Preparation method of high-strength ta18 titanium alloy components based on electron beam fuse addition

An electron beam, titanium alloy technology, applied in electron beam welding equipment, metal processing equipment, welding equipment and other directions, can solve the problems of difficulty in small batch production and high preparation cost, and achieve small batch production, low production cost, high resistance to The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of high-strength TA18 titanium alloy components based on electron beam fuse addition includes the following steps:

[0033] (1) Design the component transition area according to the actual part structure, and establish a three-dimensional CAD solid model according to the designed part structure, and slice and layer along the forming direction of the model;

[0034] (2) Import the above-mentioned slices into the computer, and generate an implementable path according to the width of the single deposition layer being W, the thickness of the single layer being L, and the overlap rate γ;

[0035] (3) Electron beam fuse additive manufacturing is carried out according to the above path. In this process, TC4 is used as the additive substrate, TC4 and TA2 are used as fuse materials, and TC4 and TA2 are mixed and deposited by wire feeding at the same time to complete the single-layer titanium alloy wire deposition. ;

[0036] (4) Complete the single-layer ...

Embodiment

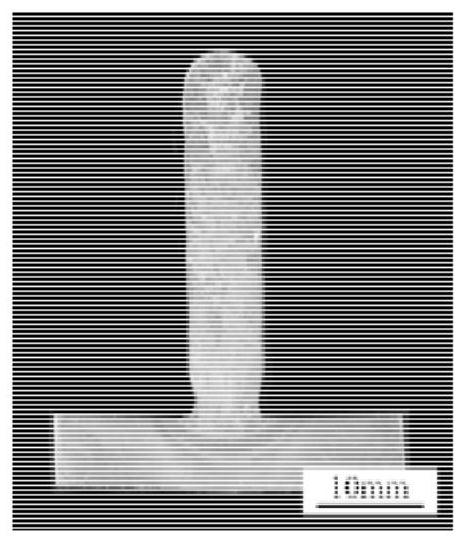

[0047] This embodiment designs a high-strength TA18 titanium alloy component preparation method based on electron beam fuse addition, taking electron beam fuse addition TA18 titanium alloy plate as an example, including the following steps:

[0048](1) The TC4 substrate with a size of 300×300×10mm is used as the substrate for additive manufacturing. The surface of the substrate is polished with 240# and 400# sandpaper, and the surface is wiped with acetone to remove surface oil. The diameter of the selected TC4 and TA2 welding wire is 1.2 mm.

[0049] (2) Fix the TC4 substrate on the workbench, and adjust the wire feeding position of TA2 and TC4, so that the wire feeding front section is in the same plane, and the angle between the wire feeding front end and the substrate is 45°, and the distance between the wire feeding front end and the substrate is controlled at 0.2 mm.

[0050] (3) The power of the electron beam fuse additive is set to 2500W, the focus center is located o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com