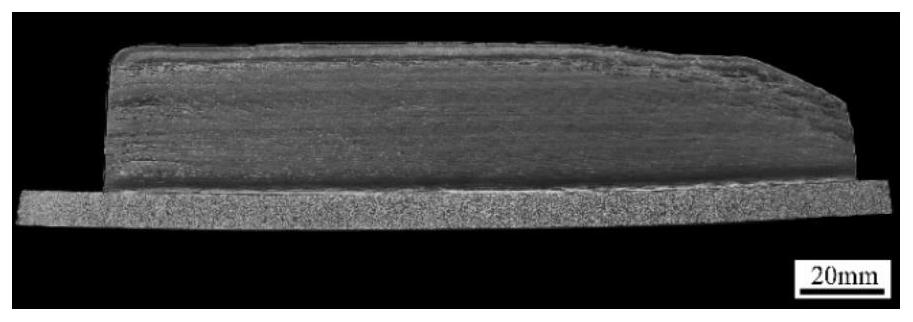

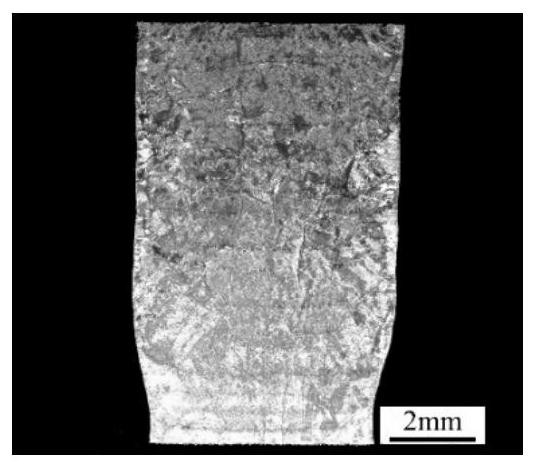

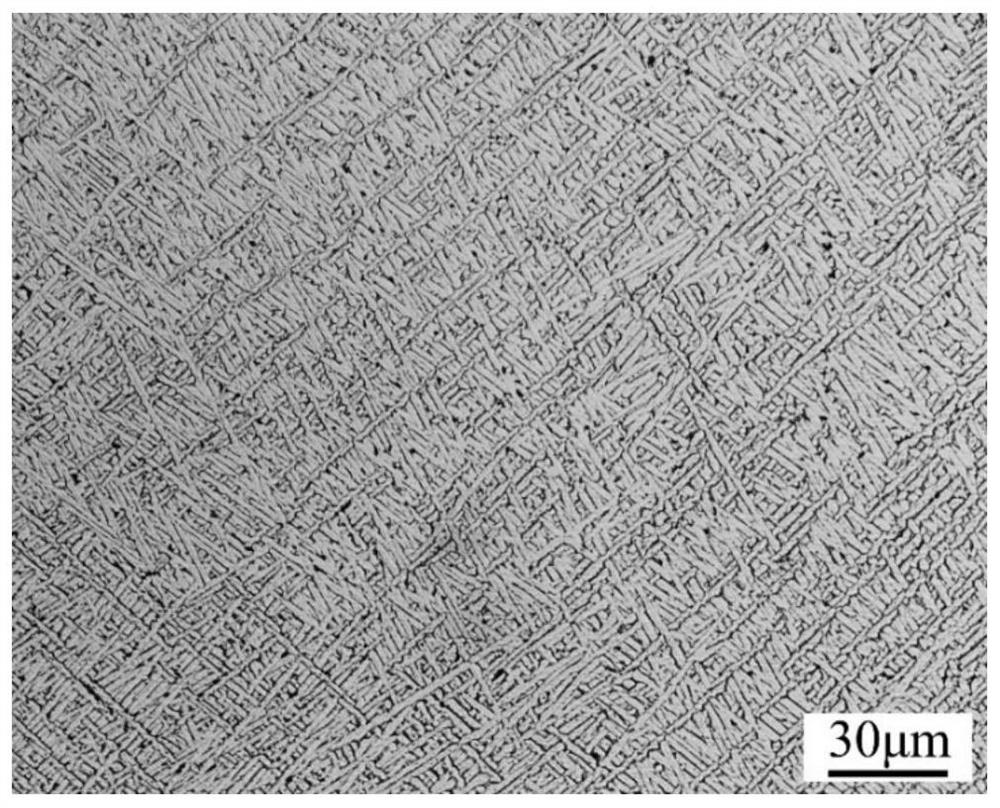

High-strength TA18 titanium alloy component preparing method based on electronic beam fuse wire additional material

ActiveCN109514067AWide variety of sourcesDirect formingElectron beam welding apparatusRapid scanHigh intensity

The invention discloses a high-strength TA18 titanium alloy component preparing method based on an electronic beam fuse wire additional material. The method comprises the following steps that the component transition area of a titanium alloy component is determined, a three-dimensional CAD solid model is established according to the titanium alloy component, and an implementable path is generatedaccording to the single-way deposition layer width W, the single-layer thickness L and the overlap rate gamma; electronic beam fuse wire additional material manufacturing is conducted according to theabove path, and single-layer titanium alloy wire deposition is finished; single-layer titanium alloy wire deposition is finished according to the above steps, and a small beam-current electronic beamis adopted for conducting rapid scanning in the direction perpendicular to the deposition direction; till all sheet layers are deposited, and component additional material manufacturing is finished;and the transition area part is cut away, and component annealing treatment is conducted. According to the method, the additional material raw material source is wide, finished TA2 and TC4 welding wires exist, and special making of TA18 welding wires is not needed. The method is high in production efficiency and low in production cost, direct complex component forming can be achieved, and the complex component manufacturing time is shortened.

Owner:NANJING UNIV OF SCI & TECH

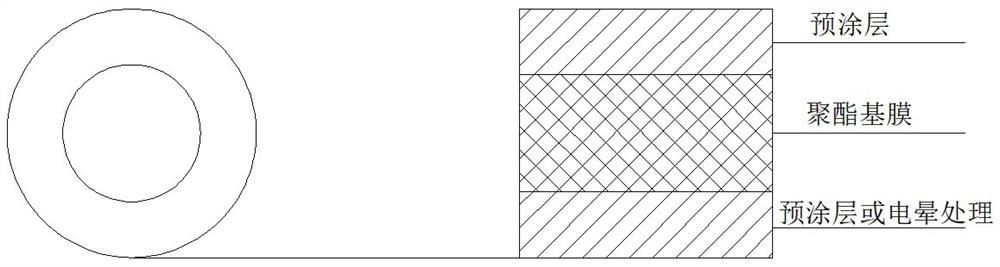

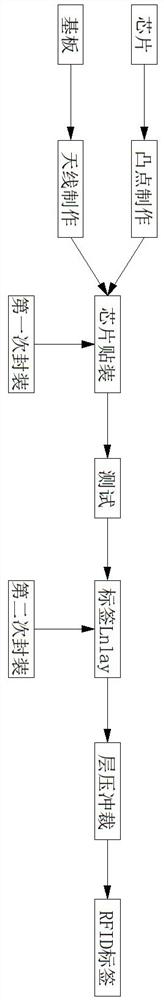

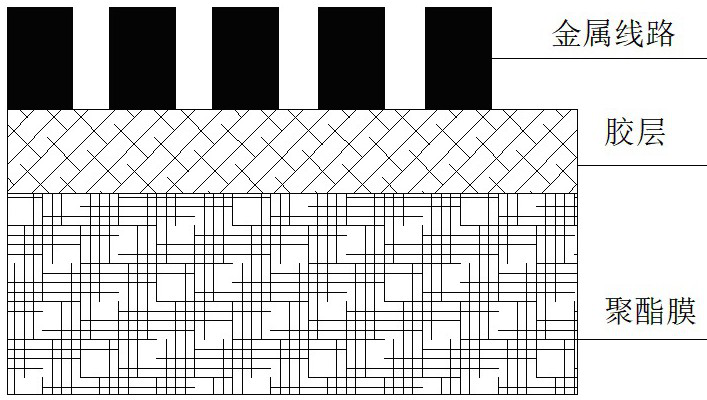

Production method of special reinforced printing base film for electronic tag

ActiveCN112356590ASolve the bond fastnessSolve the windingDuplicating/marking methodsCoatingsPolymer scienceBoPET

The invention discloses a production method of a special reinforced printing base film for an electronic tag. The production method comprises a PET resin slice, wherein the PET resin slice is a high polymer with moisture absorption tendency, the PET resin slice needs to be subjected to pre-crystallization and drying treatment before being subjected to two-way stretching, the softening point of thepolymer is increased, resin particles are prevented from being mutually adhered and caked in the drying and melt extrusion process, moisture in resin is removed, the polymer containing ester groups are prevented from being hydrolyzed and degraded and generating bubbles in the melt extrusion process, most of existing printing composite film base films adopt a corona treatment mode, a basic formulais adjusted on a production line, two or three shaping formulas are determined, formula debugging and process exploration are carried out on the basis of imported pre-coating resin, the functional requirements of a pre-coating layer are preferentially met, small-batch production is achieved, on the basis, production experience is summarized, batch production is achieved step by step, and large market requirements and good economic benefits are achieved.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

