Environment-friendly bag handle bonding machine

A technology for bonding machines and environmentally friendly bags, which is applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc., and can solve problems such as low efficiency and wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

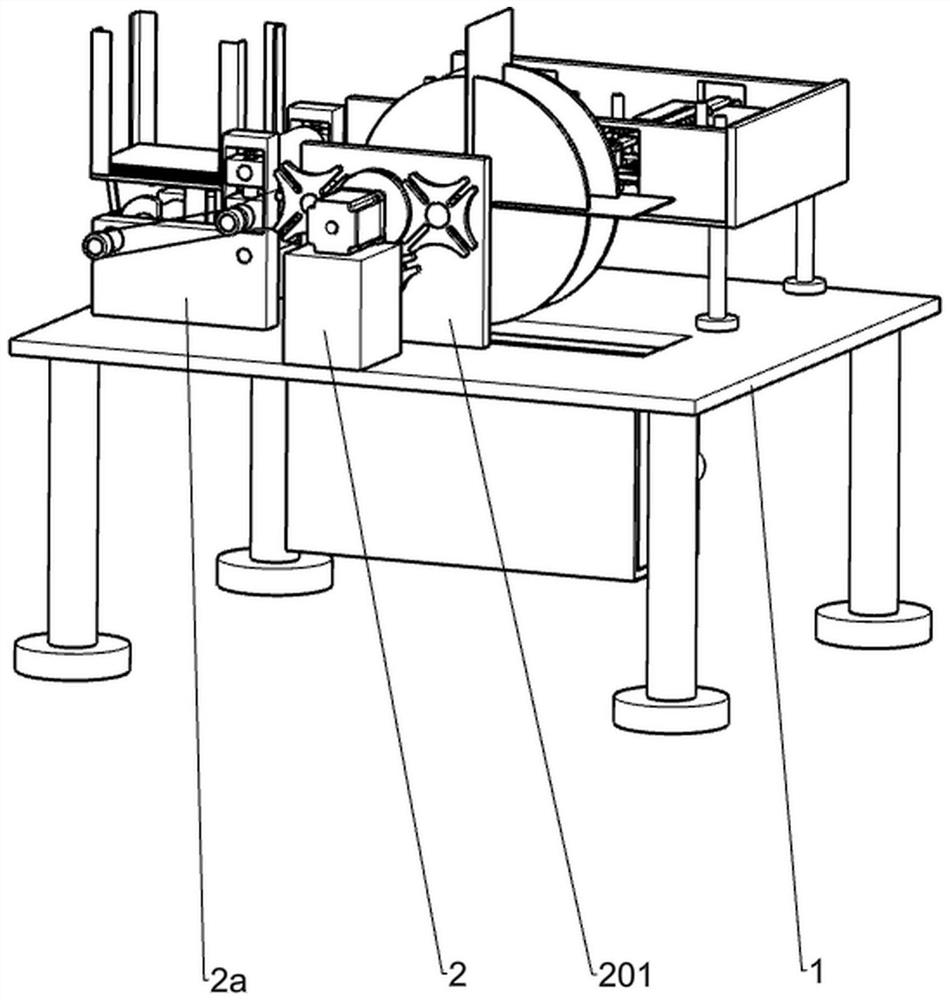

[0126] Such as Figure 1-Figure 15 As shown, an environmental protection bag handle bonding machine includes a frame 1, a power assembly, a feeding mechanism, a transmission mechanism, a turning mechanism, a glue dropping mechanism and a rope cutting mechanism, and the middle part of the frame 1 is provided with a rectangular large concave slot, the power assembly is set on one side of the frame 1, the feeding mechanism is fixedly installed on the upper left side of the frame 1, the power assembly is connected to the feeding mechanism, the transmission mechanism is installed on the upper left side of the frame 1, the transmission mechanism and the power The components are connected, the transmission mechanism is located on the right side of the feeding mechanism, the turning mechanism is installed in the upper middle of the frame 1, the turning mechanism is located above the groove opened in the frame, the turning mechanism is located on the right side of the transmission mecha...

