Production line and processing technology of a cold-worked screw plug

A production line and cold processing technology, applied in the field of screw plug processing, can solve the problems of low processing accuracy, incomplete consistency, bending deformation, etc., and achieve the effects of improving processing efficiency, reducing labor intensity, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

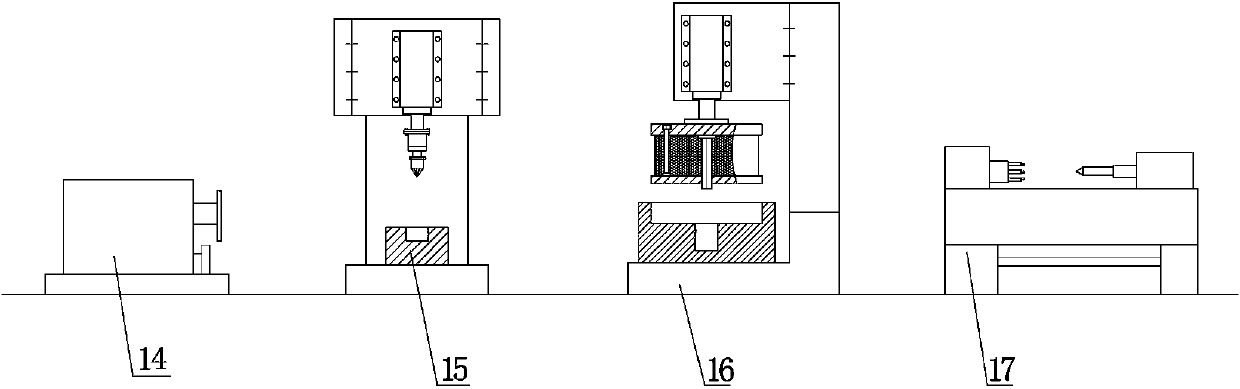

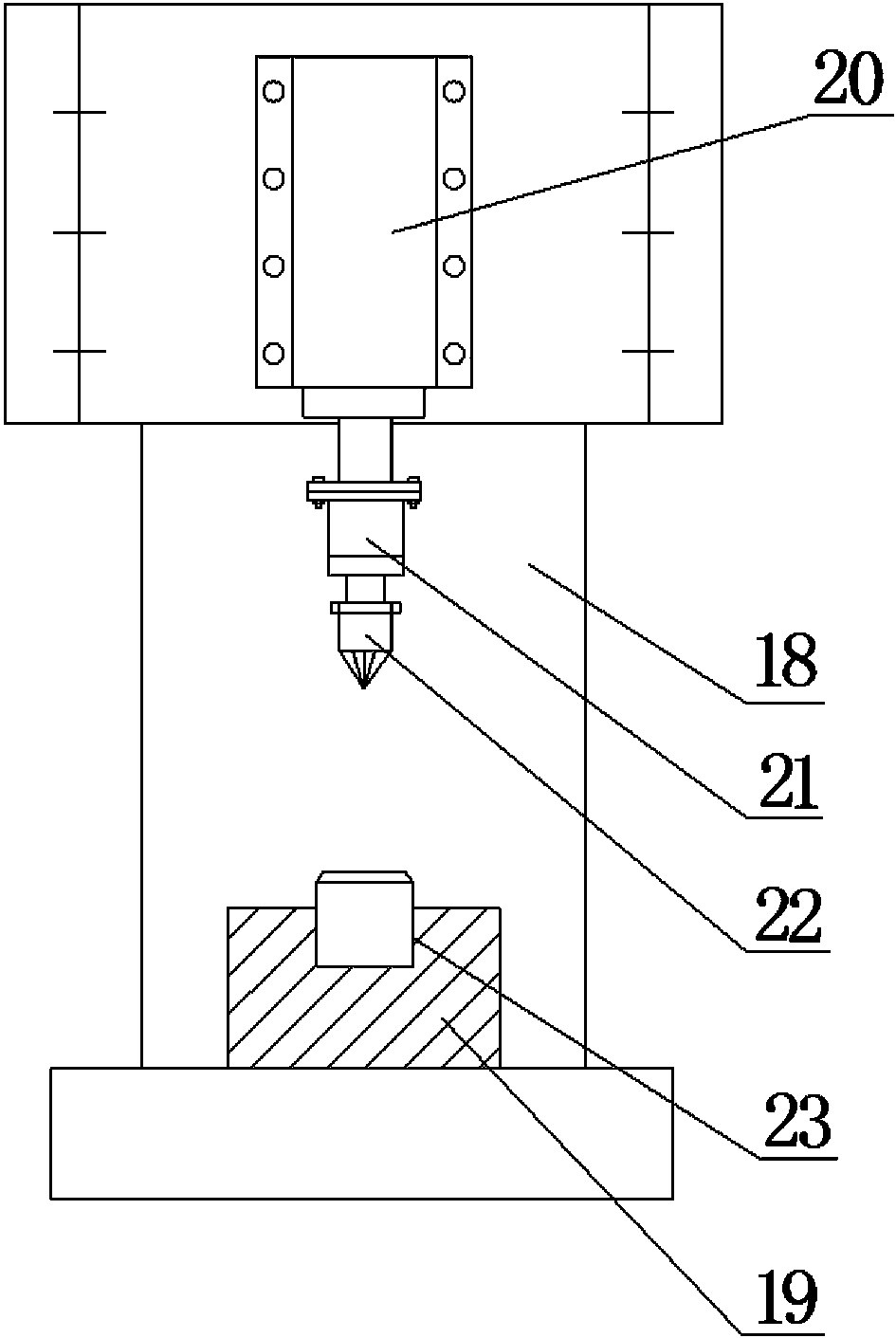

[0023] Such as Figure 1~2 As shown, a production line for cold-working screw plugs includes a sawing machine 14, a pre-hole processing device 15, a punching inner hexagonal device 16, and a lathe 17 arranged