How to make imitation leather trademark

A production method and trademark technology, applied in the field of textiles, can solve the problems of large order quantity of leather manufacturers, unable to meet the diversification of people, single color of leather, etc., and achieve the effect of good color fastness, rich colors and textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

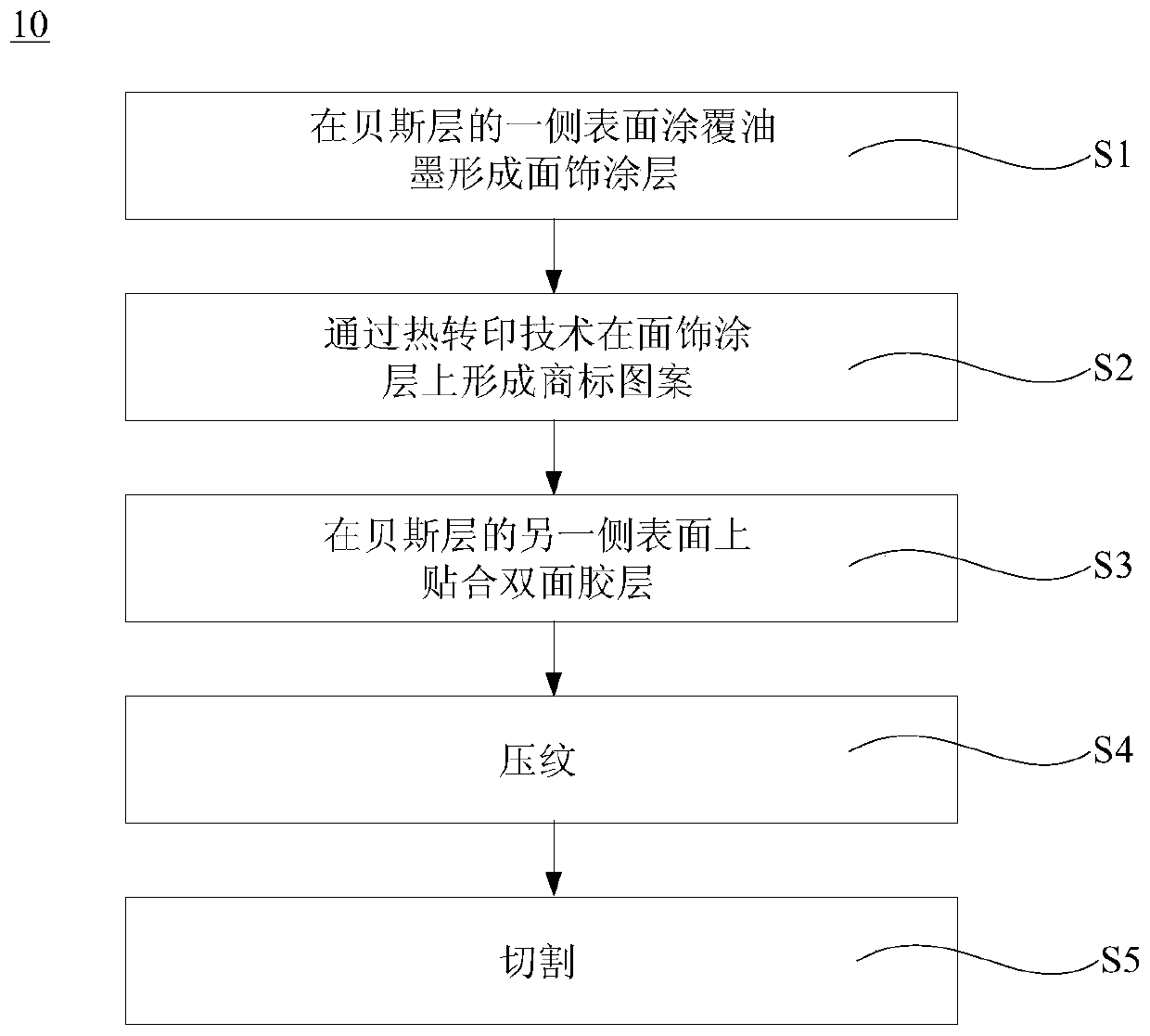

Method used

Image

Examples

Embodiment 1

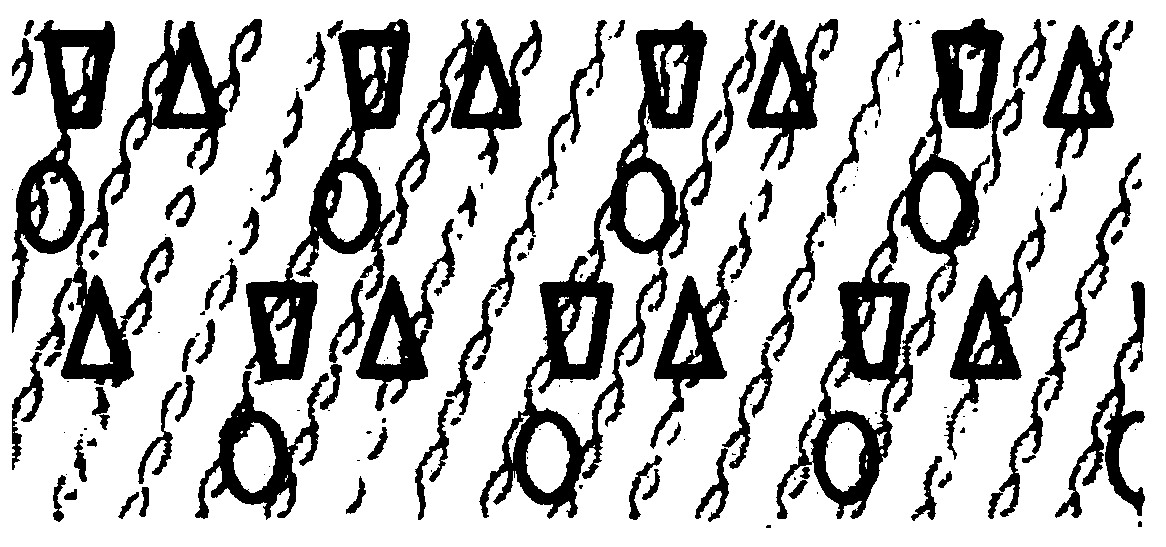

[0051] A sticky imitation leather trademark, such as Figure 3a As shown, it includes geometric figures of different colors, spiral texture, square shape, relatively stiff body, and the thickness of the trademark is about 1.8mm.

[0052]The paste-type imitation leather trademark is prepared by the following method:

[0053] (1) Prepare ink:

[0054] Take by weighing the raw material by following weight part:

[0055]

[0056] Add polyhydroxy polyester into the feeding tank, add diluent, leveling agent and hand feeling agent in turn, stir evenly, then add titanium dioxide under stirring, disperse evenly so that the viscosity is 1000mPa.s. Add curing agent before use and stir well.

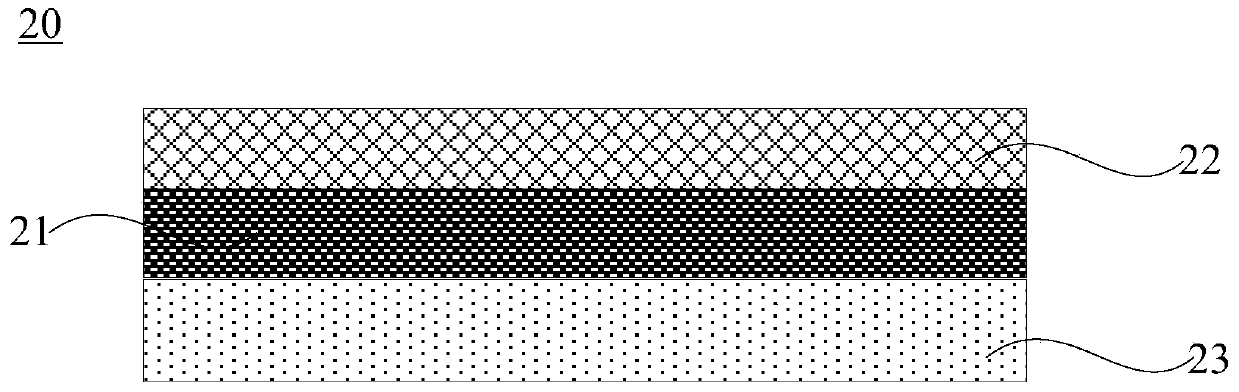

[0057] (2) Coating: adjust the thickness of the oil knife to 0.1 mm, and coat the ink on the rubber surface of the bass layer 21 with a thickness of 1.0 mm on the coater, and the modulus of elasticity of the bass layer is 10 MPa.

[0058] (3) Drying: set the temperature of the tunnel furnace ...

Embodiment 2

[0065] A stick-on colorful imitation leather letter logo such as Figure 3b As shown, it includes letter graphics in different colors, spiral texture, soft body, and the thickness of the trademark is 2.0mm.

[0066] The paste-type color imitation leather letter trademark is prepared by the following method:

[0067] (1) Prepare ink:

[0068] Prepared by weighing the following raw materials in parts by weight:

[0069]

[0070] Add polyhydroxy polyester into the feeding tank, add diluent, leveling agent and hand feeling agent in turn, stir evenly, then add titanium dioxide under stirring, disperse evenly so that the viscosity is 1000mPa.s. Add curing agent before use and stir well.

[0071] (2) Coating: adjust the thickness of the oil knife to 0.1mm, and coat the ink on the microfiber cloth with a thickness of 1.2mm on the coating machine.

[0072] (3) Drying: set the temperature of the tunnel furnace to 120° C., adjust the speed of the conveyor belt, and control the bak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com