Special-shaped curved surface metal sheet forming device and process

A technology of thin metal plates and forming devices, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of high labor intensity, high equipment investment cost, uncontrollable product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

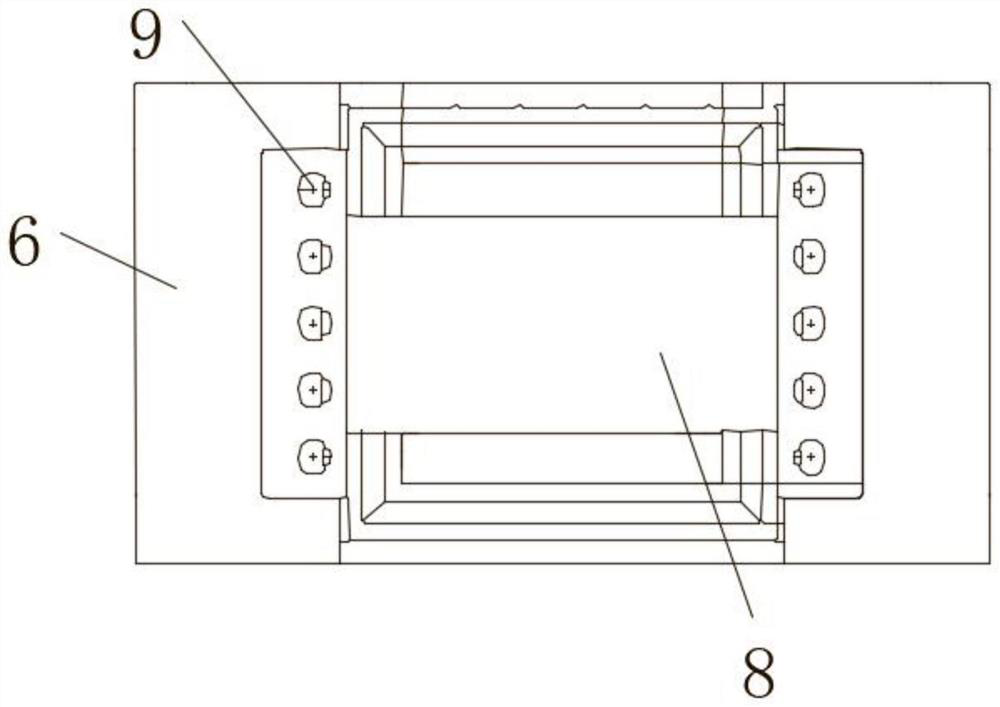

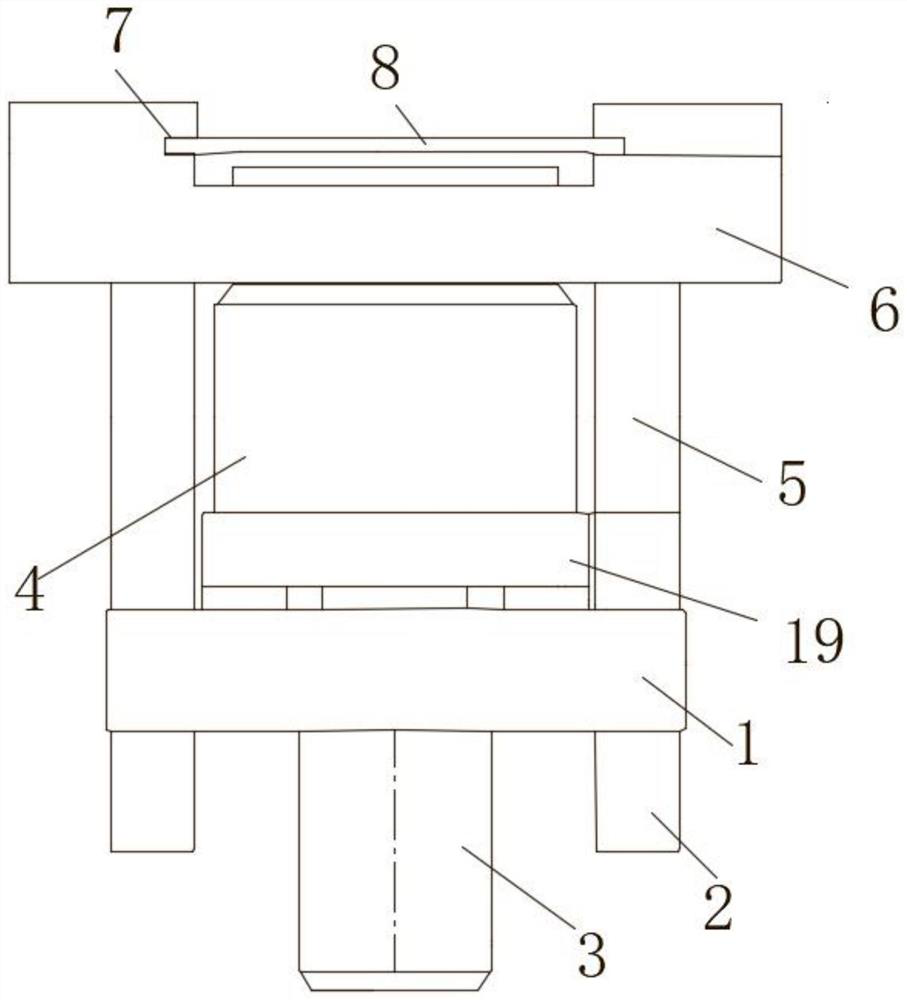

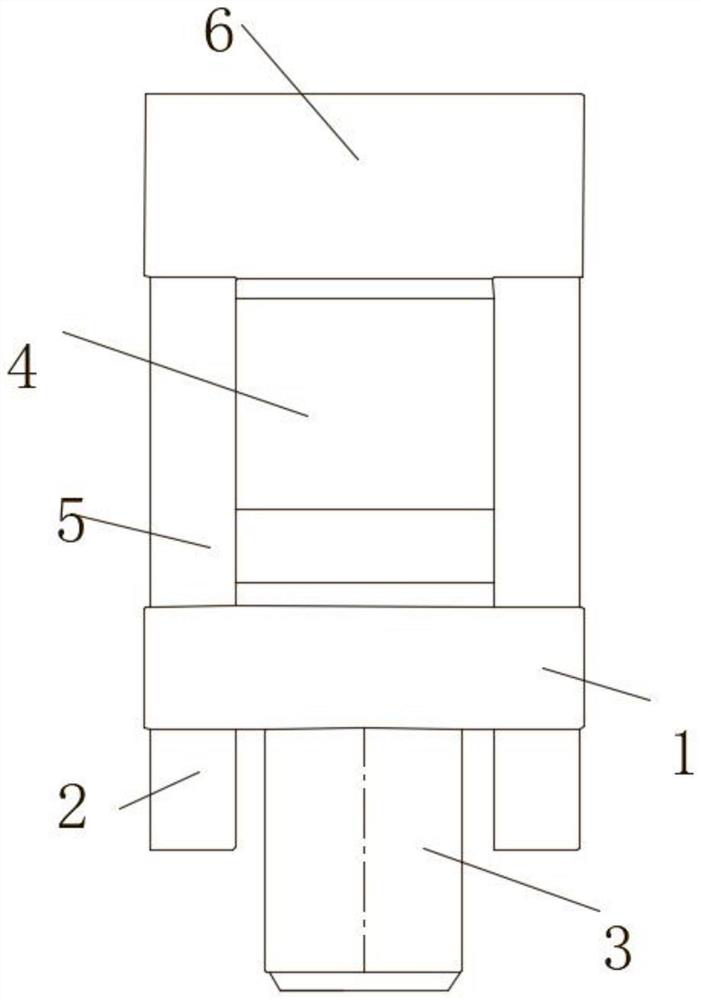

[0029] refer to Figure 1-5 The special-shaped curved metal sheet forming device of this embodiment includes a base 1, a first hydraulic cylinder 3 is fixedly installed at the center of the bottom of the base 1, and a workbench 19 is fixedly installed on the top of the piston rod of the first hydraulic cylinder 3 , a lightweight mold 4 is placed on the top of the workbench 19, support rods 5 are fixedly installed on the four corners of the top of the base 1, and the same clamping platform 6 is installed on the top of the four support rods 5, and the clamping platform 6 Two sets of second hydraulic cylinders 9 are arranged on the top of the top, and the same clamp 7 is fixedly installed on the piston rods of one set of second hydraulic cylinders 9, and the same forming plate blank 8 is clamped and fixed by the two clamps 7, The formed sheet blank 8 is located directly above the lightweight mold 4 .

Embodiment 2

[0031] This embodiment is improved on the basis of Embodiment 1:

[0032] The number of a group of second hydraulic cylinders 9 is 3-10, and the inner walls on both sides of the base 1 are rotatably connected with threaded adjustment rods 16, and the sides of the two threaded adjustment rods 16 are connected with U-shaped plates 10 by