High-wear-resistance polyphenylene sulfide/regenerated carbon fiber composite material and preparation thereof

A technology of fiber composite material and polyphenylene sulfide, which is applied in the field of high wear-resistant polyphenylene sulfide/regenerated carbon fiber composite material and its preparation, can solve the problems of high price and difficulty in large-scale production, so as to reduce pollution and improve industrialization The effect of production and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

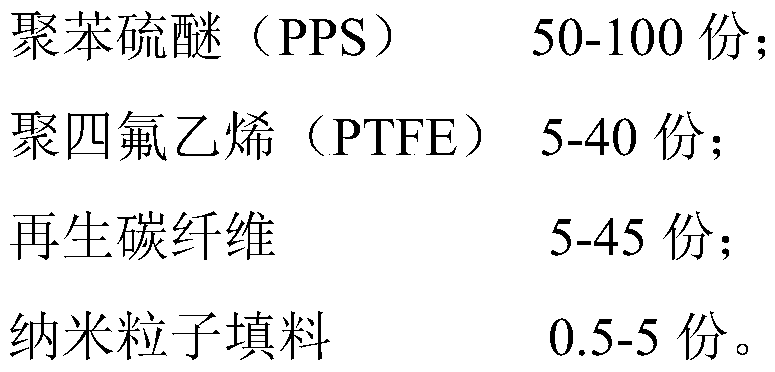

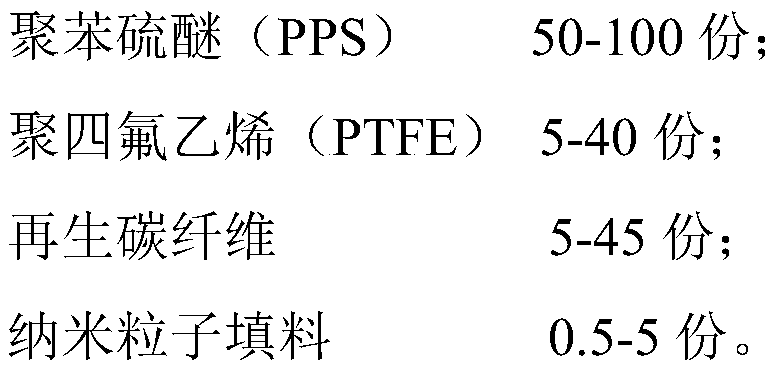

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 95 parts of PPS, 5 parts of PTFE, and 1.9 parts of 20nm-level silicon dioxide powder and mix them uniformly in a high-speed mixer.

[0030] (2) Add the mixture in step (1) to the main feeding port of the twin-screw extruder, add 15 parts of 3mm short-fiber regenerated carbon fiber to the auxiliary feeding port, melt and blend, extrude, water pull, and draw the rod The polyphenylene sulfide / regenerated carbon fiber composite material is obtained by pelletizing. The temperature of each zone of the twin-screw extruder is: the temperature of the front section of the barrel is 300-310°C; the middle section is 290-300°C; the rear section is 300-320°C; the nozzle is 290-320°C ℃.

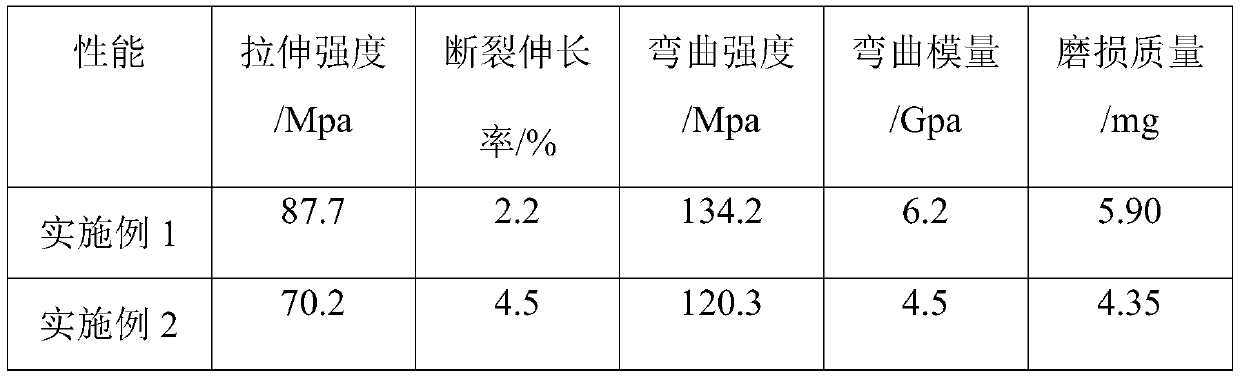

[0031] The properties of the obtained polyphenylene sulfide / short fiber recycled carbon fiber composite material are shown in Table 1.

Embodiment 2

[0033] (1) Weigh 85 parts of PPS, 15 parts of PTFE, and 1.7 parts of 20nm silicon dioxide powder in a high-speed mixer and mix them evenly.

[0034] (2) Add the compound in step (1) to the main feeding port of the twin-screw extruder, add 13 parts of 3mm short-fiber regenerated carbon fiber to the auxiliary feeding port, melt blend, extrude, water pull, and pull the rod The polyphenylene sulfide / regenerated carbon fiber composite material is obtained by pelletizing. The temperature of each zone of the twin-screw extruder is: the temperature of the front section of the barrel is 300-310°C; the middle section is 290-300°C; the rear section is 300-320°C; the nozzle is 290-320°C ℃.

[0035] The properties of the obtained polyphenylene sulfide / short fiber recycled carbon fiber composite material are shown in Table 1.

Embodiment 3

[0037] (1) Weigh 75 parts of PPS, 25 parts of PTFE, and 0.75 parts of 20nm silicon dioxide powder in a high-speed mixer and mix them evenly.

[0038] (2) Add the compound in step (1) to the main feeding port of the twin-screw extruder, add 12 parts of 3mm short-fiber regenerated carbon fiber to the auxiliary feeding port, melt blend, extrude, water pull, and pull the rod The polyphenylene sulfide / regenerated carbon fiber composite material is obtained by pelletizing. The temperature of each zone of the twin-screw extruder is: the temperature of the front section of the barrel is 300-310°C; the middle section is 290-300°C; the rear section is 300-320°C; the nozzle is 290-320°C ℃.

[0039] The properties of the obtained polyphenylene sulfide / short fiber recycled carbon fiber composite material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com