in sequence from left to right. The pre-hole processing device 15 consists of a machine base Composed of A18, die A19, hydraulic cylinder A20, motor 21 and drill bit 22, a hydraulic cylinder A20 vertically installed is fixedly installed on the machine base A18, a motor 21 is connected to the acting end of the piston rod of the hydraulic cylinder A20, and the motor 21 is vertically arranged , the output end of the motor 21 is connected to the drill bit 22, the die A19 is arranged below the drill bit 22, and the top of the die A19 is provided with a groove 23.

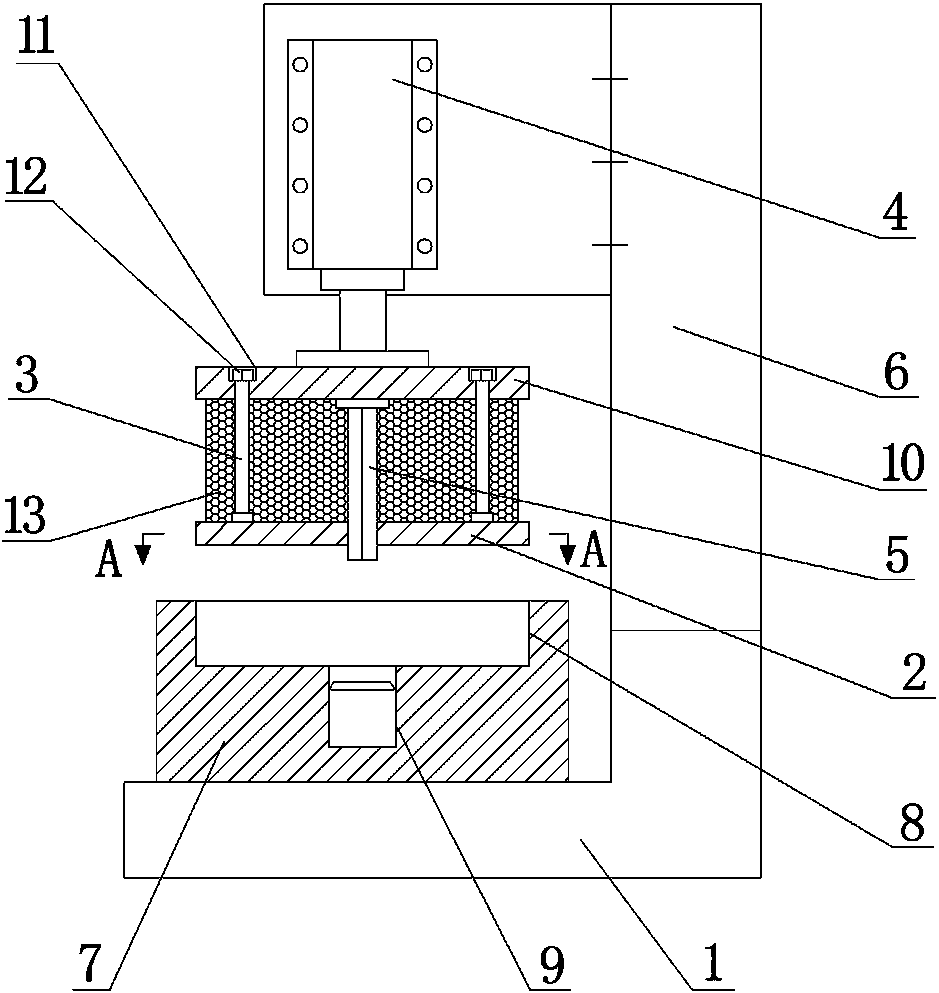

[0024] Such as figure 1 , 3 , 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com