Precise water conservancy pipeline stop valve assembling device

A technology for assembling devices and shut-off valves, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc. It can solve the problem that rubber gaskets and metal gaskets cannot be placed on the valve body, and the position where they are placed cannot be sealed well and affect the cut-off Valve quality and other issues to achieve the effect of improving installation efficiency, saving time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

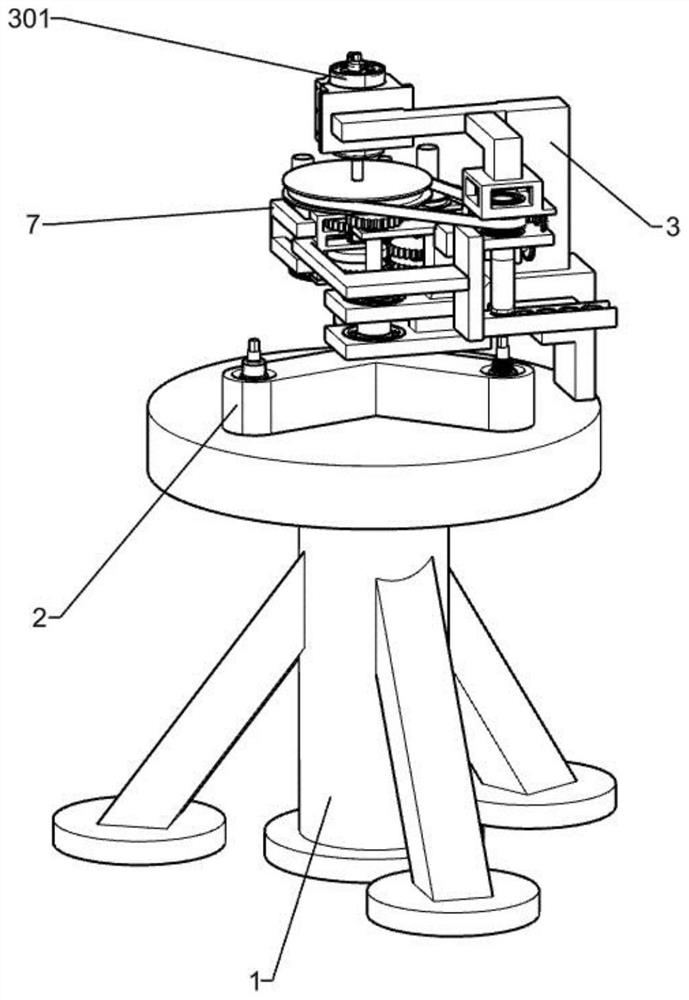

[0032] A precision water conservancy pipeline shut-off valve assembly device, such as Figure 1-11 As shown, it includes a first support 1, a workbench 2, a rotating rod 201, a first spur gear 202, a bin frame 7, a power mechanism, a feeding mechanism, a pressing mechanism and a tightening mechanism, and the workbench 2 is rotatably installed on the first The middle position of the upper part of the bracket 1, the rotating rod 201 is fixedly installed at the middle position of the workbench 2, the first spur gear 202 is fixedly installed on the upper end of the rotating rod 201, and the second bracket 3 is fixedly installed on the upper right rear side of the first bracket 1, The right bin frame 7 is fixedly installed on the second support 3, the power mechanism is fixedly installed in the middle position of the second support 3, the power mechanism cooperates with the first spur gear 202, and the feeding mechanism is fixedly installed on the upper left side of the second support...