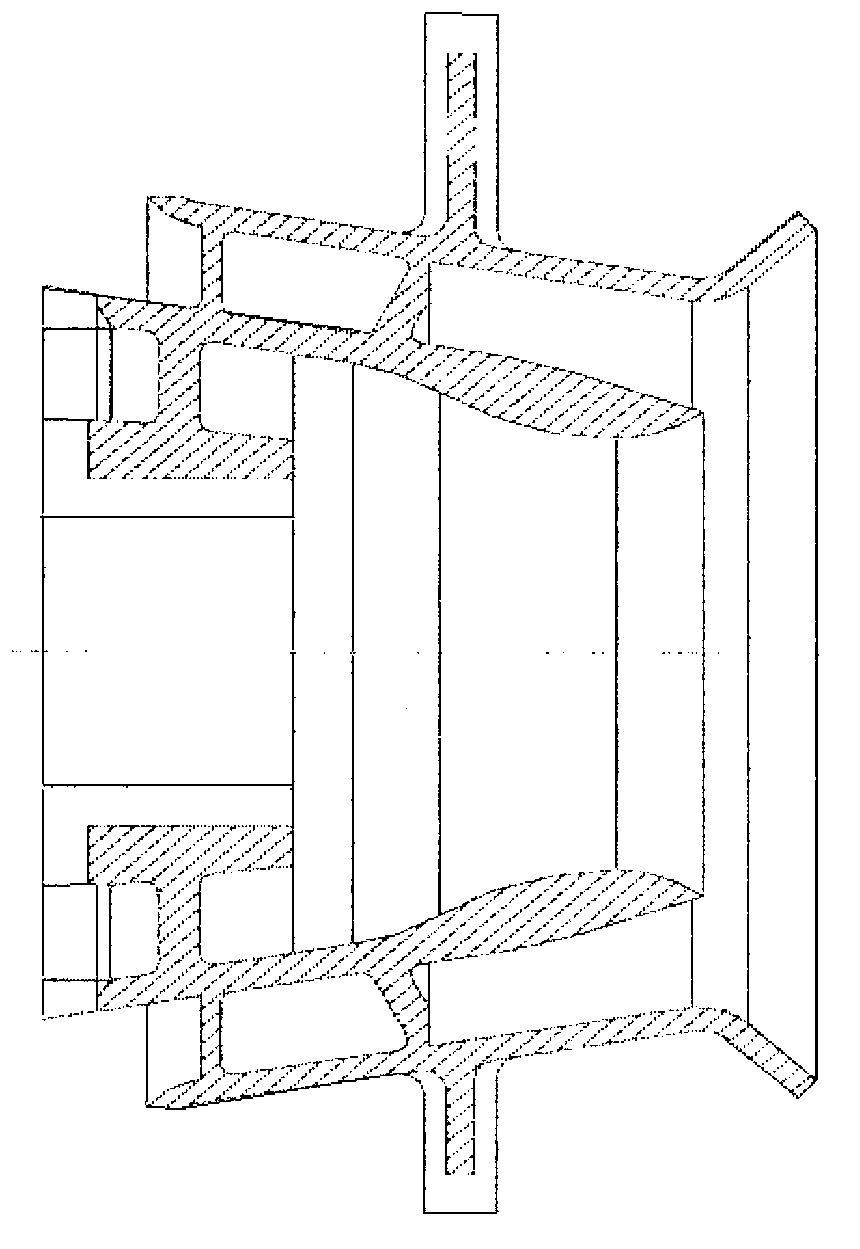

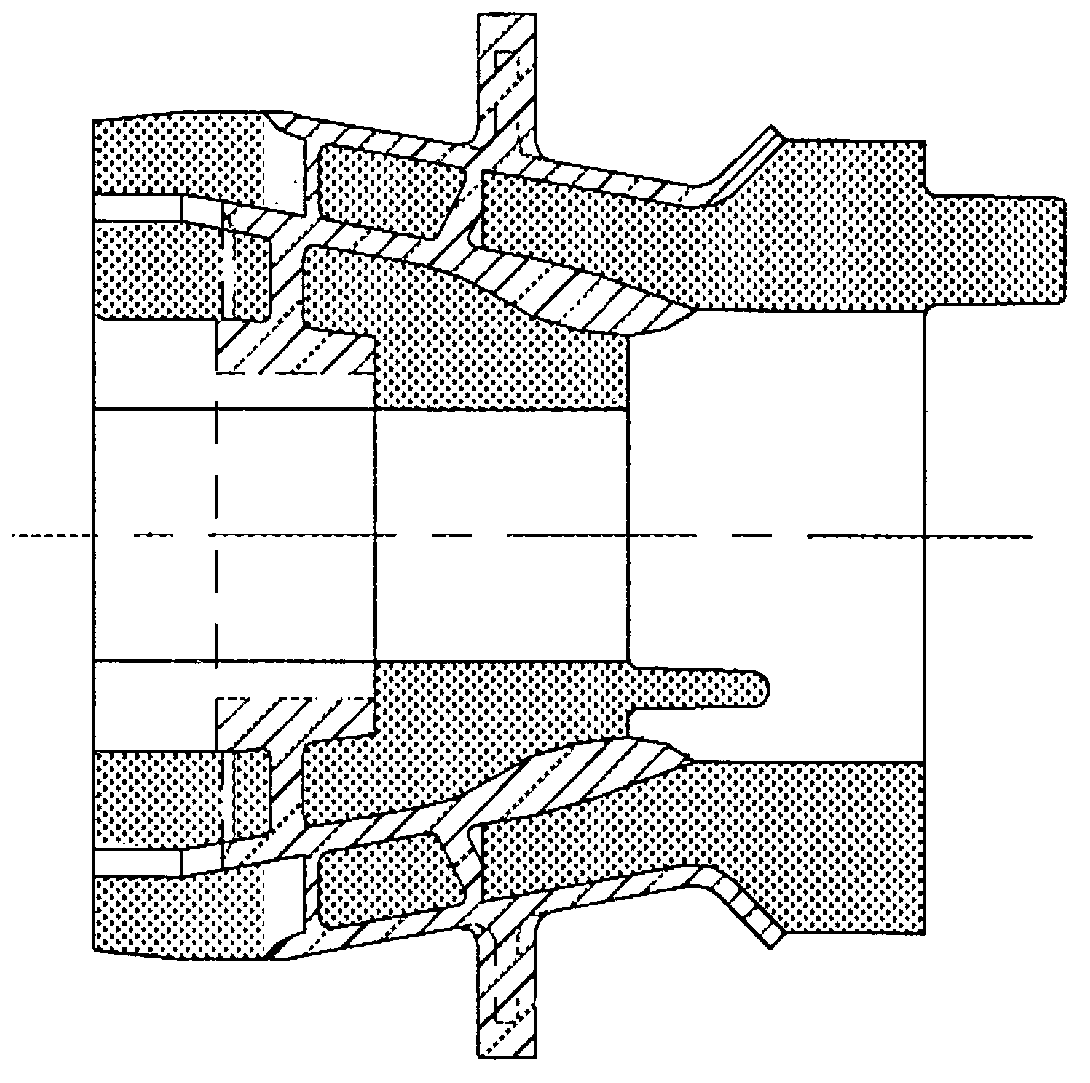

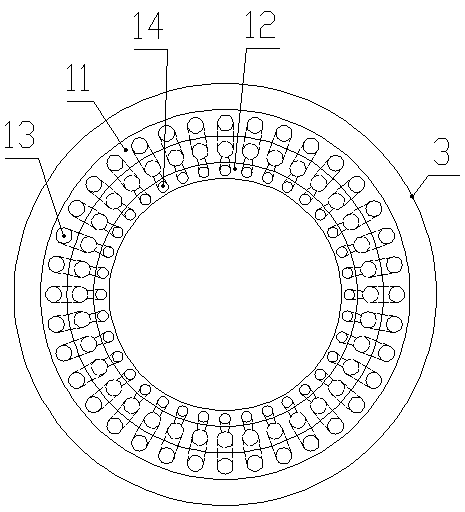

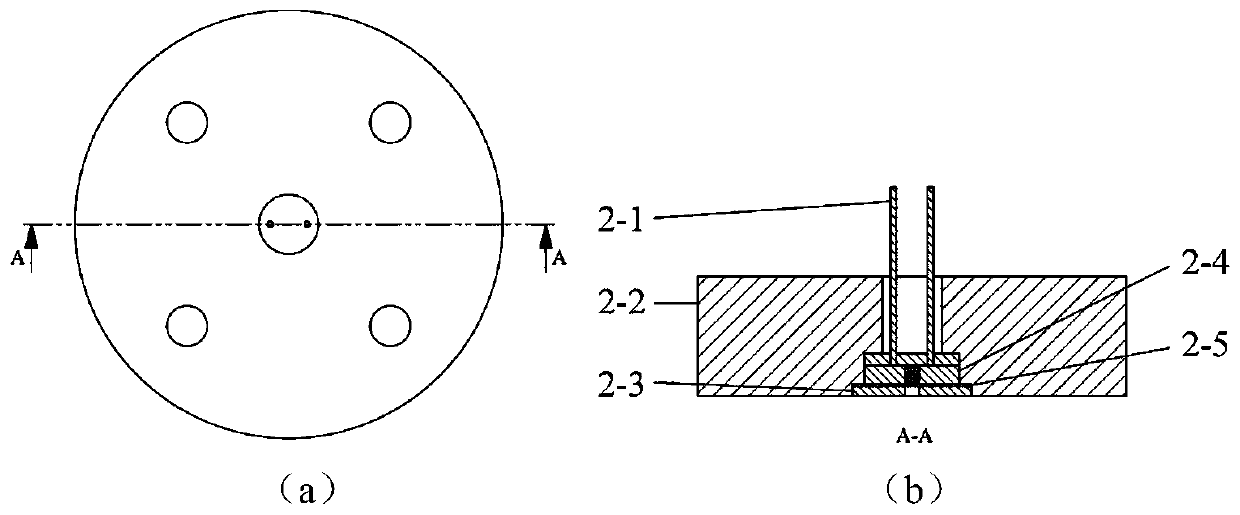

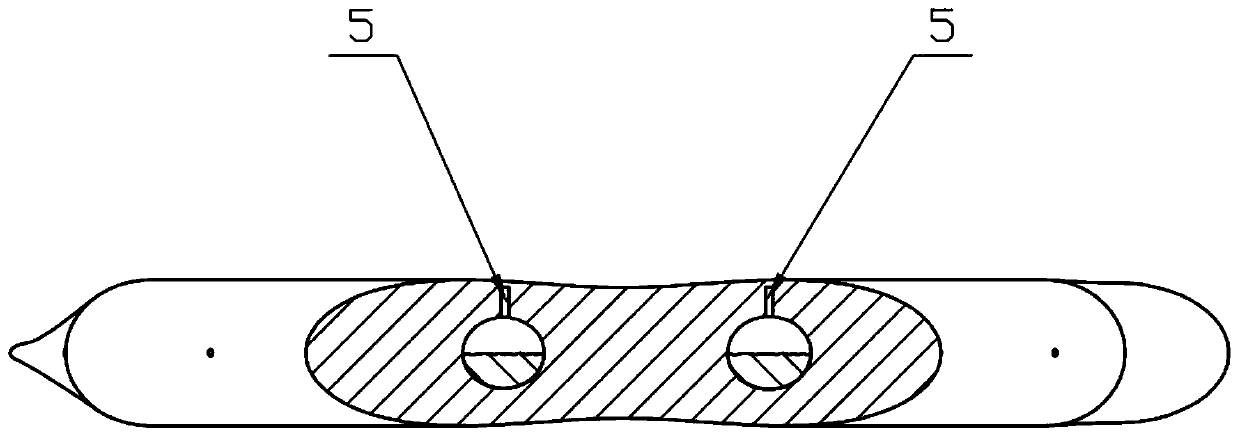

Polylactic acid color masterbatch spinning assembly

ActiveCN104278337ADistribute and mix wellReasonable designSpinning solution de-aeratingSpinnerette packsMasterbatchLaccaic acid

The invention relates to a polylactic acid color masterbatch spinning assembly, which comprises a cylinder, the top and the bottom of the cylinder are opened, a diversion gland, a mixing distribution plate, a diversion plate, a sand cup gland, a sand filling cup, a filter screen and a spinneret plate are sequentially arranged inside the cylinder from top to bottom; a polylactic acid melt injection channel and a color masterbatch melt injection channel which are through vertically are arranged in the diversion gland; a circular polylactic acid melt distribution tank and a color master batch melt distribution tank are formed in the upper surface of the mixed distribution plate, the lower end of the polylactic acid melt injection channel is connected with the polylactic acid melt distribution tank, and the lower end of the color masterbatch melt injection channel is connected with the color masterbatch melt distribution tank. The polylactic acid color masterbatch spinning assembly is reasonable in design, novel in structure and high in spinning efficiency, the even mixing of polylactic acid and color masterbatch can be guaranteed, the small-batch production of polylactic acid color silks can be realized, and the difficulty in the small-batch production of color silks can be solved.

Owner:HENAN LONGDU BIOLOGY TECH

Vertical fixture

InactiveCN106181466ARealize small batch productionShorten the timePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:陈锦