Embodiment 2

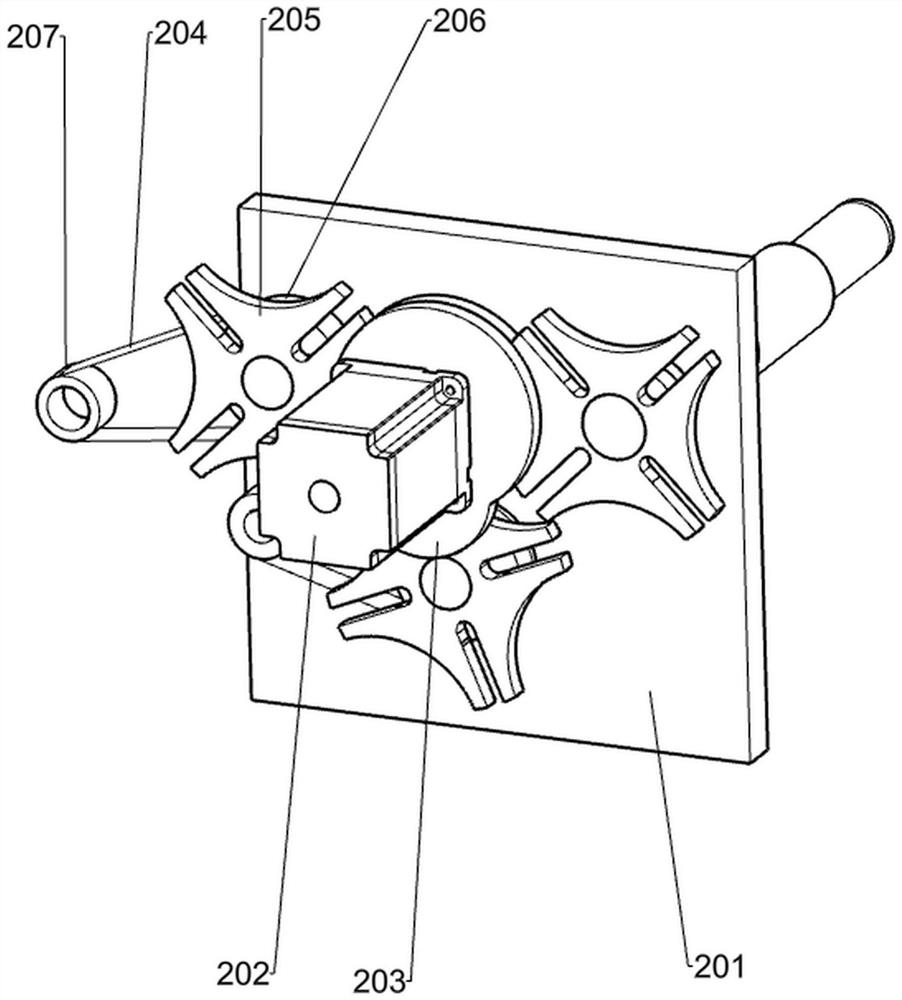

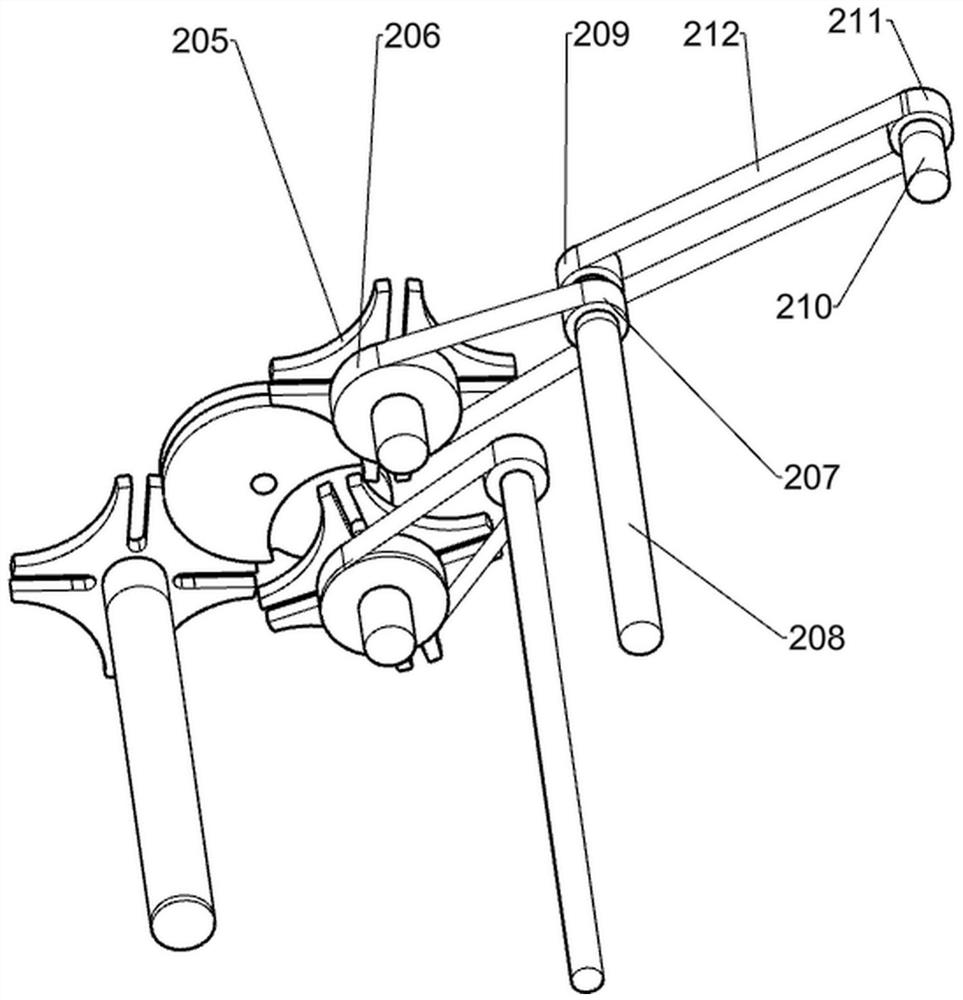

[0129] Such as Figure 3-Figure 6 As shown, based on Embodiment 1, the feeding mechanism includes a support table 2, a first support plate 2a, a second support plate 201, a motor 202, a dial 203, a first intermittent disc 205, a first pulley 206, First shaft 208, second shaft 208a, second pulley 207, first belt 204, third pulley 209, third shaft 210, fourth pulley 211, second belt 212, cam 213, set Material rack 214, slide rail 215, first slide plate 216, first slide block 2161, first spring 2162, pole 217, first roller 218 and first tension spring 219, support table 2 is fixedly installed on the top of frame 1 In the middle position of the front side, the two first support plates 2a are fixedly installed on the upper left front side of the frame 1, the two first support plates 2a are placed front and back, and the second support plate 201 is fixedly installed on the upper front side of the frame 1. The second support plate 201 is located at the rear side of the support platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com