Polylactic acid color masterbatch spinning assembly

A technology of spinning assembly and color masterbatch, which is applied in spinneret assembly, spinning solution degassing, filament forming treatment, etc., can solve the problems of unsuitability for small batch colored yarn production and insufficient mixing uniformity, etc. Achieve the effect of solving small batch production of colored yarn, novel structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

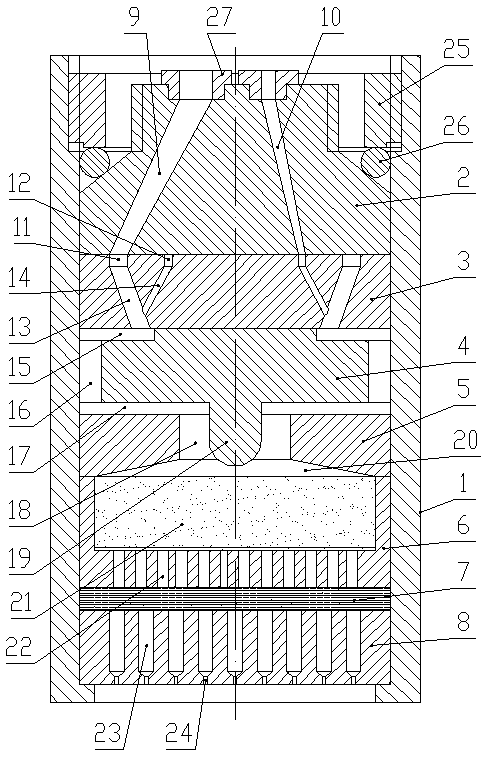

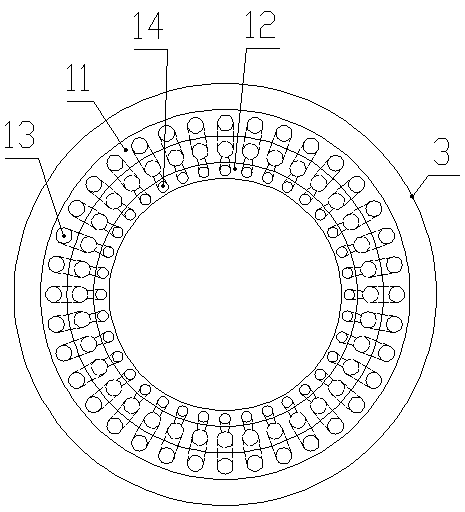

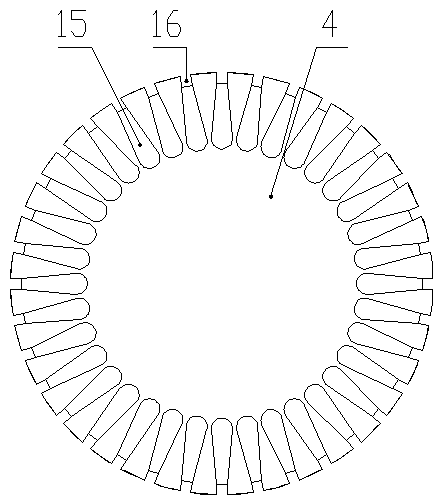

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the polylactic acid color masterbatch spinning assembly of the present invention includes a cylindrical body 1 with an open top and bottom, and the interior of the cylindrical body 1 is sequentially provided with a diversion gland 2 and a mixing distribution plate 3 from top to bottom. , deflector plate 4, sand cup gland 5, sand cup 6, filter screen 7 and spinneret 8, the diversion gland 2 is provided with upper and lower transparent polylactic acid melt injection channels 9 and color masterbatch melt body injection channel 10, the upper surface of the mixing distribution plate 3 is provided with a circular polylactic acid melt distribution groove 11 and a color masterbatch melt distribution groove 12, the lower end of the polylactic acid melt injection channel 9 is connected with the polylactic acid melt distribution groove 11 Connection, the lower end of the color masterbatch melt injection channel 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com