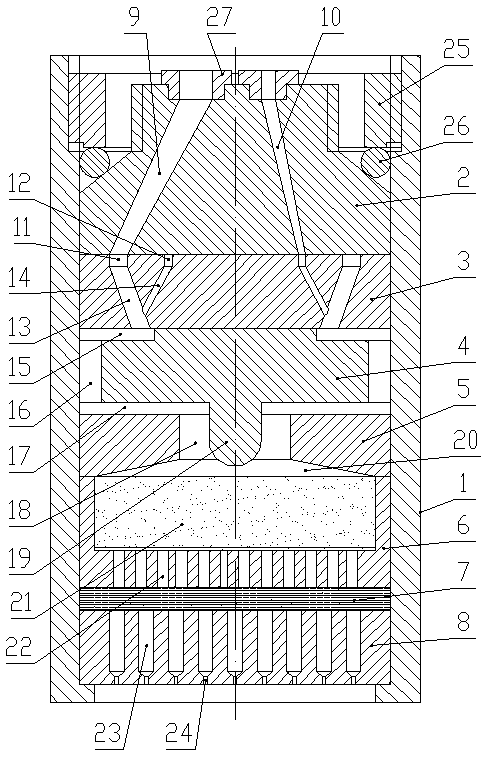

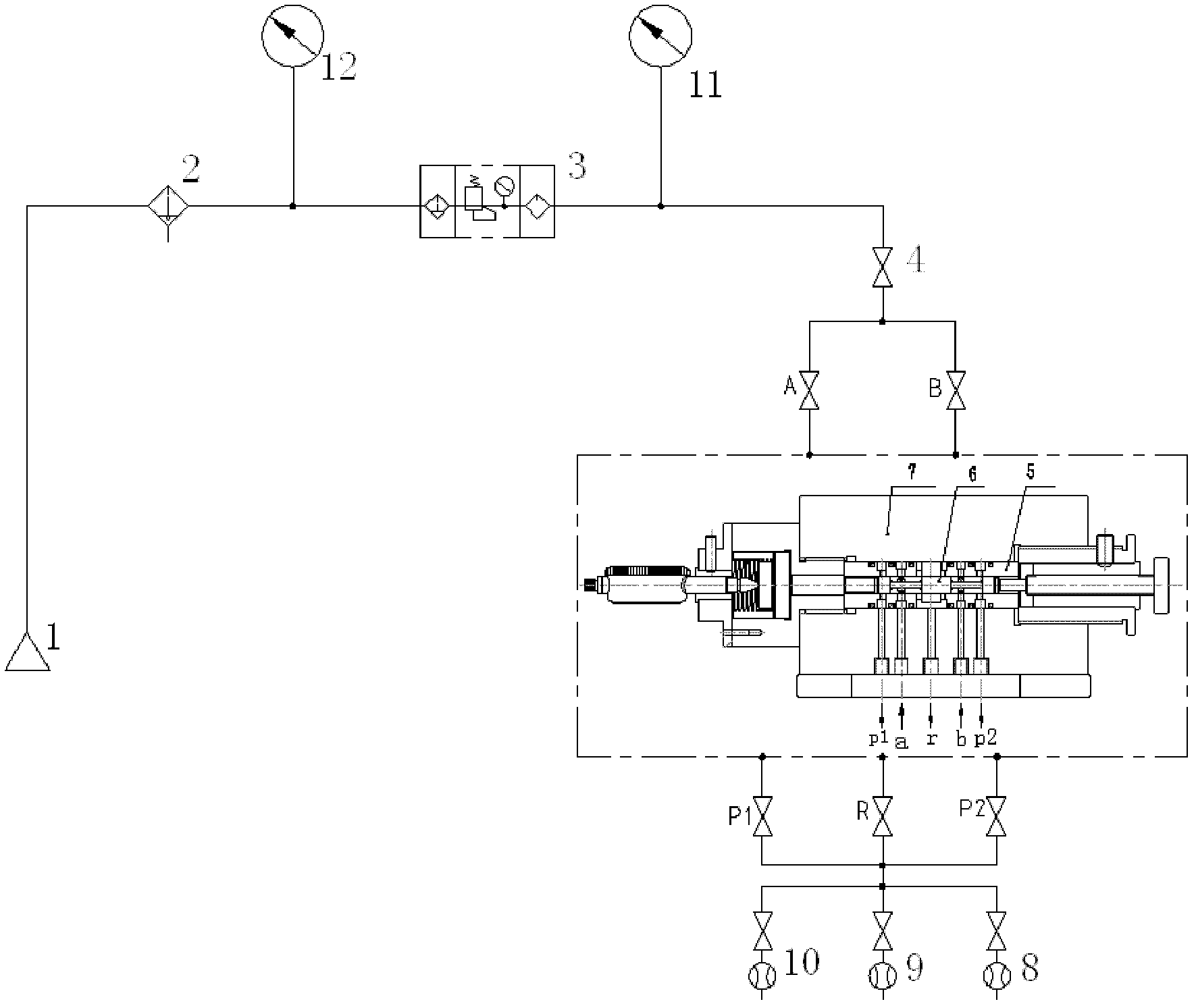

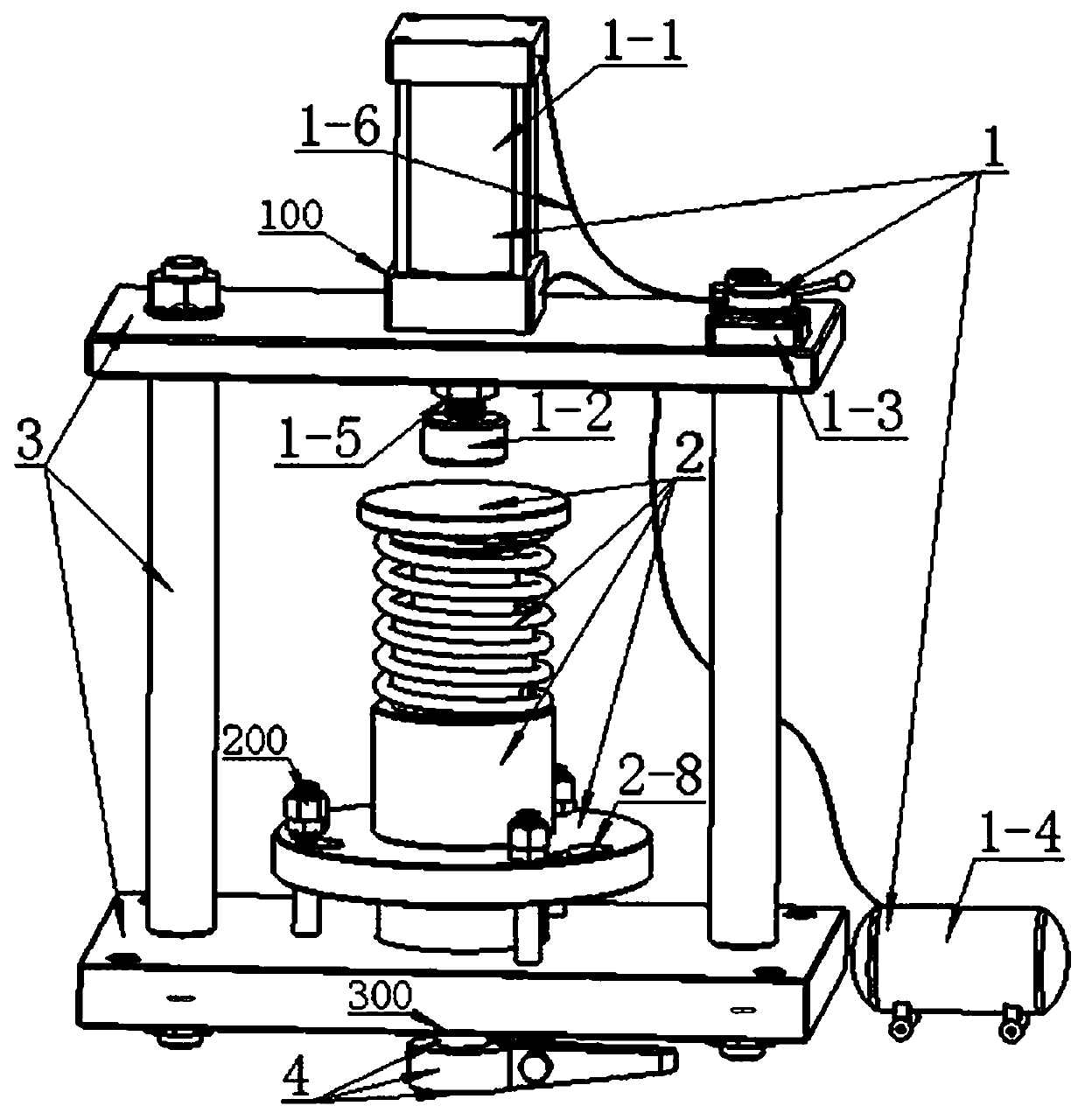

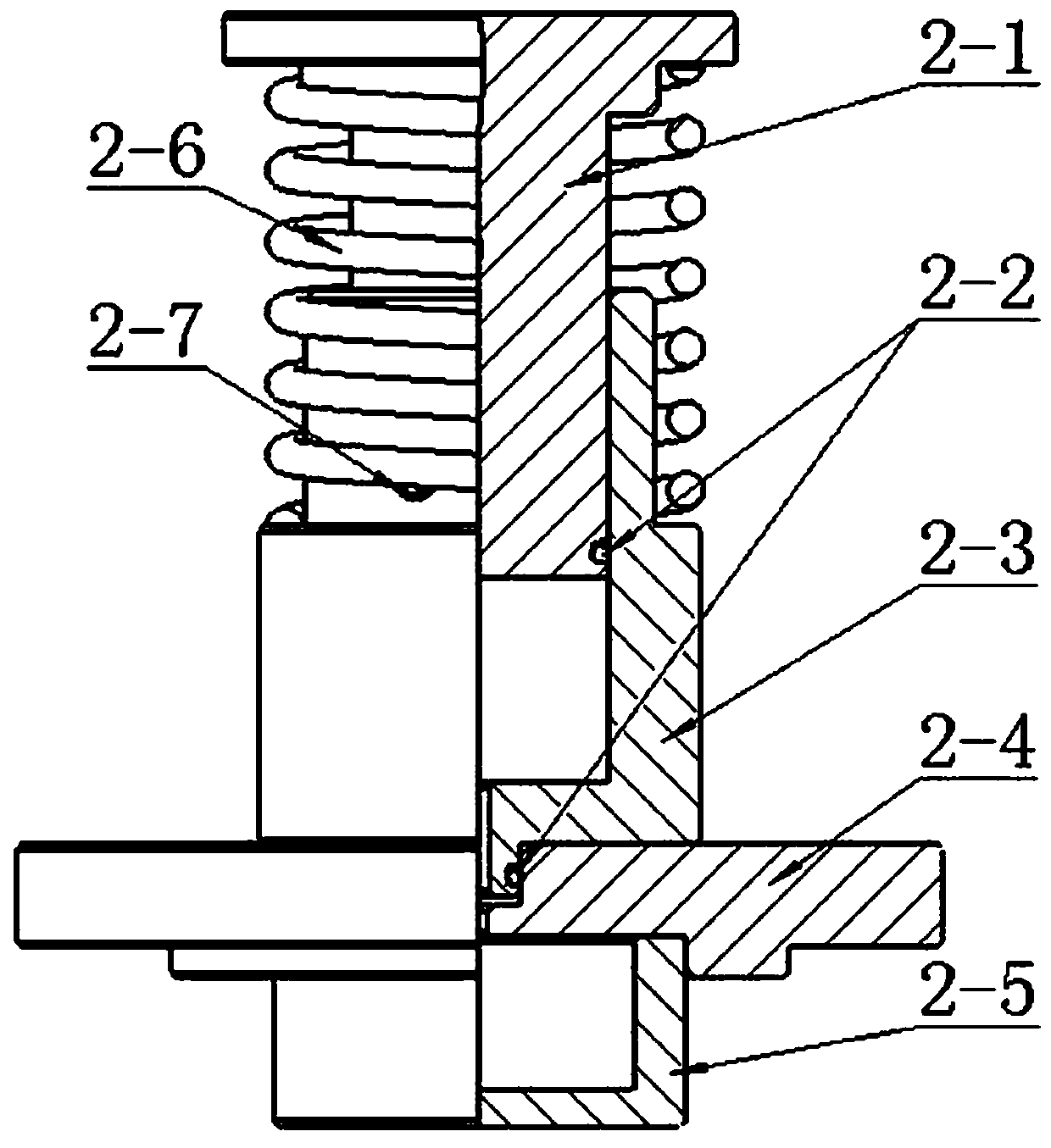

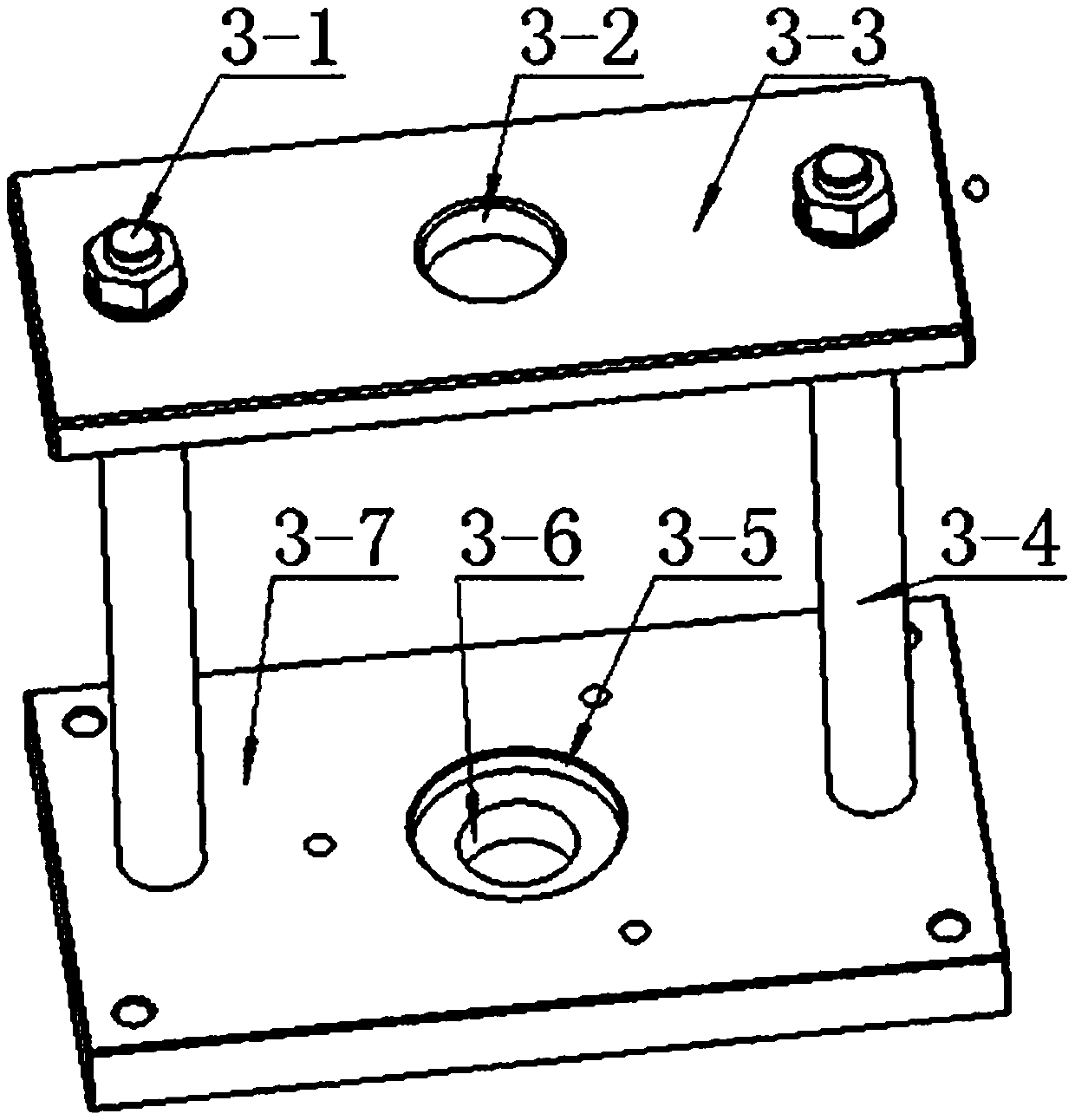

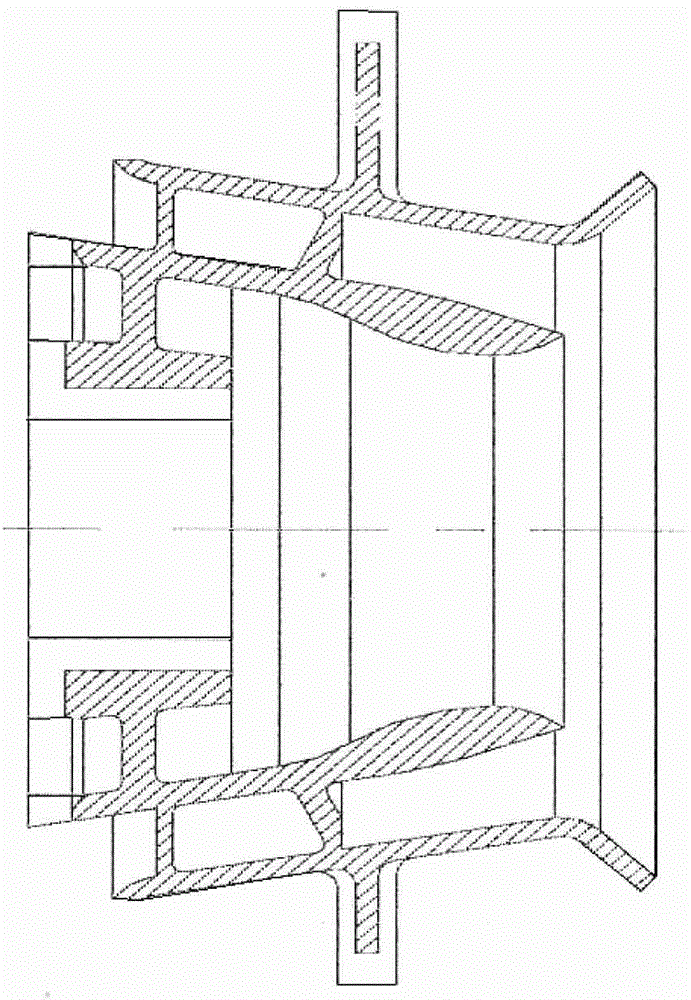

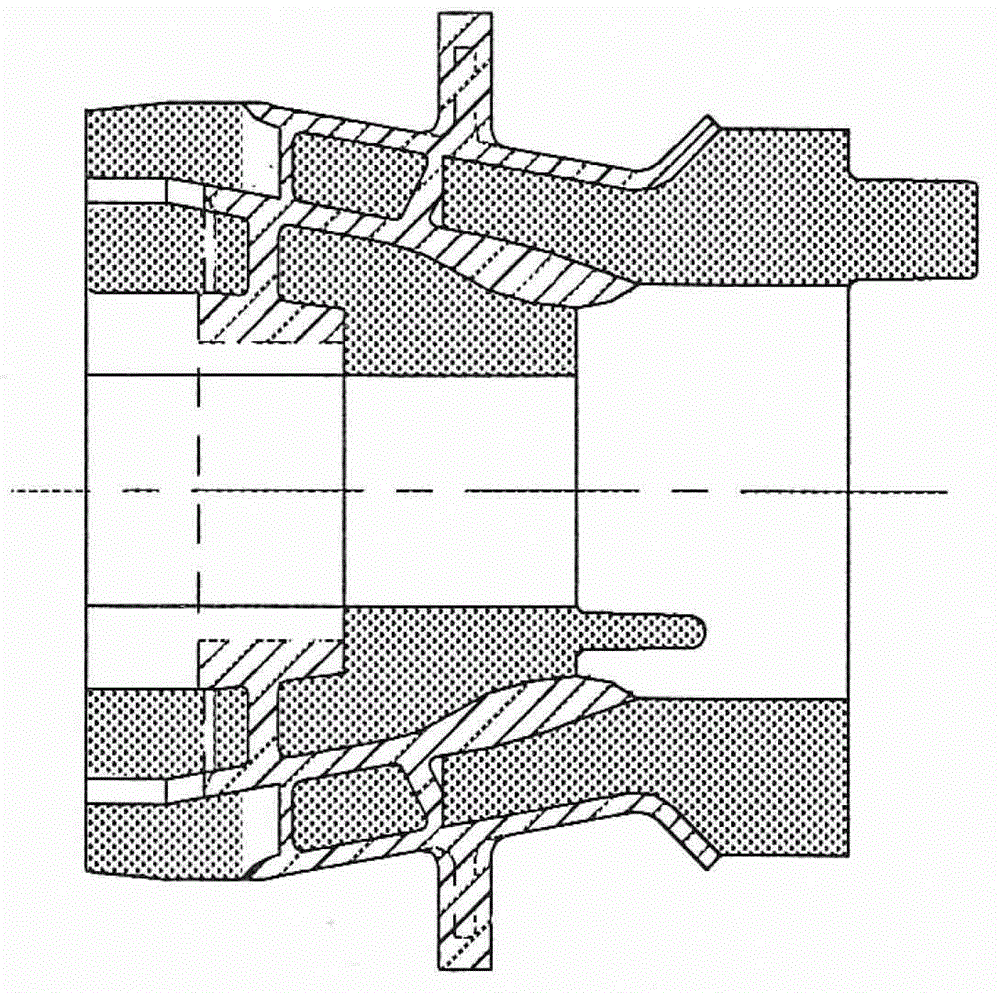

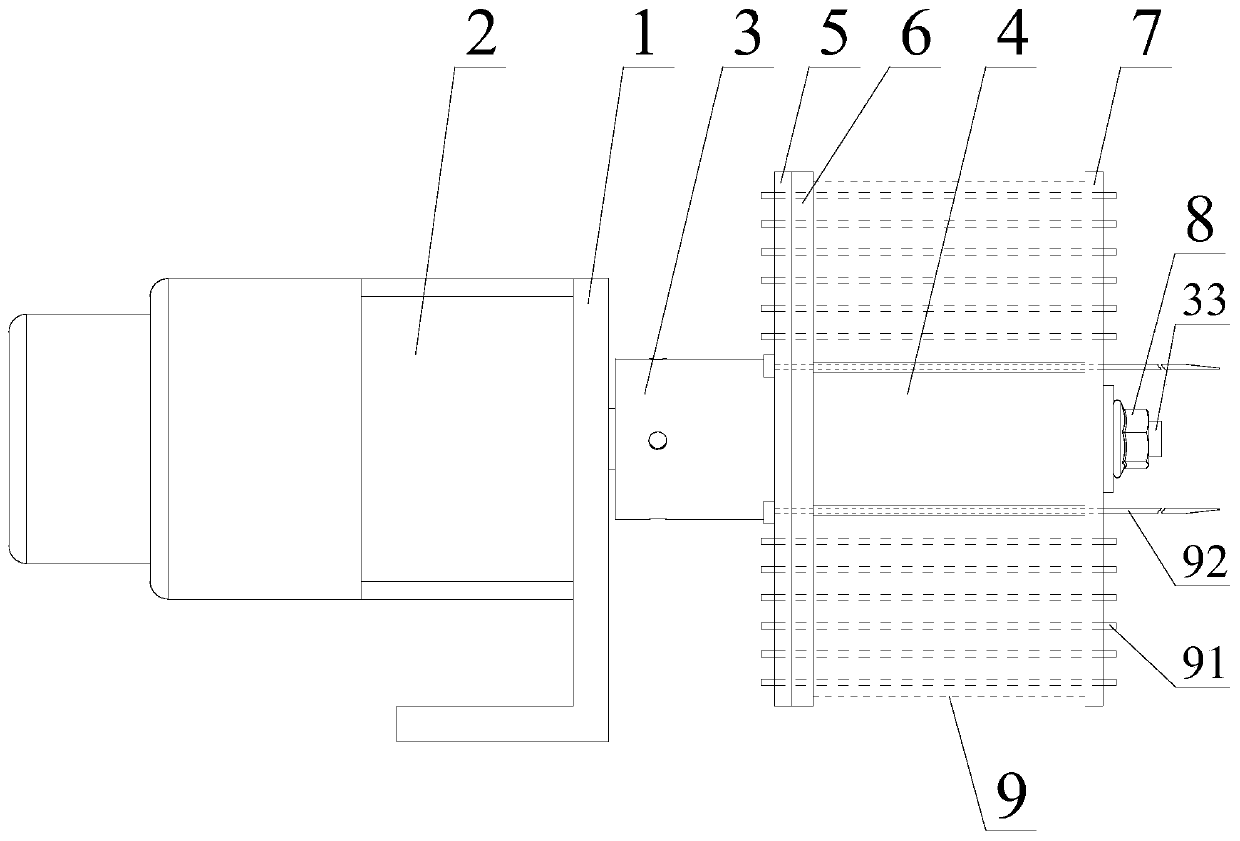

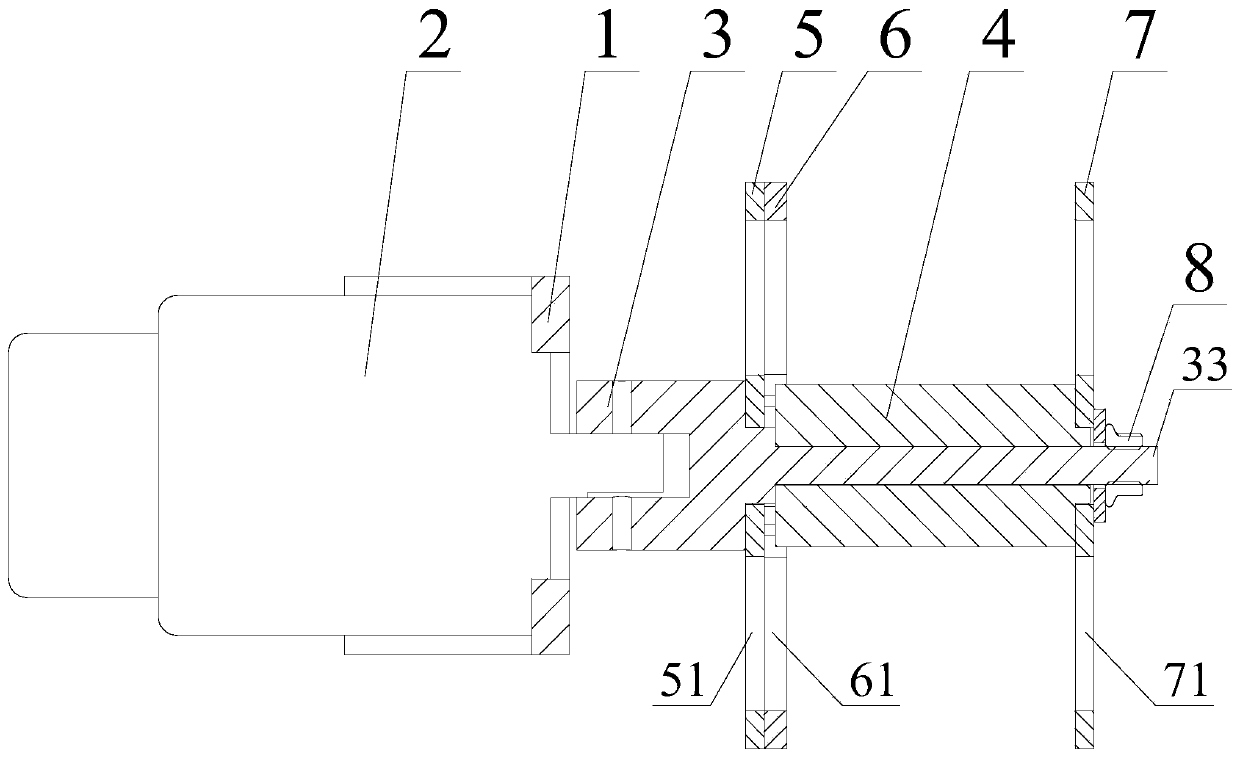

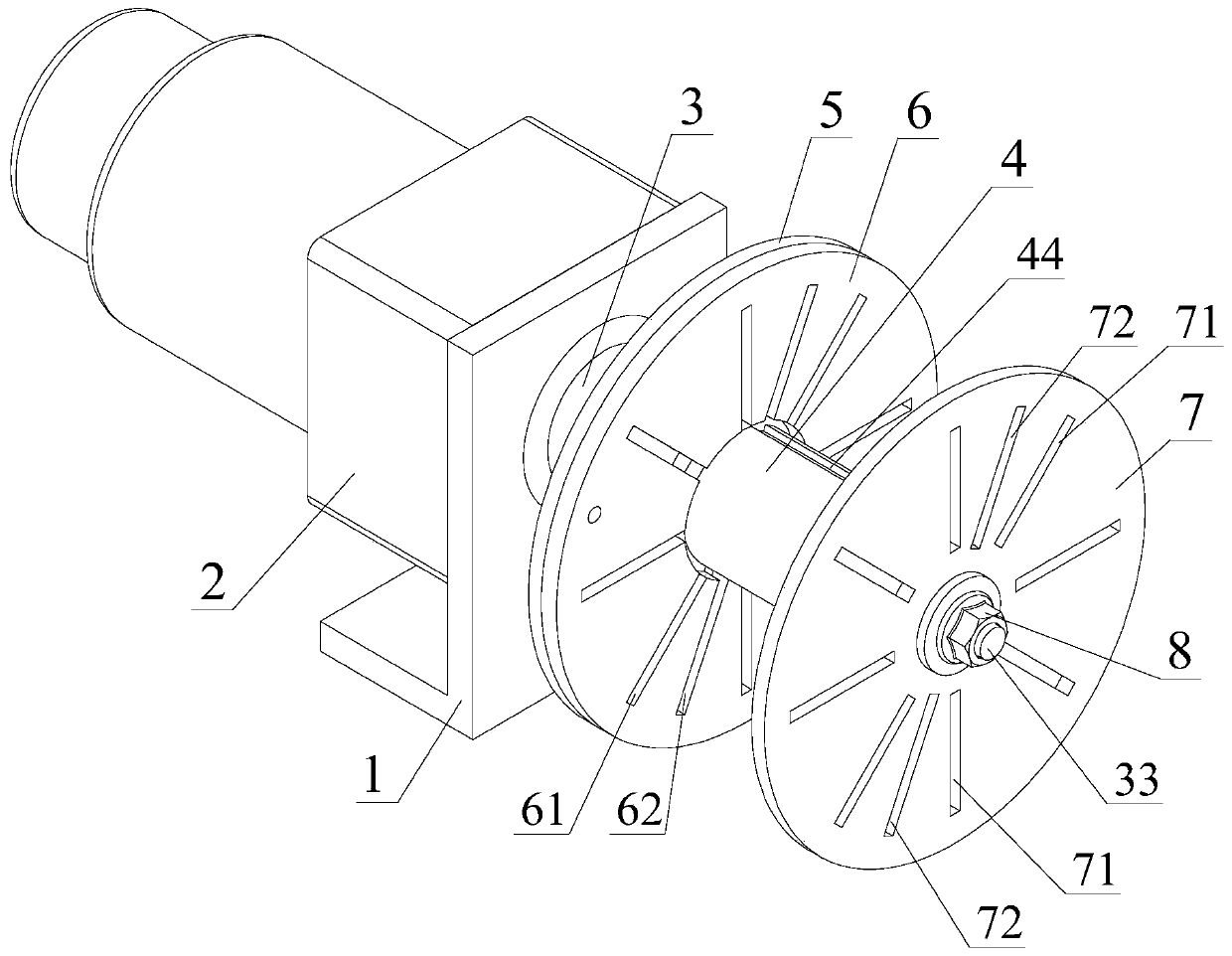

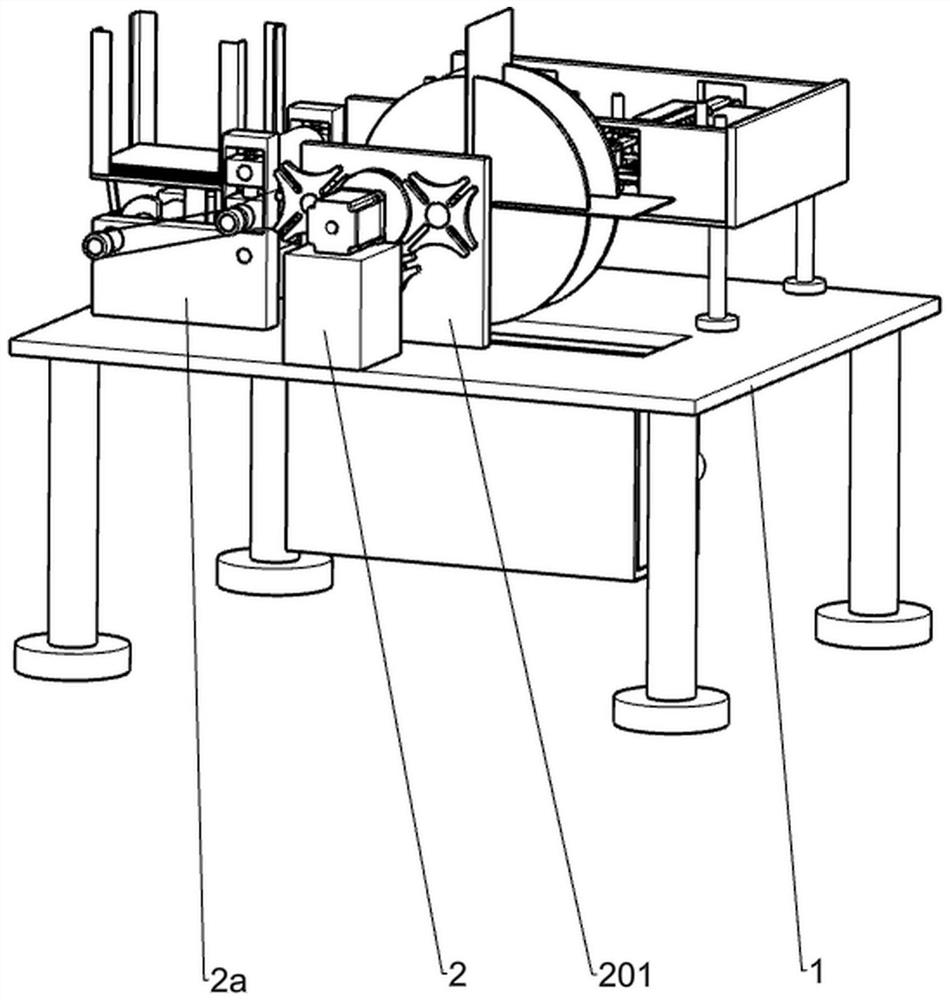

Servo valve pneumatic match grinding table

InactiveCN102873611ARealize small batch productionHigh precisionGrinding machinesAir filterElectrical and Electronics engineering

The invention discloses a servo valve pneumatic match grinding table. The servo valve pneumatic match grinding table comprises an air source, wherein the air source is connected in series with an air filter, a three unit used for reducing pressure and a main switch in sequence; the main switch is connected in series with a first air inflow switch and a second air inflow switch which are connected in parallel with each other; the first air inflow switch and the second air inflow switch are respectively connected with a first air inlet and a second air inlet which are formed in a tool body outside a valve core and a valve sleeve; a first air outlet, a second air outlet and an air outlet on the tool body are respectively connected with a first air outflow switch, a second air outflow switch and a switch which are connected in parallel with one another; a small flow meter, a medium flow meter and a large flow meter are respectively connected in series with switches and connected in parallel with one another; one end of a parallel-connection network is connected in series with the first air outlet switch, the second air outlet switch and the switch which are connected in parallel with one another. The invention provides a measuring tool capable of meeting the requirement on axial match grinding precision. The servo valve pneumatic match grinding table is simple, easy and clean and has high precision, and the small-amount production of servo valves can be realized.

Owner:JIANGSU FIRST HYDRAULIC TECH

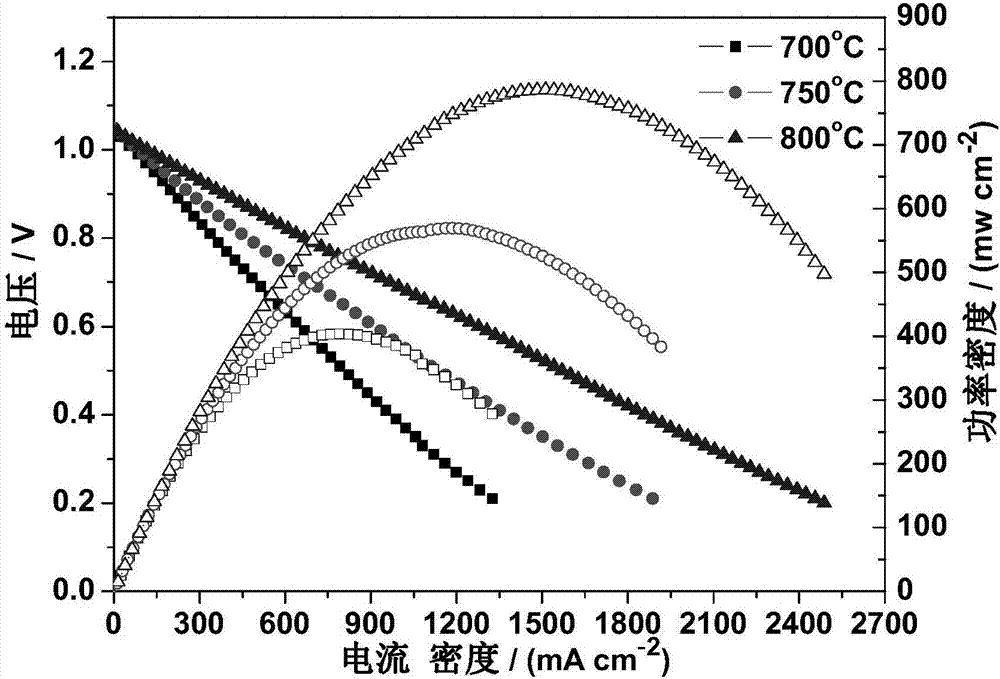

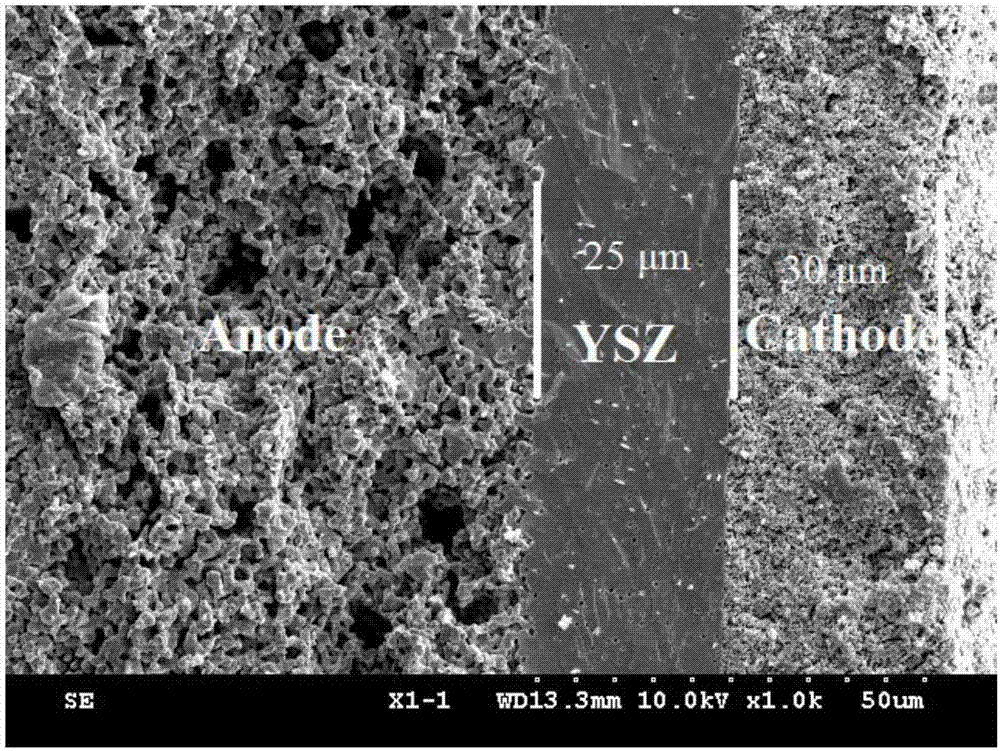

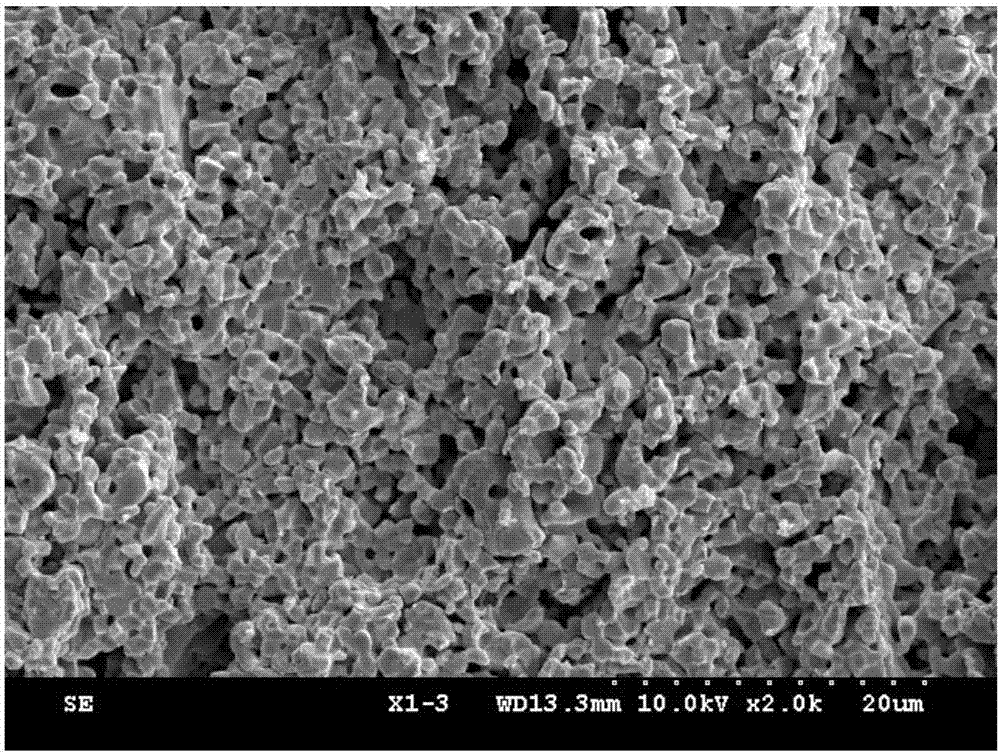

Simple preparation method for anode support of solid oxide fuel cell

InactiveCN107275657AHigh green strengthImprove toughnessFinal product manufactureFuel cellsPolyvinyl butyralPolyethylene glycol

