Adherable and peelable plastic printing ink and comprehensive antiforge mark made of said printing ink

An ink and plastic film technology, which is applied to plastic gravure printing ink and its application in the production of anti-counterfeiting signs, can solve the problems of inability to ensure performance, strong adhesion, and poor anti-counterfeiting function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

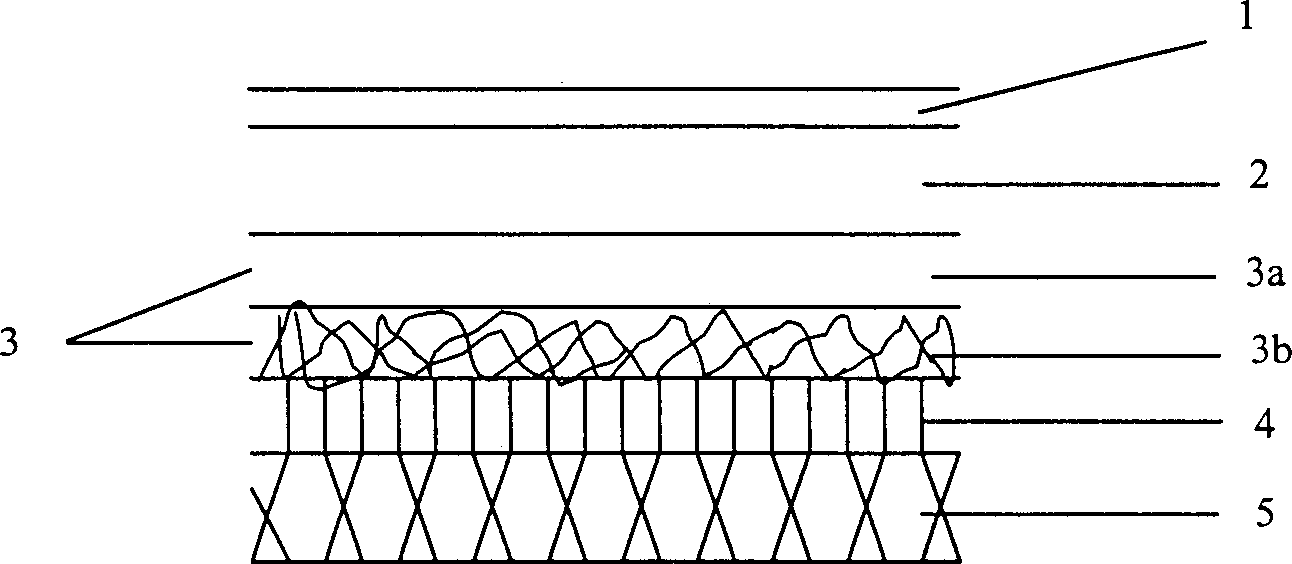

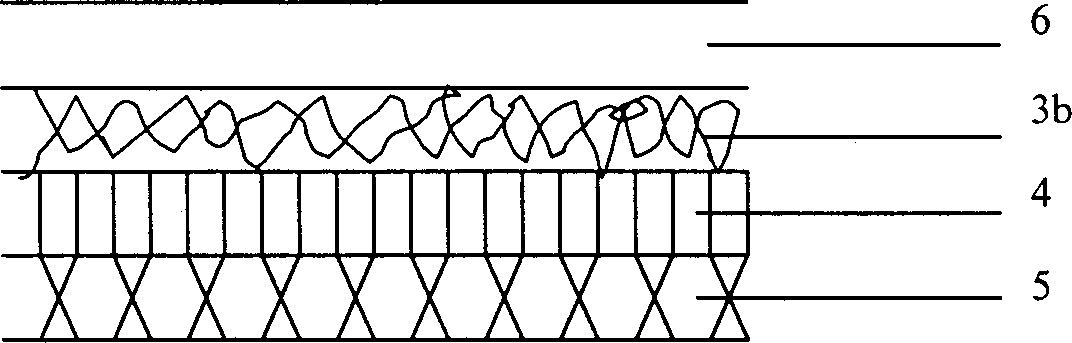

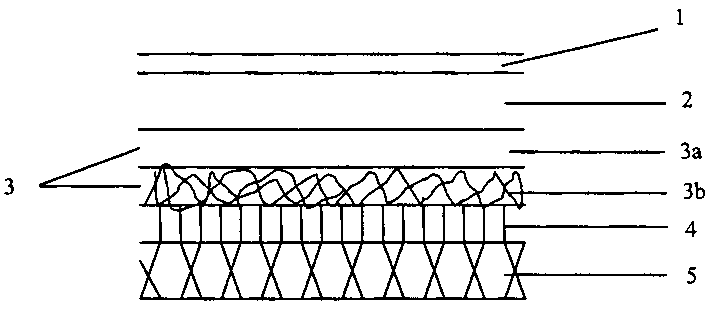

Image

Examples

Embodiment 1

Phthalo blue BGS 12.0 Peacock blue 5.5

[0065] 3) Ink production, see the main process of making ink.

[0066] 4) Use a gravure printing machine to print on polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate (PC) Such as plastic film, as the surface layer of nuclear track microporous film anti-counterfeiting mark.

[0067] 5) For the production of comprehensive anti-counterfeiting marks, see the specific steps and methods for making comprehensive anti-counterfeiting marks with adhesive-peelable plastic ink.

[0068] Various nuclear track microporous membrane comprehensive anti-counterfeiting marks with different patterns set off by different color surface layers can be made.

[0069] If after the above 1), 2), and 3) steps, then go through the following production process:

[0070] 4') Polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS...

Embodiment 2

Brilliant Red 6B 3.0

[0079] 3) Ink production, see the main process of making ink.

[0080] 4) Use a gravure printing machine to print on polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate (PC) Such as plastic film, as the surface layer of nuclear track microporous film anti-counterfeiting mark.

[0081] 5) For the production of comprehensive anti-counterfeiting marks, see the specific steps and methods for making comprehensive anti-counterfeiting marks with adhesive-peelable plastic ink.

[0082] Various nuclear track microporous membrane comprehensive anti-counterfeiting marks with different patterns set off by different color surface layers can be made.

[0083] If after the above 1), 2), and 3) steps, then go through the following production process:

[0084] 4') Polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate ( ...

Embodiment 3

Magenta 6B 3.0

[0092] 3) Ink production, see the main process of making ink.

[0093] 4) Use a gravure printing machine to print on polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate (PC) Such as plastic film, as the surface layer of nuclear track microporous film anti-counterfeiting mark.

[0094] 5) For the production of comprehensive anti-counterfeiting marks, see the specific steps and methods for making comprehensive anti-counterfeiting marks with adhesive-peelable plastic ink.

[0095] Various nuclear track microporous membrane comprehensive anti-counterfeiting marks with different patterns set off by different color surface layers can be made.

[0096] If after the above 1), 2), and 3) steps, then go through the following production process:

[0097] 4') Polyester (PET), polyethylene (PE), polypropylene (PP) nylon (PA), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate ( O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com