N-type 110-micron slice cutting process

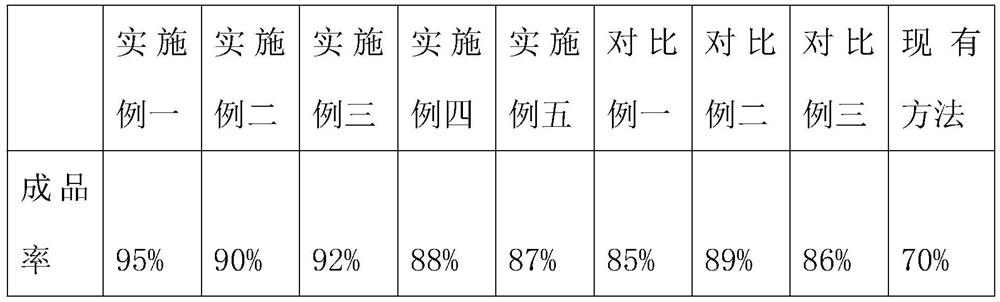

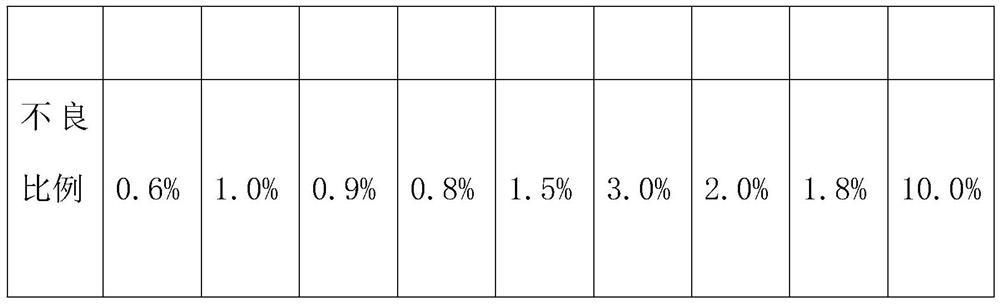

A cutting process and thin slice technology, which is applied in the field of N-type 110μm thin slice cutting process, can solve the problems of high brittleness, high hardness, and large slice thickness, achieve good flatness, increase yield, and reduce the generation of fragments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

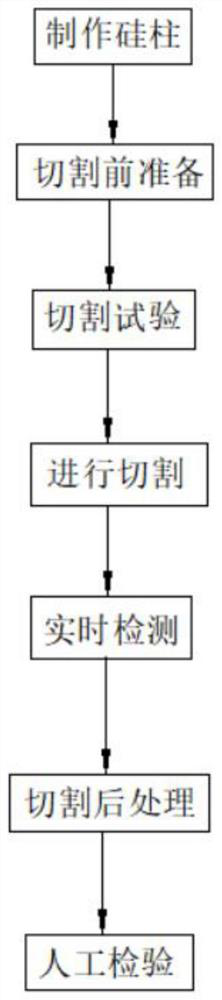

[0029] refer to figure 1 , an N-type 110 μm sheet cutting process, comprising the following steps:

[0030] S1: Making silicon pillars: choose silica sand as the raw material, heat the silica sand to separate carbon monoxide and silicon in the silica sand, and repeat the process until ultra-high-purity electronic-grade silicon is obtained, and high-purity silicon is melted into a liquid and then solidified into a single crystal solid The form makes silicon column, wherein chooses the container that diameter is 32cm when solidifying;

[0031] S2: Preparation before cutting: cut off both ends of the solidified silicon column with a diamond saw, and install a new type of main roller developed by a dedicated domestic high-tech machine installation technician. The error of the measured tension is within 0.1N, and the runout of the main roller is controlled within 10um. Within, install the bonded N-type silicon rod on the machine for cutting;

[0032] S3: Cutting test: The cutting...

Embodiment 2

[0038] refer to figure 1 , an N-type 110 μm sheet cutting process, comprising the following steps:

[0039] S1: Making silicon pillars: choose silica sand as the raw material, heat the silica sand to separate carbon monoxide and silicon in the silica sand, and repeat the process until ultra-high-purity electronic-grade silicon is obtained, and high-purity silicon is melted into a liquid and then solidified into a single crystal solid The form makes silicon column, wherein chooses the container that diameter is 32cm when solidifying;

[0040] S2: Preparation before cutting: cut off both ends of the solidified silicon column with a diamond saw, and install a new type of main roller developed by a dedicated domestic high-tech machine installation technician. The error of the measured tension is within 0.1N, and the runout of the main roller is controlled within 10um. Within, install the bonded N-type silicon rod on the machine for cutting;

[0041] S3: Cutting test: The cutting m...

Embodiment 3

[0047] refer to figure 1 , an N-type 110 μm sheet cutting process, comprising the following steps:

[0048] S1: Making silicon pillars: choose silica sand as the raw material, heat the silica sand to separate carbon monoxide and silicon in the silica sand, and repeat the process until ultra-high-purity electronic-grade silicon is obtained, and high-purity silicon is melted into a liquid and then solidified into a single crystal solid The form makes silicon column, wherein chooses the container that diameter is 32cm when solidifying;

[0049] S2: Preparation before cutting: cut off both ends of the solidified silicon column with a diamond saw, and install a new type of main roller developed by a dedicated domestic high-tech machine installation technician. The error of the measured tension is within 0.1N, and the runout of the main roller is controlled within 10um. Within, install the bonded N-type silicon rod on the machine for cutting;

[0050] S3: Cutting test: The cutting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com