The invention relates to the technical field of preparation of a solid oxide fuel cell and specifically relates to a simple preparation method for an anode support of the solid oxide fuel cell. The method comprises the following steps: 1) preparing a sizing agent: ball-milling and mixing NiO and YSZ at a weight ratio of 1:1, graphite powder and an organic additive for 3-4h, thereby forming a suspending sizing agent, wherein the organic additive includes polyvinyl butyral, triethanolamine, polyethylene glycol, di-n-octyl phthalate and absolute ethyl alcohol and the weight percent ratio of NiO to YSZ to graphite powder to polyvinyl butyral to triethanolamine to polyethylene glycol to di-n-octyl phthalate to absolute ethyl alcohol is (16-18%):(16-18%):(2-4%):(5-8%):(1.5-2%):(3-4%):(3-4%):(45-47%); 2) molding by adopting a scraper: pouring the anode sizing agent onto a glass plate, using the scraper for uniformly and smoothly filling the sizing agent into a glass carrier area between the adhesive tapes and molding; and 3) sintering under a high temperature. The method has the advantages of fast molding, simple and convenient operation, capability of realizing small scale production, and the like.

Owner:云南探源者科技股份有限公司

Metal coiled belt hollowing production equipment

InactiveCN107159782AReduce R&D costsRealize small batch productionMetal-working feeding devicesMetal working apparatusBatch productionFixed frame

The invention discloses metal coiled belt hollowing production equipment. A coiled belt is mounted on an uncoiling mechanism and conveyed into a first fixed frame assembly through supporting rollers. A discharging opening of the first fixed frame assembly is connected with a feeding opening of a second fixed frame assembly. An unloading turnover plate is arranged at a discharging opening of the second fixed frame assembly. A cutting tool is arranged between the unloading turnover plate and the second fixed frame assembly. A first perforating mechanism is arranged above the first fixed frame assembly. A second perforating mechanism is arranged above the second fixed frame assembly. The metal coiled belt hollowing production equipment has the beneficial effects that self-defining design can be carried out on a product, product hollowing and cutting are completed according to needs, small-batch production can be achieved, and the research and development cost can be reduced.

