A pneumatic injection molding device

An injection molding, pneumatic technology, applied in the field of mold manufacturing, can solve the problems of time-consuming, manpower and material resources, complex structure of the molding device, low precision of the finished product, etc., to reduce labor intensity, realize small batch production, surface good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

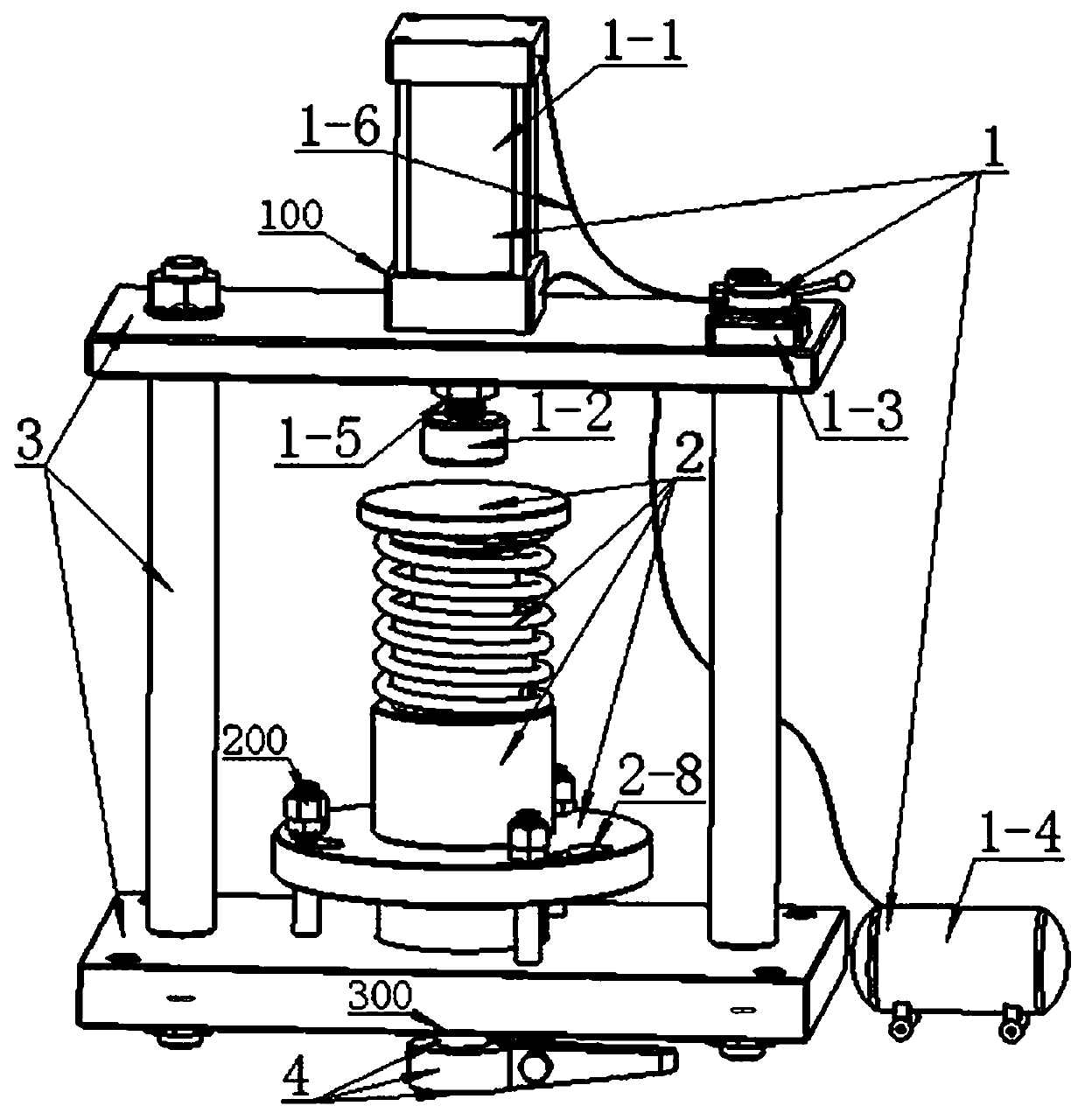

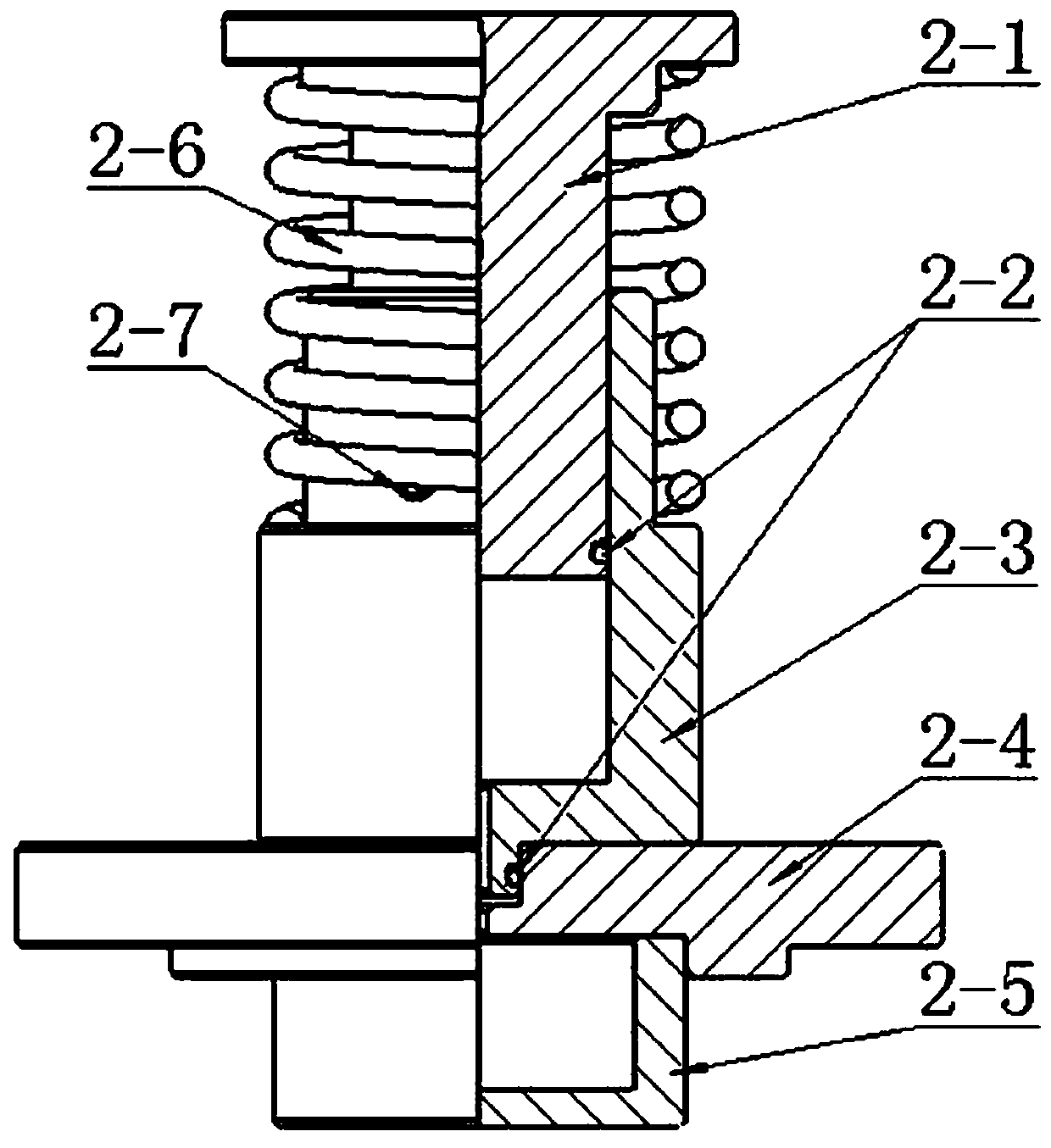

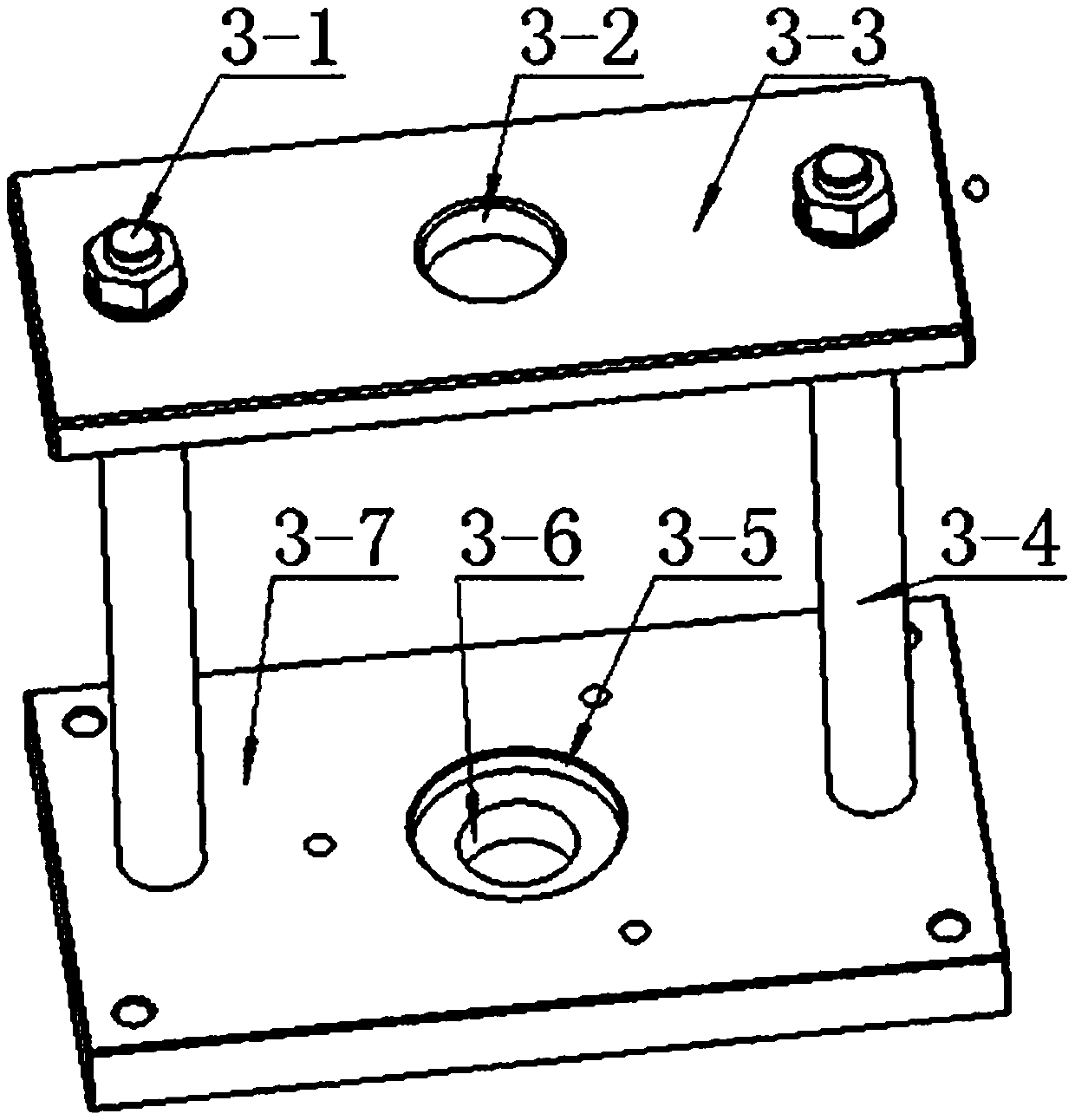

[0023] see figure 1 — Figure 4 , a pneumatic injection molding device, including a driving part 1, a molding part 2, a structural support part 3 and a quick locking part 4; the driving part 1 and the top plate 3-3 in the structural supporting part 3 pass through the first stud 100 is fixedly connected, the forming part 2 is fixedly connected with the base 3-7 in the structural support part 3 through the second stud 200, and the lock nut 4-4 in the quick locking part 4 is connected with the base in the structural support part 3 3-7 are fixedly connected by screws 300; after the quick locking part 4 compresses the molding parts 2-5 in the molding part 2, the steering of the reversing valve 1-3 of the driving part 1 is pneumatically adjusted to drive the cylinder 1-1, Make the piston 2-1 of the molding part 2 move down to quickly press the paraffin into the mold cavity.

[0024] Wherein drive part 1 comprises cylinder 1-1, cylinder block 1-2, reversing valve 1-3, air compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com