Clamp of vertical processing device

A technology for processing equipment and fixtures, applied in metal processing equipment, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of wasting loading and unloading workpieces and tool setting time, low processing efficiency, etc., to reduce the time for clamping workpieces, Wide range of use and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

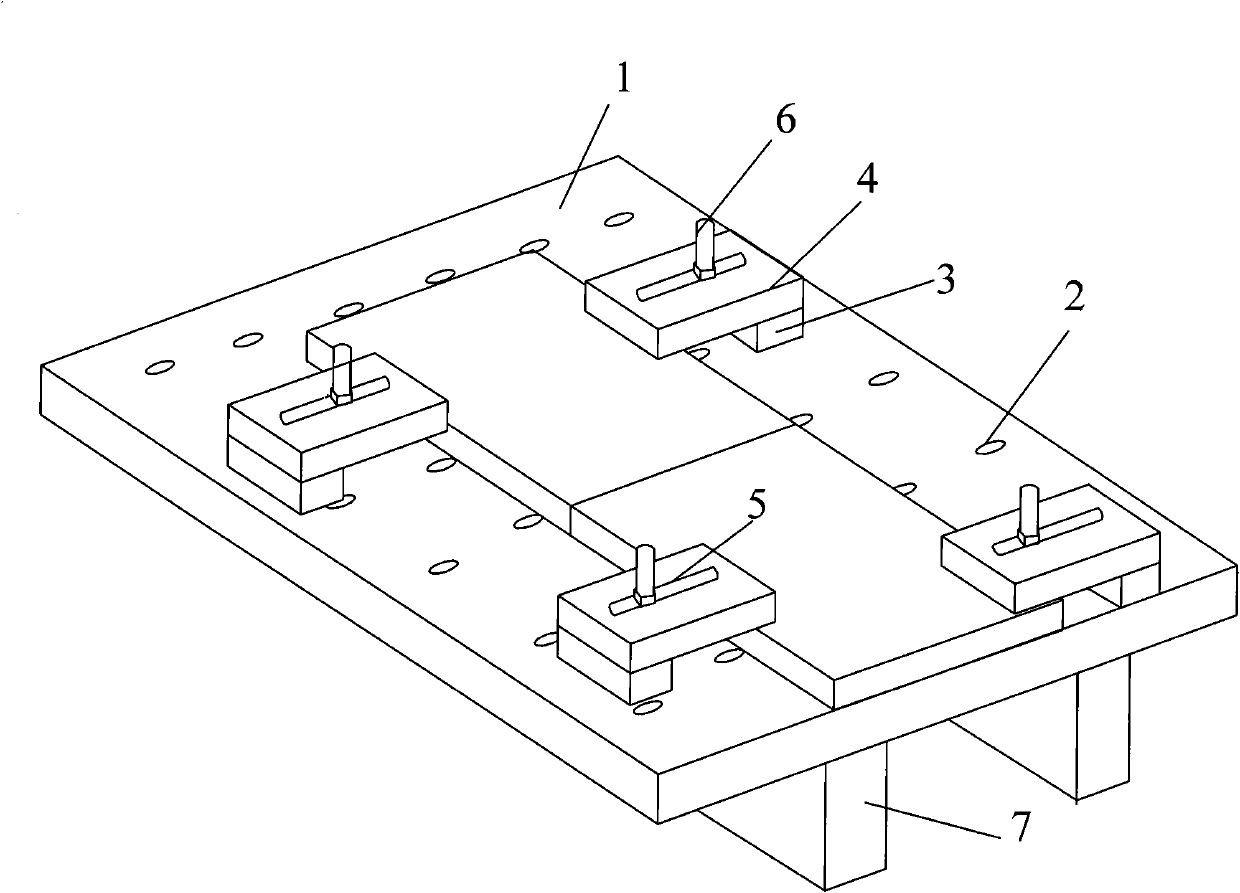

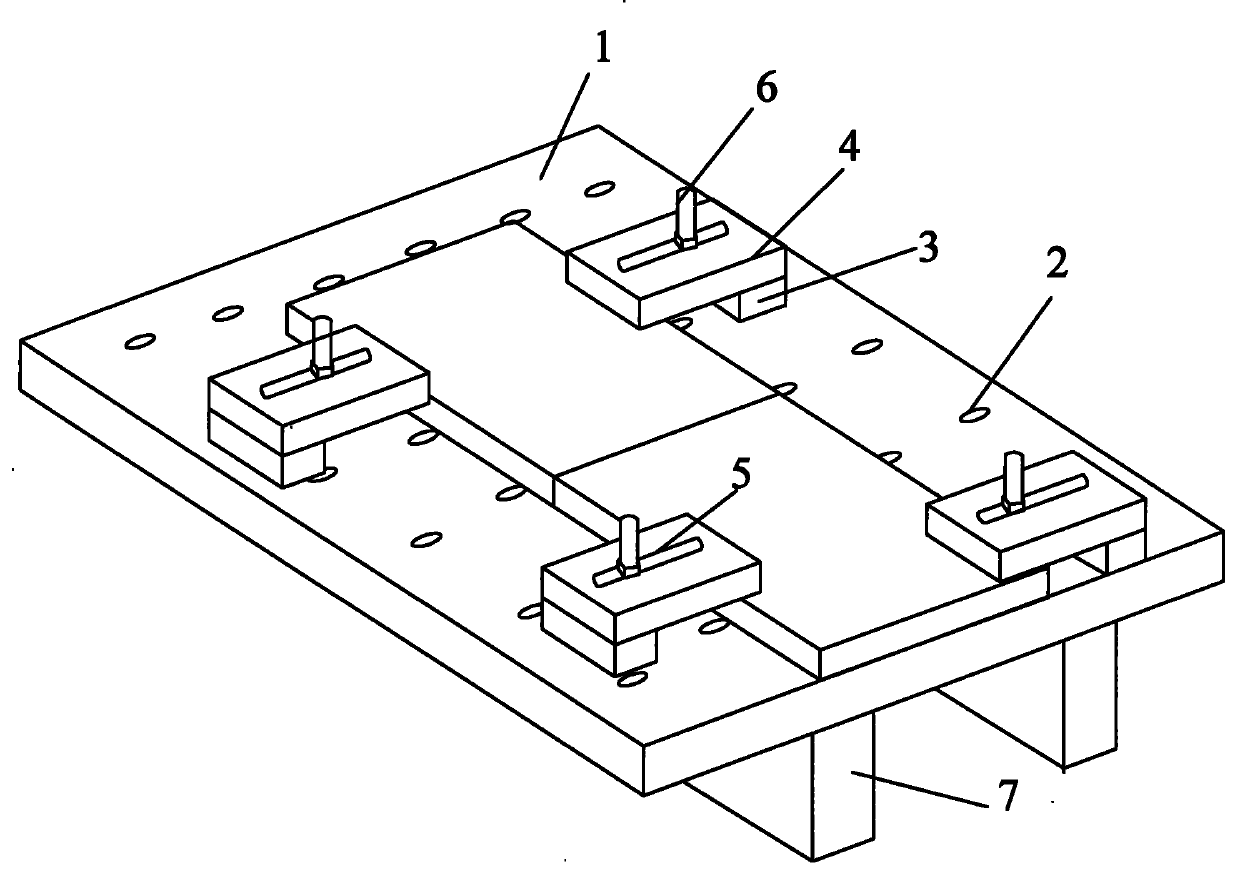

[0014] like figure 1 As shown, the fixture of the vertical processing equipment of the present invention includes a carrying platform 1, and thirty-six adjustment through holes 2 are evenly distributed in a pattern of six rows and six columns on the carrying platform 1, and the bottom of the carrying platform 1 is provided with two supports The feet 7 are used to fix the carrier 1 on the workbench of the vertical processing equipment. Four pressure plates 4 are arranged on the bearing platform 1, and each pressure plate 4 is provided with an adjustment groove 5, and a bolt 6 is pierced in the adjustment groove 5, and the pressure plate 4 is connected to the bearing platform 1 through the bolt 6.

[0015] During use, the fixture is clamped on the working platform of the machining center,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com