Owner:ANHUI WALTER MACHINERY TRADE

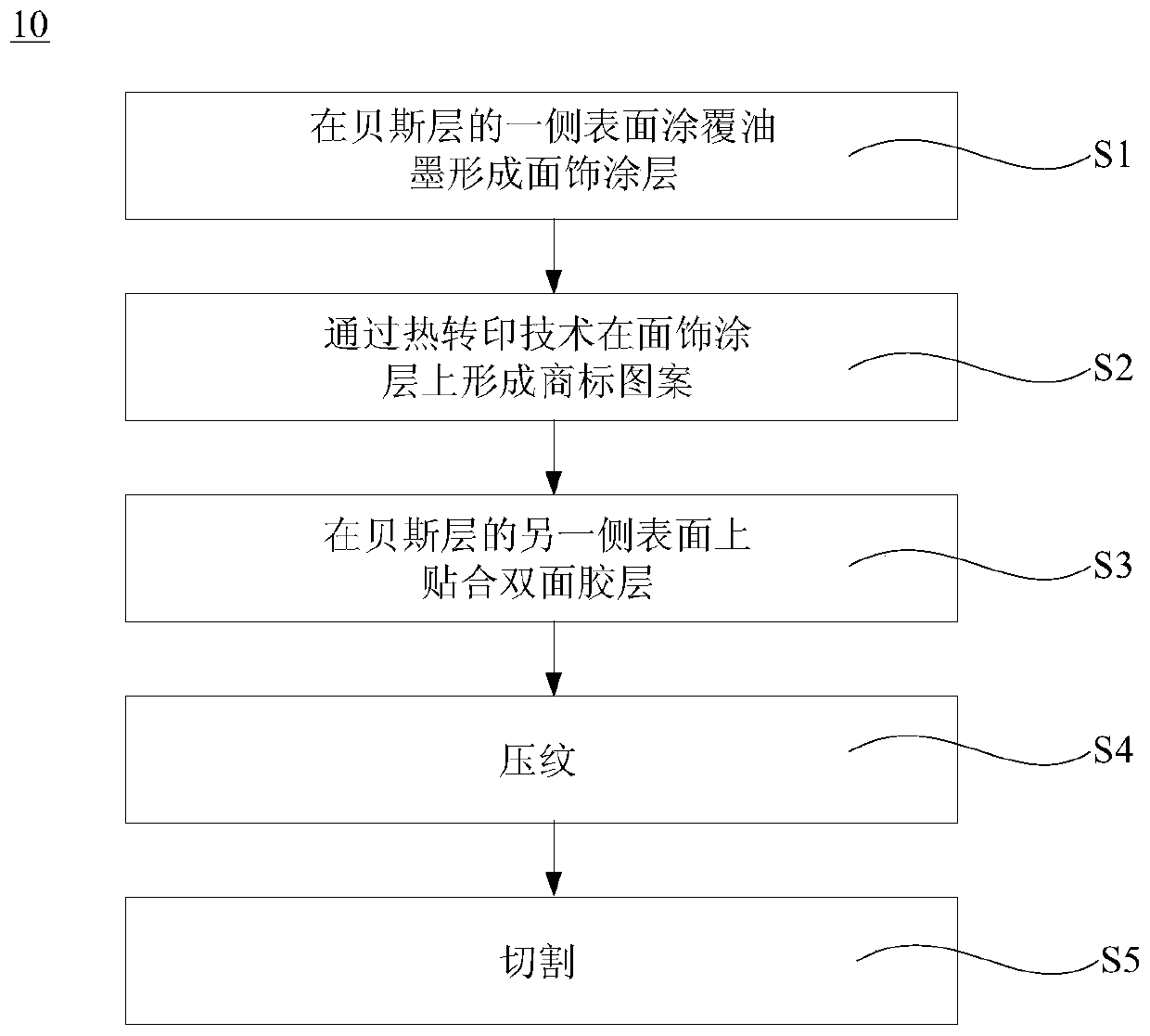

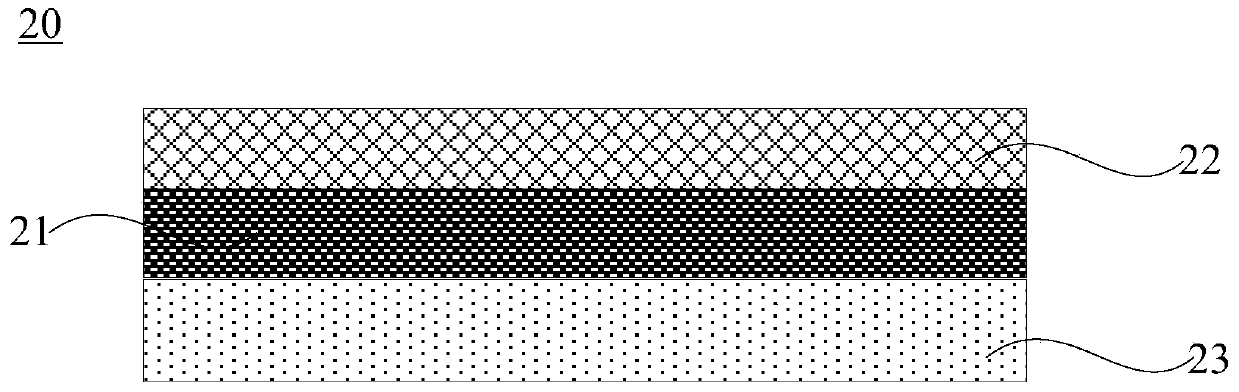

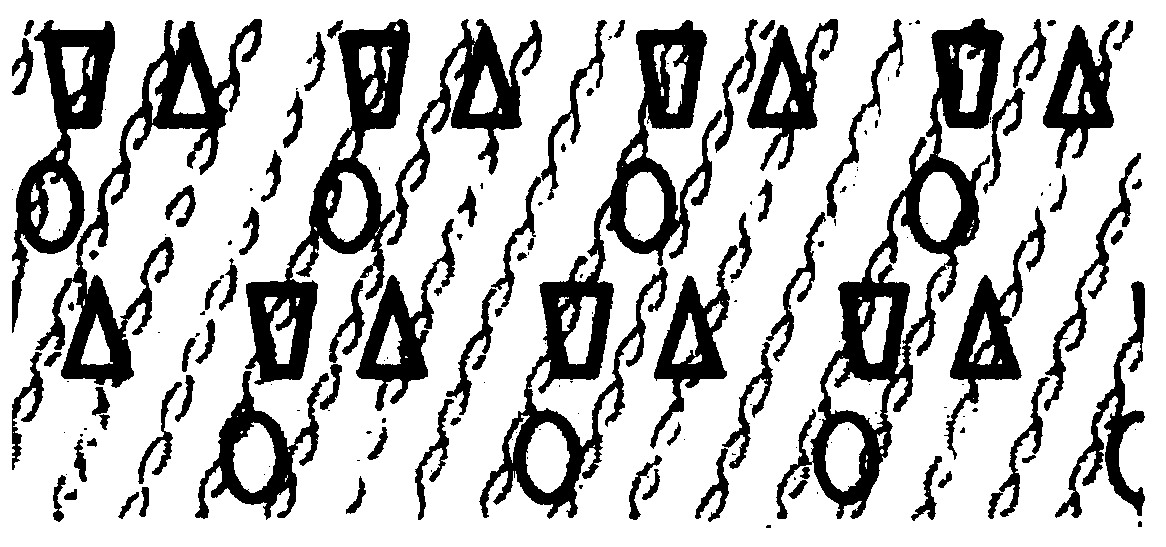

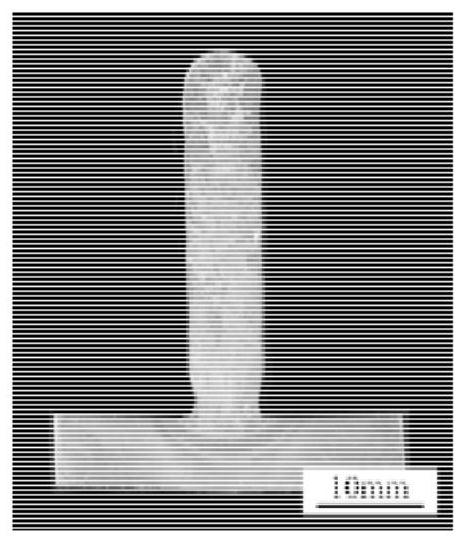

How to make imitation leather trademark

ActiveCN106739599BFriction-resistantVariety of colorsDuplicating/marking methodsPattern printingGraphicsTrademark

The invention relates to a manufacturing method for an artificial leather trademark. One side surface of a base layer is coated with ink to form a facing coating firstly; afterwards through the heat transfer printing technology, the content of a trademark pattern information unit with one single color or colors is transferred to the facing coating, and then a double-face glue layer is attached to the other face of the base layer; and finally embossing and cutting are conducted. According to the manufacturing method for the artificial leather trademark, the obtained artificial leather trademark can have DIY fashion elements, and colorful graphic and text information are formed, so that the color and texture are more abundant, attractive and the like; and hand feeling like genuine leather is achieved, good color fastness and friction resisting are achieved, residual glue is avoided after the trademark is torn off, the trademark can be torn off and adhered for many times, and diversified requirements of people can be met. Meanwhile, the process of the manufacturing method for the artificial leather trademark can achieve small scale production of products.

Owner:广东康派环创科技有限公司

Preparation method of high-strength ta18 titanium alloy components based on electron beam fuse addition

ActiveCN109514067BWide variety of sourcesDirect formingElectron beam welding apparatusRapid scanTitanium alloy

The invention discloses a high-strength TA18 titanium alloy component preparing method based on an electronic beam fuse wire additional material. The method comprises the following steps that the component transition area of a titanium alloy component is determined, a three-dimensional CAD solid model is established according to the titanium alloy component, and an implementable path is generatedaccording to the single-way deposition layer width W, the single-layer thickness L and the overlap rate gamma; electronic beam fuse wire additional material manufacturing is conducted according to theabove path, and single-layer titanium alloy wire deposition is finished; single-layer titanium alloy wire deposition is finished according to the above steps, and a small beam-current electronic beamis adopted for conducting rapid scanning in the direction perpendicular to the deposition direction; till all sheet layers are deposited, and component additional material manufacturing is finished;and the transition area part is cut away, and component annealing treatment is conducted. According to the method, the additional material raw material source is wide, finished TA2 and TC4 welding wires exist, and special making of TA18 welding wires is not needed. The method is high in production efficiency and low in production cost, direct complex component forming can be achieved, and the complex component manufacturing time is shortened.

Owner:NANJING UNIV OF SCI & TECH

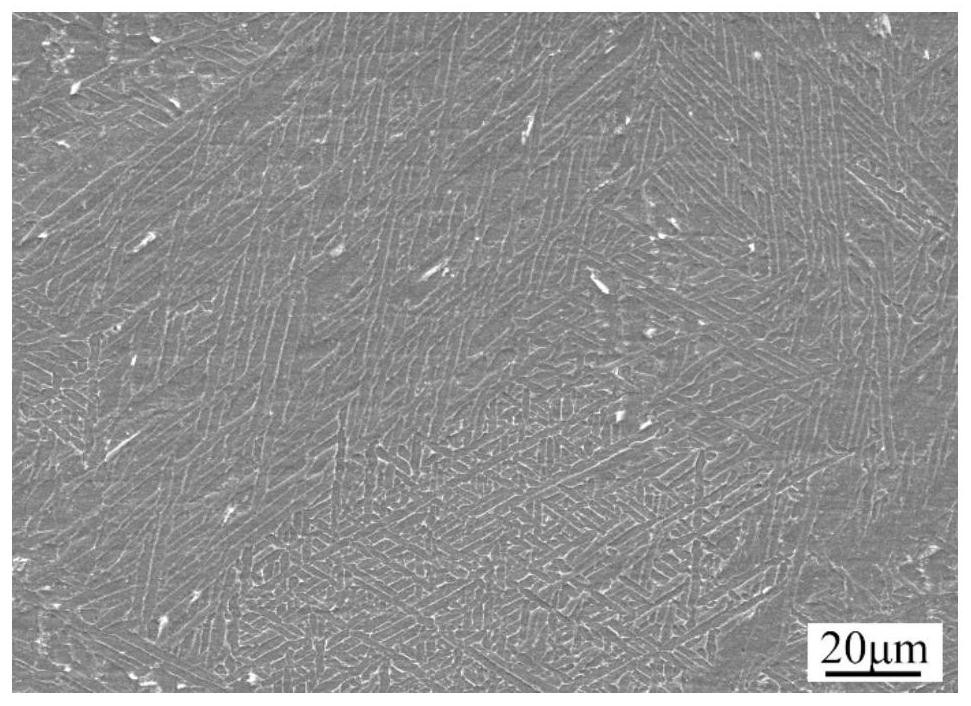

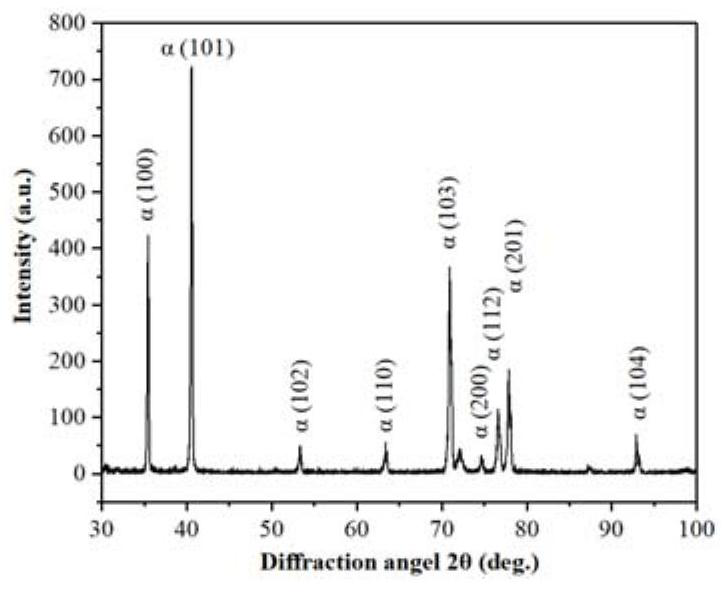

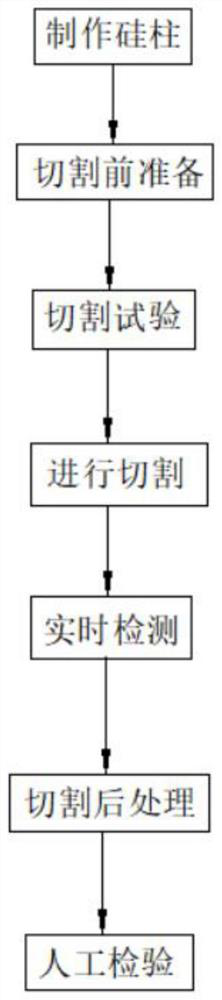

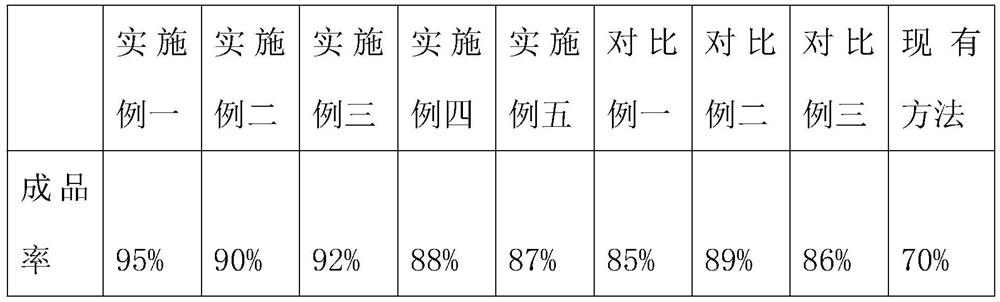

N-type 110-micron slice cutting process

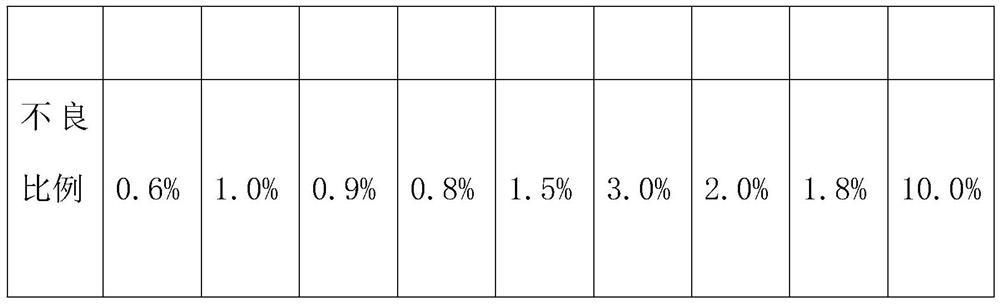

InactiveCN113997438ARealize small batch productionImprove flatnessPreparing sample for investigationFine working devicesSilicon chipBatch manufacturing

The invention relates to the technical field of slice cutting, in particular to an N-type 110-micron slice cutting process, and provides the following scheme aiming at the problem that due to the characteristics of high material hardness and high brittleness in the existing cutting process, the thickness of a cut slice is very large due to breakage and edge breakage in the cutting process. The cutting process comprises the following steps of S1, silicon column manufacturing, S2, preparation before cutting, S3, cutting test and S4, cutting. The invention aims to cut out the N-type silicon wafer with the thickness of 110 mum by improving the existing cutting mode, improve the control method in the subsequent silicon wafer cleaning and inspection process, control the defect ratio within 1%, realize small-batch production, meanwhile, the surface flatness of the cut silicon wafer is good, fragments are reduced, the yield of the silicon wafer is improved, real-time detection is carried out in the silicon wafer cutting process, and the probability of loss caused by abnormal conditions of a machine is reduced.

