A molding method for precision casting of a three-layer ring wall and two-layer vane vortex device

A blade vortex and forming method technology, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of running out of fire, small size of vortex, and inability to design and manufacture integral molds, etc., and achieve the effect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

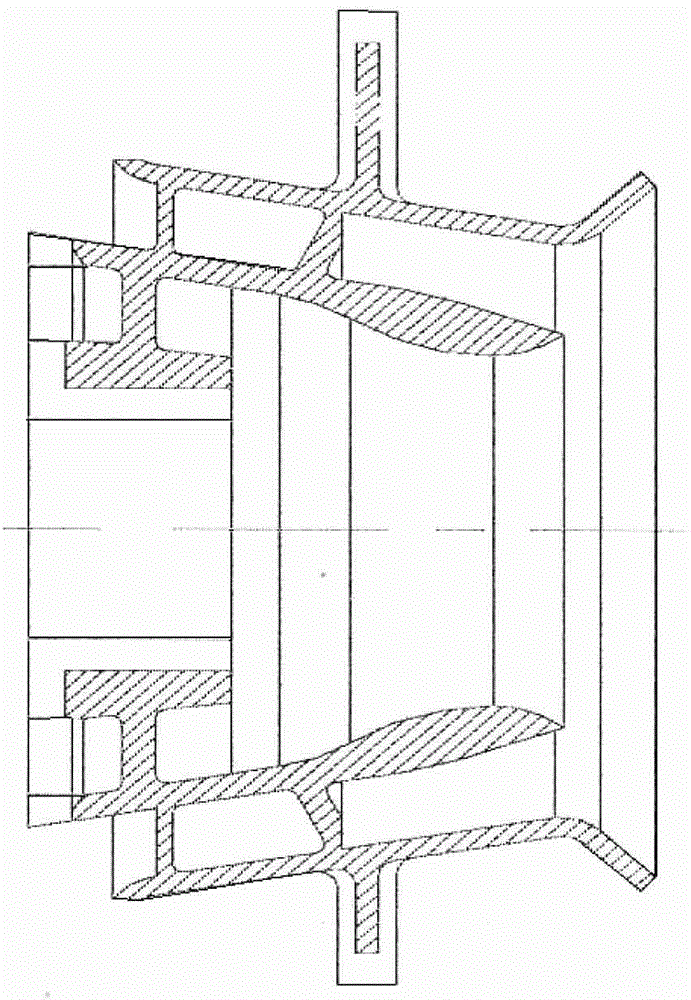

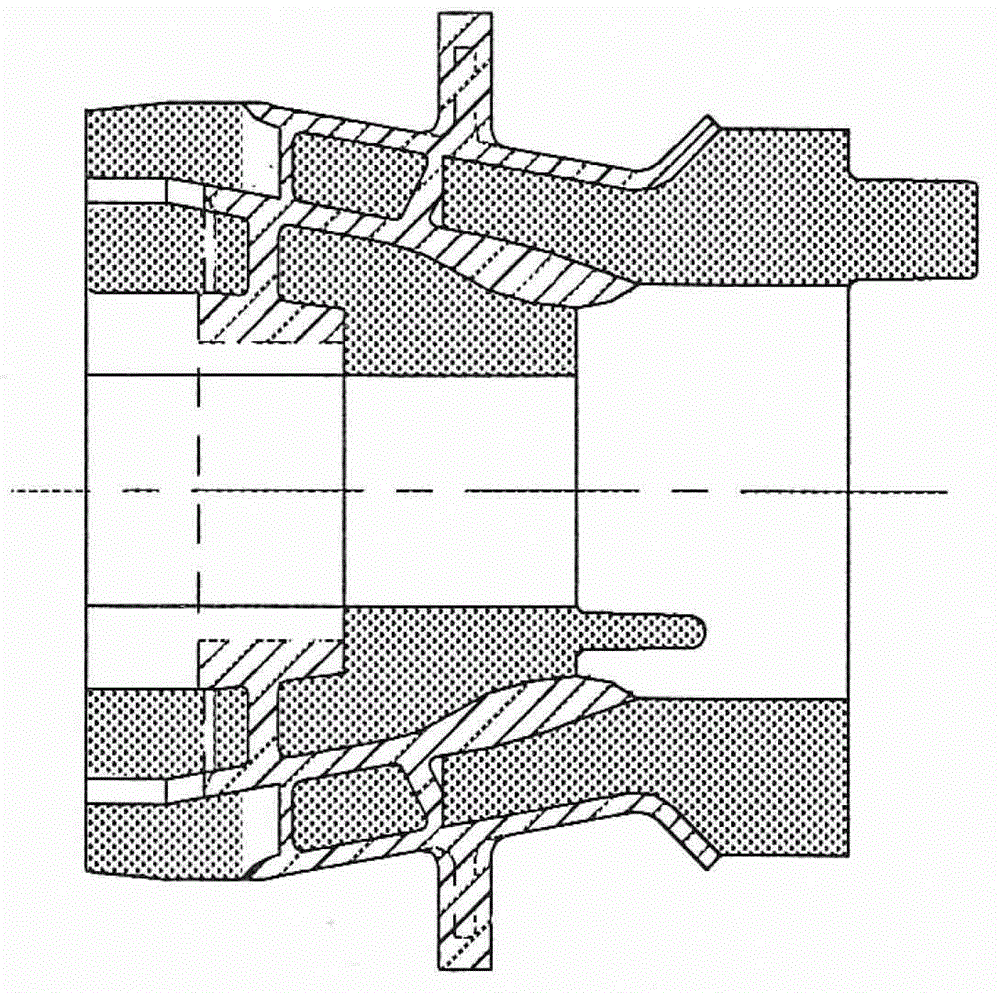

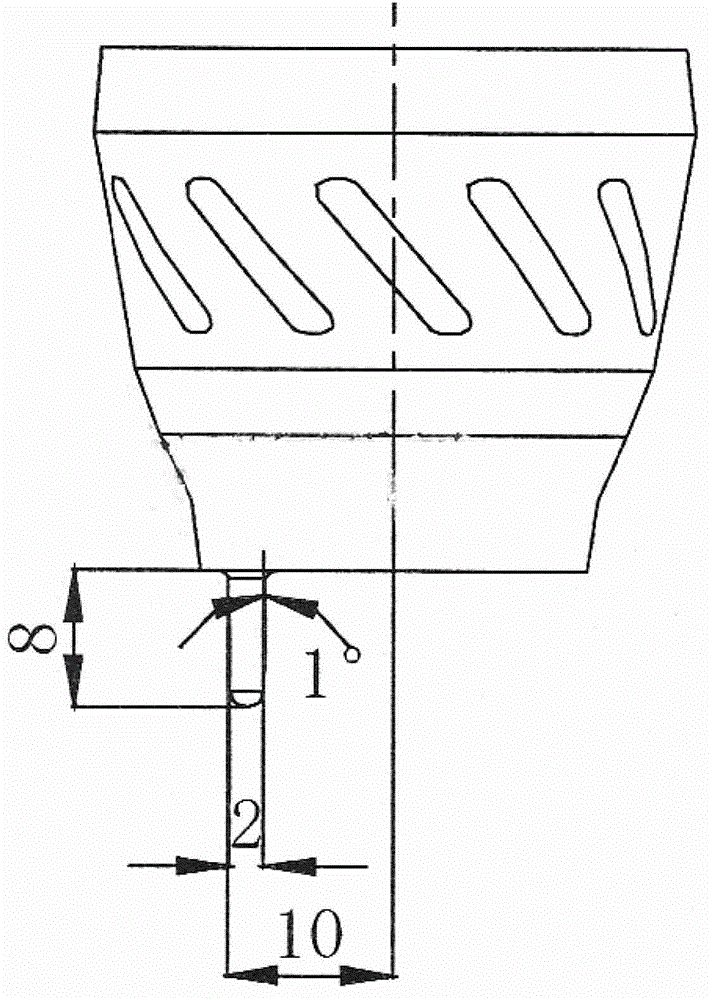

[0023] Vortex precision castings (see figure 1 The structural form of the multi-layer ring wall multi-layer blade) is small in size, thin-walled and hollow, and has a complex structure. It is composed of inner, middle and outer three-layer special-shaped ring walls, and the special-shaped 12 pieces of small blades, two layers of blades are opposite to the radial direction at 45°C, the maximum diameter is only 45mm, the height is 35mm, the thickness of the blades and the middle and outer ring walls is 1.5mm, the gap between the ring walls and between the blades Narrow, unable to paint the shell and clear the shell. Therefore, unprecedented difficulties have been brought to the precision casting of the part.

[0024] A molding method for a precision casting of a three-layer ring wall and two-layer vane vortex device, the requirement is: for the three-layer ring wall and two-layer blade vortex precision casting, two large and small ceramic cores are wrapped in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com