Embodiment 2

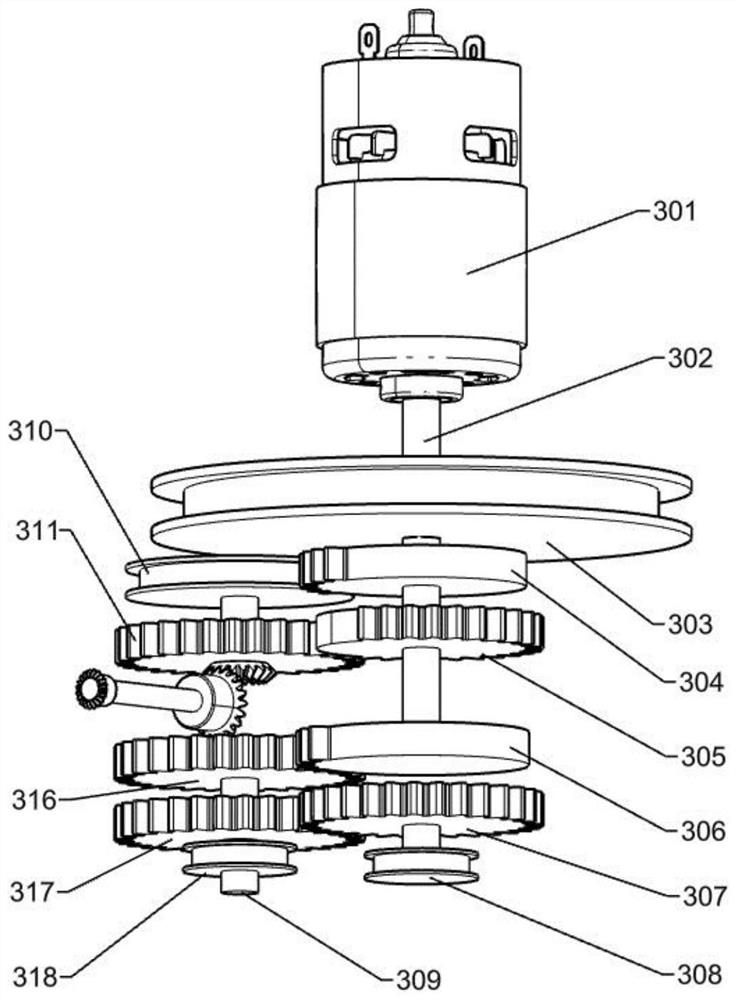

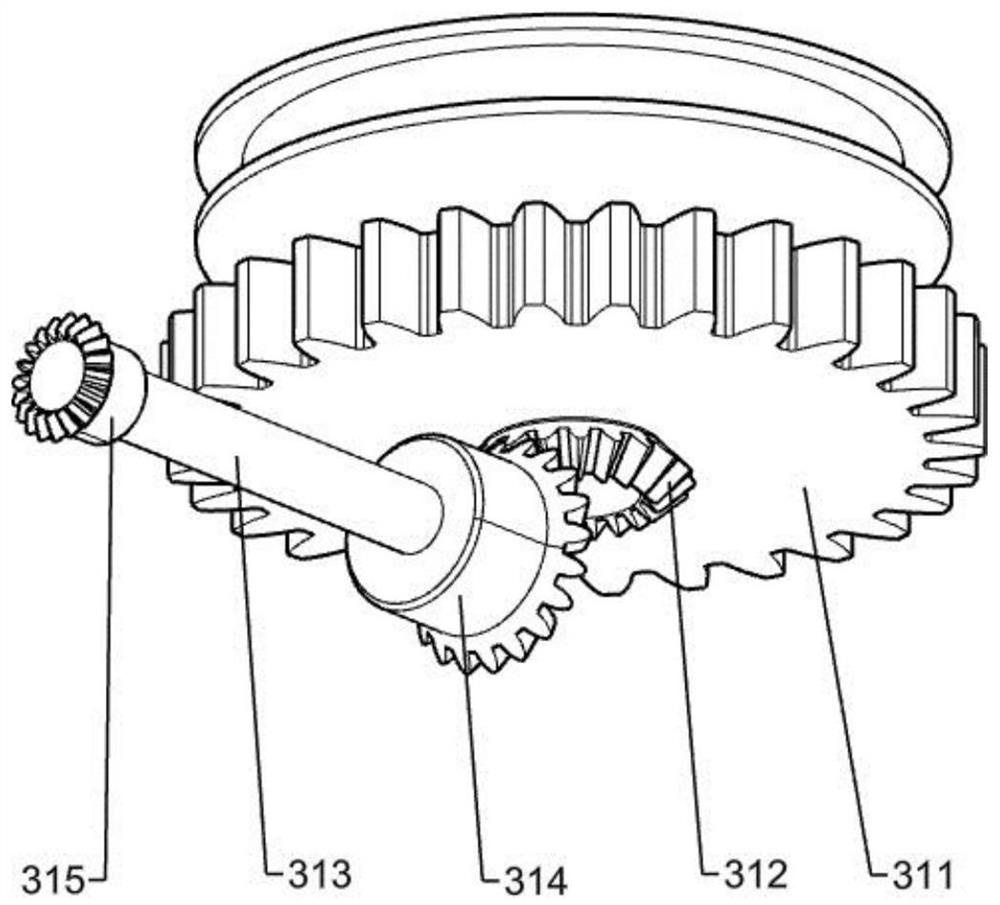

[0035] On the basis of Example 1, such as Figure 2-3 As shown, the power mechanism includes a motor 301, a first shaft 302, a first pulley 303, a first toothless gear 304, a second toothless gear 305, a third toothless gear 306, a second spur gear 307, a Two pulleys 308, second shaft 309, third pulley 310, third spur gear 311, first bevel gear 312, third shaft 313, second bevel gear 314, third bevel gear 315, fourth straight Gear 316, the fifth spur gear 317 and the fourth pulley 318, the motor 301 is fixedly installed on the upper side of the second support 3, the first shaft 302 is installed in the middle position of the second support 3 in rotation, the first shaft 302 and The output shaft of the motor 301 is fixedly connected, the first pulley 303 is fixedly installed on the upper side of the first shaft 302, the first tooth-less gear 304 is fixedly installed on the upper side of the first shaft 302, and the first tooth-less gear 304 is located on the upper side of the fi...

Embodiment 3

[0046] On the basis of Example 2, such as Figure 9As shown, the tensile elastic member is set as a tension spring 604, and the tension spring 604 acts on the second slide plate 603. After the second slide plate 603 and the pressure column 6a are pressed down to tighten the cap, they return to their original positions under the action of the tension spring 604.

[0047] The tensile elastic member is set as a tension spring 604, and the tension spring 604 acts on the second slide plate 603. After the second slide plate 603 and the pressure column 6a are pressed down to tighten the cap, they return to their original positions under the action of the tension spring 604.

[0048] Such as Image 6 As shown, after the turntable 401 sends the metal gasket and the rubber gasket to the designated position, the clamping plate 404 will temporarily prevent their movement, and they are directly pressed in by the pressing mechanism to ensure the sealing.

[0049] After the turntable 401 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com