Owner:宜春宇泽新能源有限公司

Polylactic acid masterbatch spinning pack

ActiveCN104278337BDistribute and mix wellReasonable designSpinning solution de-aeratingSpinnerette packsMasterbatchLaccaic acid

The invention relates to a polylactic acid color masterbatch spinning assembly, which comprises a cylinder, the top and the bottom of the cylinder are opened, a diversion gland, a mixing distribution plate, a diversion plate, a sand cup gland, a sand filling cup, a filter screen and a spinneret plate are sequentially arranged inside the cylinder from top to bottom; a polylactic acid melt injection channel and a color masterbatch melt injection channel which are through vertically are arranged in the diversion gland; a circular polylactic acid melt distribution tank and a color master batch melt distribution tank are formed in the upper surface of the mixed distribution plate, the lower end of the polylactic acid melt injection channel is connected with the polylactic acid melt distribution tank, and the lower end of the color masterbatch melt injection channel is connected with the color masterbatch melt distribution tank. The polylactic acid color masterbatch spinning assembly is reasonable in design, novel in structure and high in spinning efficiency, the even mixing of polylactic acid and color masterbatch can be guaranteed, the small-batch production of polylactic acid color silks can be realized, and the difficulty in the small-batch production of color silks can be solved.

Owner:HENAN LONGDU BIOLOGY TECH

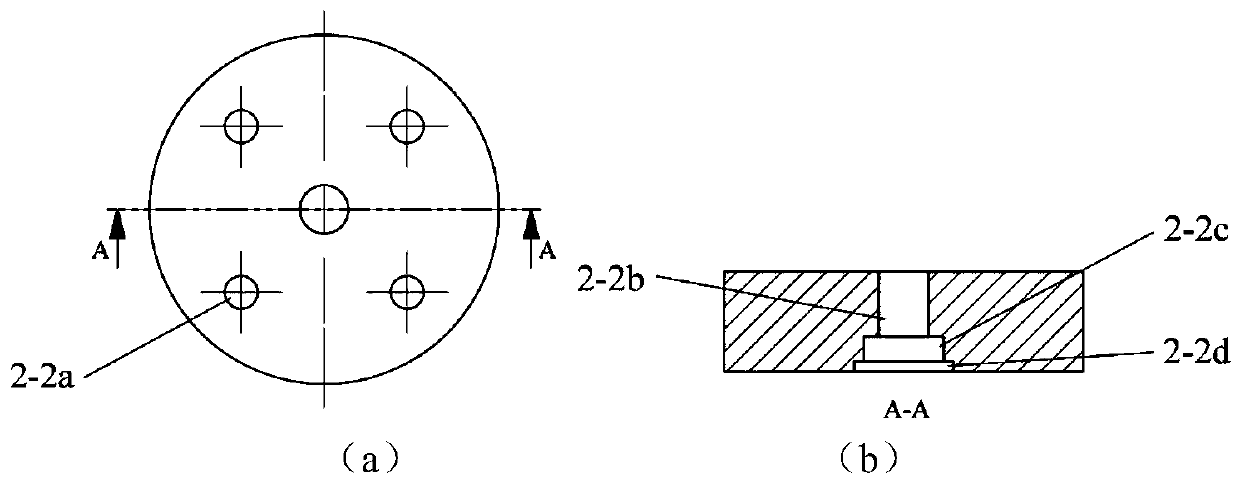

Dynamic calibration device for miniature ultrahigh pressure sensor

InactiveCN110793715AMiniaturizationAchieve thin filmFluid pressure measurementForce/torque/work measurement apparatus calibration/testingUltra high pressureMiniaturization

The invention discloses a dynamic calibration device for a miniature ultrahigh pressure sensor. The dynamic calibration device comprises a target plate device. A miniature ultra-high pressure sensor is fixed on the target plate device. A flyer driving device is arranged above the miniature ultra-high pressure sensor; a flyer output port of the flyer driving device is aligned with a sensitive element of the miniature ultra-high pressure sensor; and the flyer driving device is connected with the target plate device through a bolt. The flyer driving device includes a housing; a micro detonator, aflyer and an acceleration chamber are sequentially fixed to the housing from top to bottom through a limiting hole structure. The target plate device includes a base; and a pressure bearing block isfixed to the base through the limiting hole structure. According to the invention, the miniaturization and thinning of the flyer are realized by adopting an MEMS process and thus the requirement thatthe size of the flyer is close to the size of a sensitive element of the miniature ultrahigh pressure sensor is met, thereby improving the precision of a dynamic calibration curve of the miniature ultrahigh pressure sensor. Moreover, the calibration device with low cost is suitable for dynamic calibration of the miniature ultrahigh pressure sensor.

Owner:XI AN JIAOTONG UNIV

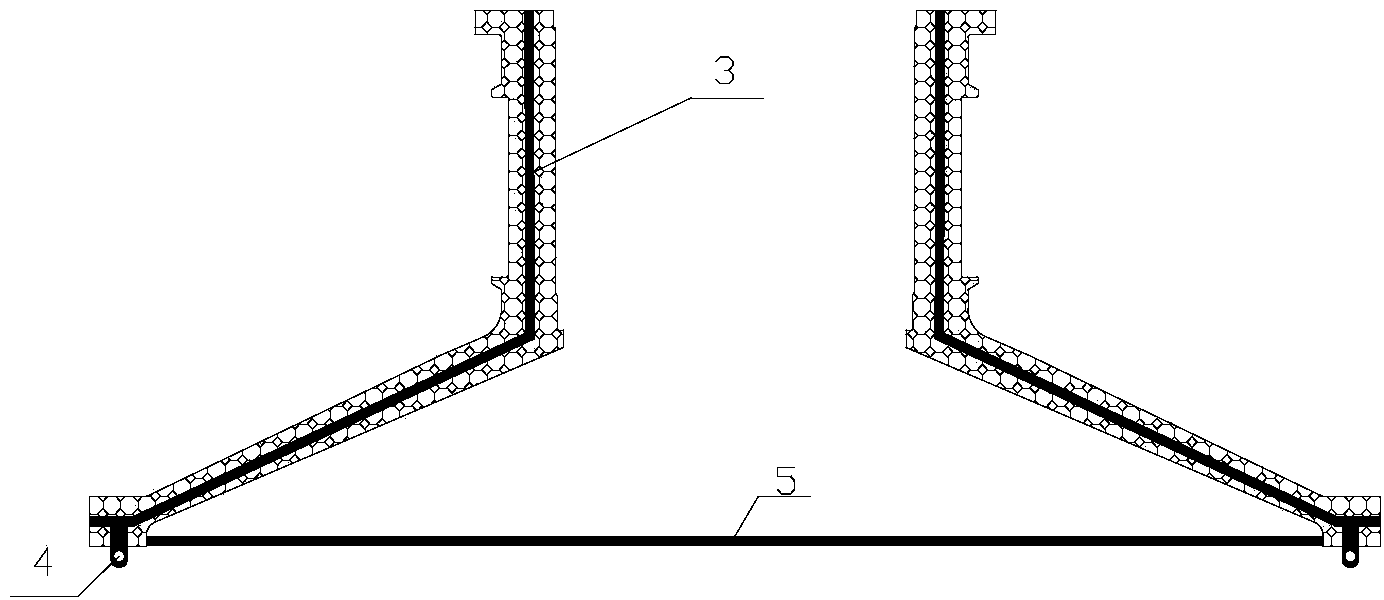

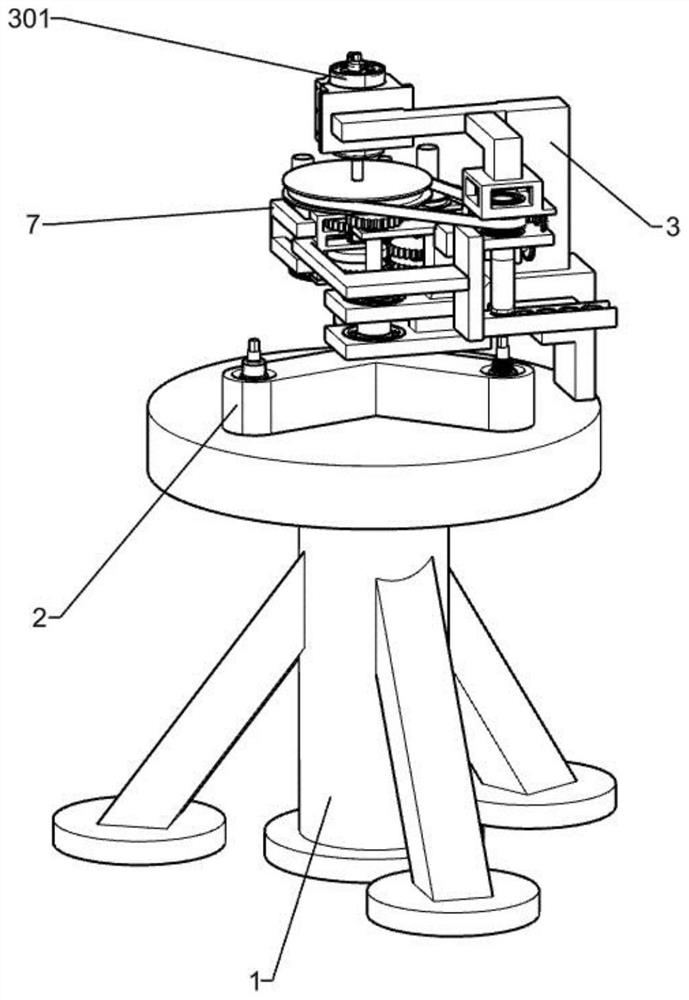

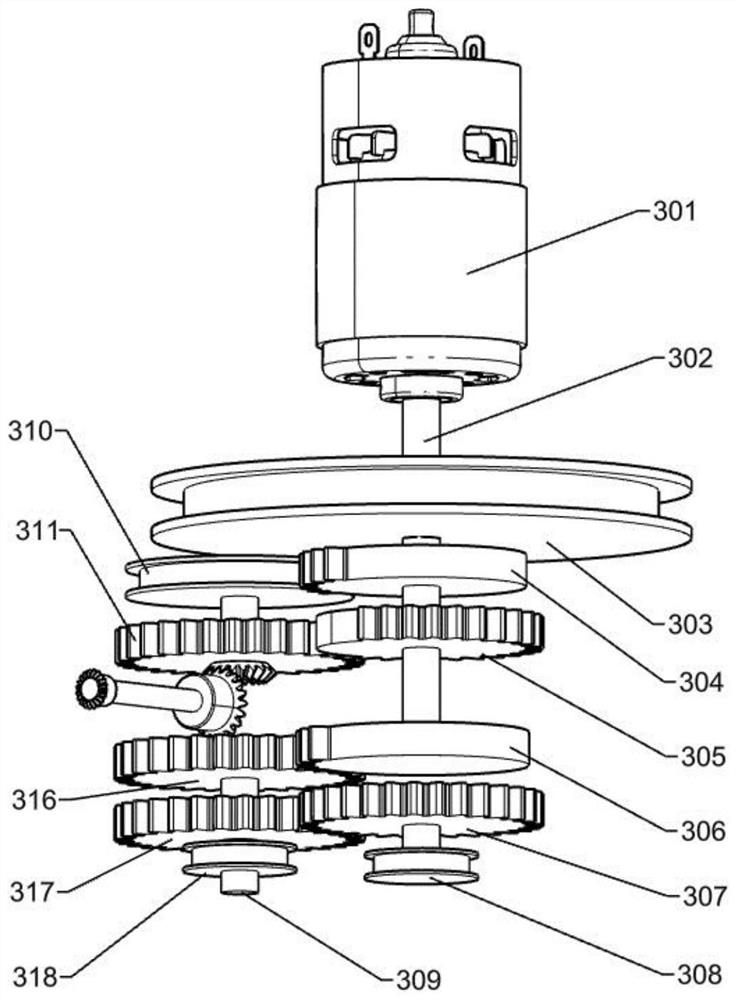

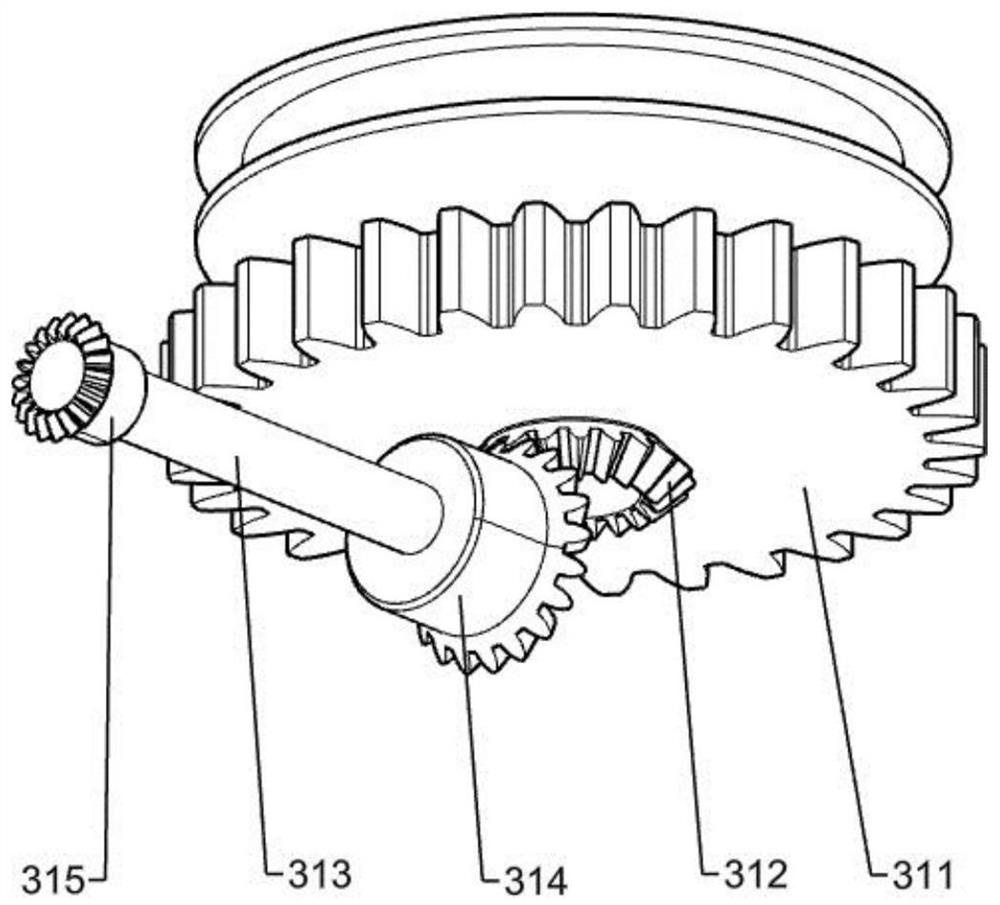

Special-shaped curved surface metal sheet forming device and process

PendingCN113182410AEasy to operateEasy to processMetal-working feeding devicesPositioning devicesHydraulic cylinderMetal sheet

The invention belongs to the field of special-shaped curved surface metal sheet forming, and particularly relates to a special-shaped curved surface metal sheet forming device and process. According to the scheme, the special-shaped curved surface metal sheet forming device comprises a base, wherein a first hydraulic cylinder is fixedly installed at the center of the bottom of the base, a workbench is fixedly installed at the top of a piston rod of the first hydraulic cylinder, a light mold is placed at the top of the workbench, supporting rods are fixedly installed at the four corners of the top of the base, the same clamping platform is installed at the tops of the four supporting rods, and two sets of second hydraulic cylinders are arranged at the top of the clamping platform. The invention further provides a machining process. According to the special-shaped curved surface metal sheet forming device and process, a special-shaped curved surface is machined and formed by adopting the process, the same light mold can be machined and used for multiple times, so that the production cost is reduced, and various technologies used in the forming process are relatively mature; and compared with traditional manual forming, the machining efficiency is high, compared with multi-point mold forming, the equipment cost is greatly reduced, and the special-shaped curved surface metal sheet forming device and process are suitable for multi-type small-batch production.

