Metal coiled belt hollowing production equipment

A technology of production equipment and tape, which is applied in the direction of metal processing equipment, metal processing, feeding devices, etc., can solve the problems of waste, cost is difficult to meet production needs, increase R&D costs, etc., and achieve the effect of reducing R&D costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

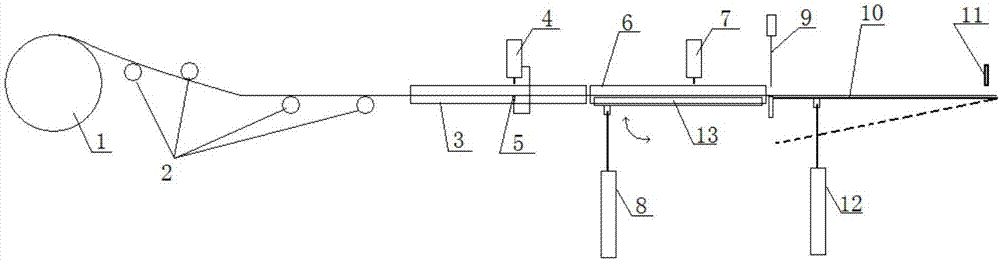

[0018] The metal strip 1 hollow production equipment is provided with an unwinding mechanism, a support roller 2, a first fixed frame assembly 3, a second fixed frame assembly 6, a cutting tool 9 and a discharge flap 10 along the moving direction of the strip 1 in sequence.

[0019] Tape 1 is fixed on the unwinding mechanism, and the unwinding mechanism is a rotating shaft driven by a motor. Tape 1 is installed on the unwinding mechanism and is transported into the fixed frame assembly by support roller 2 .

[0020] The first fixed frame assembly 3 and the second fixed frame assembly 6 have the same structure, both comprising a lower frame body and an upper frame body, the lower frame body and the upper frame body are hollow square frame structures, and square frame-shaped rubber rings are provided on the opposite faces , the square frame-shaped rubber ring is used to reliably clamp the metal sheet to ensure the accuracy and reliability of the punching, and to avoid the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com