threads. , and the sides of the two U-shaped plates 10 that are close to each other are fixedly equipped with arc-shaped clamping plates 11, and the sides of the two arc-shaped clamping plates 11 that are close to each other are all engaged with the first hydraulic cylinder 3, basically Bearings 15 are fixedly installed on the inner walls of both sides of the seat 1, and the threaded adjusting rod 16 runs through the inner ring of the bearing 15 and is fixedly connected with the inner ring of the bearing 15. The sides of the two threaded adjusting rods 16 that are far away from each other are fixedly installed with hexagonal bolts 18. Blocks 17 a...

Embodiment 3

[0034] A processing technology of a special-shaped curved surface metal sheet forming device, comprising the following steps:

[0035] S1: Classify and code the special-shaped metal curved surfaces required by the same batch according to the curvature;

[0036] S2: Process the lightweight mold 4 into the required maximum profile through the CNC machining center;

[0037] S3: installing the formed lightweight mold 4 on the special-shaped curved metal sheet forming device;

[0038] S4: Adjust the forming plate blank 8 to a suitable position;

[0039] S5: Start the first hydraulic cylinder 3 to eject, and the ejection pressure will extrude the forming plate blank 8 into a curved surface;

[0040] S6: After the production of the curved surface of the same type or roughly similar curvature is completed, the lightweight mold 4 is removed, and the surface of the next curvature level is processed by the CNC machining center again, and then put into the special-shaped curved surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com