Owner:南京筑新科技有限公司

A bionic fish driven by chemical reactions

ActiveCN109263843BAcoustic StealthSimple structurePropulsive elementsMicrocontrollerChemical reaction

The invention relates to a bionic fish, more specifically, to a bionic fish driven by chemical reactions, including a fish body, a reaction solution chamber, a microcontroller, an intelligent switch airway and a catalyst storage; the microcontroller is placed in a sealing waterproof material, the microcontroller is fixedly connected to the fish body, a reaction solution chamber is arranged in thefish body, intelligent switch airways are arranged on both sides of the reaction solution chamber, the upper end of the reaction solution chamber is provided with a catalyst storage. The reaction poolI, reaction pool II, reaction pool III, reaction pool VI and reaction pool V in the fish body can be controlled by a microcontroller to generate bubbles, which can move like a fish and realize the flexible propulsion in water, and the structure is very simple. In addition, the hydrogel is used as the fish body material, and the acoustic stealth can be realized. At the same time, the main part ofthe bionic fish is for by 3D printing at one time, and small batch production can be realized quickly.

Owner:HARBIN INST OF TECH

Off-line pipe cutting equipment

ActiveCN110103272BRealize small batch productionReduce pup production costsMetal sawing devicesMetal working apparatusStructural engineeringPipe

The invention discloses an off-line pipe cutting device, which belongs to the technical field of pipe cutting equipment, and comprises a guide rail, a stinger, a gantry and a cutting saw, the stinger is arranged on the guide rail, and the guide rail and the stinger are arranged on the gantry On one side of the gantry, the middle part of the gantry is provided with a round hole for the pipe to pass through, and a circular track is arranged along the round hole, and the cutting saw for cutting the pipe moves in a circle along the circular track; the pipe is erected on the stinger, A clamping device is provided above the stinger for clamping and fixing pipes; the stinger is connected with a lifting device for adjusting the height of the pipes on the stinger. Set up the pipe on the stinger, adjust the pipe through the lifting device to coincide with the center line of the round hole of the gantry while moving along the guide rail; use the clamping device to clamp and fix the pipe, start the cutting saw along the gantry The upper circular track makes a circular motion to cut the pipe passing through the round hole on the gantry frame to realize offline cutting of the pipe.

