Continuous production device for amorphous belt

A technology for production equipment and amorphous strips, applied in safety devices, metal processing equipment, casting equipment, etc., can solve problems such as the inability to realize continuous amorphous strip production from multi-furnace alloy solutions, and achieve small footprint and stable production , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

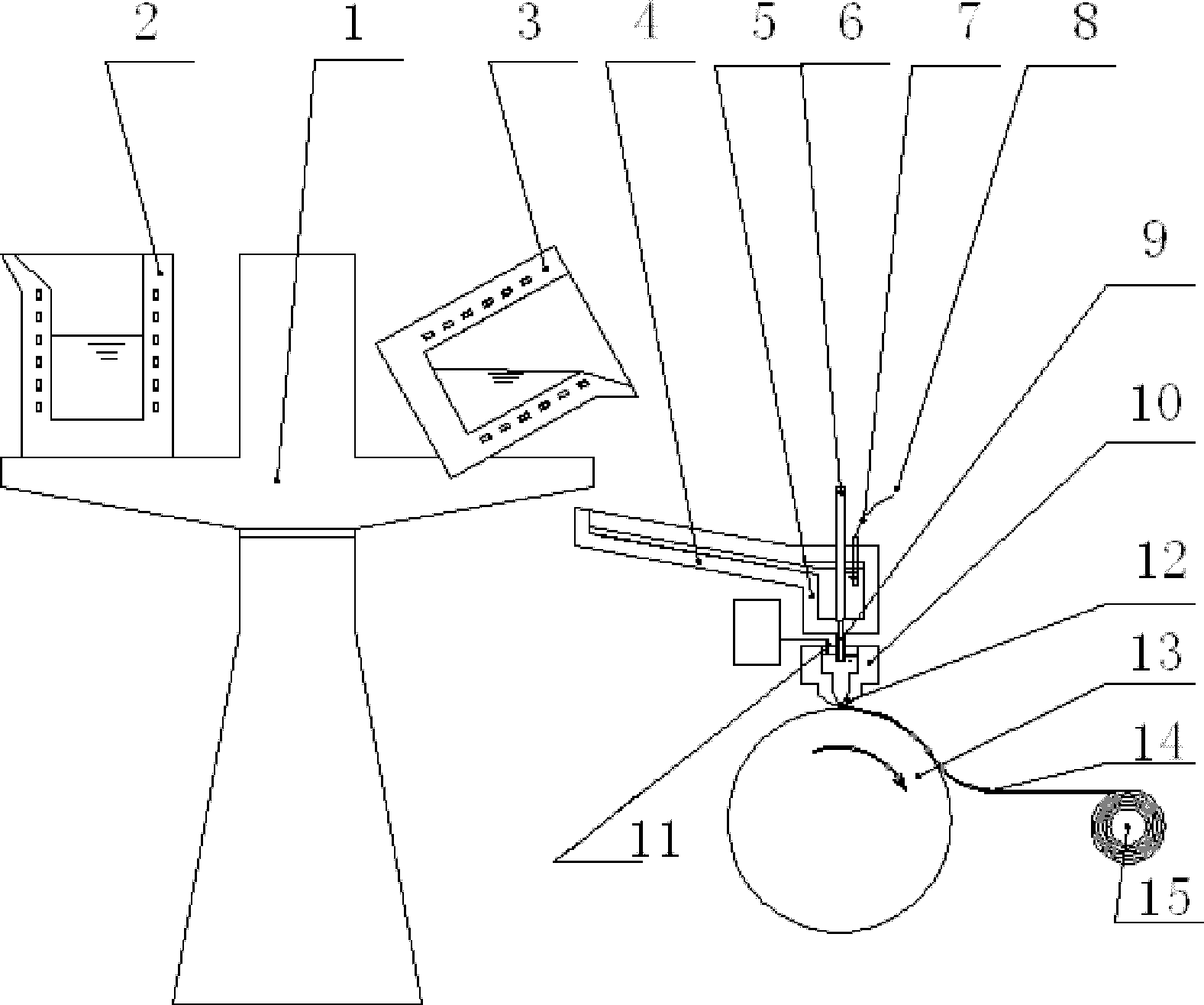

Method used

Image

Examples

Embodiment 1

[0023] Both the smelting furnace and the pouring furnace adopt the smelting method of induction heating and chemical steel; the capacity of the two furnaces is 3 tons; the pouring method is adopted, and the launder and the pouring ladle are integrated; the capacity of the pouring ladle is 100kg, and the stopper rod is used Flow control, the lower part is equipped with a nozzle; the capacity of the spray belt bag is 80kg; the system includes a set of temperature measurement and control system, which forms a closed-loop control with the power supply power of the casting induction furnace by measuring the temperature of the alloy solution in the casting bag. Control the temperature of the alloy solution in the pouring ladle to be basically constant.

Embodiment 2

[0025] Both the smelting furnace and the pouring furnace adopt the smelting method of electric arc heating chemical steel, and the flow is controlled by the slide plate in the bottom injection method; the capacity of the two furnaces is 2.5 tons; there is no flow steel channel; the capacity of the pouring ladle is 80kg, and the flow is controlled by a stopper rod , the lower part is equipped with a nozzle; the capacity of the spray belt bag is 100kg; the system includes a set of temperature measurement and control system, which controls the casting by measuring the temperature of the alloy solution in the casting bag and forming a closed-loop control with the power supply of the casting induction furnace. The temperature of the alloy solution in the ladle is basically constant. The system also includes a set of spray bag liquid level detection and control device, which forms a closed-loop control with the lifting of the pouring bag flow control plug rod to control the liquid le...

Embodiment 3

[0027] Both the smelting furnace and the pouring furnace adopt the smelting method of induction heating steel, which is the top injection method; the capacity of the two furnaces is 3.5 tons; the launder and the pouring ladle are integrated; the capacity of the pouring ladle is 150kg, and the pouring ladle is controlled by a stopper rod. flow, the lower part of which is equipped with a nozzle; the capacity of the spray bag is 100kg; the system includes a set of pouring ladle liquid level detection and control device, which forms a closed-loop control with the pouring speed of the pouring induction furnace to control the liquid level in the pouring ladle The altitude remains stable. The system also includes a set of temperature measurement and control system, which measures the temperature of the alloy solution in the casting ladle and forms a closed-loop control with the power supply of the casting induction furnace to control the temperature of the alloy solution in the castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com