Polylactic acid and masterbatch injection mixed spinning system

A technology of mixed spinning and color masterbatch, which is applied in the direction of feeding solution to the spinneret, adding pigments to the spinning liquid, and melt spinning, which can solve the problem of insufficient mixing uniformity and achieve novel structure and design Reasonable and high spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

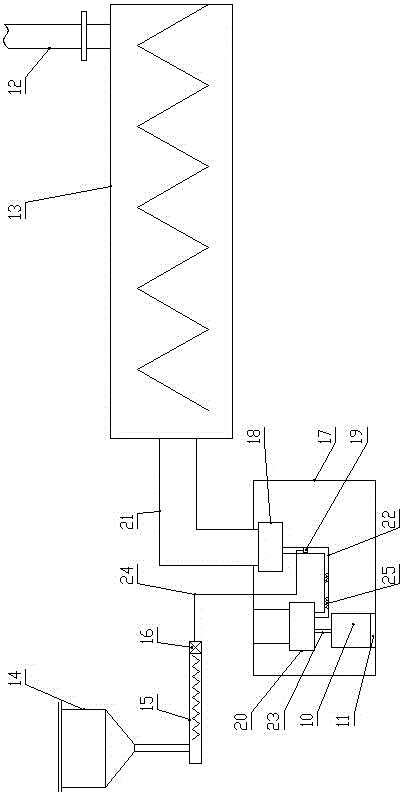

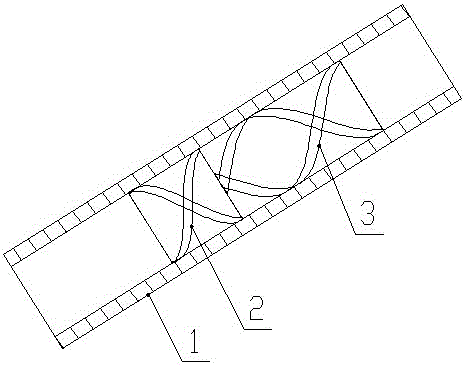

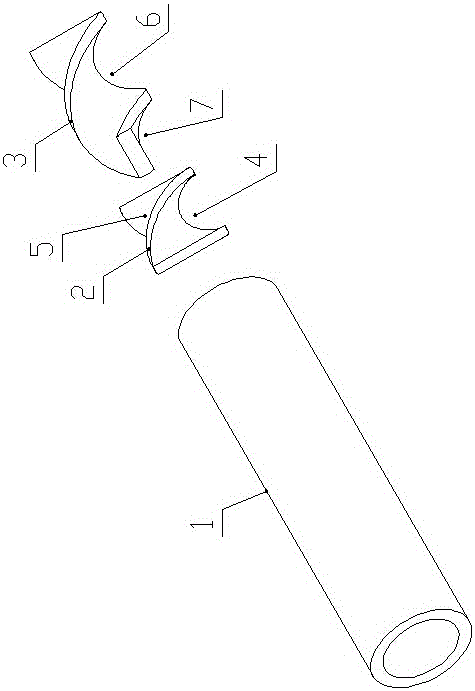

[0019] Such as figure 1 , figure 2 with image 3 As shown, the polylactic acid and color masterbatch injection mixed spinning system of the present invention includes polylactic acid dry chip conveying pipeline 12, polylactic acid screw extruder 13, color masterbatch silo 14, color masterbatch screw extruder 15. Color masterbatch metering pump 16 and spinning box 17. Polylactic acid melt distributor 18, color masterbatch melt extrusion distribution head 19, melt metering pump 20, spinning box 17 are provided. Assembly 10 and spinneret 11;

[0020] The outlet of the polylactic acid dry chip conveying pipeline 12 is connected with the inlet of the polylactic acid screw extruder 13, and the outlet of the polylactic acid screw extruder 13 is connected with the inlet of the polylactic acid melt distributor 18 through the first pipeline 21, and the polylactic acid melt The outlet of the melt distributor 18 is connected with the inlet of the melt metering pump 20 through the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com