Owner:HUACHUANG TIANYUAN IND DEVING

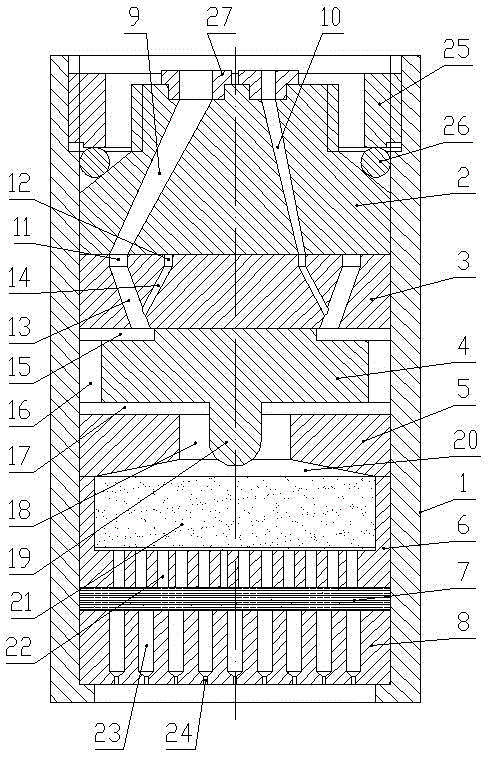

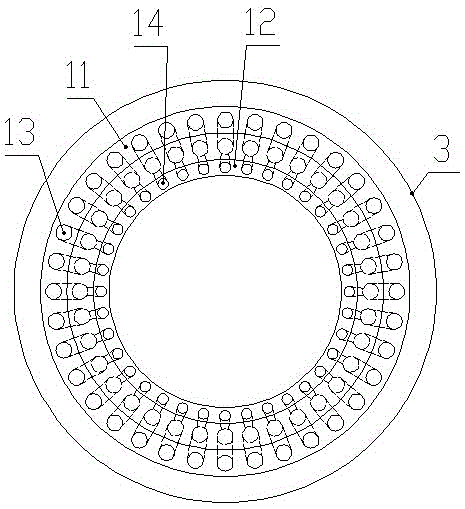

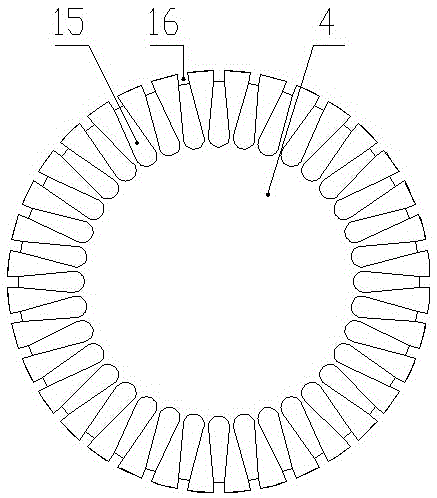

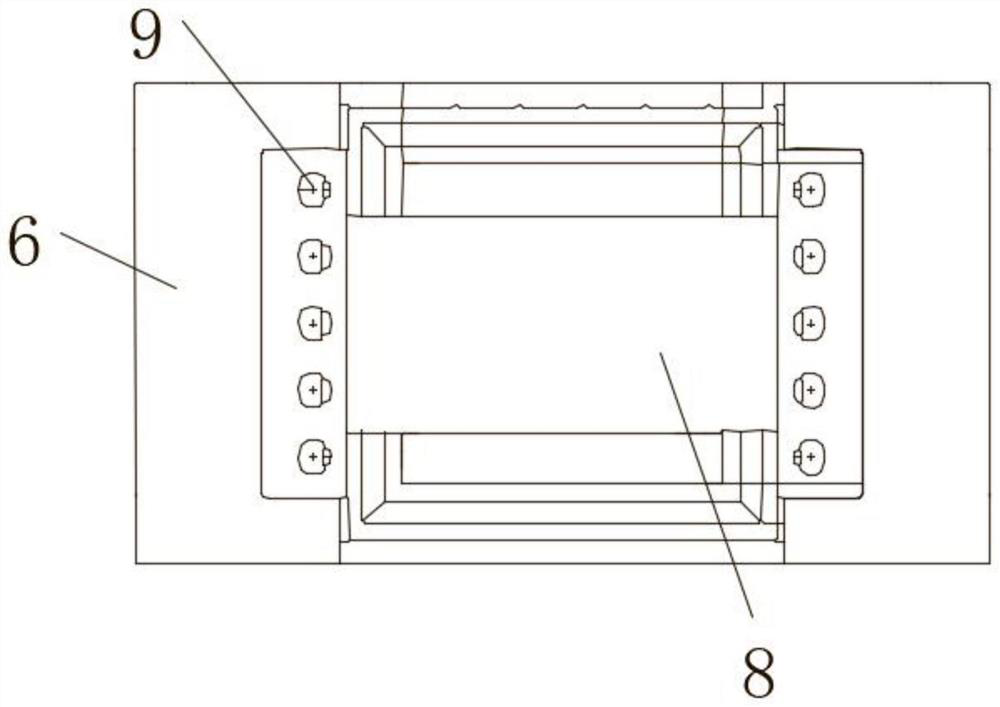

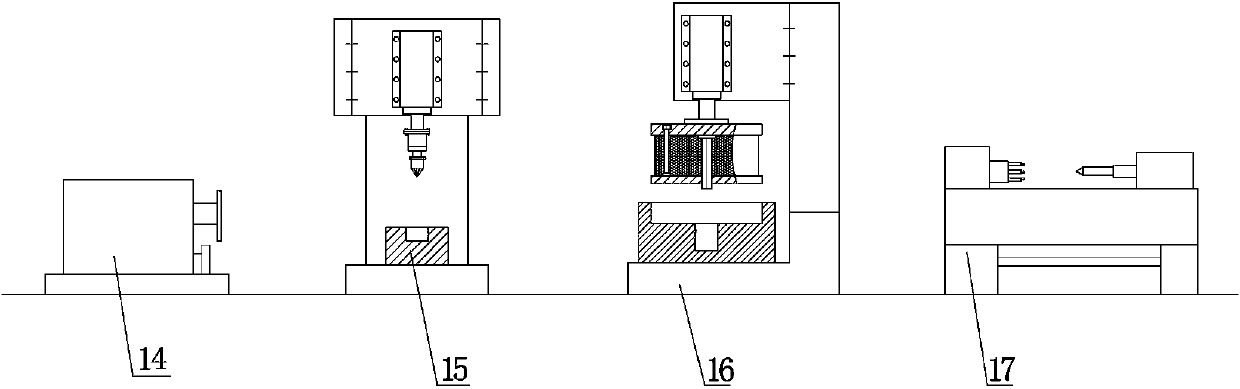

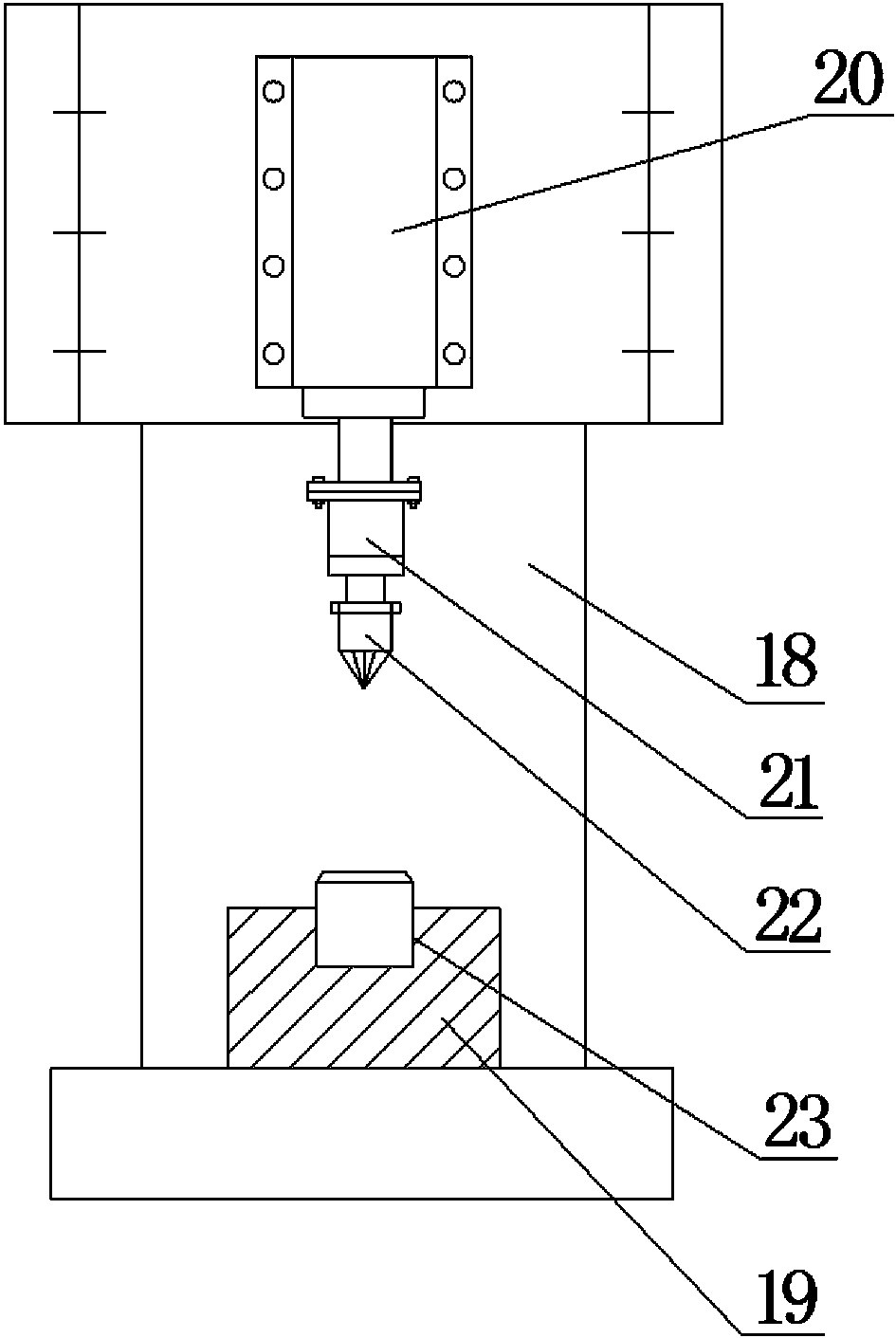

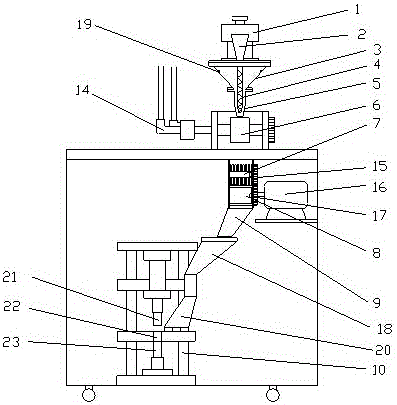

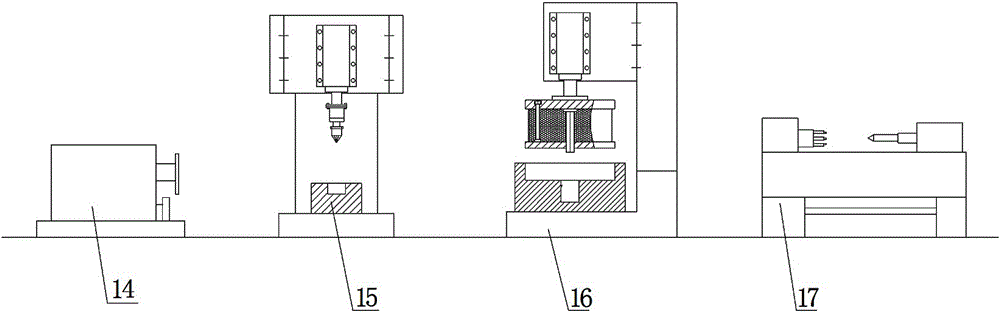

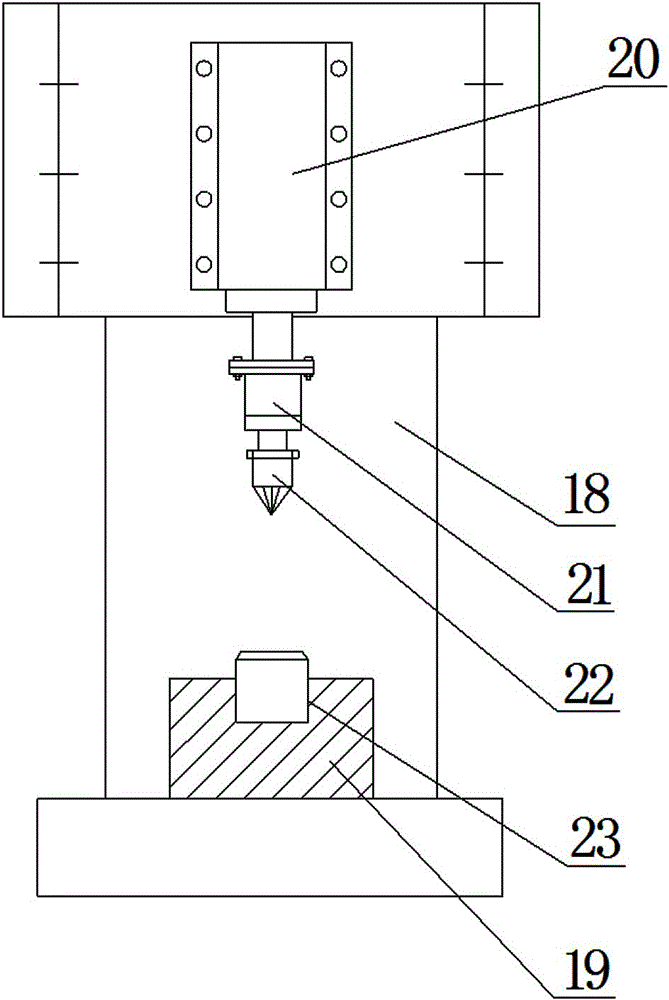

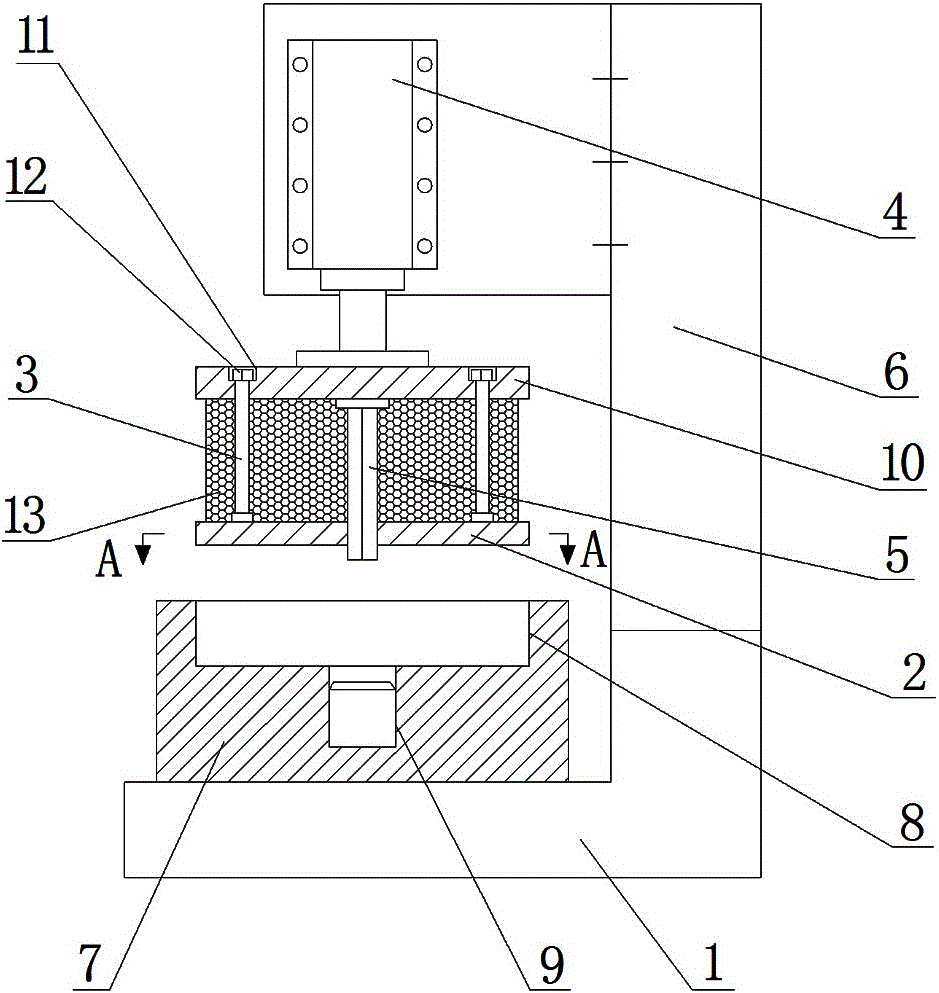

Production line and processing technology of a cold-worked screw plug

ActiveCN105945568BRealize small batch productionReduce labor intensityAssembly machinesProduction lineHydraulic cylinder

The invention discloses a production line of cold machining for plug screws. The production line comprises a sawing machine (14), a pre-hole machining device (15), an inner hexagon punching device (16), and a turning machine (17), which are all disposed in order from left to right. The pre-hole machining device (15) is composed of a base A (18), a concave die A (19), a hydraulic cylinder A (20), a motor (21), and a drill (22). The hydraulic cylinder A (20) disposed vertically is fixedly mounted on the base A (18). An acting end of the piston rod of the hydraulic cylinder A (20) is connected to the motor (21). The motor (21) is disposed vertically, and an output end of the motor (21) is connected to the drill (22). The concave die A (19) is located below the drill (22), and a grove (23) is formed in the top of the concave die A (19). The production line of cold machining for plug screws has the advantages of fast response time, realized production of small-batch plug screws, easy operation, high inner hexagon machining precision, reduction of the labor intensity of a worker, and improvement of the machining efficiency.

Owner:常熟东南高新技术创业服务有限公司

A pure powder granulating tablet press machine

ActiveCN104275822BRealize integrated productionIncrease productivityGrain treatmentsShaping pressEngineeringMedical instruments

Owner:升生健康科技(苏州)有限公司

A kind of preparation method of semi-dull nylon 6 filament

ActiveCN104032404BRealize small batch productionImprove spinnabilityMelt spinning methodsArtifical filament manufactureControl systemNylon 6

Owner:FUJIAN JINJIANG TECH

Preparation method of high-strength ta18 titanium alloy components based on plasma fuse addition

ActiveCN109277675BWide variety of sourcesDirect formingAdditive manufacturing apparatusPlasma welding apparatusMetallurgyIon beam

The invention relates to a preparation method of a high-strength TA18 titanium alloy member based on plasma fuse additional materials. The method specifically comprises the following steps of determining a component transition area of a titanium alloy member, and establishing a three-dimensional CAD solid model according to the titanium alloy member; generating an enforceable path according to thewidth W of a single-channel settled layer, the thickness L of a single layer and the overlapping rate gamma; and manufacturing the plasma fuse additional materials according to the path, and quicklyscanning in the direction perpendicular to the settling direction by adopting plasma beams with low current and low ionic gas. By adopting the method, the additional materials of the member are manufactured, finally, the transition area is cut, and annealing treatment is performed on the member. According to the method, the sources of the additional materials are wide, the production efficiency ishigh, the complex member can be directly formed, and the manufacturing time of the complex member is shortened; by adopting the method, small-scale production can be realized, and the previous designtest of the part structure is facilitated; and the TA18 titanium alloy member obtained by adopting the method has the advantages of low internal deformation stress and high tensile strength.

Owner:NANJING UNIV OF SCI & TECH

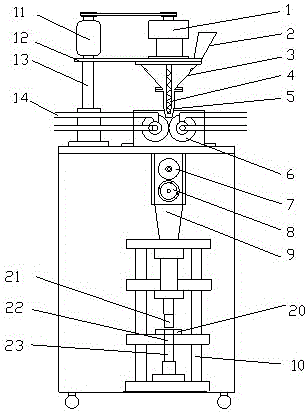

A pneumatic injection molding device

ActiveCN105690687BImprove surface qualityUniform densityFoundry mouldsFoundry coresEngineeringVolumetric Mass Density

The invention discloses a pneumatic pressure injection forming device. The pneumatic pressure injection forming device comprises a driving part, a forming part, a structure supporting part and a rapid locking part. An air cylinder is driven by adjusting the turning direction of a reversing valve, and a piston of the forming part is moved downwards and presses paraffin into a mold cavity rapidly. A base and a top plate in the structure supporting part are used for connecting the fixing forming part, the driving part and the rapid locking part. The paraffin can realize pressure injection forming of a paraffin mold at the speed of 20 ml / s through a pneumatic mode, the surface of the paraffin mold obtained through pressure injection is good in quality, and a formed part is uniform in density. The time for dismounting and mounting the mold is shortened through the arrangement of the rapid locking device, so that the processing efficiency is greatly improved. The pneumatic pressure injection forming device reduces processing cost, relieves labor intensity, can realize small-batch production, has the characteristics of convenience and high efficiency, and can realize teaching demonstration in pressure injection forming and injection forming experiment processes.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Production line of cold machining for plug screws and machining process thereof

The invention discloses a production line of cold machining for plug screws. The production line comprises a sawing machine (14), a pre-hole machining device (15), an inner hexagon punching device (16), and a turning machine (17), which are all disposed in order from left to right. The pre-hole machining device (15) is composed of a base A (18), a concave die A (19), a hydraulic cylinder A (20), a motor (21), and a drill (22). The hydraulic cylinder A (20) disposed vertically is fixedly mounted on the base A (18). An acting end of the piston rod of the hydraulic cylinder A (20) is connected to the motor (21). The motor (21) is disposed vertically, and an output end of the motor (21) is connected to the drill (22). The concave die A (19) is located below the drill (22), and a grove (23) is formed in the top of the concave die A (19). The production line of cold machining for plug screws has the advantages of fast response time, realized production of small-batch plug screws, easy operation, high inner hexagon machining precision, reduction of the labor intensity of a worker, and improvement of the machining efficiency.

Owner:常熟东南高新技术创业服务有限公司

A molding method for precision casting of a three-layer ring wall and two-layer vane vortex device

ActiveCN103317094BRealize small batch productionFilling the blank of molding technologyFoundry mouldsFoundry coresWaxCeramic molding

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Winding device for coil with air passage and winding method of winding device

PendingCN111210990AEasy to move and adjustEasy to useTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectric machineryEngineering

Owner:福州富和电子科技有限公司

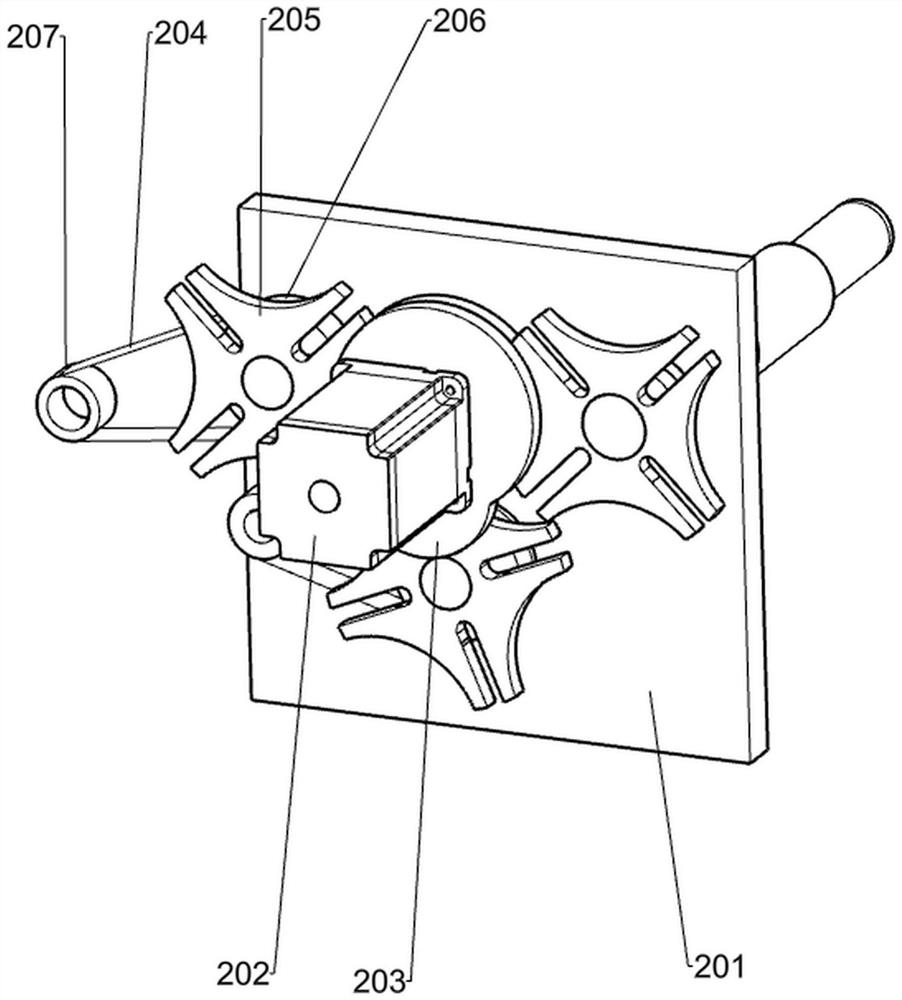

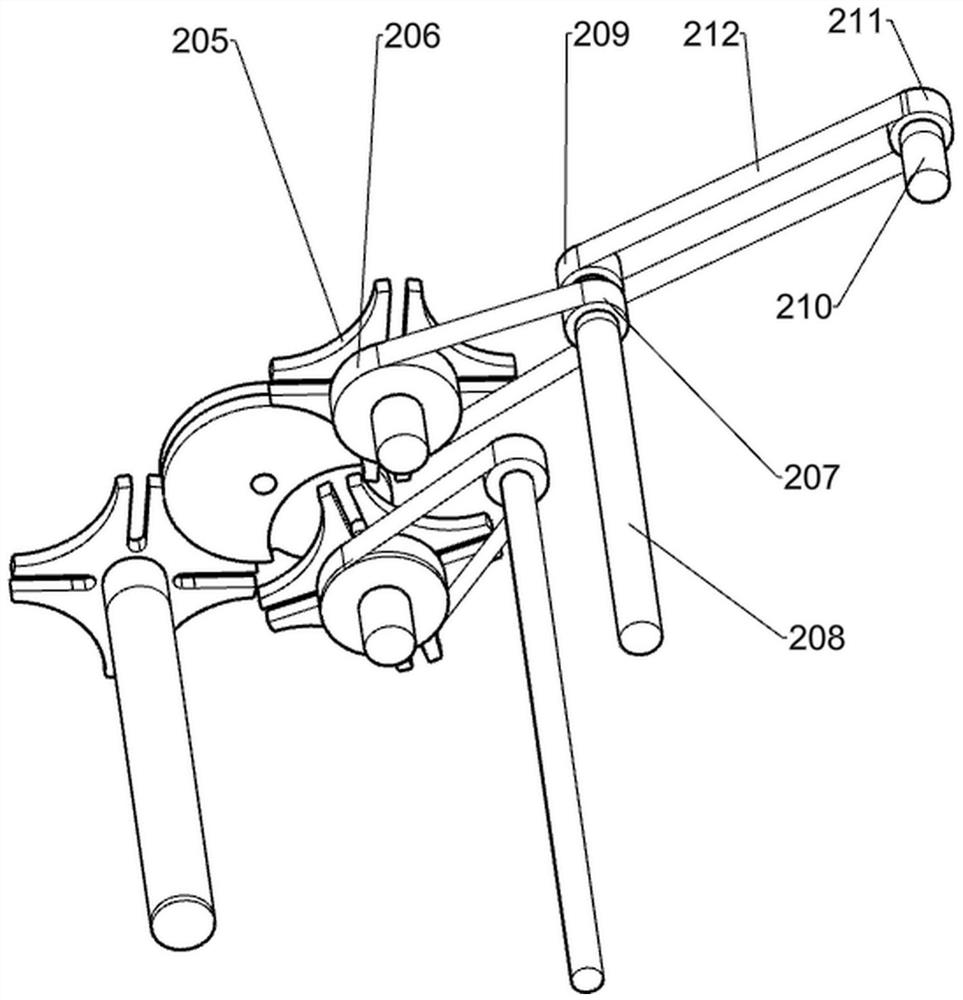

Precise water conservancy pipeline stop valve assembling device

The invention relates to a stop valve assembling device, in particular to a precise water conservancy pipeline stop valve assembling device. The technical problem to be solved by the invention is to provide the precise water conservancy pipeline stop valve assembling device capable of automatically tightening pressing caps in small-batch production. According to the technical scheme provided by the invention, the precise water conservancy pipeline stop valve assembling device comprises a first support, a workbench, a rotating rod, a first straight gear, a stock bin frame, a power mechanism andthe like. The workbench is rotatably installed on the first support, the rotating rod is fixedly installed in the middle of the workbench, and the first straight gear is fixedly installed on the side, away from the workbench, of the rotating rod. According to the precise water conservancy pipeline stop valve assembling device provided by the invention, a feeding mechanism and a tightening mechanism are adopted, a rubber gasket and a metal gasket are installed in a stop valve through the feeding mechanism, and the pressing cap is installed and fixed in the stop valve through the tightening mechanism, so that the manual assembling process is replaced.

Owner:丁红乐

Environment-friendly bag handle bonding machine

InactiveCN112339351AReduce compression timeImprove work efficiencyBag making operationsPaper-makingElectric machineryBonding process

The invention relates to an environment-friendly bag handle bonding machine. The environment-friendly bag handle bonding machine comprises a rack, a feeding mechanism, a conveying mechanism, a turnover mechanism, a glue dripping mechanism and a rope cutting mechanism. A large rectangular groove is formed in the middle portion of the rack. The feeding mechanism is fixedly arranged on the left sideof the upper portion of the rack. The conveying mechanism is arranged on the left side of the upper portion of the rack. Two first supporting plates are arranged front and back, and a second supporting plate is fixedly arranged on the front side of the upper portion of the rack. Through additional arrangement of the glue dripping mechanism and the rope cutting mechanism, manual work is replaced with machines, and the glue dripping mechanism is driven by motor power to run so as to conduct glue dripping on the positions, needing rope bonding, of environment-friendly bags. The environment-friendly bag handle bonding machine is further provided with the turnover mechanism, after one faces of the environment-friendly bags are bonded, the turnover mechanism turns over the environment-friendly bags by 180 degrees, and bonding of the other faces of the environment-friendly bags is facilitated. After the turnover mechanism turns over the environment-friendly bags, the next environment-friendlybag bonding process can be conducted at the positions of the environment-friendly bags before the environment-friendly bags are turned over, the work efficiency is improved, and small-batch production is achieved.

Owner:赵世伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com