Fluidizing bed type waste plastic continuous oil refining device with environment protection and high efficiency

A technology of oil refinery and fluidized bed, which is applied in the field of continuous waste plastic treatment equipment, and can solve problems such as poor oil quality, failure to meet environmental protection requirements, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

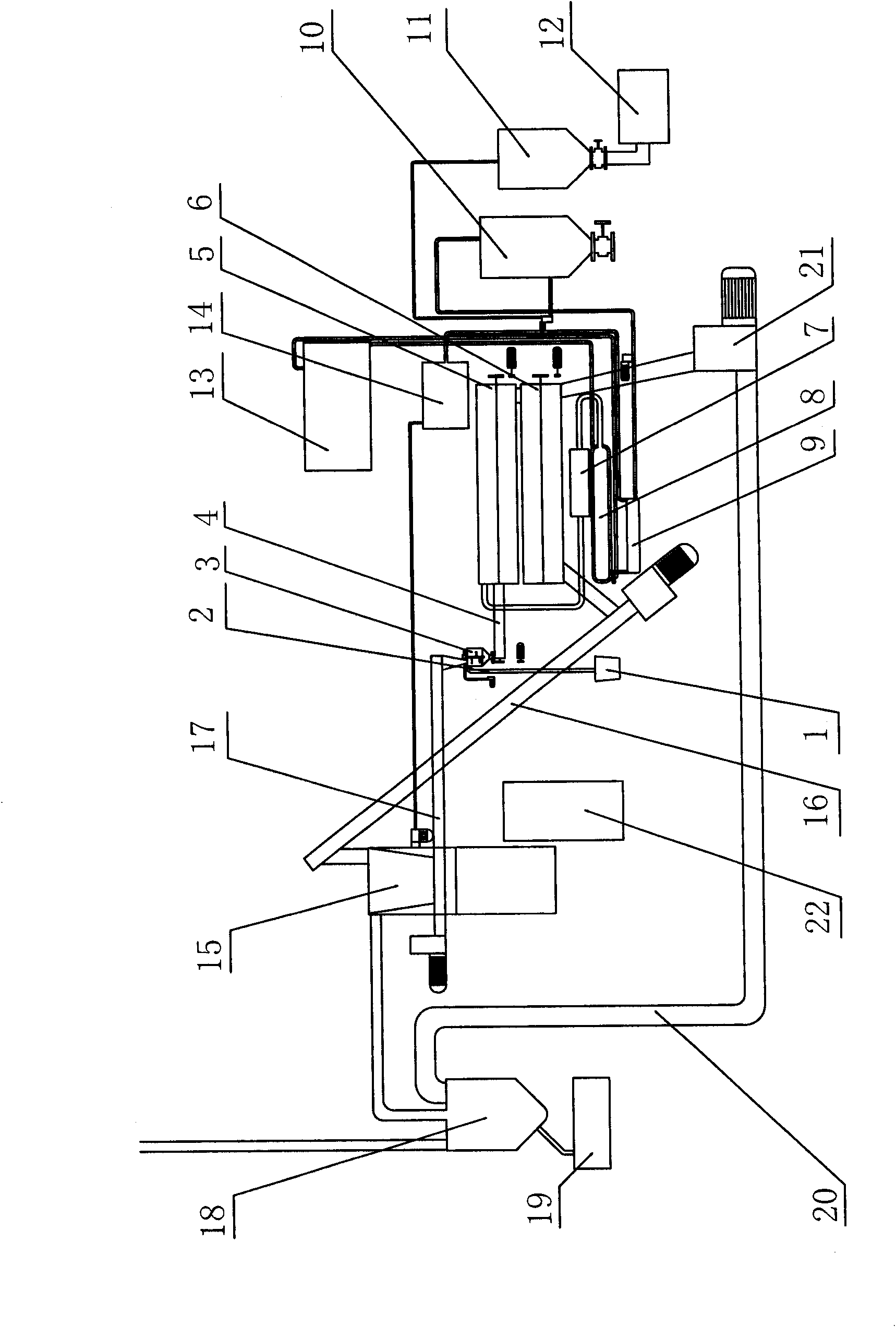

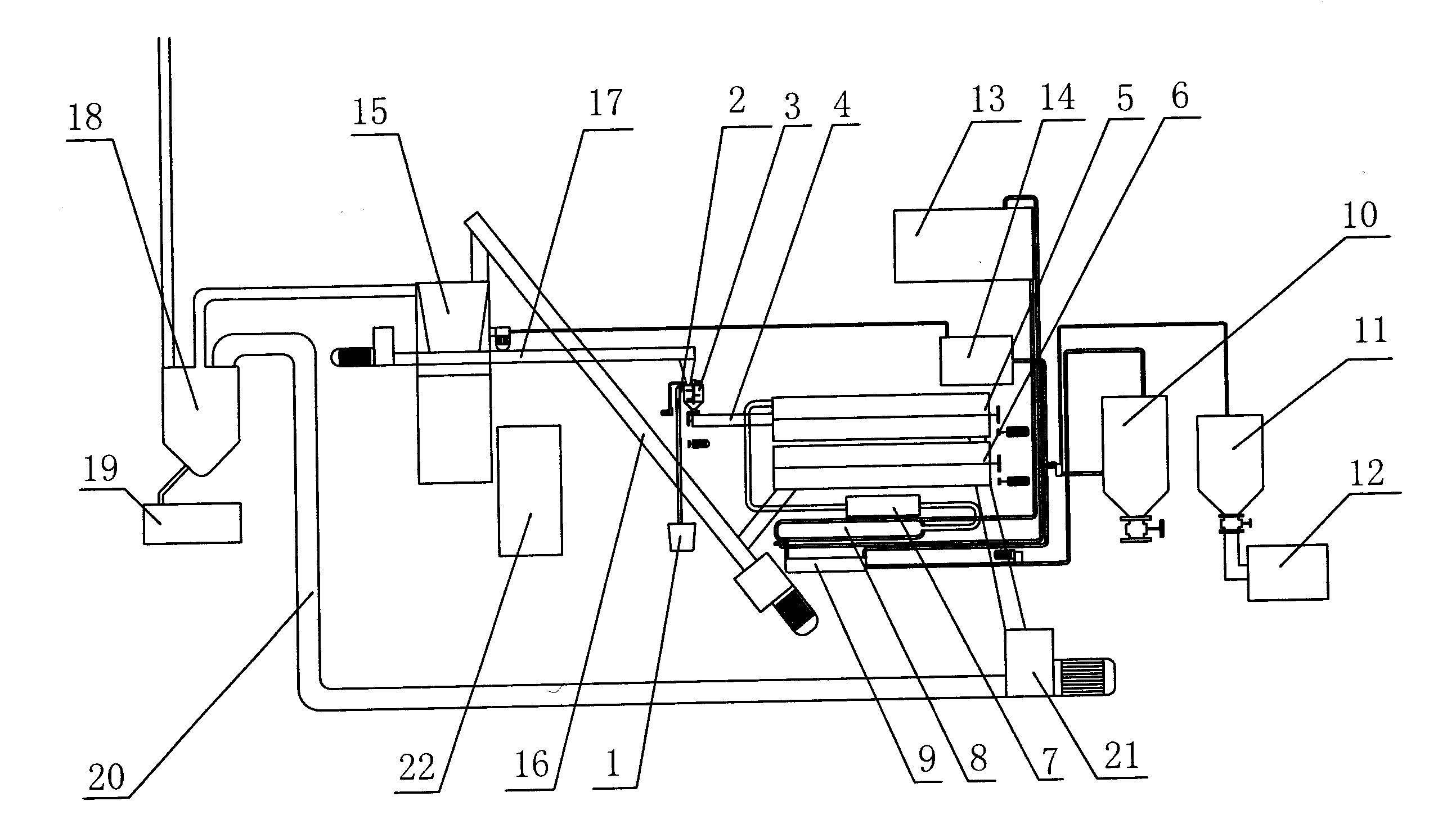

[0022] refer to figure 1 As shown, the environment-friendly and efficient fluidized bed continuous refining device for waste plastics includes a storage tank 1 filled with raw materials, the storage tank 1 is connected to the feeder 2, and the feeder 2 passes through the feeder 3 and the extruder 4 is connected to two reaction kettles 5 and 6 connected in series. The raw material enters the feeder 2 from the storage tank 1, is lifted by the feeder 2, passes through the feeder 3, and enters the first reaction kettle from the extruder 4 5, the first reactor 5 is positioned at the top of the second reactor 6, and there is a pipeline communication between the two reactors 5 and 6; the first reactor 5 is connected to the catalytic tank 7, and the catalytic tank 7 and the condensation tank 8 Connect; the oil storage tank 9 is connected to the impurity removal tank 10 by a pipeline, and the bottom of the impurity removal tank 10 is provided with a pipeline to be connected to the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com